JF_Mechanical_InterfaceDoc_ESS

advertisement

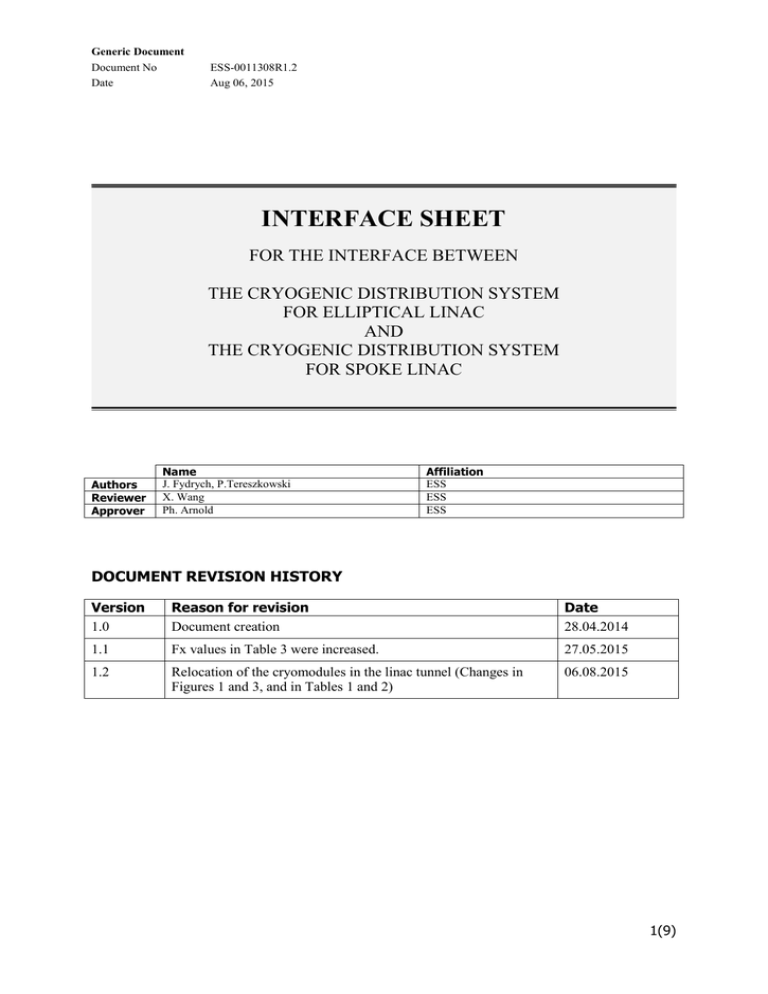

Generic Document Document No Date ESS-0011308R1.2 Aug 06, 2015 INTERFACE SHEET FOR THE INTERFACE BETWEEN THE CRYOGENIC DISTRIBUTION SYSTEM FOR ELLIPTICAL LINAC AND THE CRYOGENIC DISTRIBUTION SYSTEM FOR SPOKE LINAC Authors Reviewer Approver Name J. Fydrych, P.Tereszkowski X. Wang Ph. Arnold Affiliation ESS ESS ESS DOCUMENT REVISION HISTORY Version 1.0 Reason for revision Document creation Date 28.04.2014 1.1 Fx values in Table 3 were increased. 27.05.2015 1.2 Relocation of the cryomodules in the linac tunnel (Changes in Figures 1 and 3, and in Tables 1 and 2) 06.08.2015 1(9) Generic Document Document No Date ESS-0011308R1.2 Aug 06, 2015 SUMMARY This document provides the technical parameters of the interface between the Cryogenic Distribution System for Elliptical Linac and the Cryogenic Distribution System for Spoke Linac. The location of the interfaces for the Cryogenic Distribution Lines and four auxiliary process lines are given together with the permissible forces for the process pipes, radiation shields and external envelopes. TABLE OF CONTENT Document Revision History ................................................................................ 1 Summary .......................................................................................................... 2 Table of content ................................................................................................ 2 1. Introduction ........................................................................................................ 3 2. Location and arrangement of the interfaces ............................................................... 3 3. Mechanical properties of the interfaces ..................................................................... 8 2(9) Generic Document Document No Date 1. ESS-0011308R1.2 Aug 06, 2015 INTRODUCTION The Cryogenic Distribution system for the ESS accelerator is composed of two following system: Cryogenic Distribution System for Elliptical Linac, and Cryogenic Distribution System for Spoke Linac. Interface to the ACCP Helium recovery line HP line Purge return CDS for the elliptical linac SV relief line Cryogenic Transfer Line Auxiliary Process Lines TS supply line TS return line Interface between the CDS subsystems Figure 1 shows a flow scheme of the cryogenic distribution system for the ESS linac. The interface between the CDS for Elliptical Linac and the CDS for Spoke Linac is located between the valve boxes for crymodules Spk-13 and MB-01. The aim of this document is to provide the technical parameters of the interface between these two systems. The interface includes the connections of the Cryogenic Distribution Line and four main auxiliary process lines. The Cryogenic Distribution Line consists of external envelope, radiation shield and four main cold process lines: He supply line (MC), VLP line (MB), TS supply line (ME) and TS return line (MF). The main auxiliary process lines are Helium recovery line (MR), HP line (MH), Purge return line (MP) and SV relief line (MS). The document describes the locations of the line