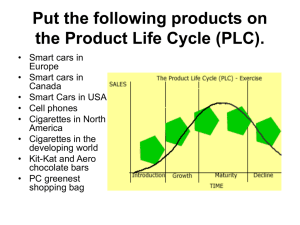

PowerPoint 프레젠테이션

advertisement

LG PLC Smart I/O LG Industrial Systems 1 LG PLC LG Smart I/O Smart I/O is: Open-type remote I/O module, connected with a field network, for real-time controlling I/O modules distributed in a field Compact Compact design supporting DIN Rail Flexible Supporting four field networks (Rnet/Profibus-DP/DeviceNet/Modbus) Having various I/O modules (16/32 points, DC/Relay/TR type) Available to systematise other devices in various ways Easy Setting parameters easily using dedicated configurator (Sycon) or GMWIN/KGLWIN without additional programming (Rnet/Profibus-DP/DeviceNet) Simplification of a program (Modbus) through the LGIS FB (command) 2 LG PLC LG Smart I/O 1. Compact Size A (Length) B (Width) C (Depth) 16-point I/O 115mm 50mm 39mm 32-point I/O 176mm 50mm 39mm 16-point Module 32-point Module 3 LG PLC LG Smart I/O 2. Four Field Networks Support Item Rnet Profibus-DP DeviceNet Modbus Protocol LGIS Dedicated Rnet Protocol (Fnet for Remote) Profibus-DP (RS-485/EN50170) DeviceNet (CAN) Modbus (RS-422) Transmission speed 1Mbps 9.6kbps~12Mbps 125/250/500kbps 2.4kbps~38.4kbps Transmission Distance 750m/segment 100m~1.2km 500/250/125m (Thin cable: 100m) 500m Topology BUS BUS Trunk & Drop BUS Transmission Method Token pass & Broadcast Token pass & Master/Slave (Poll) CSMA/NBA (Poll Cyclic,COS,Strobe) Master/Slave (Poll) Max. number of stations 32 sta./segment (in 32sta./out 32 sta.) 32 sta./segment (sta. #: 1~99) 64 stations 32 stations Link Capacity 2,048pt./master (64 sta. * 32 pt.) 1K/master: -PUEA 7K/master: -PUEB 2,048pt./Master 64pt./station 4 LG PLC LG Smart I/O ♣ Field Network Application Overview AB (Rockwell) -dominated DeviceNet applied in the U.S. and Siemens-dominated Profibus-DP standardised in Europe are a new trend Europe Fi e Lo Fi In Co nt M ld od rol Ne bu bu t s s te Co De nt vi c Pr In of te L rb onW ibu s u e o Ha rt Net s-S rks -DP Pr of De i v nW eld rbu rol Mod bus ice -D sNe Ne bu or bu SD P S t t s k s S U.S. * The above is the relative data based on the VDC document. * Dedicated network systems are not included. : Network supporting LGIS Remote 5 LG PLC LG Smart I/O 3. Various I/O Modules (24 types in total) Input Items Output DC (Sink/Source) Points 16 32 TR (Sink) 16 32 Mixed Input/Output Relay DC (Sink/Source) TR (Sink) 16 16 16 Rated Input (Load Voltage) DC 24V DC24V DC24V/ AC110V/ 220V DC24V DC24V Rated Input Current (Load Current) 7mA 0.1A/2A 2A/5A 7mA 0.1A/2A Off/On Under 3ms Under 0.5ms Under 10ms Under 3ms Under 0.5ms On/Off Under 3ms Under 1ms Under 10ms Under 3ms Under 1ms 16points/COM 16points/COM 8points/COM 16pt./COM 16pt./COM 35mA 30mA Response Time Common (point/COM) Current Consumption Supporting Network & Part Number 35mA 40mA 30mA 65mA 400mA Rnet GRL-D22A GRL-D24A GRL-TR2A GRL-TR4A GRL-RY2A GRL-DT4A Profibus GPL-D22A GPL-D24A GPL-TR2A GPL-TR4A GPL-RY2A GPL-DT4A DeviceNet GDL-D22A GDL-D24A GDL-TR2A GDL-TR4A GDL-RY2A GDL-DT4A Modbus GSL-D22A GSL-D24A GSL-TR2A GSL-TR4A GSL-RY2A GSL-DT4A 6 LG PLC LG Smart I/O 4. System Configuration - Flexible LG PLC Interface I/O I/O I/O RUEA CPU POWER GLOFA/Master-K (Master) RNET (1Mbps, Twisted Pair) #1 Smart I/O #2 Smart I/O #3 Smart I/O I/O I/O I/O CUEA CPU POWER CPU Master Module Remote I/O GM3, K1000S G3L-RUEA GM4, K300S G4L-RUEA GM6, k200S G6L-RUEA GRL-D22A GRL-D24A GRL-TR2A GRL-TR4A GRL-RY2A GRL-DT4A CPU Master Module Remote I/O GMR/1/2/3 G3L-CUEA GM4 G4L-CUEA GM6 G6L-CUEC GSL-D22A GSL-D24A GSL-TR2A GSL-TR4A GSL-RY2A GSL-DT4A GM7, K80S G7L-CUEC #N Smart I/O GM7/K80S (Master국) GLOFA-GM (Master) Modbus (RS-422, Max 38.4kbps) #1 