Total Quality Management TQM - Questrom Publish

advertisement

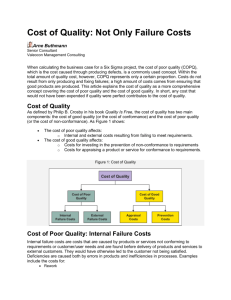

SIGN UPS TODAY Ski Trip - Mount Stowe, VT Sat., Mar. 18 from 5:30 AM - 4:30 PM $65.00/person ($20.00/person ski rental) Blue Man Group - Boston Playhouse Fri., Mar. 24 at 7:00 PM and Sat., Mar. 25 at 4:00 PM Free Guest Speaker Panel – SM 105 Mon., Mar. 20, 7:00 PM - 9:00 PM Free Quality Management Boston University School of Management Professor Peter Arnold What is Quality? The ability of a product or service to consistently meet or exceed customer expectations. The Customer Internal and External Customer Requirements Customer Satisfaction Conflict between Heterogeneous Customer Populations The Customer Who are the customers of the Boston University School of Management? The Customer Customers of the School of Management Alumni Boston University Employers Of Students Of Faculty (e.g. consultants) Faculty Governments Potential Students (applicants) Staff (including administration) Students Universities (other than BU) The Customer What are the requirements of the student customers at BU SMG? The Customer Student Requirements Reputation Housing Qualified Instructors Feedback Small Classes Convenience Strong, Relevant Curriculum Fun Case Studies Varied Learning Experiences Practical Skills Career Services Strong Peer Groups Campus Life Affordable Education Dimensions of Quality Performance: Features: Conformance: Reliability: Durability: Perceived quality: Serviceability: Aesthetics: Primary operating characteristics Secondary characteristics How well specifications are met Consistency of performance Product life Brand image/reputation Ease of service/friendliness of server Effect on senses Garvin Managing Quality If Quality improvement is about any one thing it is about variance reduction. Variation is a term used to describe deviation from the expected. High variation or variability creates great uncertainty in outcome. Variation How much variation in outcome is there? Variation Which has more variation in outcome? Variation Source of Variation? Source of Variation? Six Sigma “The statistical representation of Six Sigma describes quantitatively how a process is performing. To achieve Six Sigma, a process must not produce more than 3.4 defects per million opportunities. A Six Sigma defect is defined as anything outside of customer specifications.” http://www.isixsigma.com/sixsigma/six_sigma.asp Six Sigma focuses on process capability – Develop and operate processes that are capable of producing only “good” units of output. Why would that be an appealing? Savings – less waste, lower capacity utilization, lower fixed costs, increased premium…. Basketball and Six Sigma Suppose there was an outcry by fans of college basketball over the dearth of scoring in the game. Suppose further that the czar of basketball asked us to increase the scoring in college basketball games. The focus of the effort might be the process of shooting hoops. The best field goal percentage in Men’s NCAA Division I basketball is about 65%. How could the average be improved? 1. 2. 3. 4. 5. Study the data Identify patterns in the data Develop countermeasures Implementation Review Fundamental approach to quality improvement F G C G F Division 1 NCAA Men’s Basketball Statistics 2002-3 ncaa.org Rank Name School 1 Adam Mark Belmont 2 Rickey White 3 Field Goals Tried Field Goal % Field Goals per Game Height Position Jr. 6-8 F 28 199 297 67 7.1 Maine Sr. 6-4 F 24 131 198 66.2 5.5 Matt Nelson Colorado State So. 7-0 C 31 205 319 64.3 6.6 4 Armond Williams Ill.