Micropile Bond Strength to Concrete

advertisement

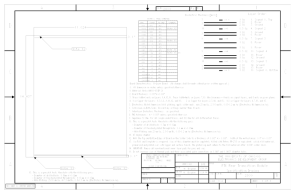

Micropile Bond Strength to Concrete Fundamental Full Scale Test Program Preliminary Results Allen Cadden, P.E. Jesus Gomez, Ph.D., P.E. Schnabel Engineering, Inc. A Privately Funded Research Project – Phase 1 Footing Connection What do you use for the bond stress? Can you prove it? Are you being conservative or unconservative? Test Summary •Tested Steel Bar •Tested Steel Casing •Tested Casing with Weld Beads •Hole Drilled with DHH •Type I grout w:c=.45± Test Setup 4” Block Summary Block Summary Hole 1 Diameter (nom.) Block 1 Drill Length 2 Pile Length (nom.) Diameter cast Drill Length 3 Pile Length (nom.) Diameter cast Drill Length Pile Length (nom.) cast 2 4.5 29.75 18 4.5 30 24 4.5 35.5 36* 3 5 32 18 5 31.75 24 5 38.25 36 4 6 28 24 6 39.25 36 5 8 38 36 8 27? 24 6 6 38 36 6 26.5 24 7 8 23 18 6 21+ 18 dimensions in inches block drilled for strain gage wires All dimensions in inches. 1 inch = 25.4 mm Comments Shear Ring Welds Construction Testing Preliminary Results Preliminary Stress At Hole Perimeter Stress At Reinforcing -0.01 -0.01 B1P1 B1P1 1 mm B2P2 B2P3 B3P1 Bar 0.09 8 inch hole B3P2 2.3 mm B3P3 B4P1 Weld bead B4P2 B5P1 3.5 mm 0.14 Deflection (in) Deflection (in) 0.04 B1P3 B1P3 B2P2 1 mm 0.04 B2P3 B3P1 Bar 0.09 B3P2 Weld bead B3P3 B4P1 8 inch hole 0.14 B4P2 3.5 mm B5P1 B5P2 B5P2 B6P1 B6P1 B6P2 0 200 (1.4 MPa) 400 600 Stress (psi) 800 (5.5 MPa) 4.8 mm 0.19 4.8 mm 0.19 1000 0 300 (2.1 MPa) 600 900 Stress (psi) 1200 (8.3 MPa) B6P2 1500 Summary Data Preliminary Strain Stress 6.0% 16.0 5.0% Strain at Failure (%) 12.0 10.0 8.0 6.0 4.0 3.5 4.0% 3 2.5 3.0% 2 2.0% 1.5 1 1.0% 0.5 2.0 0.0% 0.0 3 53 103 153 203 253 0 0 50 Steel Perimeter 150 200 250 Hole Diameter (mm) Hole Diameter (mm) Hole Perimeter 100 Linear (Hole Perimeter) % of Hole Diameter % of Steel Diameter Deformation vs Hole Diam. Deformation at Failure (mm) 4 14.0 Stress (psi) 4.5 Conclusions and Request Good bond can be achieved with normal grout Use of 200 psi allowable bond value in typical situations is reasonable. Greater stress and strain to failure was observed with deformed steel surface. Shrinkage may be a concern with larger annulus space. Please provide comparative data if you have any.