Smart I/O #2 Smart I/O #3 Smart I/O #N Smart I/O 7 LG PLC LG Smart I/O LG PLC Interface I/O I/O I/O PUEA CPU POWER GLOFA/Master-K (Master) Profibus-DP (Max 12Mbps) #1 Smart I/O #2 Smart I/O #3 Smart I/O I/O I/O I/O DUEA CPU POWER CPU Master Module Remote I/O GM3, K1000S G3L-PUEA/B GM4, K300S G4L-PUEA/B GM6 G6L-PUEA/B GPL-D22A GPL-D24A GPL-TR2A GPL-TR4A GPL-RY2A GPL-DT4A CPU Master Module Remote I/O GM3, K1000S G3L-DUEA GM4, K300S G4L-DUEA GM6 G6L-DUEA GDL-D22A GDL-D24A GDL-TR2A GDL-TR4A GDL-RY2A GDL-DT4A #N Smart I/O GLOFA/Master-K (Master) DeviceNet (Max 500kbps) #1 Smart I/O #2 Smart I/O #3 Smart I/O #N Smart I/O 8 LG PLC LG Smart I/O Interface with other PLCs Other PLC (Master) Profibus-DP (Max 12Mbps) Maker CPU (Master Module) Remote I/O Siemens S7-315-2DP (built-in) S7-413-2DP (built-in) S7-300 (CP342-5) S7-400 (CP443-5), etc Mitsuishi Q (QJ71PB92D) AnA/AnU (AJ71PB92D) AnS (A1SJ71PD92D) GPL-D22A GPL-D24A GPL-TR2A GPL-TR4A GPL-RY2A GPL-DT4A Omron C200H/CS1 (C200HW-PRM21), etc Other PLCs available #1 Smart I/O #2 Smart I/O #3 Smart I/O #N Smart I/O Other PLC (Master) Maker CPU (Master Module) Remote I/O Rockwell SLC500 (1747-SDN/B) ControlLogix (1756-DNB) Mitsuishi Q (QJ71DN91) AnA/AnU (AJ71DN91) AnS (A1SJ71DN91) GDL-D22A GDL-D24A GDL-TR2A GDL-TR4A GDL-RY2A GDL-DT4A Omron C200H/CS1 (C200HW-DRM21) CQM1 (CQM1-DRT21) DeviceNet (Max 500kbps) #1 Smart I/O #2 Smart I/O #3 Smart I/O #N Smart I/O 9 Other PLCs available LG PLC LG Smart I/O Interface with other PLCs Maker CPU (Master Module) Remote I/O Schneider Modicon Series Telemechanic Series Squae D Series Mitsuishi AnA/AnU (AJ71UC24-S2) AnS (A1SJ71UC24-S2) GSL-D22A GSL-D24A GSL-TR2A GSL-TR4A GSL-RY2A GSL-DT4A Other PLC (Master) Modbus (RS-422, Max 38.4kbps) Other PLCs available #1 Smart I/O #2 Smart I/O #3 Smart I/O #N Smart I/O 10 LG PLC LG Smart I/O PC Interface Maker - PC Board Remote I/O General RS-422 Board GSL-D22A GSL-D24A GSL-TR2A GSL-TR4A GSL-RY2A GSL-DT4A PC Application Others available Modbus (RS-422, Max 38.4kbps) #1 Smart I/O #2 Smart I/O #3 Smart I/O #N Smart I/O 11 LG PLC LG Smart I/O PC Interface PC Application Profibus-DP (Max 12Mbps) Maker PC Board Remote I/O Siemens CP5614 FO PCI Softing Profi Board for PCI ComSoft DF PROFI PCI GPL-D22A GPL-D24A GPL-TR2A GPL-TR4A GPL-RY2A GPL-DT4A Others available #1 Smart I/O #2 Smart I/O #3 Smart I/O #N Smart I/O PC Application Maker PC Board Remote I/O Rockwell 1784-PCID (S) Hilscher CIF50-DNM Beckhoff FC5201 GDL-D22A GDL-D24A GDL-TR2A GDL-TR4A GDL-RY2A GDL-DT4A DeviceNet (Max 500kbps) Others available #1 Smart I/O #2 Smart I/O #3 Smart I/O #N Smart I/O 12 LG PLC LG Smart I/O Device comparison - DC input module LGIS (Smart I/O) AB (Compact Block) Mitsubishi Omron Part Number G□L-D22A (16P) G□L-D24A (32P) 1791D-16B0 AJ65SBTB1-16D AJ65SBTB1-32D DRT1-ID08(-1) DRT1-ID16(-1) Point 16 / 32 16 16 / 32 8 / 16 Type Sink / Source Sink / Source Sink / Source Sink / Source Rated Input DC 24V DC 24V DC 24V DC 24V Rated Input Current 7mA 2~11mA 7mA 10mA Operation Voltage On More than 19V More than 10V More than 14V More than 15V Off Under 6V Under 5V Under 6V Under 5V Response Time Off/On Under 3ms 1~32ms setting Under 1.5ms Under 3ms On/Off Under 3ms 1~32ms setting Under 1.5ms Under 3ms Connection Terminal block Terminal block Terminal block Terminal block Common 16/com 8/com 16 or 32/com 8 or 16/com Size 116 * 51 * 40 (16P) 184 * 51 * 40 (32P) 148 * 48 * 38 118 * 50 * 40 (16P) 179 * 50 * 40 (32P) 125 * 50 * 40 (8P) 150 * 50 * 40 (16P) Support Network DeviceNet ● ● × ● Profibus ● × × × Modbus ● × × × CC-Link × × ● × 13 LG PLC LG Smart I/O Device comparison – Tr Output module