B2 presentation

advertisement

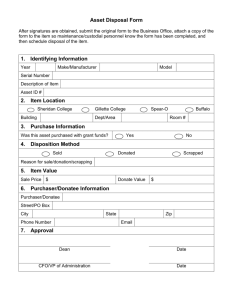

Developing WaveRiders approach to Knowledge and Asset Management to meet the Criteria of EFQM Group B 2 Jerry, Nikhil, Kidd, Fabienne, Gurbani Contents Current status of WaveRiders Knowledge Management Concept of Knowledge Management Learning Organisation Asset Management Maintenance Facilities Management Life Cycle Management Security Health & Safety and Environmental Management Budget Timeline Final Result for WaveRiders Current Status of WaveRiders Costs are too high Cases of Overproduction Possibility of savings in distribution No clear future strategy New product development, like engines, clothing and accessories No communication network or knowledge base within the company Employees concerned about redundancy Unsafe working environment Knowledge Management Knowledge Management Concept Learning Organization Knowledge Management Concept The concept of Knowledge management focuses on the life-cycle of knowledge process where knowledge is generated and then stored so that it can be distributed and applied within an organisation. WaveRiders Knowledge Management GOALS: Transform tacit knowledge into explicit knowledge Develop and Implement knowledge management system for WaveRiders Benefits of Knowledge Management for WaveRiders Creates a learning environment Facilitates better Inventory and Maintenance Management Ensures Shared Vision and Culture within all the organisational levels Enriched understanding of customers needs, requirements and expectations Enable the company to quickly adapt to changes Enable the organisation to identify and take advantage of opportunities and learn from its mistakes Increase in intellectual assets and corporate value Currently, there is no effective system in place for the company to adequately manage its knowledge resources. . Practices to convert tacit knowledge into explicit knowledge This is basically “how” the knowledge-creating company’s, structures and practices translate a company’s vision into innovative technologies and products. Western View: Organization is “a machine for information processing” Useful knowledge is: Japanese View: Formal and systematic, Quantifiable (“hard”), Easily measurable Use of slogans, Tacit insights, intuitions, and hunches of employees, Company is not a machine but a living organism, “Everyone is a knowledge worker” WaveRiders will convert tacit knowledge into explicit knowledge by following the Japanese View and will create knowledge by: by linking contradictory things and ideas through metaphor; then, by resolving these contradictions through analogy; and by crystallizing the created concepts and embodying them in a model, which makes the knowledge available to the rest of the company. Knowledge Management and EFQM criteria Knowledge management includes a people and IT focus Leadership plays a crucial role in implementing knowledge management within organisations Allows leaders to predict their future performance EFQM: 4e. Information and Knowledge are managed to support effective decision making and to build the organization’s capability. Learning Organization Areas in which change is required to become a Learning Organization Vision Culture Strategy Structure Recommendations for Waveriders to become a Learning Organization Creation of a vision: “To develop and maintain a sustained effort towards a culture of continuous improvement along with focusing on the creation of an environment where innovation and learning is encouraged.” Create time, space and environment for learning and continuous improvement Change in policies and structures within the organization Establishment of a Centre of Excellence Encourage managers to act as transformational leaders Empowering and enabling the people of the organization Career development plans Case Study: Rover How Rover turned losses of $100 million into profits of $56 million by becoming a Learning Organization: The management made it clear regarding the company’s commitment to learning and how this tied in with the strategy of the company as a whole Establishment of Rover Learning Business in 1990 Each employee attended a course in any area of their choice Structured career development plan The Rover New Deal Asset Management Maintenance Management Facilities Management Security management Life Cycle Management Health & Safety and Environment Management Maintenance Management Strategic planning Identify objectives, functions, process to meet stakeholders’ requirements Enhance competiveness through effectiveness management Asset Operation Utilize the current asset and feedback on it Achieve efficiency and quality under operating conditions Maintenance Fulfill workable function, technical refreshment, condition improvement Review asset configuration to fit to Strategical objectives Make value adding in manufacture and end up with satisfying level Ensure efficiency and longevity to retain asset or decrease rate of deterioration Replace/ Disposal Enhance service through reconstructing/ replacing existing asset; Continuous improvement in order to provide service Maintenance Process associate with knowledge asset Material Requirement Planning Material Requirement