Ch4 Supply Chain Management Supplementary Homework

advertisement

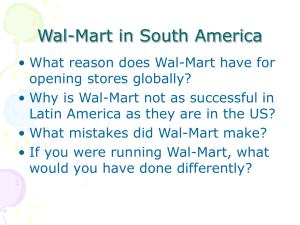

Chapter 4 Supply Chain Management 1 Importance of Supply Chains Every organization is part of a supply chain, either as a customer or as a supplier. The reason is that every organization that produces a finished product is involved, directly or indirectly, with all of the functions needed to make a finished product. 2 These Functions Include: Making or purchasing parts and materials, Assembling or processing them into finished products, Warehousing them, and Delivering them to the customer. 3 Need For a Supply Chain These functions are increasingly being outsourced to other entities that can perform more cost effectively. Consequently, organizations many have reduced their ownership of raw materials sources and distribution channels by outsourcing them. Result: Less control and more supply chain partners. 4 What is a Supply Chain? A supply chain is the seamless integration of all the functions needed to make a finished product, from the purchase of parts and materials through the sale and delivery of the product to the end user. 5 Members of Supply Chain Suppliers Company Distributors Wholesalers Customers 6 How Good Supply Chains Operate Supply chains are not zero-sum games, where manufacturing customer’s gain from buying something a bit cheaper is the supplier’s (seller’s) loss. 7 How Good Supply Chains Operate Old, adversarial relationships in which the buyers push for lower prices and higher quality while sellers push for just the opposite are pretty much a hallmark of losers these days. 8 How Good Supply Chains Operate If your company really wants to operate efficiently and win customers, it should team up with your suppliers rather than bargain with them. 9 How Good Supply Chains Operate When you give up the notion of the winner-loser zero-sum game and start working together with your suppliers, you can please more customers down the line and create a win-win situation for both of you. 10 How Supply Chain’s Operate Rather than just haggle over prices, quality and delivery schedules, work to align your processes and eliminate the friction that costs you both time and money. Supply chains are based on mutual benefits rather than straight cost. 11 Benefits of Successful Supply Chains Better supplier quality. Reduced dependence on inspection of incoming materials. Greater on time delivery. Shorter cycle times. Sharing of supplier expertise, which leads to greater process improvements. 12 Benefits of Successful Supply Chains Sharing of demand information at all levels of the chain results in more effective planning of production schedules. Better capacity utilization. Less inventory. 13 Benefits of Successful Supply Chains Benefits mean ??? at all levels of the supply chain. In essence, successful supply chains integrates supply and demand within and across companies. 14 Role of Inventory Inventory is the last resort for resolving supply-and-demand imbalances between the levels in the supply chain. Goal of chain is to reduce inventory at all levels of the chain through JIT delivery. Less inventory means lower cost. 15 Pull vs. Push Production Supply chains are based on demand pull production system rather than a push system. 16 Pull production Production is pulled through system based on demand forecasts. As demand changes, production changes. This balances supply and demand, assuming accurate demand forecasts are transmitted throughout the supply chain. 17 Pull production Balance between supply and demand means ??? Pull is foundation of JIT, where parts and materials are received as needed. Potential problem is “Bullwhip” effect (later.) 18 Push production Production is pushed through system based on fixed production schedules without regard to demand. Since demand changes, production may exceed or fall short of demand, creating inventory or shortages. 19 What is Supply Chain Management (SCM)? Supply chain management is the seamless integration, evaluation, and improvement of the processes involved in the movement of goods and information through the supply chain, from suppliers to manufacturers to distributors to final customer. 20 Criteria for selecting suppliers Quality Are their processes in statistical control Are their processes capable? Require statistical evidence in form of control charts and capability indices. Price On time delivery 21 Supply Chain Successes Procter & Gamble P & G reorganized its product supply chain by combining formerly independent functions of purchasing, engineering, and distribution. A product supply manager was created for each division and the functions report to him. Benefits: reduced flow time Reduced inventories, and increased on-time delivery and quality. 22 Supply Chain Successes General Electric (GE) GE actively draws on the experience of its various suppliers when designing new products. It also works with suppliers to teach them what it knows about building winning organizations. 