Sustainability a contractors perspective

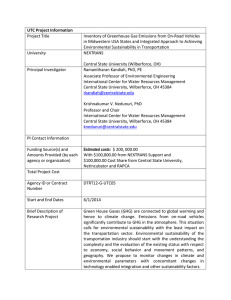

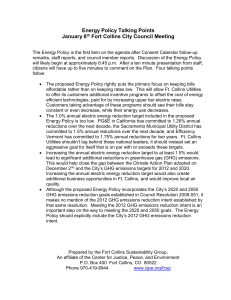

advertisement

Sustainability – A Contractors Perspective Paul O’Connell, Abigroup Environment & Sustainability Manager National Local Government Asset Management & Public Works Engineering Conference 2010 Overview • Business Drivers • Embracing Sustainability – ‘Ability’ – 5 Dimensions of Sustainability • Sustainable Construction & Innovation – 5 Key Examples • Where to from here? Abigroup • Abigroup is one of Australia’s leading national contractors, with 50 years of experience delivering works in: – building – roads – rail – water – mining services, and – telecommunications Sustainability - Business Drivers • Reputation and social licence to continue to operate • Strengthened relationships with clients and other stakeholders • Stimulate internal innovation and learning Business Drivers continued……. • Climate change and carbon compliance Energy Efficiencies Opportunities Act 2006 (EEO Act) National Greenhouse Emissions Reporting Act 2008 (NGERs Act) Carbon Pollution Reduction Scheme 2012? (CPRS) • Improved energy efficiencies and cost savings GHG emissions now have a cost Energy costs increase considerably $ Carbon Carbon Regulation = $$$$ Electricity Transport Freight costs increase Waste Waste costs increase Gas Fuel Raw material and parts costs will go up as manufacturers pass on their cost increases Business drivers continued...... • Rating schemes and tools eg. Australian Green Infrastructure Council (AGIC) • Employer of choice • Increased employee morale, motivation and productivity • Corporate values “its just the right thing to do” • Over 80 actions identified • 5 Dimensions of Sustainability Ensuring a Strong, Healthy and Innovative Workforce Making a Difference in our Community Leadership Driving Performance through Culture Minimise our Impact on Resources and Biodiversity Building a Strong, Stable and Profitable Business Leadership in Focus • • • • • • • Company values Sustainability Champions and Panel Policy and Strategy Communications Plan Training Compliance Financial Performance Our People in Focus • • • • • Safety – Pulse Program Women@Abigroup Employee Wellbeing Graduate Programs Learning and Development – Leadership Training – RTO Society in Focus • Community Partnerships and Legacy – National Stakeholder Forum • Corporate Social Responsibility – beyondblue partnership • Indigenous Relationships – Structured Training & Employment Project (STEP) – Red Dust Partnership Business in Focus • Internal Innovation and Systems – National Innovation Capture and Rewards Scheme • R&D Programs and Strategic Business Partnerships • Guideline for the Set-up of Sustainable Compounds Environment in Focus • • • • • Environmental Leadership Biodiversity Water Conservation Waste Minimisation Energy Efficiency Sustainable Construction & Innovation 5 Key Examples Abigroup GHG Reporting Tool • Developed in partnership with Ndevr and fits in to existing financial reporting system (JDE) • Meets legislative reporting requirements • Ability to provide reports to key stakeholders and clients • Ability to accurately assess carbon footprint and set company targets • Ensures auditable and high integrity of data and emissions reports • Reports Scope 1 (Direct) and Scope 2 (Indirect) emissions separately or in any combination GHG Reporting Tool GHG Reporting Tool Note: Energy and emissions data not accurate. Example data set created for the purpose of presentation Abigroup Wins Global Sustainability Award! • Winner Oracle’s “Enable the Eco-Enterprise” award. This international award was presented at the Oracle Open World Conference on 12 October 2009 in San Francisco. TPAR Ecoflex Platorms • Townsville Port Access Road (TPAR) Project • Client: Department of Main Roads • heavy vehicle corridor linking the existing Flinders and Bruce Highways with the Port of Townsville • Two Stage project – approx 9.5km two lane road • 5 bridge structures allow for design flows • Construction of pile driver and crane platforms during bridge works at Stuart Creek. • Structure was used to form engineered, structural platform to support a 110T piling rig • Ecoflex platforms constructed from 2200 recycled truck tyres • Ecoflex are placed on geofabric laid on Pad surface and arranged in honeycomb pattern • Each tyre is butted up to adjoining tyres • Tyre void filled with recycled crushed concrete • Topping layer is applied • Alternative options involved greater disturbance to creek banks • Platforms were also to be exposed to seasonal flooding • Abigroup first contractor to receive ‘Beneficial Reuse’ Approval from DERM SLU Low Emissions Lighting • Southern Link Upgrade (SLU) • Client: Transurban • One component of the overall MonashCityLink-West Gate (M1) Upgrade project in Melbourne • Investigated opportunities to minimise GHG emissions during operation of the freeway SLU Low Emissions Lighting • Trial of Low emissions lighting technology – Lighting Energy Controllers (LECs) – 12 Month • Trial Section - controlled 16 light poles and 32 luminaries, that included a combination of 400, 250 and 150 watt globes. • Involved SLU, Saving Point, CityLink & VicRoads • Objectives included: • GHG Reductions during operation • Extended luminaire life & reduced maintenance costs • Ease of installation and retro-fit • Voltage reduced by 33v, directly leading to a 26% reduction in energy consumption and GHG emissions. • Simple and inexpensive installation at virtually any location • Integrated automatic bypass that disconnects the LEC without extinguishing lights in case of failure • Increased life expectancy of lamps – approx 10% • Permanently installed along CityLink – data collection ongoing PenLink Eco-Operator Training • Peninsula Link Project • Client: Linking Melbourne Authority • Provides for a dual carriage way freeway from the Eastlink in North Frankston to Mount Martha PenLink Eco-Operator Training • Abigroup partnership with Caterpillar Institute • Provides machine operators with knowledge, skills & techniques to operate plant and reduce fuel consumption • All plant operators will be required to undertake Eco Operator Training on the Peninsula Link Project • Potential savings include: • Saving of approx 4 litres per hour Business as Usual Materials in Construction • Reuse of asphalt profilings for access track stabilisation and dust suppression • Use of Recycled Asphalt Pavement where within specification (typically 10-30%) • Reuse of demolition concrete as Cement Treated Crushed Concrete used in pavement sub-base layers • Hollow trees felled placed into adjacent land as habitat • Alternative water use – reducing potable water use • Mulch used for Erosion and Sediment controls Where to from here? • Want to see clients continue to encourage innovation on projects • Contracts/specifications to lean toward recycled or reused materials • Project delivery models that push beyond compliance or business as usual practices • Shared risk in product performance driving innovation Questions, Queries, Comments...