ethical concerns in engineering: self-healing polymers

advertisement

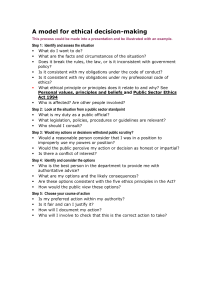

0011 Sanchez 4:00 L03 ETHICAL CONCERNS IN ENGINEERING: SELF-HEALING POLYMERS Victoria Mbakwe (vcm8@pitt.edu) A NEW DIRECTION A vast majority of materials used for industrial products are inert, meaning that they do not chemically or biologically react to external stimuli—temperature, pH, or moisture—and thus are susceptible to permanent damage. Researchers at the American Institute of Physics have synthesized a new polymer that can sense and repair damage, such as fragmentation or fracking in a particular material or fiber, induced by mechanical or chemical factors. This material is known as a self-healing polymer. Self-healing materials are polymers, plastics, metals, and their composites that possess the ability to recognize, repair, and restore themselves to their original state when they are mechanically, thermally, and/or chemically damaged [1]. Self-healing polymers have a vast array of applications, especially in transportation. Structural cracks in the structure of vehicles such as cars, airplanes, and spacecraft not only diminishes the vehicle’s lifespan, but reduces the vehicle’s safety for passengers. Self-healing materials could mend the cracks, improving both the life and safety of the vehicle [2]. Currently, the auto manufacturing company Nissan is utilizing this technology in their innovation of the Scratch Shield. This scratch resistant clearcoat helps repair scratches on a vehicle’s surface, restoring the vehicle’s exterior back to its original condition and giving it a new look for an extended length of time. The benefits of this emerging technology include an increased lifetime and strength of materials used in manufactured product, reduction of the product’s replacement costs, as well as improvement of the product’s safety [3]. Although there are great strides in this new direction of self-healing materials, there lies ethical implications that may impede this technology’s advancement. This paper discusses the engineering code of ethics and how it relates to my ethical dilemma, the ethics in engineering, my personal research, the ethical implications of engineering self-healing polymers, as well as my solution to my dilemma. THE CODE OF ETHICS FOR ENGINEERING “Engineers [shall] uphold and advance the integrity, honor, and dignity of their engineering profession by using their knowledge and skill for the enhancement of human welfare and the environment,” as stated in The National Society of Professional Engineers (NSPE) Code of Ethics. The NSPE Code of Ethics establishes the obligations of all engineers, including myself, have to their company, the public, and society. To qualify, the code explicitly states that University of Pittsburgh, Swanson School of Engineering 1 Submission Date 2014-10-28 “engineers shall hold paramount the safety, health, and welfare of the public,” striving to serve the public and “adher[ing] to the principles of sustainable development in order to protect the environment for future generations” [4]. The American Institute of Chemical Engineering (AICE) Code of Ethics defines that engineers shall “advance the integrity, honor and dignity of the engineering profession by striving to increase the competence and the prestige of that engineering profession and perform professional services only in areas of their competence” [5]. This code applies to chemical and materials engineers, myself included, and stresses the importance of professionalism and conscientiousness for all engineering disciplines. MY ETHICAL DILEMMA Before transferring overseas to Nissan Motor Corporate Ltd. Headquarters in Nishi-ku, Yokohama, Japan, I worked for Nissan Technical Center North America in the metallurgy department as a new graduate student from the University of Pittsburgh, majoring in Materials Science and Engineering and specializing in metallurgy. I followed a team of chemical and materials engineering professionals, who ran tests and evaluated which materials would be appropriate for various automobile components or parts. We researched, synthesized, and developed materials––self-healing polymers––that would be used in coating a vehicle’s body or its engine surface. The purpose of this technology was to give the bodies of Nissan vehicles the ability to “heal” themselves when they are scratched, damaged, corroded, or deformed. After two months of working with the U.S. branch, I was given the opportunity to do polymer research with engineers at the Nissan Motor headquarters in Japan, and a month later, I transferred to the international company. My supervisor at the international company assigned me to the polymer research team, consisting of mostly Japanese post-graduate engineering students, and a few other foreign engineering students, like myself, who were all proficient English.