Validation Master Plan

advertisement

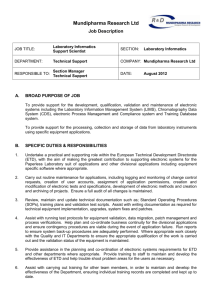

Radiopharmaceutical Production Process Validation STOP Process Validation • • Process validation is one of the most important aspects of the GMP process. It is impossible to carry out sterility testing and perhaps some other quality control testing on radiopharmaceuticals which have short half-lives. The best way to predict a safe and effective product is to document a history of successful production using a set of standard operating procedures (SOPs) and to always use exactly those same procedures to produce the radiopharmaceutical. Contents • Validation in General • Why do we validate the Process? • The Scope of Process Validation • Validation Protocol • Process Validation Example • The Validation Report • Literature STOP Validation in General Radiopharmaceutical Production Process Validation Contents Validation in General Why do we validate the Process? The Scope of Process Validation Validation Protocol The process of validation starts with the construction (or renovation) of the facility to be in compliance with GMP guidelines. These processes should be outlined in a Validation Master Plan (VMP). The VMP should include: • Water (generation, receipt, and distribution) • Heating, ventilation, and air conditioning (HVAC) • Terminal sterilization of product (either by autoclave or filter sterilization) • Compressed air (generation and distribution) • Premises (to be sure they meet all GMP practices – see the section on Facilities) • QC laboratories (analytical and microbiological) • Production and control operations involved in the manufacture of radiopharmaceuticals. Process Validation Example The Validation Report Literature STOP Validation continues with validation plans for individual processes and equipment. These include: • The development of validation SOPs • The development of process SOPs • Testing of the production process • Development of analytical methods • Validation of the process • Revalidation of the process whenever there is a change in the procedure or new or repaired equipment is used. • A summary table is given on the next page Validation in General Radiopharmaceutical Production Process Validation Contents Validation in General Elements Develop a Validation Master Plan Validation Protocol Project Design Engineering and Construction Operational Readiness Review Construction Equipment Choose and install equipment Perform validation protocols Start-up Validation Plan Write validation protocols Perform the protocols Operation Analytical Methods Write SOPs for GMP required tests Test product and refine analytical methods Operation Process Test and Develop SOPs Optimize parameters Operation Analytical Methods Revise SOPs for GMP required tests Refine analytical methods Revalidation Process Revise SOPs Refine operational parameters Revalidation The Scope of Process Validation Stage Premises Why do we validate the Process? Summary Table for Validation Installation Operation Qualification Qualification Process Validation Example The Validation Report Literature STOP Why do we validate the Process? Radiopharmaceutical Production • Process Validation Contents Validation in General • Why do we validate the Process? The Scope of Process Validation Validation Protocol Process Validation • It is necessary to show that the product being delivered is safe for human use and is identical in every way to the product we intend to produce. This can be referred to as pharmaceutical equivalence Pharmaceutical equivalence – For PET products Pharmaceutical equivalence implies the same amount of the same active substance(s) and meeting the same or comparable standards (ie strength, quality, purity and identity) every time the product is produced. Since we are taking only a sample of the batch, we must ensure that the sample is representative of the entire batch. Example The Validation Report The whole batch is released for patient use Literature BATCH But only the sample is tested Sample STOP The Scope of Process Validation Radiopharmaceutical Production Process Validation Contents Validation in General Why do we validate the Process? The Scope of Process Validation Validation Protocol Process Validation Example The Validation Report Literature STOP • Process validation requires the identification of critical elements of the production process. It also includes qualification of supporting systems such as water production, air supply systems and equipment qualification. Qualification and validation: • Validation is applicable to any aspect of operation which may affect the quality of the product - Directly or indirectly. Qualification is a part of validation usually applied to equipment and premises. Since validation is applicable to all aspects of operation which may affect the quality of the product, it includes premises (environment conditions, space, contamination levels), supporting utilities (e.g. water), processing equipment performance and the actual process. • Any significant change (e.g. adaptation of equipment or systems, major repairs etc) may require re-qualification or re-validation. Of critical importance, with particular attention, is the validation of: • Analytical test methods • Automated systems and • Cleaning procedures The Scope of Process Validation Process validation is a stepwise path that leads to a product that is safe and effective. It starts with validation of equipment and premises Once any problems