interfaces, the positions and tolerances of the interface centres as well as the permissible forces between the pipes in the interfaces. CDS for the spoke linac He supply line VLP line Cryogenic Distribution Line Splitting box Valve box Valve box Cryomodule HB-30 Valve box Cryomodule MB-01 End box Valve box Cryomodule Spk-13 Cryomodule Spk-01 Figure 1. General flow scheme of the cryogenic distribution system for the ESS linac 2. LOCATION AND ARRANGEMENT OF THE INTERFACES The interface between the Cryogenic Distribution Systems for Elliptical Linac and for Spoke Linac is located in the accelerator tunnel between Medium Beta Valve Box 01 and Spoke Valve box 13. Figures 2 and 3 show the locations of interface points for the Cryogenic Distribution Line (interface point 1) and auxiliary process lines (interface point 2). The locations of these points are dimensioned from interface point MB01 at the interface between the Valve box and Medium Beta Cryomodule No 01. The coordinates of interface point MB01 are X = 488934 mm, Y = 244 mm and Z = -3255 relative to the TCS coordinate system (refer to ESS-0002691). The arrangement of the cold process lines in the interface of Cryogenic Distribution Line (CDL) is shown in Figures 4 and 5. The centre of the interface (Interface point 1) is in the centre of the external envelope end. The positions of the cold process lines are given in respect to Interface point 1. Table 1 3(9) Generic Document Document No Date ESS-0011308R1.2 Aug 06, 2015 gives the coordinates and tolerances for the external envelope (Interface point 1), cold process lines and thermal shield. The arrangement of the auxiliary process lines in the interface is shown in Figure 6. The positions of these lines are given in respect to Interface point 2, which is placed in the cross section centre of Helium recovery line. The coordinates and tolerances for the auxiliary process line interfaces are given in Table 2. Figure 2. Locations of the interface points at the medium beta valve box MB-Vbox01 in the accelerator tunnel – side view 4(9) Generic Document Document No Date ESS-0011308R1.2 Aug 06, 2015 Figure 3. Locations of the interface points at the medium beta valve box MB-Vbox01 in the accelerator tunnel – top view 5(9) Generic Document Document No Date ESS-0011308R1.2 Aug 06, 2015 Figure 4. Arrangement of the cold process pipes in the CDL interface - side view Figure 5. Arrangement of the cold process pipes in the CDL interface - front view 6(9) Generic Document Document No Date ESS-0011308R1.2 Aug 06, 2015 Figure 6. Arrangement of the interface of the auxiliary process lines - front view Table 1. Coordinates and tolerances for the Cryogenic Distribution Line interface Coordinates Pipe Tolerances X [mm] Y [mm] Z [mm] X [mm] Y [mm] Z [mm] TS supply line (ME) 273 a -151 a -91 a 2 a 2 a 2 a TS return line (MF) 273 a 0a -194 a 2 a 2 a 2 a He supply line (MC) 257 a 107 a -132 a 2 a 2 a 2 a VLP line (MB) 256.5 a 0a 72 a 2 a 2 a 2 a Thermal shield 70 a 0a 0a 2 a 2 a 2 a 495056 b 1350 b -4591 b 6270 c 1106 c -1336 c 10 b 5 b 5 b External envelope (Interface point 1) a Coordinates and tolerances in respect to Interface point 