LGIS (Smart I/O) AB (Compact Block) Mitsubishi Omron Part Number G□L-TR2A G□L-TR4A 1791D-0B16P AJ65SBTB1-16T AJ65SBTB1-32T DRT1-OD08(-1) DRT1-OD16(-1) Point 16 / 32 16 16 / 32 8 / 16 Type Sink Sink / Source Sink Sink Rated Input DC 24V DC 12/24V DC 12/24V DC 12/24V Rated Input Current 0.1A / 2A*1 0.5A / 4A 0.5A / 3.6A (16P) 0.5A / 4.8A (32P) 0.3A Response Time Off/On Under 0.5ms Under 0.5ms Under 0.5ms - On/Off Under 1ms Under 1ms Under 1.5ms - Connection Terminal block Terminal block Terminal block Terminal block Common 16/com 8/com 16 or 32/com 8 or 16/com Size 116 * 51 * 40 (16P) 184 * 51 * 40 (32P) 148 * 48 * 38 (16P) 118 * 50 * 40 (16P) 179 * 50 * 40 (32P) 125 * 50 * 40 (8P) 150 * 50 * 40 (16P) Support Network DeviceNet ● ● × ● Profibus ● × × × Modbus ● × × × CC-Link × × ● × *1 Support afterward: 0.5A/4A (May, 2003) 14 LG PLC LG Smart I/O Device comparison - Relay Output module LGIS (Smart I/O) AB (Compact Block) Mitsubishi Omron Part Number G□L-RY2A - AJ65SBTB2-8R GT1-ROP16 Point 16 - 8 16 Type Relay - Relay Relay Rated Input DC 24V/AC 240V - DC 12/240V DC 24V/AC 240V Rated Input Current 2A / 5A - 2A / 4A 2A Response Time Off/On Under 10ms - Under 10ms Under 10ms On/Off Under 10ms - Under 12ms Under 12ms Connection Terminal block - Terminal block Terminal block Common 8/com - 8/com 16/com Size 184 * 51 * 40 - 118 * 50 * 40 160 * 60 * 50 DeviceNet ● - × ● Profibus ● - × × Modbus ● - × × CC-Link × - ● × Support Network 15 LG PLC LG PLC APM Advanced Position Module LG Industrial Systems 16 LG PLC APM (Advanced Position Module) 1. Features LGIS ASIC-embedded processor for APM 3-axis linear/2-axis arc interpolation operation Simultaneous/synchronous/separate operation Parameter setting with mm, inch, degree, and pulse unit Parameter, position data change by external device or program 3-axis APM module Direct Start by external input signal (without program) LGIS ASIC 17 LG PLC APM (Advanced Position Module) 2. Specifications ( I ) Item K300S (GM4) G4F-PP1 / 2 / 3O G4F-PP1 / 2 / 3D K200S (GM6) G6F-PP1 / 2 / 3O G6F-PP1 / 2 / 3D Open Collector Differential Output type No. of axes 1, 2, 3 Positioning data 400step/axis Unit mm, inch, degree, pulse Pos. address range -2,147,483,648 ~ +2,147,483,647 Max. output pulse Differential output: 1Mpps Open Collector output: 200kpps Data back-up Flash memory Origin point return Near-zero point dog, Z phase, upper/lower limit switch Speed range 0.1 ~ 1200.00 / 6000.00 (mm/min) 0.01 ~ 120.000 / 600.000 (inch/min) 0.01 ~ 120.000 / 600.000 (degree/min) 1 ~ 200000 / 1000000 (pulse/s) 18 LG PLC APM (Advanced Position Module) 2. Specifications ( II ) Item K300S (GM4) G4F-PP1 / 2 / 3O G4F-PP1 / 2 / 3D K200S (GM6) G6F-PP1 / 2 / 3O G6F-PP1 / 2 / 3D Interpolation Max. 3-axis linear/2-axis arc interpolation Control method Position, speed, position/speed, speed/position, PTP Acc/Dec pattern Trapezoidal & S curve Acc/Dec time 4-type Acc/Dec pattern selection available Ext. command signal JOG For/Rev Signal / Automatic Operation / Simultaneous Start / Emergency Stop / Speed Position Conversion Operation indication 17 segment indicator, LED Max. installation Without limit (main and extension base) I/O occupation point 32 point (MASTER-K series only) Connector 40-pin connector 19 LG PLC APM (Advanced Position Module) 3-axis linear interpolation - 3-axis linear interpolation control moves an object to its corresponding point in space Z X Y 20 LG PLC APM (Advanced Position Module) 2-axis circular interpolation - 2-axis circular interpolation moves an object to its corresponding point on the circle Y Start Point (CW) -Easy to manufacture an object like