have been corrected, a new protocol is written and approved Revise Protocol Validation and Qualification of Premises, Equipment And Utilities Process Validation A protocol is generated and and a pre-validation approved and the validation process begins review STOP Determine Causes If there are problems, these must be Non-conforming investigated Results and resolved And the process begins again Approved Protocol Pre-Validation Review Adjust Process Prepared Validation Package Start Production A validation package is prepared containing all the results of the validation. If there are no problems, production can begin The Validation Protocol Radiopharmaceutical Production Process Validation • • Contents Validation in General Why do we validate the Process? The Scope of Process Validation Validation Protocol Process Validation Example The Validation Report Literature STOP • A validation protocol is a detailed document relating to a specific part of the validation process. It outlines the tests that are to be carried out, the acceptance criteria and the information that must be recorded. It also defines the approval process for the validation. The protocol should clearly describe the procedure to be followed for performing validation. It should include at least the objectives of the validation and qualification study, the site of the study, the responsible personnel, a description of the equipment to be used (including calibration before and after validation), SOPs to be followed (e.g. the operation and cleaning of the equipment) and the standards and criteria for the relevant products and processes. The type of validation and time/frequency should also be stipulated. The processes and/or parameters to be validated should be clearly identified. The Questions to be answered include: • What will be validated? • Who is responsible for the validation tasks? • How will the equipment be qualified and the processes validated? • How will the validation be documented? • What are the criteria by which a successful validation will be judged? Validation Example – Aseptic Processing Radiopharmaceutical Production Process Validation • Contents Validation in General Why do we validate the Process? The Scope of Process • Validation Validation Protocol Process Validation Example The Validation Report Literature STOP Media Fill test – simulation of the process replacing reagents and solvents by growth media – gives the support for eventual bacteria – tests the process without inhibiting bacteria growth by reagents – every operator, at least 3 times BioBurden test – real test production without sterile filtration at the end – gives the idea of how aseptic is the process • test for sterility • detect type of bacteria present • count the microbial contamination The Validation Report Part 1 Radiopharmaceutical Production Process Validation • Contents • • • • • • • • Validation in General Why do we validate the Process? The Scope of Process Validation Validation Protocol Process Validation Example The Validation Report Literature STOP A qualification or validation report should reflect the elements of the protocol, and should contain elements such as: - Title - Objective of the study - Reference to the protocol - Details of materials, equipment, instruments, personnel - Program and cycles used - Details of procedure and test methods ... etc. The results obtained during the performance of the validation, must be recorded. The Validation Report Part 2 Radiopharmaceutical Production • Process Validation Contents Validation in General Why do we validate the Process? The Scope of Process • Validation Validation Protocol Process Validation • Example The Validation Report Literature STOP The validation report reflects the final test results and other documents such as instrument calibration certificates. It is on the basis of this report that the decision is taken on whether a particular process is judged to be validated. All results should meet the criteria of acceptance and satisfy the stated objective. If necessary, further studies should be performed. If the results are found to be acceptable, the report should been approved and authorized (signed and dated). The report should include the title and objective of the study, and refer to the protocol, details of material, equipment, programs and cycles used, together with details of procedures and test methods. It should provide a comparison of the results with the acceptance criteria. In addition, it should include recommendations on the limits and criteria to be applied to all future production batches. It is common practice in many companies for the protocol and the report to be combined into a single set of documents. The protocol is approved as a form on which the test results are recorded as they become available. This reduces the amount of paperwork that needs to be stored and makes an overall assessment of the validation results easier to carry out. Literature Radiopharmaceutical Production • Literature on Validation Master plans and the Validation Process can be found in the references to GMP Process Validation Contents More Validation Master Plan More PICS Validation Master Plan Validation in General Why do we validate the Process? The Scope of Process Validation • The major references and some presentations on GMP are available by following the MORE arrow. Validation Protocol Process Validation Example The Validation Report Literature STOP More GMP Regulations Return to Main Menu