HCl

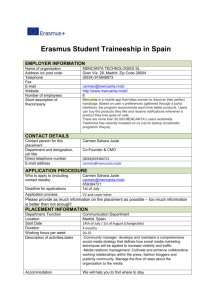

advertisement

A Presentation by Carmen Omota 27 April 2001 Carmen Omota 1 Appearance: colorless, fuming liquid Solubility: infinite in water with slight Odor: pungent odor Boiling point: 53C (127F) Melting point: evolution of heat Vapor pressure: 190 mm Hg @ 25C (77F) Density: 1.18 (water = 1) -74C (-101F) 27 April 2001 Carmen Omota 2 Health Rating: 3 – Severe (poison) Flammability Rating: O - None Reactivity Rating: 2 - Moderate Contact Rating: 3 – Severe (Corrosive) Lab Protective Equipment: goggles & shield; lab coat & apron; vent hood; proper gloves Storage Color Code : white (corrosive) 27 April 2001 Carmen Omota 3 Inhalation: Corrosive! Inhalation of vapors can cause coughing, choking, inflammation of the nose, throat, and upper respiratory tract, and in severe cases … DEATH! Ingestion: Corrosive! Swallowing HCL can cause immediate pain and burns of the mouth, throat, esophagus and gastrointestinal tract. May cause nausea, vomiting, and diarrhea (ewww!) Skin Contact: Can cause redness, pain, and severe skin burns. Concentrated solutions cause deep ulcers and discolor skin. 27 April 2001 Carmen Omota 4 Eye Contact: Vapors are irritating and may cause damage to the eyes. Contact may cause severe burns and permanent eye damage. Chronic Exposure: Long – term exposure to concentrated vapors may cause erosion of teeth. Long – term exposures seldom occur due to the corrosive properties of the acid. 27 April 2001 Carmen Omota 5 Stability: stable under ordinary conditions of use and storage. Hazardous Decomposition Products: when heated to decomposition, it emits toxic hydrogen chloride fumes and will react with water or steam to produce heat and toxic and corrosive fumes. Incompatibilities: A strong mineral acid, concentrated HCl is incompatible with many substances and highly reactive with strong bases, metals, metal oxides, hydroxides, amines, carbonates, and other alkaline materials. It is also incompatible with materials such as cyanides, sulfites, sulfides, and formaldehyde. Conditions to avoid: heat and direct sunlight. 6 27 April 2001 Carmen Omota Store in a cool, dry, ventilated storage area with acid resistant floors, and good drainage. Protect from physical damage. Do not wash out container and use it for other purposes. When diluting, the acid should always be added slowly to water, and only in small amounts. Never use hot water and never add water to the acid. Water added to acid can cause uncontrolled boiling and splashing. Observe all warnings and precautions listed for the product!!! 27 April 2001 Carmen Omota 7 Environmental Fate: When released into the soil, this material is NOT expected to biodegrade. When released into the soil, this material may leach into groundwater. Environmental Toxicity: This material is expected to be toxic to the aquatic life. 27 April 2001 Carmen Omota 8 Whatever cannot be saved for recovery or recycling should be handled as hazardous waste and sent to a R C R A approved waste facility. 27 April 2001 Carmen Omota 9 Technology Description: Although HCl acid recovery technology exists for large scale manufacturers, no cost-effective method had been developed for galvanizers and small – to medium – steel plants until Beta developed its new system between 1989 and 1994. The new HCl recovery recycles used acid solution from the pickling process. Without recycling, waste HCl solution is disposed of by injection into deep wells or the acid is neutralized and the waste is then transported to a disposal site. With the new recovery system, acid is pumped through a prefilter to an evaporator where it is heated until the water and acid vaporize, leaving only concentrated iron chloride that is recuperated. The water /acid vapor is condensed into HCl, reconcentrated, and pumped to the pickling tanks. reused, 10 27The Aprilacid 2001 is recovered, the water Carmen Omota [] product is sold at a profit. 27 April 2001 Carmen Omota 11 The acid recovery system delivers significant savings. Currently, a typical small – to medium – size steel manufacturing plant spends $14 / ton to clean its products. With Beta’s recovery system, manufacturers can slash that cost to just $3.40 / ton. More over, acid recovery requires minimal labor, and the life expectancy of a recovery system exceeds that of a conventional acid neutralization system by at least 3 yrs. The recovery system also saves energy by eliminating the acid – neutralization step and the need to transport and dispose of waste. 27 April 2001 Carmen Omota 12 27 April 2001 Carmen Omota 13 27 April 2001 Carmen Omota 14