-Chicago Jr. 6-5 F 30 168 263 63.9 5.6 5 Michael Harris Rice So. 6-6 F 28 172 276 62.3 6.1 6 Chris Kaman Central Michigan Jr. 7-0 C 31 244 392 62.2 7.9 7 David Gruber Northern Iowa Jr. 6-6 F 28 141 231 61 5.0 8 Ike Diogu Arizona State Fr. 6-8 F 32 209 344 60.8 6.5 9 Omar Barlett Jacksonville State Sr. 6-8 G 30 178 293 60.8 5.9 Jason Keep San Diego Sr. 6-10 C 30 195 323 60.4 6.5 10 Class Field Goals Made Games Division 1 NCAA Men’s Basketball Statistics 2002-3 ncaa.org Free Throws Tried Free Throw % Free Throws per Game Class Height Position Games Free Throws Made Belmont Jr. 6-0 G 29 78 82 95.1 2.7 Matt Logie Lehigh Sr. 6-5 G 28 91 96 94.8 3.3 3 Hollis Price Oklahoma Sr. 6-1 G 34 130 140 92.9 3.8 4 Brian Dux Canisius Sr. 6-4 G 28 115 125 92 4.1 5 J.J. Redick Duke Fr. 6-4 G 33 102 111 91.9 3.1 6 Tim Parker Chattanooga Sr. 6-5 G 30 78 85 91.8 2.6 7 Dwayne Byfield Monmouth So. 6-2 G 28 72 79 91.1 2.6 8 Gerry McNamara Syracuse Fr. 6-2 G 35 90 99 90.9 2.6 9 Kyle Korver Creighton Sr. 6-7 F 34 109 120 90.8 3.2 Jeb Ivey Portland State Sr. 6-2 G 27 69 76 90.8 2.6 Rank Name School 1 Steve Drabyn 2 10 Improving Field Goal Percentage Outlaw defense Do not take very many shots Practice, Practice, Practice Only shoot from short distances Permit only very tall players to shoot Decrease the height of the basket Increase the diameter of the basket Make the rim out of thick fluffy cotton material Make the backboard convex Decrease the size of the ball Make the ball out of sponge materials Poor Quality What happens when quality is poor? • Costs increase • Customers complain more costs • Customers don’t come back highest costs • And along with increasing costs, you have fewer goods or services to sell. Cost of Quality • • • • • Conceptual Framework Not Always Totally Quantifiable Useful for Attention Getting Useful as a Mechanism for Keeping Score Consistency of Measurement Four Categories of Cost • Cost of Prevention • Cost of Appraisal Increasing overall quality results from investment in these • Cost of Internal Failure • Cost of External Failure Increasing overall quality results in lower experience with these Total Cost Cost Internal and External Failures Prevention and Appraisal Poor Superior Level of Quality Cost of Prevention • • • • • • Quality Planning Design (Prototyping, Field Testing) Education and Training Process Control Information reporting Quality Improvement Programs, Quality Improvement Teams (QIPs and QITs) • Supplier Involvement Cost of Appraisal • • • • • • Incoming Inspection In-Process Inspection Final Inspection Testing Devices Destructive Testing Inventory Safeguarding Cost of Internal Failures • • • • • • Scrap – wasted materials and labor Rework – doing the job twice Retesting – checking the second time Downtime - Capacity Yield Losses – goods unavailable for sale Managing Defective Materials – making sure the bad ones do not get out. Calculating the Cost of Scrap: Yield Loss DataStor – Perfect Quality – Disk Fabrication Pre-Stage Material Labor Stage Stage-End Cost Cost Cost Yield Cost Coat & Polish $0.000 $0.050 $0.010 100.0% $0.060 Assemble $0.060 $0.080 $0.040 100.0% $0.180 Package $0.180 $0.010 $0.030 100.0% $0.220 $0.140 $0.080 100.0% Stage Overall Calculating the Cost of Scrap: Yield Loss (cont.) DataStor – Yield Loss – Disk Fabrication Pre-Stage Material Labor Stage Stage-End Cost Cost Cost Yield Cost Coat & Polish $0.000 $0.050 $0.010 92.0% $0.065 Assemble $0.065 $0.080 $0.040 71.0% $0.010 $0.030 99.0% $0.140 $0.080 64.7% Pre-Stage Material Labor Stage Stage-End Cost Cost Cost Yield Cost Coat & Polish $0.000 $0.050 $0.010 92.0% $0.065 Assemble $0.065 $0.080 $0.040 71.0% $0.261 Package $0.261 $0.010 $0.030 99.0% $0.304 $0.140 $0.080 64.7% Stage Package Overall Stage Overall Cost of External Failures • • • • • Customer Complaint Adjustment Returned Materials - Restocking and Reshipping Warranty Charges Allowances for Defective Materials Lost Business Trade-offs • Appraisal and Prevention (Investment) • Internal and External Failures (Expense) • As the level of Quality Improves – Appraisal and Prevention Increase – Internal and External Decrease Cost of Prevention • • • • • • • • Quality Planning Design (Prototyping, Field Testing) Education and Training Process Control Quality Information Systems Quality Reporting Quality Improvement Programs, Quality Improvement Teams Supplier Involvement What are the long-run consequences of investment in these items? Total Cost Cost Internal and External Failures Prevention and Appraisal Poor Superior Level of Quality