Diapositive 1 - Water & Wastewater Equipment, Treatment

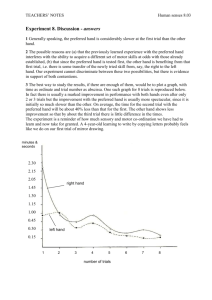

advertisement

Coconut Husk Fragments-Based Biofiltration Ensuring the Availability and Sustainability of Filtering Media Materials Andy McKinlay Market development director Residential North America Content Review of our Current Offer Premier Tech Aqua (PTA) Maintenance Program Review of Current Options to Homeowners and Regulators Veolia Test Platform Real Facts Comparative Research Energy Consumption & Annual Operating Costs Filter Replacement & Spent Peat Studies New Offer Ecoflo Biofilter Ecoflo Biofilter is a peat-based biofilter Life span of the filtering media: 10 to 15 years Ecoflo® Biofilter Septic tank Drainfield PTA Maintenance Program Performed by a network of local partners trained by PTA Good presentation to the customer Professionalism on the property Inspection of all components Good and complete information Maintenance Steps What is the current offer? Operation and Maintenance Apply to ALL septic systems No maintenance = progressive system failure Conventional, mound, buried CTDS (non accessible) If you are unable to visually inspect the components of a system, you do not know if it is working Conventional, mound, buried CTDS (non accessible) Replacing a failed system is an operating cost How long it actually lasts is a mystery! Performance????? Inspections????? Veolia Test Platform To reflect the high variations of flow and loads, characterizing individual installations, Veolia Water developed, with expert groups, a new testing protocol. 200% 50% 100% Q 12 weeks Week-end high occupancy 4 weeks Vacation period 3 weeks Peak flow 3 weeks Q 4 weeks Week-end high occupancy 2 weeks 3 power/equipment failure 6 weeks Low occupancy 2 weeks Veolia Test Platform In 2011, Veolia Eau performed the 40-week Stressful Condition Test Platform at the Center for Scientific and Technical Building Studies in Europe. Most stringent test platform in the onsite wastewater industry. Ecoflo Biofilter ranked no. 1 among the eight technologies tested. Veolia Protocol Global Results Veolia Protocol Global Results Veolia Protocol Global Results Veolia Protocol Global Results Veolia Protocol Global Results The Real Facts Comparative Research Comparative Research The higher maintenance requirements of ATU’s were often neglected by homeowners, resulting in higher failure and marginal performance rates. Conclusions When ATU’s are included in the design system, failure rates increase. When ATU’s are designed to discharge off-lot, the nuisance rate increase. Energy Consumption Vendor 1 yr Electrical Consumption (kWh/year) Increased Electrical Costs per Year Assuming $0.11 per kWh Verified by Fixed film 979.66 $107.76 NAT testing lab Fixed film 1934.5 kWh/year $212.80 Vendor Attached Growth 2584 kWh/year $284.24 Pump Manufacturer BC Hydro Rates and Usage ATU#1 – 7.728 kWh (daily usage) ATU#2 – 4.8 kWh (daily usage) ATU#3 – 4.248 kWh (daily usage) 1,350 kWh over typical 2 month billing period = 22.1918 kWh (daily usage) Average Annual Operating Costs $450 $400 $350 $300 $250 $200 Hydro Consumption $150 Blower Replacement $100 Filter Replacement $50 $0 ATU#1 ATU#2 ATU#3 Ecoflo Assuming blower replacement at 5-year intervals Does not include annual maintenance costs or other component replacement (eg. recirculation pump, diffuser, etc.) Accumulative Operating Costs $10,000.00 $9,000.00 $8,000.00 $7,000.00 $6,000.00 ATU#1 $5,000.00 ATU#2 $4,000.00 ATU#3 $3,000.00 Ecoflo $2,000.00 $1,000.00 $1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Years The Real Facts One Ecoflo biofiter (at the time of media replacement) contains a volume of media between 4 and 4.5m³, or approximately 3.6 dry tonnes. It’s estimated that the volume of biosolids produced annually by centralized wastewater treatment plants in BC is approximately 47,000 dry tonnes. The Real Facts Permanent vs. Temporary Systems $3,000.00 $2,500.00 $2,000.00 $1,500.00 $1,000.00 $500.00 Temporary System $- Filter Replacement System replacement costs expressed as annual operating costs Assuming temporary system total replacement cost of $15K Ecoflo media replaced at 10-year intervals