fan shape, oval, etc End Point X 21 LG PLC APM (Advanced Position Module) 3-axis simultaneous operation - With one start command, each axis starts its operation simultaneously - 3-axis simultaneous pulse output Speed Command Time X Time Y Time Z Time 22 LG PLC APM (Advanced Position Module) Synchronous operation (by Speed) - Axis synchronous selection by internal/external signal (Synchronous speed ratio) - Application to its subordinate axis for the main axis speed ratio Speed Main Axis Time Sub Axis Time 23 LG PLC APM (Advanced Position Module) Synchronous operation (by Position) - Axis synchronous selection by internal/external signal (Synchronous start by the absolute position of the main axis) Speed - Synchronous start of the subordinate axis by the current position of the main axis Main axis Time Absolute position of main axis Sub axis Time 24 LG PLC APM (Advanced Position Module) Position Speed Override - Speed change during position operation available by Speed Override command - Temporary operation speed change available Speed Time 1st 2nd 3rd 25 LG PLC APM (Advanced Position Module) Position Override - Position Override to the changed position during position operation - Temporary goal position change available during position operation Speed Time Goal position before change 26 Goal position after change LG PLC APM (Advanced Position Module) Acceleration / Deceleration Profile - Trapezoidal & S-curve Acceleration/Deceleration (automatic detection of deceleration point) Speed -Smooth Motor Control (Acc/Dec) Time S-curve Acc/Dec Trapezoidal Acc/Dec 27 LG PLC APM (Advanced Position Module) External Start -Fast control and Easy use thanks to External Start External Signal Types Signal Delay Element Internal Start (Function Block) JOG Forward/Reverse Delay time = D/I filtering + Program Scan time + FB processing + function processing time (Start delay time occurrence: scores of ms) Separate Start Simultaneous Start External Start (Terminal Input) Emergency Stop Delay time = function processing time (Start delay time occurrence: scores of s) ZONE 1 / 2 / 3 Output 28 LG PLC APM (Advanced Position Module) 3. APM Software Package - Operation features and information setting in a parameter format WINDOWS-based software APM modules support Powerful parameter editing function (copy, move, undo, redo, etc) Various monitoring information supply (operation method of each axis, etc) Profile tracking and operation monitoring available Profile graph and circular interpolation simulation available Available to edit operation parameter data in EXCEL 29 LG PLC APM (Advanced Position Module) Operation Parameter - Sets basic operation features and limit value setting for each axis 30 LG PLC APM (Advanced Position Module) Operation Data - Defines separate operation method of each axis, Sub Address, Speed, etc. 31 LG PLC APM (Advanced Position Module) Monitoring (On-line) - Monitors basic operation features and operation status of each axis. 32 LG PLC APM (Advanced Position Module) Profile Tracking (On-line) - Supports real-time monitoring of operation speed change for time axis and saving the tracking screen as a file 33 LG PLC APM (Advanced Position Module) Profile Simulation (Off-line) - Supports virtual operation speed monitoring for each axis and saving its result as a picture file 34 LG PLC APM (Advanced Position Module) Circular Interpolation Simulation (Off-line) - Able to check in advance for the moving trace after position operation with parameter settings when you use circular interpolation function 35 LG PLC LG PLC HSC (High Speed Counter) New LG Industrial Systems 36 LG