stability studies - World Health Organization

advertisement

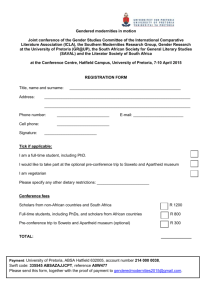

Supplementary Training Workshop on Good Manufacturing Practices (GMP) MANUFACTURING PROCESS VALIDATION Solid Dosage Forms János Pogány, pharmacist, PhD, consultant to WHO Pretoria, South Africa, 28 June 2005 E-mail: pogany@t-online.hu 2005.06.28. Dr. Pogány - WHO, Pretoria 1/59 WHO GMP and related guides WHO good manufacturing practices (GMP): main principles for pharmaceutical products Section 4. Qualification and validation Supplementary guidelines on good manufacturing practices (GMP): Validation (2003) – Draft. 2005.06.28. Dr. Pogány - WHO, Pretoria 2/59 WHO GMP and related guides WHO good manufacturing practices: main principles for pharmaceutical products – Validation of manufacturing processes Good manufacturing practices for pharmaceutical products. In: WHO Expert Committee on Specifications for Pharmaceutical Preparations. Thirty-second report. Geneva, World Health Organization, 1992:14–79 (WHO Technical Report Series, No. 823). 2005.06.28. Dr. Pogány - WHO, Pretoria 3/59 ICH guidelines PHARMACEUTICAL DEVELOPMENT, Q8, Draft ICH Consensus Guideline, Released for Consultation on 18 November 2004, at Step 2 of the ICH Process QUALITY RISK MANAGEMENT, Q9, Draft ICH Consensus Guideline, Released for Consultation on 22 March 2005, at Step 2 of the ICH Process 2005.06.28. Dr. Pogány - WHO, Pretoria 4/59 PROSPECTIVE VALIDATION Pharmaceutical Development Laboratory scale R + D Physicochemical and physical properties of API Physicochemical Physical hygroscopicity particle size solubility bulk density (g/100ml) water content flowability polymorphism color, olor, taste permeability consistency 2005.06.28. Dr. Pogány - WHO, Pretoria 6/59 Equilibrium Moisture Content At relative humidities (RHs) <100%, a solid API (that does not form crystalline compounds with water) will loose some bound and all its unbound water until it is in equilibrium with the surrounding atmosphere. The sum of both these moistures is the free moisture of the API (granules) at the specified RH. 2005.06.28. Dr. Pogány - WHO, Pretoria 7/59 Rate of Water Absorption at Different RHs 0,45 Lg RH, % 0,40 35% 0,35 55% 75% 0,30 100% 0,25 28 25 22 19 16 13 10 7 4 1 0,20 Lg time, t (3 min. units) 2005.06.28. Dr. Pogány - WHO, Pretoria 8/59 Solubility of Zidovudine at 25oC pH Dissolved material (mg/ml) 3.0 21 4.0 20 5.3 20 6.0 21 7.0 22 Distilled water 20 8.0 21 2005.06.28. Dr. Pogány - WHO, Pretoria 9/59 Solubility of Artesunate 2005.06.28. pH Dissolved API (mg/ml) 1 1,9 5 1,5 6 3,5 7 10,2 8 12,2 Dr. Pogány - WHO, Pretoria 10/59 Decomposition of Artesunate in aqueous solution Solvent Water 2 Decomposition (%) 0 0.1N HCl 2 74 0.1N NaOH 2 100 2005.06.28. Time (h) Dr. Pogány - WHO, Pretoria 11/59 Relationship between Permeability Coefficient and Octanol-Water Partition 1 Prednisolone ... 3 Dexamethazone ... 9 Dexamethazone-acetate ... 11 Progesterone 2005.06.28. Dr. Pogány - WHO, Pretoria 12/59 NORVIR (Ritonavir) EPAR/CPMP /527/96 1. 2. 3. 4. 5. No polymorphism observed at the time of first submission (only form I : hard capsules and oral solution registered) Failure in dissolution during stability studies for hard capsules Emergence of form II (contamination of form I) Production of hard capsules discontinued Development and registration of soft capsules 2005.06.28. Dr. Pogány - WHO, Pretoria 13/59 Particle Size When the solubility of an API is less than 0.1 mg/ml, the optimization of the particle size during preformulation may be critical to efficacy or pharmaceutical equivalence. Other researchers believe that particle size may be critical at a solubility of 1 mg/ml or less. 2005.06.28. Dr. Pogány - WHO, Pretoria 14/59 Effect of Particle Size on Dissolution of Nevirapine tablets % Drug Dissolved USP Type II / 0.01N HCl 50 RPM / 900 ml 120 100 80 60 40 20 0 Time (Min) Nevipan MGS(1024)05 (90%LT81.12) Nevipan MGS(1024)60B (90%LT30.89) Viramune 992633B 2005.06.28. 0 0.00 0.00 0.00 10 50.80 80.00 83.30 Dr. Pogány - WHO, Pretoria 20 73.80 92.00 96.60 30 83.98 96.00 97.70 15/59 Screening of Compositions Compatibility of an API with the excipients and the APIs with each other in FDCs is studied in open system stress stability experiments, e.g., 6080 oC, 100% RH. Regulatory stability studies of the final composition are frequently initiated in the pharmaceutical R + D laboratory. 2005.06.28. Dr. Pogány - WHO, Pretoria 16/59 Compatibility of Acetylsalicylic Acid with Excipients Time (week) Talc A Salicylic acid, % Talc B Salicylic acid, % 0 0.10 0.10 4 0.32 5.85 8 0.41 13.00 12 0.80 28.50 2005.06.28. Dr. Pogány - WHO, Pretoria 17/59 Triomune - WHOPAR Experimental „studies showed chemical incompatibility for the lamivudine with stavudine and nevirapine with stavudine combination. Lamivudine with nevirapine showed no change indicating that they are compatible. Stavudine was found incompatible with both the drugs, indicated by the brown colouration and increase in the impurities. Therefore it was decided to separate stavudine from the other two drugs. Hence the formulation was proposed to be bilayered tablet formulation, where stavudine is in one layer and lamivudine + nevirapine in other layer. Thus contact of stavudine with the other two drugs was minimised.” 