Operation & Maintenance Costs – Ecoflo vs. ATU 1 yr 2 yr 3 yr 4 yr 5 yr 6 yr 7 yr 8 yr Free $0.00 $150.00 $0.00 $150.00 $0.00 $150.00 $0.00 $150.00 $0.00 $150.00 $0.00 $150.00 $0.00 $150.00 $0.00 $1,500.00 Free Free $200.00 $200.00 $200.00 $200.00 $200.00 $200.00 $300.00 $300.00 $300.00 $300.00 $300.00 $300.00 $300.00 $300.00 Ecoflo Annual maintenance fees Annual electricity costs* *Less than $10/yr if pump is required Filter replacement Total operating costs after 8 years Average annual costs $2,550.00 $318.75 ATU Annual maintenance fees (estimated) Annual electricity costs (estimated) Compressor replacement/rebuild (estimated) Pump scum/sludge from ATU (estimated) Total operating costs after 8 years Average annual costs $400.00 $400.00 $250.00 $4,650.00 $518.25 From Theory to Reality: Peat replacement after 8 Years – Characterization Results and the Challenges of Finding New End Uses Presented by Andy McKinlay Denis Pettigrew PUMPER & CLEANER ENVIRONMENTAL EXPO INTERNATIONAL Louisville, Kentucky, February 25th, 2010 Filter Replacement When the life span of the filter is reached, the spent media is pumped out with a vacuum pump truck Filter Replacement Sludge requires to be managed periodically All onsite wastewater treatment systems produce sludge ATU’s: sludge is accumulated in the settling area and needs to be pumped on a 1 to 2 year basis Media filter bed: sludge is accumulated in the filtering media, requiring its replacement over the years Spent Peat Studies First study in 2002-2005 in Canada Characterization of spent peat Storage, composting and revegetation trials Lime stabilization Soil amendment for tree nursery Second study by Virginia Tech University (since 2008) Characterization of spent peat Standard bioassay trials (laboratory and greenhouse) Storage (Penn State University) and composting trials Characterization Campaign 2002 and 2003: Sampling of 19 filtering beds after 8 years of use 2009: sampling of 10 filtering beds in PA after 8 years of use Sample volume 2-3 gal (5-10 L) Parameters Uniformity and texture Physico-chemical properties Macro-elements Oligo-elements & metals Microbiology Storage, Composting & Re-vegetation Trials Monitor the impact of storage & evaluate new alternative end uses: 1. Storage & composting Use of spent peat as a bulking agent in compost Effect of storage on pathogen reduction and leachate characterization Composting trials with addition of a nitrogen source 2. Erosion control and revegetation (first study only) Organic amendment for the protection & stabilization of degraded soils (erosion control on sloppy site) Agronomic potential for plant growth on altered/degraded sites Monitor possible run-off contamination resulting from application of spent peat as an organic amendment Storage & Composting Trials First study: storage and composting platform (100 x 30 ft) divided in 4 cells 4 3 2 1 10 meters 35 meters + Collecting pool for existing leacheates Existing leachate storage lagoon Virginia Tech study First exploration drum composting trials 2009 Second run composting trials and storage trials to be initiated in spring 2010 Re-vegetation Trials Erosion control and re-vegetation trials using 22 plots of 8 x 21ft: 2 slopes: 3 and 25% Comparison of amended vs. control plots (3-5 reps) Collection of run-off water and sediments at the bottom of each plots Plant growth evolution Weather station Bioassay at Virginia Tech Facilities Designed to test for beneficial effects of spent peat as an amendment and to observe any potential negative effects on soil properties and plant growth. Seed germination and greenhouse pots trials Plant sensitive and tolerance indicators (Snap beans and Tall fescue) 2 amendment materials: Spent peat VT compost mix (with spent peat) 4 application rates (0,10, 20 and 30%) Randomized block (4 reps/treatment) Characterization Campaign Overall results Same spent peat characteristics observed from the 2 studies (Canada and USA) Good physical, chemical and agronomical properties: pH close to neutral 84% of organic matter (≈40% of carbon content) C/N ratio in the range of 35 Homogenous fibrous and porous structure High water holding capacity Characterization