PLC New HSC (High Speed Counter) 1. Main Features 4 types for K300S (GM4) / K200S (GM6) Separate 2 channels Improved pulse input speed (200Kpps / 500Kpps) Broad counting range (32 bits) 7 functions like comparison, Tr output, etc Various additional functions 37 LG PLC New HSC (High Speed Counter) Specifications K300S (GM4) G4F-HO1A G4F-HD1A K200S (GM6) G6F-HO1A G6F-HD1A Item Signal Type Open Collector Line Driver Counting Speed Max. 200kHz Max. 500kHZ Counting Range Multiplication -2,147,483,648 ~ + 2,147,483,647 1-phase input 1 / 2 multiplication 2-phase input 1 / 2 / 4 multiplication Tr. Output Additional Function OUT 1 / 2 / 3 Counter Clear / Counter Latch / Interval Counter Input period measurement / Counter per Timebase 38 LG PLC New HSC (High Speed Counter) Counter Clear - Changes current value to “0” - Additional function mode ( 1 ) - Additional function EN 1000 500 900 500 39 LG PLC New HSC (High Speed Counter) Counter Latch - Latches current value - Additional function mode (2) - Additional function EN 1000 800 CV: 800 500 500 CV: 500 40 LG PLC New HSC (High Speed Counter) Interval Counter - Monitors the counter value during the interval to count - Additional function mode (3) - Additional function EN Pulse Input 1000 500 700 500 750 950 Counter Value 1000 Setting Time 200 500 41 200 LG PLC New HSC (High Speed Counter) Input Period Measurement -Measures the input pulse every one second or during user-defined period of time - Additional -function mode ( 4 / 5) - Additional function EN Pulse Input 950 1000 1000 850 500 300 200 Clocks per sec. 500 250 * Period * Period: mode 4: 1 sec mode 5: user-defined period of time 42 LG PLC LG PLC PMU (Programmable Monitoring Unit) LG Industrial Systems 43 LG PLC PMU Lineup PMU-830 12.1” PMU x30 Series PMU-730 10.4” PMU-530 7.5” PMU-830TT PMU-330 5.7” PMU-730TT PMU-730ST PMU-530ST PMU330TT PMU330ST PMU-330BT 44 LG PLC PMU x30 Series PMU-330 PMU-530 PMU-330TT PMU-330ST PMU-330BT PMU-530ST • 320 x 240 dot, 5.5”/5.7” • 32 bit RISC CPU • Display Element 256 Color TFT (PMU330TT) 256 Color STN (PMU330ST) Blue & White STN (PMU330BT) • Matrix touch-key: 16x12/screen • Various bitmap functions bitmap touch/lamp, background bitmap • O/S downloading for version upgrade • Flash Memory (screen: 1MB/2MB) • Internal 256K SRAM (data logging/recipe) • RS-232C/422 comm. port • Waterproof (IP65F) • Size: 206 x 136 x 64 (Panel cut: 198 x 128) • Power: 21 ~ 28V DC • 640 x 480 dot, 7.5” • 32 bit RISC CPU • 256 Color STN • Analog touch-key: 640x480 • Various bitmap functions bitmap touch/lamp, background bitmap • O/S downloading for version upgrade • Flash Memory (screen: 2MB) • Internal 256B SRAM (data logging/recipe) • RS-232C/422 comm. port • Waterproof (IP65F) • Size: 240 x 170 x 62 (Panel cut: 231 x 161) • Power: 21 ~ 28V DC 45 LG PLC PMU-x30 Series PMU 730 PMU 830 PMU-730TT PMU-730ST PMU-830TT • 640 x 480 dot, 10.4” • 32 bit RISC CPU • Display Element 256 Color TFT (PMU 730TT) 256 Color STN (PMU 730ST) • Matrix touch-key: 32 x 24/screen • Various bitmap functions bitmap touch/lamp, background bitmap • O/S downloading for version upgrade • Flash Memory (screen: 2MB/4MB) • Internal 256K SRAM (data logging/recipe) • RS-232C/422 comm. & printer port • Waterproof (IP65F) • Size: 305 x 239 x 55 (Panel cut: 294 x 228) • Power: 85 ~ 265V AC (Free) • 800 x 600 dot, 12.1” • 32 bit RISC CPU • 256 Color TFT • Analog touch-key: 800x600 • Various bitmap functions bitmap touch/lamp, background bitmap • O/S downloading for version upgrade • Flash Memory (screen: 4MB) • Internal 256K SRAM (data logging/recipe) • RS-232C/422 comm. & printer port • Waterproof (IP65F) • Size: 305 x 239 x 55 (Panel cut: 294 x 228) • Power: 85~265V AC (Free) 46 LG PLC Numeric & String Display Numeric data display: DEC, HEX, BCD type Displays data with 8 different colours depending on the numeric range variance Data from PLC or controller can be displayed after calculation ASCII CODE, read from PLC or controller, can be displayed with characters 47 LG PLC Data Setting & Clock Display ★ Key display tag Min/max value of data setting & input range limit available Data input using TENKEY PASSWORD encrypted ★ Clock Display RTC data display (year, month, date, hour, minute, second) using RTC element embedded in PMU 48 LG PLC Touch Function ★ TOUCH Input function: commands PLC touching a specific region on screen Bitmap touch: Displays different bitmaps according to the device status (ON/OFF) after Touch button operation Caption: Displays 2 letters according to the device status (ON/OFF) after Touch button operation Touch colour: Lamp function embedded in Touch button displays the devices status (ON/OFF) after Touch button operation Maximum 10 functions can be set up with one Touch tag 49 LG PLC Lamp Function ★ LAMP Tag: displays ON/OFF information of a bit in colour/picture Bitmap lamp: Displays different bitmaps according to the device status (ON/OFF) Caption function: Displays different letters according to the device status (ON/OFF) Data lamp: Displays lamp with 8 colours according to data range 50 LG PLC Graph Meter graph - Sets the lowest/highest value of data and displays current data in rate - Analog data (voltage, current) display TREND graph - Input value change is visually shown with the time axis - 10 data can be set up with one graph - Logging data and recipe data trend available Others – bar graph, X/Y chart 51 LG PLC Recipe (parameter moving) Running data of each work are stored in PMU and when work changes, they are batch-transferred to the controller Easy to operate: converts the setup data into EXCEL format 52 LG PLC Data Logging Data generated during operation are stored in PMU through periodic or conditional data logging Condition setting Operation setting Convenient to report: converts logging data into an EXCEL report DATA LOGGING screen 53 LG PLC Various Bitmap Functions Background bitmap function: Uses a background bitmap of the same screen resolution Transparent bitmap and lettering functions: Does not display the unnecessary part of bitmap and background letters No limit in size: Available to register regardless of bitmap size (only to be smaller than screen size) Image Character: All fonts available as long as WINDOWS support 54 LG PLC Simulation Functions Simulates the status of each device's address operation and communication while disconnected with PLC. Monitors data when you turn on each address or input data. RS-232C Simulation on drawing: If the status of a bit tag (ON/OFF) changes while drawing the screen, the screen changes can be displayed on PC monitor 55 LG PLC Convenient Memory Management Overall display of PLC address registered in the screen Overall change available in PLC address change Display of PLC address of tags registered in the screen Overall display of the contents of screen User-defined library registration 56 LG PLC PMU Communication 1:N Communication 1:1 Serial Communication Connecting more than one PLCs to one PMU through RS-422/485 communication One PLC connection to one PMU RS-232C 15m MAX. RS-422/485 500m MAX •1:N communication by using RS-422/485 should be organised as choosing identical PLC types 57 LG PLC PMU Communication N:1, N:M (N+M ≤ 64) Communication Using MASTER-K/GLOFA-GM Fnet module