Planning – A tool to help answer: What? How many? And when items are required? Improvement of inventory turnover, Inventory control, production planning, manufacturing control Factory-Master Case Study – Benefits of MRP Forecasts Greater proactivity Time saved identifying and ordering requirements Forecasting results in shorter lead times Confidence to manage expansion Transactions Customer Orders Engineering Changes Lean thinking in maintenance Asset Management and EFQM Policy Deployment Facilities Management – Introduction WaveRiders currently has no Facilities Management in place. It is important to manage assets in support of WaveRiders’ core business activities. We recommend a Facilities Manager being employed by WaveRiders who will have the experience and expertise needed to manage the company’s needs. Benefits of introducing Facilities Management: Increased employee productivity Efficient management of property and space in the company Costs may be minimized, while always predicted and in the long-run, capital expenditures are planned and controlled. Facilities Management – Case Studies Process and Engineering savings plan - Major Industrial Company: Immediate increase in productivity of 35% Deliverables, milestones and plans clearly defined £1m cost reduction Staff turnover reduced by 50% within first 6 months Top Technology House Cost Savings 17% Supplier improved service levels Better use of the workspace resulting in improved staff productivity International Pharmaceutical Company: First-Year savings of 30% Year-on-year savings of 12% Outsourcing – Fleet Management Improved transportation management will work to reduce time, costs and final customer satisfaction. Ensure vehicle specifications are met. Most efficient routes (and trips) are taken to reduce total fuel consumption. Introduction of live GPS system which can monitor changes in traffic. Facilities Management – Emergency Planning No emergency plan in place An emergency plan needs to be developed so that the company can respond efficiently and quickly to any potential emergency situation. Draw together experience and knowledge to identify potential threats. 5 phases in implementing the plan (Reuvid and Hinks, 2002): As a result a solid plan will be in place, the correct people will be contacted and necessary measures will be taken within the organization to control the problem. Facilities Management – Information Systems Computer-aided Facilities Management deals with automated tools which increase the productivity within FM. Can assist with the following we have already and will soon discuss: Space management Internal communications Maintenance Security Systems Life Cycle costing Alexander (1996) Security Virtual Security and Physical Security Organizational Operational Security Both Physical and Virtual Security need to be addressed for the protection of the company. Virtual: Introduction of username/password protected information system. Authorization – Controlled access throughout system. Data back-up policies to be introduced. A session with employees of what is acceptable/unacceptable within company computer facilities. Physical Security: Introduction of CCTV cameras Security Patrols Lone worker policies Access control Reception tasks Life Cycle Management The process of managing the lifecycle of a product. Some of the Benefits: More efficient use of materials Ability to identify potential sales opportunities. Better control of the finances within WaveRiders Life Cycle Management Market Analysis Data Management Planning Data Accounting Data Engineering Design Data Life Cycle Costing Value Analysis and Related Data Reliability and Maintainabilit y Data Logistic Support Data Consumer Utilization Data Production or Construction Data Health & Safety Statistics Lastest key annual figure in UK 2010/2011 1.2 million working people were suffering from a work-related illness. 171 workers killed at work. 115 000 injuries were reported under RIDDOR. 200 000 reportable injuries (over 3 day absence) occurred (LFS). 26.4 million working days were lost due to work-related illness and workplace injury. Workplace injuries and ill health (excluding cancer) cost society an estimated £14 billion (in 2009/10) Accidents and ill health are costly to company workers and their families Health & Safety Management Key elements of Successful Health and Safety Management Source: HSE,2008 Health & Safety at Work Act 1974 Employer Responsibilities Establish healthy and safe systems of work and a safe working environment Provide information and necessary training to ensure employees’ health and safety Provide safe plant, machinery, equipment and appliances Employee Responsibilities comply with general workplace policies and procedures on attending mandatory training sessions provided by Wave Riders. Appoint a health and safety representative from the workforce Risk Management Health & Safety at work is not a one-off situation it is part of a constant cycle. Most of which takes place before you even commence work on site This is Wave Riders responsibility to identify potential risks and hazards in the workplace, for example through Environmental Risk Assessment How to assess the risks the work