Campaign Overall results (cont’) Good physical, chemical and agronomical properties: Good plant nutritional mineral content (macro & available nutrients) Moderate level of pathogen (E. coli range of 24 to 100,000 MPN/g, Salmonella (BDL)) Compared to sewage sludge, very low metals content Higher level of Cu and Na, can be found in certain sites (water softner, aggressive water and copper plumbing) Lime Stabilization Preliminary trials Stabilization with hydrated lime to get Class A biosolid level Get the pathogen reduction through pH and heat drastic change pH > 11.5 for more than 22hrs Re-vegetation Trials Erosion control & re-vegetation Significant contribution of the amendment of spent peat (A) for erosion control as well as for the establishment of the vegetation cover. 14 d 38 d 21 d A A A 8 months 10 months A A 12 months A Re-vegetation Trials Erosion control & re-vegetation Sediments volume & leachate quality Non amended Amended Sediments volume (mL) 254 118 Turbidity (NTU) 386 47 Conductivity (mho/cm) 159 90 Fe (mg/L) 11.4 1.2 COD (mg/L) 43 48 PO4 (mg/L) 0.11 0.57 Fecal Coliforms (UFC/100 mL) 156 55 Cu (mg/L) 0.05 0.05 NH4 (mg/L) 0.29 0.37 Parameters Bioassay at Virginia Tech Facilities Seed germination and greenhouse pots trials Land Reclamation Reclamation Objectives Highly disturbed throughout site Dust mitigation / erosion control Aesthetic improvement Habitat establishment Aforestation Biosolids identified as a tool to achieve these objectives Conclusions Spent peat, with its inherent physical properties and mineral nutrients concentrations, has great fertilizing potential for plant growth and for soil stabilization and enrichment. The simple storage trials of the spent peat for periods > 80 days contributes to a sufficient level of stabilization. The stabilized spent peat could be used for forage crop and forestry (tree farms). Composting trials demonstrated the very high potential of reusing the spent peat as a bulking agent. Conclusions Re-vegetation trials have demonstrated the beneficial contribution of the spent peat amendment for the protection of bare surfaces and the establishment of a vegetation cap. First results from Virginia Tech study (bioassay) indicate that spent peat amendment has no adverse effects on seedling and improve plant growth. Based on results obtained up to now, spent peat should not be classified as a sewage sludge (septage), considering its handling and agronomical properties (low elemental toxicity). Ecoflo Ecoflo Coco Premier Tech Compact Organic Filter Branding Premier Tech offers a technological approach Proven and recognized technology Compact absorbent organic filter Finished product PT Compact Organic Filter is made of qualitycontrolled natural media A compact, highperformance, no energy and permanent solution Zero energy required for the treatment process Easy to install system Filter acts as a true physical barrier between the existing soil and the absorption bed Best way to protect the investment (the property) and the environment Coco – Advantages Natural and recyclable organic filter Same module can handle more flow or more concentration Increased treatment flexibility and compactness Ecoflo Coco vs. Ecoflo Ecoflo Coco Ecoflo HLR 12.5 USG/ft²-d 8.6 USG/ft²-d OLR 0.012lb DBOC5/ft2-d 0.009lb DBOC5/ft2-d 25 in 31.5 in Q=750 USG/d Q=525 USG/d FM height Polyethylene (570/750 unit) NSF Testing – Standard 40 Class I Completed May 15, 2014 Septic tank effluent sampling port Influent coming from bench test Aeration pipes PL-22 Effluent filter Filtering media Discharge to bench test sampling point Spacers1 Primary treatment: Secondary treatment: 750 gallons working capacity septic tank Ecoflo® Coco Filter NSF Testing – Standard 40 Class I Completed May 15, 2014 New Unit Compact rotomolded unit The Strength of Premier Tech Aqua Network of 2,000 installers, 700 consultants, 250 service partners and 420 distribution centers in North America, Europe and Asia 100,000 Ecoflo Biofilter installations worldwide 1,200 commercial, community, institutional, municipal and industrial installations 400,000 system maintenances 13,000 successful filter changes 120,000 peripheral products sold