Fnet 64 stations, 750m MAX. Enet option module installed in PMU MASTER-K GLOFA-GM (GㅁL-FUEA) 58 LG PLC PMU Communication PLC Communication with other devices Controls two different PLCs using one PMU 2nd comm. Ch. RS-232C Main comm. Ch. RS-232C/422/485 59 LG PLC Applicable Equipments PMU Option PMU830 PMU730 PMU530 PMU330 PMU710 PMU320 Built-in Serial comm. Maker LGIS Type Model name PLC Inverter Samsung Mitsubishi PLC PLC Loader Link MASTER-K O O GLOFA-GM O O GOLDSEC-M O O STARCON-MF - O iG5 RS-485 iS5 RS-485 option board iH RS-485 option board SPC O - FARA-N O O FARA-N70/700+ O - MELSEC-A, QnA, Q O O MELSEC-FX O O Fuji PLC MICREX-F - O Omron PLC SYSMAC-C, CS1 - O Siemens PLC 3964R - O S7-300/400 MPI O - S7-200 PPI O - 60 LG PLC Applicable Equipments PMU PMU830 PMU730 PMU530 PMU330 PMU710 PMU320 Option Built-in serial comm. Maker AB Yaskawa PMUㅁㅁㅁ-F Type PLC PLC Model name Loader Link SLC500[5/03,04] O - PLC-5 O - Progic-8 O - MP-920 O - CP-9200SH O - Modicon PLC KDT PLC Cymon O O Koyo PLC DL-205/305/405 - O GE Fanuc PLC 90-30[SNP-X] O - POSCON PLC POSFA phld-1a/2a - O Yokokawa PLC FA-M3 - O Delta PLC DVP-ES - O LGIS PLC MASTER-K GㅁL-FUEA GLOFA-GM GㅁL-FUEA PMUㅁㅁㅁ-E Ethernet PMUㅁㅁㅁ-C CC Link Modbus Under development 61 LG PLC LG PLC GM4-CPUB/C Fast Ethernet MASTER-K120S LG Industrial Systems 62 LG PLC New Product (GM4 – CPU B/C) 1. GLOFA CPU GMR GM1/2 GM3 GM4C GM4/4B GM6 GM7 Direct 7680 16000 /4096 2048 3584 2048 384 10~80 Remote 32000 32000 /16000 4096 32000 2048 /8192 512 - Speed (㎲/Step) 0.12 0.12 0.2 0.12 0.2 0.5 0.5 Program Capacity 2MB /512K 512KB 256KB 1MB 128KB 68KB 68KB Data Capacity(KB) 512KB 512KB 128KB 428KB 64KB 32KB 32KB Flash Memory Option Option Option 6M 512KB 128KB Option Base No. of Extension 15 31 3 6 3 × 3 Distance 100m 100m 3m 15m 3m × - Floating ○ ○ X ○ X X X Built-in Cnet × × × × × ○ ○ Loader Conn. RS-232C ○ ○ ○ ○ ○ ○ ○ USB × × × ○ × × × I/O Capacity 63 LG PLC New Product (GM4 – CPU B/C) 2. Down Sizing & High Lebel Functions GM2 Function is moved to GM4 GM4C GM4B GM4 Direct 3584 2048 2048 Remote 32000 8192 2048 Proce Speed 0.12 0.2 0.2 Floating Process O X X Program Capacity 1MB 128KB 128KB Data Capacity 428KB 26KB 26KB Flash Memory 6MB 512KB × Base No. of Extension 6 3 3 Extension Distance 15m 3m 3m I/O 64 LG PLC New Product (GM4 – CPU B/C) 3. Network Module High Speed Link Network Module Ethernet GM4C GM4B GM4 Total 4 Total 4 Total 2 Basic/Extension Basic/Extension Basic Base Fnet/Rnet Profibus Devicenet Position of Network Module 4. High Speed Loader Port (USB / High Speed Serial Port ) High Speed Downloading via USB Port Loader Port GM4C GM4B GM4 USB 12Mbps × × RS-232C 115.2Kbps 115.2Kbps 38.4Kbps 65 LG PLC New Product (GM4 – CPU B/C) 5. Bases and Extension Cables -To realize the Full functions of GM4-CPUC, New type Bases, Extension Cables are required. - Old type Bases or Extension Cables are used, the function of only CPU will be upgraded. Basic Base Ext. Base New New New CPU Efficiency Function Base Efficiency New - Full Upgrade - High Speed, 6 Exts. - Support Full functions of GM4-CPUC System Old - Partial Upgrade - Low Speed, 3 Exts. - Support Upgraded functions of GM4-CPUC (CPU Only) New - Partial Upgrade - Low Speed, 3 Exts. - Support Upgraded functions of GM4-CPUC (CPU Only) Old - Partial Upgrade - Low Speed, 3 Exts. - Support Upgraded functions of GM4-CPUC (CPU Only) New - Partial Upgrade - Low Speed, 3 Exts. - Support Upgraded functions of GM4-CPUC (CPU Only) Old - Partial Upgrade - Low Speed, 3 Exts. - Support Upgraded functions of GM4-CPUC (CPU Only) New - Partial Upgrade - Low Speed, 3 Exts. - Support Upgraded functions of GM4-CPUC (CPU Only) Old - Partial Upgrade - Low Speed, 3 Exts. - Support Upgraded functions of GM4-CPUC (CPU Only) Old Old Old Ext. Cable Old New - Names of New type Bases and Extension Cables Basic Base Extension Base 4 Modules GM4-B4MH GM4-B4EH 6 Modules GM4-B6MH GM4-B6EH 8 Modules GM4-B8MH GM4-B8EH 66 Name Length Name Length G4C-E061 0.6m G4C-E102 10m G4C-E601 6m G4C-E152 15m LG PLC New-Product (Fast Ethernet) 1. Fast Ethernet 100/10Mbps Fast Ethernet for Industrial systems. 