Context of Manufacturing

advertisement

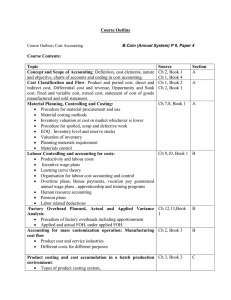

Manufacturing Systems Context of Manufacturing Manufacturing Systems 1.The Context of Manufacturing 2.Quality Management 3.Project Management 4.Concurrent Engineering 5.Manufacturing System Design and Control The Context of Manufacturing Manufacturing is part of a bigger scheme known as operations. Operations takes in all systems that involve getting work done. •services •manufacture The same principles apply to both. The Context of Manufacturing Operations is a transformation process. Inputs are transformed into outputs. Goal is to create and add value to the inputs during the transformation. Inputs Materials Labour Equipment Capital Outputs Transformation process Goods Services Manufacture: adding value to a raw material by changing its shape or properties. Manufacturing Technical terms: manufacturing process is used to turn raw material into finished items. Machinery Power Starting material Manufacturing process Processed Part Tooling Labour Scrap and waste Manufacturing Economics terms: the value added to the inputs is important. Manufacturing Process Added Value €€ € Starting material Material in process €€€ Processed Part Manufacturing Industries can be grouped into: • Primary – exploit natural resources • Secondary – converts primary outputs into consumer goods - manufacturing • Tertiary – contributes to the service sector Business Strategies •Companies exist to make a profit •Products offered by more than one company •Companies compete for market share •Company needs a strategy Direction Focus Business Strategies A strategy consists of four steps: 1. Define a primary task 2. Assess core competencies 3. Determine order qualifiers and order winners 4. Position the firm Business Strategies 1. Define a primary task Represents the purpose of the firm - what is its business Identifies the area in which it will be competing stated in broad terms. e.g. Iarnrod Eireann is in the business of Transportation, not Railways Often expressed as a mission statement. Amazon.com - ‘To provide the fastest, easiest, most enjoyable shopping experience’ Business Strategies 2. Assess core competencies Identify what the company does best Usually based on knowledge or processes Rarely single product or technology – easily copied Dell Computer: is the ability to quickly assemble computers to order and to deliver them to customers without delay. Business Strategies 3. Determine order qualifiers and order winners An order qualifier is a characteristic of a product that will make a consumer consider buying it. An order winner is the characteristic of a product that will make the consumer purchase it. Buying a car: Order qualifier - price Order winner - model with the most features Business Strategies 4. Position the firm Choose one or two important things to concentrate on and do extremely well. Defines: •how well the firm competes in the marketplace •what unique value it will deliver to the consumer Relative strengths of competitors must be taken into account Apple computers do not compete with companies such as Dell for its market – they concentrate on a niche market for innovative products such as the iPhone, IPod where they are often first to the market. Manufacturing Strategies Different ways of offering a product: •Make to stock Products are designed, produced and delivered to customer specifications in response to an order •Make to order Products are designed and produced for a ‘standard’ customer in anticipation of demand. •Assemble to order Base unit or module is produced onto which options can be added according the specification of the customer. Manufacturing Strategies Types of Production Processes: 1. Project • Long time to complete • Large investment in resources • One item to customer order 2. Batch production • Product produced in batches • Volume relatively low • Demand for item can fluctuate Manufacturing Strategies Types of Production Processes: 3. Mass Production • Large volume of standard product • Demand is stable • Demand is high 4. Continuous Production • Very high volume products • Highly standardised • Highly automated systems Product Process Matrix Relationship between volume levels and standardisation of a product and its manufacturing process Continuous Production High Volume of products Mass Production Batch Production Projects Low Low High Standardisation Functional Organisation of a Manufacturing Enterprise Finance / Accounting Orders Quality requirements Design Specs Material availability Quality data etc. Manufacturing Hiring/Firing Training Legal requirements Job design Union negotiations etc. Human Resources Sales Forecasts Customer orders Customer feedback Promotions Status of order Marketing Suppliers Budgets Stockholder requirements Cost Analysis Production and Inventory data Key Success Factors in Manufacturing Competitiveness Global market means more customers but also more competition Companies will usually compete on: •Cost - Ryanair, Penneys •Quality - Toyota, Mercedes •Flexibility - Dell •Speed - Dell, McDonalds Simple System for Costing Often a choice is available: •Make the product individually →Costs more →No setup cost •Set up tooling and mass produce →Setup cost →Cost less to make once set up Simple System for Costing Break even Analysis Used to choose the most economical method for making a given number of parts. or Finding the least number of parts to justify setting up a mass production system Simple System for Costing Break even Analysis Total Cost of process A Break Even Quantity Total Cost of process B Cost Choose Process A Number of units made Choose Process B Simple System for Costing Example: Qty: 500 required •Skilled labour costs €2.50 per item to manufacture using the lathe. •Unskilled labour costs €0.50 to manufacture using the automated press. •The setup cost of the press tool is €500 Simple Systems for Costing €1,000 €900 €800 Cost €700 €600 €500 €400 €300 €200 €100 €0 0 50 100 150 200 Quantity Made 250 300 350 400 Simple Systems for Costing Calculating BEQ numerically BEQ Setup Cost ( Manual Cost per item) ( Automated Cost per item) BEQ = 500/(2.50 – 0.5) = 500/2 = 250 Items