PowerPoint Template for a TSL Presentation - MUSSL

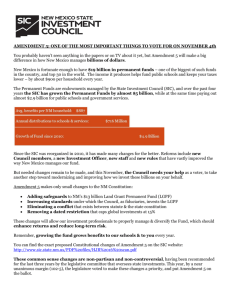

advertisement

Powder Production through Atomization & Chemical Reactions N. Ashgriz Centre for Advanced Coating Technologies Department of Mechanical & Industrial Engineering University of Toronto NSERC CRSNG Outline Overview of the previous work MMC Present research nanomaterial Spray (Aerosol) method Colliding drops Metal Matrix Composite Powder Ceramic Particles (high strength, stiffness & thermal stability) Metal Matrix (high toughness, strength, machinability) MMC Properties Compared to Matrix Material: Up to a 20% Improvement in Yield Strength Lower Coefficient of Thermal Expansion Higher Modulus of Elasticity (50%) More Wear Resistant Low Fracture Toughness Poor Fatigue Properties Powder Production Methods Atomization (Over 60% by weight of all powders produced in North America. ) Mechanical crushing Chemical reduction Vapor condensation Electrolytic method World wide Atomization capacity is 106 metric tons/year. Annual market size of metal powder is $3 billion and corresponding P/M size is $6 billion. MMC Matrix: Al, Ti, Ni, Steel Particles: SiC, TiC, Al2O3, SiN4, Si Difficult to incorporate due to non-wetting (>90o) behavior Undesirable interfacial reaction at high T (brittle interfacial phase) Methods of MMC Production 1. Atomization of Premixed MMC SiC particles mixed into molten aluminum alloy; Without stirring SiC particles settle (Al = 2400 kg/m3 and SiC = 3200 kg/m3); Brittle interfacial reactions occur due to long resident times Rotating Disk Atomization Highest atomization energy efficiency. Better control of the breakup process. Vz(r,z) V(r,z) Vr(r,z) Sever stresses due to high RPM. Thermal shock due to sudden impingement of the melt. (r) R Controlling Parameters RPM Feed Rate Disk Design Liquid Metal Properties Atomization Modes Direct Drop Mode; Ligament Mode; Sheet Formation Mode. Ligament Formation Qd l 0.096 Re R Re 2 0.95 We 1.15 R We 3 2 Centrifugal Atomization With Particle Injection Disk •Minimized interfacial interaction; •Limited reinforcement segregation; •Rapidly solidified microstructure. Experimental Apparatus Tank X-Y Controls Motor for Raising Rod Crucible and Furnace Connection for Argon SS Plate Gasket Bolt Crucible 6061 Aluminum alloy chosen as matrix Bottom of Rod Air Motor And Disk Disk preheated to 750 oC with 4000 Watt light A pneumatic die grinder was used to rotate the 3 inch diameter disk. Disk speed:24,000 RPM. Disk is centered with X-Y table during experiment. Heating Light Disk Nozzle Air Motor Rotating Disk Atomization in He N=45000RPM m=0.2kg/s Cupper alloy: Cu-1% Cr - 0.6%Zr Titanium Alloy: Ti15%Mo -2.7%Nb – 3%Al - 0.2%Si ASTM 112 - 95 Grain Size 25.4 m Magnification 1000X Microstructure of particle in 150-106 m size range. The ASTM grain size of this microstructure is approximately 10 SiC Volume Fraction in Composite Powder SiC Particle Average: SiC 18% Vol. Void 1.2% Vol. Void Aluminum Particle SiC Volume Fraction in Composite Powder Significant Particle Penetration. SiC Particle Magnification 1000X 25.4 m Microstructure of particle in 150-125 m size range. The ASTM grain size is 11.9. The area of SiC particles is 11.1%. The area fraction of the void is 0.3%. SiC Volume Fraction in Composite Powder 25.4 m Magnification 1000X Microstructure of particle in 90-106 m size range. The ASTM grain size is 10.6. The area of SiC particles is 13.3%. The area fraction of the void is 0.6%. Conclusions A new method of MMC powder production is developed; SiCp are successfully injected into the Al matrix. (18% vol SiC) MMC particles are not spherical; Mainly, ligaments, teardrops & tad poles. Oxidation believed to be the main cause. THANK YOU