100BaseT, 100BaseF(Fiber Optic), 10BaseT, 10BaseF(Fiber Optic) Support 2 type Ethernet - Open Type(Information Level) Ethernet and Dedicated (Between LG PLCs) Ethernet Support Internet Service - Mail Server (POP3, SNMP) - Web Server (Next version) Realized High Reliance and functions using 32Bit Processor. Keep the functions of old version Ethernet (GMWin Service, Frame Editor etc.) Server 100BaseF (Fiber Optic) MAU MAU HUB HMI PC HUB 100BaseT (TP) 100BaseT (TP) HMI PC 67 LG PLC New-Product (Fast Ethernet) 2. Specifications General Specifications Fast Ethernet (Open) Fast Ethernet (Dedicated) Ethernet Baud Rate 100/10Mbps 100/10Mbps 10Mbps Media 100BaseT/F(Fiber) 10Base5/T/F(Fiber) 100BaseT/F(Fiber) 10Base5/T/F(Fiber) 10Base5/2/T Processor 32Bit RISC Processor 16Bit Processor Protocol TCP/IP, UDP/IP TCP/IP, UDP/IP Data Capacity 200word / Block (Max 64Block), 1446Byte / Frame No. of Channel 16Ch Token Passing Dedicated Service ● × ● FB Service ● ● ● High Speed Link Service ● ● ● E-Mail Service ● × × Usage Communication between PC(MMI) and LG PLCs Communication between LG PLCs 68 Communication between PC(MMI) and LG PLCs LG PLC New-Product (MASTER-K120S) 1. Characteristic of MASTER-K120S √ Main Unit AC Power(85~264V), IO Points : 60 Points (DC24V Input 36Points, Relay Output 24Points) Total 120Points Extension is Possible(3 Modules can be connected to 1 main base) Enlarge P area for Remote control(P000 ~ P63F) √ Various Extension module 10 Points I/O, (DC/Relay), 20 Points I/O(DC/Relay), 10 Points Output (TR) Hybride Analog I/O (A/D 2Ch,D/A 1Ch), AI(A/D 4Ch), AO (D/A 4Ch, Current Output) Analog Timer(4Ch), RTC Pack, Memory Pack(G7M-256B, for Back-up the program) RS-422 Module, RS-232C Module(Modem), FNET, RNET (Master), PNET , DNET (Slave) √ Hign Speed Processing (Speed enlarged 2 times than MK80S ) Basic Sequence : 0.1 ~ 0.9us / instruction Application function : some us ~ 10s of us /instruction Special Module Processing : 100s of us ~ 1ms /Module √ Battery-less Back-up Program Back-up : EEPROM (EEPROM Back-up when Edit on Run) *Automatically Data Back-up : Super Capacitor(Over than 2000h in ) 69 LG PLC New-Product (MASTER-K120S) √ Built-in High Speed Counter (32bit signed processing) 1Phase : 100khz 2ch, 20khz 2ch(Total 4Ch) 2Phase : 50Khz 1ch, 10Khz 1Ch (Total 2Ch) Additional Function : Ring counter, Value Compare / Band compare, Compare value agreement Interrupt, RPM Function √ Input Processing Functions Input Filtering Function : Set Filtering time (1 ~ 15ms) Pulse Catch Function : 10us(P0,P1), 50us(P2~P7) External Interrupt Function : 10us(P0,P1), 50us(P2~P7) √ Position Control Function Number of Ch. : 2 Ch(100Kpps) Operating Mode : Single, Repeat, Automatic, Continuous, Uniform Velocity Operating Additional Function : Return to Origin, Jog Operating, PWM Output √ Enlarging No. of Communication ch. And Functions. Built-in RS-232C / RS-485 2Ch(Simultaneous Use is available) Supports User-defined Protocol and Monitoring protocol with KGLWIN √ Add Built-in PID Functions Relay/PRC Auto-tuning / PWM Output Position/Velocity calculation type / Prevention overcrowding Differential Calculation 70 LG PLC