Mass Balance Slides

advertisement

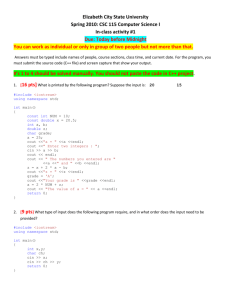

Mass Balances Fundamental Principle of (Dynamic) Mass Balances The rate at which something accumulates in a region of interest (a “control volume”) equals the net rate at which it enters by physical movement plus the net rate at which it is generated inside the control volume by chemical reactions. Processes for Transport Across the Boundaries of an Aquatic System Advection: Bulk flow, carrying the substance of interest with it Molecular Diffusion: Random thermal kinetic motion, leads to net transport down a concentration gradient Dispersion: Random motion of small packets of fluid, leading to same result as molecular diffusion, but usually faster The Mass Balance in Words Rate of change of the amount of i stored within the system (rate of accumulation) = Net rate (in - out) at which i enters by advection + Net rate (formation - destruction) at which i is created by chemical reaction The ‘Storage’ or ‘Accumulation’ Term d Vci Rate of Accumulation dt Special Cases dci Well-Mixed, Rate of Accumulation V Fixed Volume: dt Steady State: Rate of Accumulation 0 The Advective Term Net Advective Inflow Q c in i ,in inlets - Q c out i ,out outlets Special Case Batch system: Net Advective Flow 0 The Reaction Term Mass or moles of i formed Reaction Rate ri Volume Time Net Reaction Term rV i CV ri fcn ci , c j , ck ,..., T The Reaction Term Special Cases Non-reactive Substance (Conservative Tracer): ri 0 nth-order Reaction Dependent Only on ci: ri k c n n i The Overall Mass Balance for Constant-Volume Systems d cV i CV Qin ci ,in - Qout ci ,out dt inlets outlets all reactions rV i CV Hydraulic Characteristics of Reactors Idealized Model Reactors Limiting Case #1. Unidirectional advection with no mixing: A Plug Flow Reactor (PFR). Often used to model rivers, pipe flow, settling basins, disinfection processes. Q, cin Q, cout x L All parcels of fluid have identical residence time: L LA V vx vx A Q Concentration Anticipated Tracer Output for a Pulse Input to a PFR Output Input 0 Time Concentration Anticipated Tracer Output from Step Input to a PFR Input F t Output cs t cin ,t 0 0 Time More Realistic Tracer Profiles after a Pulse Input into a PFR-Like Reactor Dimensionless Conc., c /c o Concentration 12 t / = 0.3 10 0.5 0.7 8 0.9 6 4 2 0 0.0 0.2 0.4 0.6 Dimensionless Distance, x /L 0.8 1.0 Idealized Model Reactors Limiting Case #2. Advection with intense mixing: a Completely Stirred Tank Reactor (CSTR, CMFR, CFSTR, CMR). Often used to model lakes, reservoirs, flocculation basins. Q, Cin V Q, Cout • All parcels of fluid have identical chance of exiting in any instant, so they have a wide range of residence times; still =V/Q CSTR Response to a Pulse Input of Tracer, Steady Flow Evaluate from t = 0+ to Q, Cin Q, Cout • Constant V, Q • cin = 0 (at t>0+) • ci = ci,out • No reaction d cV i Qin ci ,in - Qout ci ,out rV i dt dci V Qin ci ,in - Qout ci ri V dt dci V -Qci dt CSTR Response to Pulse Input dci V -Qci dt c t t t dci Q 1 c 0 ci - V 0 dt - 0 dt c t t ln c 0 t c t c 0 exp M t exp - V CSTR Response to Pulse Input 1.0 0.9 0.8 t c t c 0 exp - 0.6 0.5 0.4 0.3 1/e 0.2 0.1 0.0 0 2 Time 3 4 5 6 0 c t t ln c 0 -1 -2 ln(cp /c o) cp /c o 0.7 -3 -1 -4 1 -5 (b) -6 -7 0 2 3 Time 4 5 6 CSTRs-in-Series: Response to a Pulse Input of Tracer 0.035 0.030 20 E (t ), min- 1 0.025 0.020 0.015 N =1 0.010 2 4 0.005 0.000 0 20 40 60 80 100 t (min) 120 140 160 180 Representing Intermediate Degrees of Mixing PFR with Dispersion: Zero dispersion is PFR; increasing dispersion increases mixing; infinite dispersion is a CSTR CSTRs in Series: Increasing N (keeping V and Q constant) segregates (conceptual) segments of reactor and decreases mixing; as N increases, overall mixing decreases, and reactor becomes more PFR-like Summary of Key Points Reactor hydraulics can be characterized by the range of residence times of entering water ‘packets’ Ideal, limiting cases include PFRs (no mixing) and CSTRs (infinite mixing) For both CSTRs and PFRs, the average residence time, , is V/Q. For PFRs all the fluid spends time in the reactor; for CSTRs, different packets of fluid spend different amounts of time in the reactor, but the average is Summary of Key Points Conformity to a limiting case can be assessed by a pulse or step input test combined with a mass balance analysis Intermediate mixing can be modeled as dispersion and/or CSTRs in series Designing and Evaluating Systems in which Chemical Reactions are Occurring Extent of Reaction in a Batch Reactor dc dc VV Q cinin - Qc Q cout Vr Vr Qc out dtdt dc r dt c t t dc c 0 r 0 dt t 1st-Order Reaction in a Batch Reactor In a disinfection process, bacterial kill follows the first-order reaction expression: rX = -(1.38 min-1)cX. How long is required for 99% disinfection? ct c t c t dc dc 1 dc 1 c t t - - ln r c 0 -k1c k1 c 0 c k1 c 0 c 0 1 tln 0.01 3.3 min -1 1.38 min Extent of Reaction in a CSTR at Steady State Q Q Cin Cout d Vc dt Qcin - Qcout Vr V Cout cout V - cin r r Q cout - cin r 1st-Order Reaction in a CSTR at Steady State What average residence time is required for the same, 99% kill of bacteria, if the reactor is a CSTR? If the flow rate is 1.5 m3/min, how large must the reactor be? cout - cin 1 - 100 71.7 min -1 -k1c - 1.38 min 1 m3 60 s 3 V Q 1.5 71.7 min 6450 m s min Extent of Reaction in a PFR at Steady State Because a PFR is essentially a batch reactor on a conveyor belt, the extent of reaction in a PFR with a given detention time is identical to the extent of reaction over an equivalent time period in a batch reactor. dc r dt cout cin dc dt r 0 A contaminant decomposes according to the rate expression: ri=-kci0.5, with k=750(mol/L)0.5/s. What residence time is required in a PFR to reduce ci from 10-3 to 10-4 mol/L? cout cin dc r cout cin dc 1 0.5 -kc k 2 7.5x10 -5 mol/L s 0.5 cout cin dc 2 0.5 0.5 - cout - cin 0.5 c k -4 mol 0.5 -3 mol 0.5 10 - 10 577s L L Summary of Key Points The extent of reaction that occurs in a reactor depends on both the intrinsic reaction rate and the hydraulics. The net result can be obtained by applying appropriate parameter values and appropriate assumptions to a mass balance on the reactant. PFRs are identical to batch reactors moving through space. The instantaneous dilution of reactants in a CSTR causes those reactors to be less efficient than PFRs or batch reactors