23 Role of Distributors Move goods from different suppliers or producers closer to consumer at a lower cost than can be performed by any one supplier or producer. 24 Role of Distributors How? Transportation consolidation – warehouses consolidate less-than-truckload (LTL) quantities into truckload (TL) quantities Product mixing – grouping a variety of orders into a direct shipment to the customer. Cross-docking 25 Cross-docking Practice of unloading materials from an incoming trucks or rail cars and loading these materials onto outbound trucks or rail cars, with little or no storage or warehousing in between. This may be done to sort material intended for different destinations, or to combine small shipments of materials from different origins. 26 Cross-docking In practice many "cross-docking" operations require large staging areas where inbound materials are sorted, consolidated, and stored until the outbound shipment is complete and ready to ship. 27 Cross-docking If the staging takes hours or a day, the operation is usually referred to as a "cross-dock" distribution center. If it takes several days or even weeks, the operation is usually considered warehousing. 28 Wal-Mart's Cross-docking Distribution System Cross docking has been most successfully implemented in Wal-Mart's distribution system. Individual Wal-Mart stores transmit point-of-sale (POS) data from the cash register back to corporate headquarters several times a day. 29 Wal-Mart's Cross-docking Distribution System This provides instant feedback on customer demand, which is transmitted up the supply chain. Demand information is used to order shipments from suppliers to the Wal-Mart distribution center and from the Wal-Mart distribution center to the store. 30 Wal-Mart's Distribution System Wal-Mart’s supply chain is a demanddriven supply chain. Benefits are JIT delivery, less inventory, Fewer stock-outs and shortages, lower costs throughout the supply chain. 31 Bullwhip Effect Small changes in demand at the end user level can result in large swings in orders placed upstream. That is, demand variability increases as one moves up the supply chain away from the retail customer. This is called the “Bullwhip Effect.” 32 Bullwhip Effect Result is that supply and demand patterns do not match. If supply exceeds demand, inventory accumulates at various stages. If demand exceeds supply, shortages and delays occur. 33 Causes of Bullwhip Effect Time delays in the transmission of demand information upstream. Inaccurate demand forecasts. Misinterpretation upstream of actual demand at the end-user level. 34 Example of Misinterpreting Actual Demand Suppose there is a 10% increase in demand at the consumer level. This could cause a much larger increase in orders at the factory. Why? 35 Example of Misinterpreting Actual Demand The factory will responds by ordering 10% more (the actual increase). Factory may also order an additional amount, called safety stock, if it felt that the increase in demand was actually the beginning of an upward market trend when it is actually due to a seasonal effect. 36 Sourcing Issues – Make or Buy Decision Should company can make parts and materials in-house – insourcing - or buy from outside supplier – outsourcing? Depends on total cost of two alternatives. 37 Sourcing Issues – Make or Buy Decision FCBuy = fixed cost of buying item from supplier VCBuy = variable cost per unit of buying item from supplier FCMake= fixed cost of making item in-house VCMake = variable cost per unit of making item in-house Q = number of units of items needed 38 Sourcing Issues – Make or Buy Decision Total Cost of Outsourcin g : TC Buy FC Buy VC Buy Q Total Cost of Insourcing : TC Make FC Make VC Make Q 39 Make or Buy Analysis Make in - house if : FC Make VC Make Q FC Buy VC Buy Q or if : Q FC Buy FC Make VC Make - VC Buy Q* 40 Example, Page 114, Text Mary and Sue, have decided to open a bagel shop. Their first decision is whether they should make the bagels on-site or by the bagels from a local bakery. If they buy from the local bakery they will need airtight containers at a fixed cost of $1000 annually. They can buy the bagels for $0.40 each. Example, Page 114, Text If they make the bagels in-house they will need a small kitchen at a fixed cost of $15,000 annually. It will cost them $0.15 per bagel to make. They believe they will sell 60,000 bagels. 1. Develop the total cost functions of the two alternatives. 2. Should they make or buy the bagels? Solution #1 FCBuy = $1,000 VCBuy = $0.40 FCMake= $15,000 VCMake = $0.15 43 Solution #1 TCBuy = $1,000 + $0.40Q TCMake = $15,000 + $0.15Q 44 Solution #2 Make in - house if Q FC Buy FC Make VC Make - VC Buy Q $1,000 $15,000 $0.15 $0.40 Q 56,000 Bagels 45 Graphical Solution: FCBuy > FCMake and VCMake > VCBuy TCBuy TCMake $15,000 $1,000 Q* = 56,000 If Q < 56,000, “Make” Q If Q > 56,000, “Buy” 46 Solution #2 Since Mary and Sue expect to sell 60,000 bagels and 60,000 > Q* = 56,000, they should buy bagels from a local bakery. 47