Scheduling in the Pharmaceutical Industry

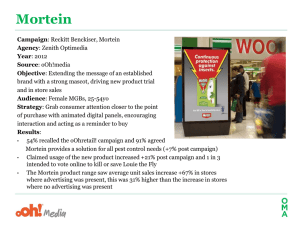

advertisement

SCHEDULING IN THE PHARMACEUTICAL INDUSTRY Kristinn Magnusson Sigrun Gunnhildardottir IEOR 4405 – Production Scheduling Pharmaceutical Industry Most important driver: time-to-market Highly Competitive Very regulated industry High amount of cleaning and set up time needed between jobs Life and death: no room for mistakes Real Life Case High but uncertain demand Supplier’s have long lead times 40 different product families 1000 different product variations (SKU’s) Production Process Goals and Objectives Determine a campaign plan and schedule customer orders within the campaigns Provide realistic and accurate models that are solvable within acceptable computational time General objective of the plans and schedules: meet the quantity and delivery date of customer orders minimize the unproductive production time maximize economic performance of the company Three Level Hierarchical Framework Level 1 Level 2 Level 3 • Based on demand forecasts • Product groups are placed on each machine at each time • Updated at least every 3 months. Horizon: 1 year • Plan is adjusted to the orders that have been received • Updated every week. Horizon: 3 months • Detailed schedule of prodcution tasks • Based on confirmed customer orders • Updated every day. Horizon: 1 month Level 1: Campaign Planning Optimize campaign plan Fulfill predicted demand Minimize production time Helpful for purchasing raw material The model is updated every 3 months Level 1: Model Objective: Minimize Subject to: Allocation Sequencing Delivery Capacity Campaign Mutually Exclusivity Level 2: Campaign Planning and Order Allocation Actual orders are known Revise campaign plan Allocate orders to campaigns Specify in which campaign each order are produced on every production stage It gives the latest allowed completion time for the order Level 3: Detailed Schedule Actual timing of activities Objective to minimize late deliveries The model gives: Machine/Campaign for each order for every production stage Production sequence of orders Start and processing time of tasks Setup time required between orders Heuristic: Decomposition of Production Stages Improving Lower Bounds... ... by adding valid inequalities A constraint for the minimum number of campaignes needed for a feasible solution A constraint for the minimum number of delayed jobs Solution Times These models have been tested with real data and have been shown to be solvable within acceptable computational time 1. level: 14 hours 2. level: 6 hours 3. level: 6 minutes References P. Jensson, N. Shah and H. Stefansson, “Multiscale Planning and Scheduling in the Secondary Pharmaceutical Industry”, Published online October 26, 2006 in Wiley InterScience (www.interscience.wiley.com) N. Shah, “Pharmaceutical supply chains: key issues and strategies for optimisation”, Computers and Chemical Engineering 28 (2004) 929–941 Any Questions ?