Site & Situation Factors of Industry: AP Human Geography

advertisement

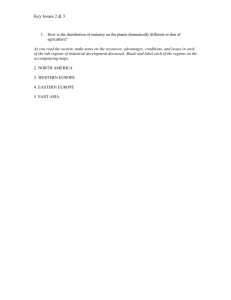

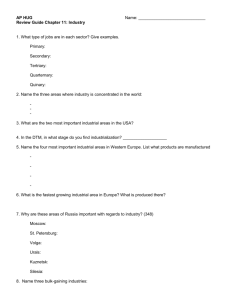

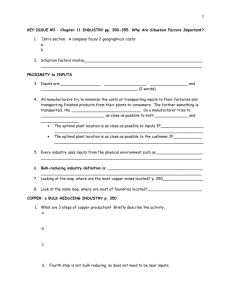

SITE AND SITUATION FACTORS OF INDUSTRY AP HUMAN GEOGRAPHY INDUSTRIALIZATION AND ECONOMIC DEVELOPMENT UNIT FOR TODAY, 03/09 Arm yourselves with scholarly weapons used to battle note-tays (this means you will be taking notes, so get ready ) Vocab and Map Exam is Thursday, which is a short period FYI Chapter 11 Reading Quiz and FRQ is Friday FACTORS AFFECTING DISTRIBUTION OF INDUSTRY Site: physical characteristics of a location Deals with industry’s factors of production Land, labor, capital Situation: location relative to other things Deals with industry’s proximity to markets and inputs Bulk-gaining vs. Bulk-reducing SITE FACTOR 1: LAND Factories are usually rural, suburban, or foreign Large tracts of cheap land for one story buildings More energy efficient and cheaper Lower electricity rates Less environmental regulations Tax incentives offered by state, county, city governments Modes of transportation are critical factor – rail, road, river, etc. SITE FACTOR 2: LABOR Most important site factor Labor intensive industry: labor is a high percentage of the expense Agriculture, coal mining, construction, textiles Skilled vs. unskilled Skilled workers likely in MDCs in cities with high number of colleges or college graduates Unskilled workers likely in LDCs due to cheap labor costs Hourly Wages for Countries The global division of labor: companies hire out foreign workers to aid in the manufacturing of a single product (selective transfer of jobs) SITE FACTOR 3: CAPITAL Manufacturers need to borrow money to establish new factories or expand existing ones Examples: Automotive industry concentrated in Michigan due to availability of banks to provide loans High tech industry of Silicon Valley (California) 2/3 of these companies fail ¼ of all capital in U.S. is spent on new industries here SITUATION FACTOR 1: LOCATION NEAR INPUTS Bulk-reducing industries The finished product weighs less than inputs Ideal location is near the inputs due to high transportation costs Easier to transport good to market than input to factory Examples: Steel industry, copper industry Steel mills are located close to the source or iron ore and coal, which are both used to make steel. SITUATION FACTOR 2: LOCATION NEAR MARKETS Bulk-gaining industries Final product has more volume than inputs Ideal location is near consumers due to high transportation cost of finished product Examples: Soft-drink bottling, automobile assembly, breweries, Beer: inputs heavy to transport. WATER IS EVERYWHERE produce near customers. TRANSPORTATION Ship, rail, truck or air? Choose cheapest according to weight and distance shipped Trucks = short distance Trains = long distance Air = small bulk/high value; fast but costly Ship = slow, but very low cost Break of bulk point: location where transportation among many modes is possible Truck, train, ship, and/or air Houston BREAK OF BULK POINTS Hong Kong Singapore Rotterdam YOUR ASSIGNMENT (1.) Analyze the Site and Situation factors for the Honda plant in Greensburg, IN using a mapping browser (2.) Identify and explain the Site and Situation factors for the Honda plant (American Honda Motor Co.) in Irving, Texas