*** During the week I arrived at company, my supervisor scheduled a meeting with my polymer research team. While at the meeting, my supervisor asked us to develop a self-healing material or composite by the end of the month that would be applied to automobile paint coatings for Nissan vehicles. Before meeting was adjourned, my supervisor informed us that if we complete this assignment by the deadline, the company would obtain patent rights for its innovation and as a result, the company will gain huge profits. In this short time-constraint, will we, as a team, be able to follow all safety procedures associated with synthesizing these materials such as safely disposing of toxic waste from Victoria Mbakwe multiple trials of polymer chemical reactions? Will the safety of my team be sacrificed for the Nissan’s profit? Is it ethical for my supervisor to assign my research team to a task where safety is sacrificed for the profit that the company would gain from its innovation? With little experience with polymer research, is it appropriate for my supervisor to assign me to this polymer research, which is not within my area of competence? How will my input influence my team’s final product? On a broader spectrum, what will be the long-term effect of my research and tests of self-healing polymers on the environment, in terms of recyclability, as well as on the public, in general? these products are safe for my clients and the public. I realized that as an employee of the Nissan Motor Company headquarters in Japan, I must ensure I ensure that I discuss my incompetence of physically synthesizing self-healing materials for various automobile uses with my supervisors and members of the polymer research team. This will not only reflect my professionalism and responsibility, but it will also reflect my decision making. University of Illinois at Urbana Champaign professor, Dr. Michael C. Loui, proposes in his video lecture, “Ethical Engineering Decision Making,” ways in which engineers can approach moral problems. First, identify the affected parties, groups of individuals who are directly affected because of my decision and the rights and responsibilities of an engineering company, the public, and myself. Second, consider alternative actions for designing a more environmentally-friendly self-healing polymer, for instance. Third, imagine potential or possible consequences due to my lack of professionalism or conscientiousness [8]. Engineers take risks when they synthesize new products and try to respect their clients and the public by being committing to “public health, safety, welfare, the integrity of data, loyalty, and accountability.” PERSONAL RESEARCH In order to resolve my ethical dilemma, I consulted many resources, including the NSPE and AICE Code of Ethics, so that I could decide what specific action I would need to follow. Additionally, I referenced engineering ethics videos, specifically presented by Texas Tech University STEM (Science Engineering and Math) as well as Dr. Michael C. Loui from the University of Illinois at Urbana-Champaign. These videos detail potential solutions to current engineering ethical problems. Lastly, I read ethical engineering case studies and articles, which focused on key ethical issues engineers confront on a daily basis. ETHICAL IMPLICATIONS OF ENGRINEERING SELF-HEALING POLYMERS ETHICS IN ENGINEERING After conducting personal research with the code of ethics and other engineering case studies, I am now able to analyze my ethical dilemma of engineering self-healing polymers. Although the implementation of self-healing polymers in automobile paint coatings, for instance, will improve the durability and lifetime of vehicles and provide economic gains for auto companies, such as Nissan, if they receive rights to patent their innovation, ethical implications arise. In the case of my ethical dilemma, there are issues of safety versus profit, environmentally-friendliness,” as well as the competence of my team as well as myself. As I divulge into the engineering code of ethics as well as my other resources, I am discovering a way to solve my ethical dilemma. I first began reading academic articles about the ethics in engineering. “One of the most powerful gifts of engineering,” as Eric Butterman, engineering journalist for the American Society of Mechanical Engineers explained, “is how it improves lives. But, in the wrong hands, [engineering] can be the opposite” [6] Every day, engineers are challenged to synthesize and develop products that are cost-efficient, long-lasting and highly-functional. However, performing this feat is difficult because of all the ethical issues that are associated with the manufacturing of these products, such as whether or not the product is safe and/or environmentallyfriendly. It is important for me as an engineer to not only be technical, but also be ethical in my decisions. Joseph R. Herkert, a Lincoln Associate Professor of Ethics and Technology at Arizona State University, highlights a key concept in engineering ethics, “professional responsibility,” which is an individual’s moral