lec 6

advertisement

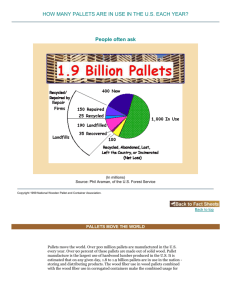

Course of MT- 362 Material Handling Lecture # 6 Material Feeding and Metering Devices Batch Feeding and Weighing Systems: • The manufacture of any blended product typically involves the intermediate process steps of transfer and weighing or batching of individual ingredients based upon their weight percentage in a blend. Depending on this percentage, materials are categorized as majors, minors and micros. There are two principle batching methods for weighing and feeding bulk materials: 1. 2. A Gain-in-Weight (GIW) batching station includes volumetric metering devices, such as screw feeders or valves, that deliver the product to a hopper on load cells. GIW batchers for the major ingredients. The Loss-in-Weight (LIW) batching system employs gravimetric feeding devices, such as loss-in-weight screw or vibratory feeders, which are mounted on individual load cells or scales. LIW feeders for the micros and minors. Material Feeding and Metering Devices Material Feeding and Metering Devices Gravimetric Feeders: In gravimetric feeding, dry bulk material or liquid is fed into a process at a constant weight per unit of time. Consistent control and complete monitoring are possible. In principle, gravimetric feeding combines monitoring of the feeding process with a feedback loop that enables accurate material control. For example spice industries, glass bottle making industries Volumetric Feeder: volumetric feeding is the simplest, most economical feeding solution available. Bulk material is held in a hopper and constantly fed into a process per unit of time. Although there is no weight feedback to assure feeding accuracy over time, this may not be a concern for materials with consistent bulk density. For example Beverage industries. Material Feeding and Metering Devices Continuous Feeders: In a continuous process, all equipment components related to the required unit operations function as a single system and are designed to operate 24 / 7, except for periods of required maintenance. This increased equipment utilization. Material Feeding and Metering Devices • Centerboard feeder -shaped to match part, -dips and then rises -through parts to select part, - which then slides into feed groove CHUTE: a sloping channel or slide for conveying things to a lower level • Reciprocating feeder Either hopper or tube reciprocates to obtain, orient, and feed items Material Feeding and Metering Devices • Rotary centerboard feeder - Blade, with edge shaped to match part, rotates through parts, catching those oriented correctly. Parts slide on contour of blade to exit onto feeder rail Material Feeding and Metering Devices • Escapement feeder - Escapement is weighted or spring-loaded to stop part from leaving track until it is snared (trapped) by the work carrier. Slope of track feeds next part into position • Lead screw feeder -Parts stack up behind the screw - Rotation of screw feeds parts with desired separation and timing. Material Feeding and Metering Devices Hopper Adjustment mechanism Supports Motor Screw Outlet Vehicle bulk conveyor systems Such systems consist of conveyors that can be moved easily so that they can be used for loading and unloading of bulk material from vehicles like Trucks Rails Aircrafts Consists of Conveyer systems (belts, rollers etc.) Driving mechanism (motor, gears, pulleys etc.) Control cabinet (electronics, sensors, transducers etc.) Transportation modes (wheel carriages, trucks etc.) Vehicle bulk conveyer systems Conveyer system Controls cabinet Drive mechanism Transportation mode Electronics Vehicle bulk conveyer systems Marine Bulk Material Handling Marine handling equipments • Those equipments which are used for handling of material related to sea or ocean • These may include transportation to or from Directly from sea From islands Ships Ports Marine Bulk Material Handling Products associated with marine may include Mining (coal, iron, sulfur, etc.) Import export bulk materials (grains, wheat, etc.) Chemical plants (chemical processing) Petroleum products Food products Material handling equipments is performed by Cranes Conveyers Elevators Rails Containers Lifters Marine Bulk Material Handling Different stages in marine material handling Loading/ unloading Stacking Conveyers Reclaimers Wagon loading Marine Bulk Material Handling • Bulk material loading to ships Marine Bulk Material Handling • Loading/ unloading Marine Bulk Material Handling • Stacking Marine Bulk Material Handling • Reclaimers Marine Bulk Material Handling • Conveyers Marine Bulk Material Handling • Wagon loading Packaged material handling • Packaged materials are those materials that can be easily packed in single units • Few examples are – Food items – Medicines – Glassware – Industrial products – Electronics Packaged material handling • Pallets and palletizing operations – These are unit load formation equipments – The objective is to use recyclable material for the product containers – Such material handling consist of • Boxes • Cartons • Crates • Totes • Bags • Packets Packaged material handling • Pallets – Pallets are probably the most common platform for moving unit loads. – Perhaps the most obvious area of concern associated with the use of pallets today involves cost and quality – Poor quality pallets annually cost industry billions of dollars in the form of • Product damage, • Lost productivity, and • Damaged handling Packaged material handling • Pallet construction – A pallet consist of • Top deck/ slat • Bottom deck/ slat • Blocks • Stringer board (support/ connector) • Guide ways for fork lifter forks • Guide ways for hand-trucks forks Packaged material handling Packaged material handling • Pallet construction – Size of pallet is specified by its depth (i.e., length of its stringers or stringer boards) and its width (i.e., length its deck-boards)—pallet height (typically 5 in.) is usually not specified – 48 × 40 in. (1200 × 1000 mm) pallet is most popular in the US, because its compatibility with railcar and truck trailer dimensions; e.g., the GMA (Grocery Manufacturers of America) pallet is four-way and made of hardwood – 1200 × 800 mm “Euro-Pallet” is the standard pallet in Europe – Single-face pallets are sometimes referred to as “skids” Packaged material handling • Pallet material – A key decision affecting the overall life cycle cost of pallets is the materials used in their manufacture – The pallet materials include • Wood • Pressed wood fiber • Corrugated fiberboard • Plastic • Metal Corrugated : a material shaped into a series of parallel ridges and grooves so as to give added rigidity and strength Packaged material handling Wooden pallets Corrugated fiberboard Packaged material handling Pressed wood fiber pallets Packaged material handling Plastic pallet Metal pallet Packaged material handling • Advantages of using different material pallets – Wooden pallets are sold each year than any other type due to the versatility, low cost, biodegradability and recyclability of this material – Pressed wood fiber is a combination of wood fibers and organic resins which eliminates the need for nails and enables the molding of pallets into more space efficient designs Packaged material handling • Advantages of using different material pallets – Disposable, corrugated fiberboard pallets can be made of recycled paper materials and provide a light weight, low cost alternative for one way shipping when loads do not need to be stored outdoors – Durable plastic and metal pallets may provide the low cost alternative over the full pallet life cycle despite their high initial cost • Both of these materials are recyclable, can be sanitized for clean applications, and can be used in the most demanding applications Packaged material handling • Palletizing – It is the process of stacking the product to form a unit load – Palletizing operation may be through the following methods • Manual • Automated /robotic Packaged material handling • Manual palletizing Packaged material handling • Automated/ robotic method Packaged material handling • Pallet positioner – It is a tool which fulfills the ergonomics requirements of an operator – It consist of a turn-table, drive mechanism, damping system and control device – It can be operated • Manually • Hydraulically Ergonomics (or human factors) is the scientific discipline concerned with the • Motorized understanding of interactions among humans and other elements of a system, and the profession that applies theory, principles, data and methods to design in order to optimize human well-being and overall system performance. Packaged material handling • Pallet positioner