place: Step 1: Identify the hazards Step 2: Decide who might be harmed and how Step 3: Evaluate the risks and decide on precautions Step 4: Record your findings and implement them Step 5: Review your assessment and update if necessary Source: HSE 2011 Environmental Management EFQM criteria 8 (Society Results) states : Excellent organisations comprehensively measure and achieve outstanding results with respect to society A long-term goal of EM systems (EMS), like that of QM systems, is to move towards a proactive, preventive stance through the incorporation of environmental issues into product design, technology-related decisions, the entire manufacturing process and customer service. (Tari and Molina-Azorin, 2009) Environmental Management System (EMS) • EMS structure is commonly referred to as Plan Do Check Act • A measureable continual improvement • This is recommended Wave Riders should follow the structure provided by ISO 14001 ISO 14001 – Effective EMS for Wave Riders An internationally accepted standard Designed to address the balance between maintaining profitability, reducing environment impacts and risks Benefits for WaveRiders of using EMS Reduce operating costs through waste reduction, energy conservation, and other saving Reduced legal risk and potential liabilities – Fewer fines and other regulatory complications over time since regulatory requirements are identified and met Increase employee awareness and accountability Create a positive image for Wave Riders – Enhances customer trust Costs Establishment of a Centre of Excellence: £100,000 Career development plans: £50,000 Maintenance p.a.: £11,000 (Edwards, Holt, & Harris, 2000) Training employees in Health and Safety: £18,000 Security: £10,000 Knowledge and Asset Management Time Implementation Plan Gantt chart to show how we advise time to be spent on these implementations: Q2.1 Q3.1 Q4.1 Q1.1 Q2.1 Q3.1 Q4.1 Q1.1 Q2.1 Q3.1 Q4.1 Q1.1 Quarters 2 2 2 3 3 3 3 4 4 4 4 5 Inform Organization 1 Asset Management Organizational Learning 11 Knowledge Management Security 1 Health and Safety 1 Environment 1 Maintenance 2 Facilities Management 8 Life Cycle Management 8 The Future of WaveRiders WaveRiders will become a Learning Organization Regular maintenance plan in place. Transportation Outsourced. Controlled finances Increased employee productivity Managed facilities A Safe, Secure Environment to work in for all employees and customers. WaveRiders : you are on your way to Excellence! References Burton, I. "Factory-Master Case Study: The Benefit of Material Requirments Planning (MRP)." CompeteIt, n.d. Park, A. Facilities Management: an explanation. Basingstoke: Macmillan, 1998. Property & Facilities Management - Case Studies. 2012. 19 April 2012 <http://www.haywardsllp.co.uk/case-studies/property-facilities-management-case-studies>. Saint-Germain, R. "Information Security Management Best Practice Based on ISO/IEC 17799." The Information Management Journal (2005): 61. Davies, C. & Greenough, R.M., 2003. Measuring the effectiveness of lean thinking activities within maintenance. White paper, http://www. plant-maintenance. com/articles/Lean_Maintenance. pdf (accessed 4 January 2005). Haider, A., Koronios, A. & Quirchmayr, G., 2006. You cannot manage what you cannot measure: an information systems based asset management perspective. Engineering Asset Management, pp.288–300. Kedar, A.P. et al., 2008. A Comparative Review of TQM, TPM and Related Organisational Performance Improvement Programs. In Emerging Trends in Engineering and Technology, 2008. ICETET ’08. First International Conference on. pp. 725 –730. Martín-Castilla, J.I. & Rodríguez-Ruiz, Ó., 2008. EFQM model: knowledge governance and competitive advantage. Journal of Intellectual Capital, 9(1), pp.133–156. References Tersine, R.J., 1994. Principles of Inventory and Materials Management 4th ed., Englewood Cliffs, N.J. ; London: Prentice-Hall International. Zhu, G., Gelders, L. & Pintelon, L., 2002. Object/objective-oriented maintenance management. Journal of Quality in Maintenance Engineering, 8(4), pp.306–318. Nonaka, I (1991), ‘The knowledge-Creating Company’, Harvard Business Review, Vol.69, Iss:6, pp.96-104, Business Source Premier, EBSCOhost, viewed 26th April 2012 Mario J. Donate, J. Ignocio Canales, (2012) ‘A new approach to the concept of knowledge strategy’, Journal of Knowledge Management, Vol. 16, Iss:1, pp.22-44, viewed 26th April 2012 WorkSafeBC (2008), How to Implement a Formal OHS Program, [Online], Available at: http://www.worksafebc.com/publications/health_and_safety/by_topic/assets/pdf/howtoimplement_ohs.pdf (assessed on 22/4/2012) Epa (2011), Environmental Protection Agency, [Online], Available at: http://www.epa.gov/ems/ (assessed on 23/4/2012) DOE (2011), U.S. Department of Energy, Joint Environmental Management System, [Online], Available at: http://www.lm.doe.gov/default.aspx?id=4271 (assessed on 23/4/2012 Alexander, K. (1996). Facilities management: theory and practice. Abingdon: Taylor & Francis Kinsella, J. & McCully, A.D. (2005). Handbook for implementing an ISO 14001 Environmental Management System, 3rd Ed. Bothell, WA: Shaw Environmental Scarrett, D. (2010). Property asset management, 3rd Ed. London:Routledge