responsibility based on his or her unique knowledge. Herkert expands on this idea, stating: “for someone to have a moral responsibility for some matter means that the person must exercise judgment and care to achieve or maintain a desirable state of affairs” [7]. Herkert emphasized the importance of being professional as well as responsible. I understand that as an engineer, I am responsible for creating and developing safe, useful, as well as inexpensive technological products, and I must ensure that SAFETY VS. PROFIT Sacrificing public and/or employee safety for the profit that a company can gain for a patented product is a violation of the engineering code of ethics. Companies are obligated to implement safety measures or support safety of its employees and the public over profitability. This violation raises issues of no only safety, but also risk and an individual’s duty to obey the law. One of the fundamental canons of the NSPE Code of Ethic states that “engineers shall hold paramount the safety, health, and welfare of the public.” In my ethical dilemma, safety would be sacrificed for Nissan’s profitability, if my team met the deadline. Synthesizing self-healing polymers is an extensive process that involves multiple trials and experiments. The Oak Ridge National Laboratory (ORNL) explains this complex process below: 2 Victoria Mbakwe only requires a license, but they machines must be handled carefully. Due to the short time-constraint of synthesizing this self-healing polymer, the possibility of mishandling the equipment may be slightly higher. This potential consequence could lead to reduced safety because there is a higher risk of getting injured while working with these machines. In Dr. Heather Fotheringham’s case study titled, “Safety Measures,” she poses the question, “Is there any level of safety risk to the public that is acceptable?” [10]. Although car manufacturing companies, specifically Toyota, who had numerous recalls stemming from unintended acceleration due to faulty gas pedals and floor mats, there is no level of safety risk to public, or in my dilemma, to my team [11]. My supervisor is not holding safety and health of my team paramount, and would be violating the engineering ethical code that engineers should place the safety, health, and welfare of the public above their interests [4]. In violating this ethical code, we could advance the profitability of Nissan; however, we would not be supporting the advancement of the company’s integrity, honor, and dignity, and therefore does not respect the engineering ethical code that engineers shall “advance the integrity, honor and dignity of the engineering profession by striving to increase the competence and the prestige of that engineering profession and perform professional services only in areas of their competence” [5]. In [these] experiments, researchers begin with a silicon wafer, which they coat with a thin film that is a mixture of deuterated poly(methyl methacrylate) as the matrix polymer, and a branched copolymer of methyl methacrylate and ethylene oxide. As they heat this sample, allowing the mixture to approach thermal equilibrium, the graft copolymer (containing ethylene oxide) diffuses to the surface so that they can measure the water contact angle to verify that the copolymer segregates to the surface. This information is obtained using the Liquids Reflectometer at SNS. ENVIRONMENTAL CONCERN With every product that is manufactured and produced by a company, questions are asked about the sustainability of that particular product: Is the product hazardous to the environment or is it “environmentally-friendly?” Does it consist of biodegradable or renewable materials? Although a majority scientists and polymer engineers propose that selfhealing polymers could “contribute to the extension of polymer lifetime and reduction of waste, and bring us closer to realizing an environmentally sustainable society,” as Dr. Hideyuki Otsuka, materials engineering professor at the Institute for Material Chemistry and Engineering, Kyushu University in Fukuoka, Japan, insists, there is still the possibility that new pollutants could result from the chemical reactions these polymers must undergo for their production. We could potentially be exposed to these pollutants while experimenting with these polymers, which would immediately affect our health, and eventually, if the material is produced and applied to automobile paint coatings, could endanger the public. Another possible environmental concern is the efficiency of the machines used in creating these selfhealing polymers. Dr. Oboetswe S. Motsamai explains in her Journal of Energy Engineering article, “Opportunities for Efficeint and Environmentally Friendly Energy Systems: BMC Case Study in Lobatse, Botswana” that industrial plants need to consider investing in energy efficient methods for producing technologies that require power and heat. This recommendation could lead to low emission of pollutants into the