1 (refer to Figures 4 and 5) b Coordinates relative to the TCS coordinate system. X, Y and Z-axes of the local coordinate system correspond to the coordinate axes in TCS c Coordinates in respect to Interface point MB01 at the interface to the Medium Beta Cryomodule No 01 (refer to Figures 2 and 3) 7(9) Generic Document Document No Date ESS-0011308R1.2 Aug 06, 2015 Table 2. Coordinates and tolerances for the interface of the auxiliary process lines Coordinates Pipe X [mm] Y [mm] Tolerances Z [mm] X [mm] Y [mm] Z [mm] HP line (MH) 0a 0a -420 a 2 a 2 a 2 a Purge return line (MP) 0a -60 a -340 a 2 a 2 a 2 a SV relief line (MS) 0a 140 a -230 a 2 a 2 a 2 a 494936 b 1950 b -2700 b 10 c 5 c 5 c Helium recovery line (MR) (Interface point 2) a 6150 c 1706 c 555 c Coordinates and tolerances in respect to Interface point 2 (refer to Figure 6) b Coordinates relative to the TCS coordinate system. X, Y and Z-axes of the local coordinate system correspond to the coordinate axes in TCS c Coordinates in respect to Interface point MB01 at the interface to the Medium Beta Cryomodule No 01 (refer to Figures 2 and 3) 3. MECHANICAL PROPERTIES OF THE INTERFACES The cold process pipes at the interface of the Cryogenic Distribution Line and the process pipes of Helium recovery line and SV relief line at the interface of the auxiliary process lines shall be manufactured in austenitic stainless steels suitable for the use at very low temperatures. The choice of materials has to be in line with the Pressure Vessel Directive 97/23/EC and must be done according to SS-EN 13480-2. All process gas carrying components must be fabricated of austenitic stainless steel and/or austenitic stainless steel tubes with test certificate according to EN 10204-3.1. The vacuum vessels of the cryogenic transfer line and Helium recovery line shall be made of appropriate austenitic stainless steel like 1.4306 or equivalent from welded pipes or rolled sheets. The permissible forces for the process pipes, thermal shield and external envelope for the interfaces between the Cryogenic Distribution Lines and between the auxiliary process lines are presented in Table 3 and 4, respectively. 8(9) Generic Document Document No Date ESS-0011308R1.2 Aug 06, 2015 Table 3. Permissible forces in the Cryogenic Distribution Line interface Pipes Dimensions [mm] Pressure [bar] Fx [kN] Fy [kN] Fz [kN] VLP line (MB) DN200 (219.1x2.6) 6.0 40.0 10.0 15.0 TS supply line (ME) DN50 (60.3x2.3) 25.0 17.0 10.0 15.0 He supply line (MC) DN65 (76.1x2.3) 6.0 10.0 10.0 15.0 TS return line (MF) DN50 (60.3x2.3) 25.0 17.0 10.0 15.0 Thermal shield 475x2 NA 0.0 0.0 0.0 External envelope DN550 (558.8x4.8) 50.0 20.0 40.0 from -1.0 (g) to 0.5 (g) Table 4. Permissible forces in the interface of the auxiliary process lines Pipes Dimensions [mm] Pressure [bar] Fx [kN] Fy [kN] Fz [kN] Helium recovery line (MR) DN80 (88.9x2.3) 6.0 10.0 10.0 10.0 HP line (MH) DN32 (42.4x2.0) 25.0 10.0 10.0 10.0 Purge return line (MP) DN50 (60.3x2.3) 6.0 10.0 10.0 10.0 SV relief line (MS) DN200 (219.1x2.6) 6.0 10.0 10.0 10.0 External envelope of Helium recovery DN150 (168.3x2.6) line from -1.0 (g) 20.0 20.0 40.0 to 0.5 (g) 9(9)