environment and bring financial benefits to these Figure 1 [9] The image above is the Liquids Rfelctometer (LR). The Liquids Reflectometer (LR), shown in Figure 1, mentioned in the excerpt is a machine that is used to observe and study the dynamics of various polymer mixtures for applications, including self-repairing automobile body materials [9]. Machinery similar to the LR are used by my polymer research team at Nissan. Running these machines not 3 Victoria Mbakwe [2] “Polymeric Self-healing Composites for Longer Lasting Products.” Office of Technology Management, Chicago (online article). http://otm.uic.edu/technologies/polymeric-self-healingcomposites-longer-lasting-p>. [3] “Scratch Shield.” (2014) Scratch Shield - Nissan Technological Advancement Activities. (online article). http://www.nissanglobal.com/EN/TECHNOLOGY/OVERVIEW/scratch.html [4] “Code of Ethics.” (2013). American Institute of Chemical Engineers. (online article). http://www.aiche.org/about/codeethics [5] “Code of Ethics.” (2013). National Society of Professional Engineers. (online article). http://www.nspe.org/Ethics/CodeofEthics/index.html [6] "Ethics in Engineering." (2013) ASME. (online article). https://www.asme.org/engineeringtopics/articles/engineering-ethics/ethics-in-engineering [7] J. Herkert. (2014). “Continuing and Emerging Issues in Engineering Ethics Education.” (online journal article). https://www.nae.edu/Publications/Bridge/EngineeringEthics 7377.aspx [8] “Ethical Engineering Decision Making” Illinois Foundry. (2008). (Video). https://www.youtube.com/watch?v=u1BZ3MWpPuk&index =5&list=PL746AE3CCB29B64B8 [9] “Research In Progress Self-Healing Polymers.” (2014) ORNL NEUTRON SCIENCES. (online article). http://neutrons.ornl.gov/research/highlights/polymers_0902f eb.pdf [10] “Safety Measures.” (2008). Inter-Disciplinary Ethics Applied. (online article). http://exchange.ac.uk/downloads/scholarart/ethics/safety_me asures.pdf [11] “Toyota Will Take More Time to Develop New Vehicles After Massive Recalls.” (2014). Huffington Post. (online article). http://www.huffingtonpost.com/2010/07/07/toyotawill-take-more-tim_n_637489.html [12] “Opportunities for Efficient and Environmentally Friendly Energy Systems: BMC Case Study in Lobatse, Botswana.” (2008). ASCE. (online journal article). http://ascelibrary.org/doi/abs/10.1061/(ASCE)EY.19437897.0000022 [13] “Self-healing Polymers.” (2013). http://ascelibrary.org/doi/abs/10.1061/(ASCE)EY.19437897.0000022 companies [12], including Nissan. These environmental concerns breaches the engineering code of ethic that engineers “shall hold paramount the safety, health, and welfare of the public” [4] MY SOLUTION After evaluating and analyzing my ethical dilemma, I can now propose a solution. First, I consulted my polymer research team and explained to them the ethical implications of our engineering project. Second, I collaborated with my team and we develop written statement of the engineering code of ethics we would be violating if we completed the project. The written statement would include the violation of the code that engineers should place safety, health, and the welfare of the public before their interests as well as the code that engineers should increase the integrity of their profession and company by being honorable. Third, we scheduled a meeting with our supervisor, and presented our statement to him. We explained in a professional and responsible matter that in lieu of what Nissan will gain monetarily, we would be violating the engineering code of ethics by sacrificing employ and public safety, as revealed in the statement. In order to adhere to the engineering code of ethics and safety regulations, we asserted that we would need an additional two months and showed him a timeline of how we would complete this project. Whether he rejected our proposal or agreed with our viewpoint, informing our supervisor would agree with the engineering ethical code of advancing the company’s integrity and prestige. For engineers who find themselves in this situation, I recommend collaborating with other engineers, developing a “game plan” or plan for action, and finally, presenting your plan to you manager or supervisor. Ethics play an integral role in engineering because it forces engineers to make ethical and moral decisions, and as a result, we ensure the safety, health, and welfare of the public, and maintain the integrity, honor, and dignity of our profession. ACKNOWLEDGEMENTS I want to thank my Engineering Analysis professor for motivating me to write my paper. Additionally, I want to thank the head writing instructor for giving me ideas of how I should address my engineering ethical dilemma. I also want to thank my peers for reviewing and critiquing my paper. REFERENCES [1] B. Aissa, D. Therriault, W. Jamroz. (2012). “Self-healing materials systems: overview of major approaches and recent developed technologies.” Advances in Materials Science and Engineering. (online article). DOI: 10.1155/2012/854203 4 Your Name 5