2005.06.28. Dr. Pogány - WHO, Pretoria 18/59 Dissolution Test and Profile A (discriminating) dissolution test method should be developed for the final composition of the FPP. Limits should be set for each API in fixed-dose FPPs. The dissolution method should be incorporated into the stability and quality control programs. Multipoint dissolution profiles of both the test and the reference FPPs should be compared. 2005.06.28. Dr. Pogány - WHO, Pretoria 19/59 Dissolution Profile of Viramune and Generic Nevirapine Tablets on the Indian Market % Drug Dissolved USP Type II / 0.01N HCl 50 RPM / 900 ml 120 100 80 60 40 20 0 Time (Min) Viramune B.No.992633B Brand C B.No.C00139 Ranbaxy B.No.(1024)17 2005.06.28. 0 0.0 0.0 0.0 10 83.3 34.3 88.9 20 96.6 51.3 97.6 Dr. Pogány - WHO, Pretoria 30 97.7 61.2 99.2 45 99.7 70.8 99.7 20/59 F2 20 73 % dissolved Hypothetical Dissolution Profile of a 2-FDC FPP 120 100 80 60 40 20 0 Series1 Series2 Series3 Series4 0 15 30 45 60 minutes 2005.06.28. Dr. Pogány - WHO, Pretoria 21/59 Pivotal Batches A tabulated summary of the compositions of the clinical, bioequivalence, stability and validation FPP batches together with documentation (batch number, batch size, manufacturing date and certificate of analysis at batch release) and a presentation of dissolution profiles must be provided. Results from comparative in vitro studies (e.g., dissolution) or comparative in vivo studies (e.g., bioequivalence) should be discussed when appropriate. 2005.06.28. Dr. Pogány - WHO, Pretoria 22/59 Excipients – Lactose (L) Different grade, different physical properties: Angle of repose: 32- 47o (Specs.) Bulk density: 0.34 – 0.80 g/cm3 (Specs.) Bulk density (tapped): 0.41 – 0.95 g/cm3 Flowability (spray processed): 4.1 g/s (Specs.) Hygroscopicity: L monohydrate is stable in air at room temperature. Anhydrous L may absorb humidity. Moisture content: L monohydrate contains approx. 5% w/w water of crystallization 2005.06.28. Dr. Pogány - WHO, Pretoria 23/59 Excipients – Lactose (L) Solubility in water 1 in 4.63 at 25 oC 1 in 3.14 at 40 oC 1 in 2.04 at 50 oC 1 in 1.68 at 60 oC 1 in 1.07 at 80 oC Particle size distribution: depends on grade. Stability: may develop brown colouration (≥ 80% RH) Incompatibility: APIs with a primary amine group (base catalysed), aminophylline and amphetamines. 2005.06.28. Dr. Pogány - WHO, Pretoria 24/59 Surface of a film-coated tablets containing a high level of a superdisintegrant 2005.06.28. Dr. Pogány - WHO, Pretoria 25/59 Packaging Materials Moisture-impermeable containers: glass ampoules, vials closed with rubber stoppers and fixed with metal caps, aluminium/aluminium blisters, high density polyethylene (HDPE) or glass bottles fitted with metal metal or HDPE closures, etc. Moisture-permeable containers: polyvinyl chloride (PVC) blisters, low density polyethylene (LDPE) bottles, HDPE bottles fitted with polypropylene closures. Specifications of packaging materials should include thickness and permeability coefficient. 2005.06.28. Dr. Pogány - WHO, Pretoria 26/59 CONCURRENT VALIDATION Commitment Batches Technical pharmacy Pharmaceutical production system (from purchasing API to packaging FP) Utility support system (HVAC, water, HPLC, etc. equipment containing many items) Process (tablet making) (Unit) operation (granulation, compression) Step (sifting, sizing) Procedure, method, technique (SOP) 2005.06.28. Dr. Pogány - WHO, Pretoria 28/59 Causes of variation Man (different operators - lack of proper training) Machine / equipment (variation of tablet weight) Measurement (lack of calibration) Method (validated manufacturing methods) Material (batch-to-batch variation of the same crystal form – different crystal forms (ASA)] Environment (OoS T and RH in capsule filling) 2005.06.28. Dr. Pogány - WHO, Pretoria 29/59 4.10 Scientific approach „Processes and procedures should be established on the basis of the results of the validation performed.” Objectives To prove that the tests, measurements, results and interpretation of formal studies on (manufacturing) processes and procedures/methods are appropriate and accurate. To stabilize new processes (to reduce variability, to increase batch to batch consistency of quality attributes of products). To reduce defect levels (standardize yields). To reduce production costs. 2005.06.28. Dr. Pogány - WHO, Pretoria 30/59 Process approach CONTINUOUS IMPROVEMENT OF THE QUALITY MANAGEMENT SYSTEM C U S T O M E R S A T I S F A C T I O N Management responsibility R E Q U I R E M E N T S Resource management Inputs 2005.06.28. Monitoring, improvement Manufacture Dr. Pogány - WHO, Pretoria Product 31/59 C U S T O M E R Measure of variation (spread of data) 68.26% 95.46% 2005.06.28. Dr. Pogány - WHO, Pretoria 32/59 Mean (average) chart Abnormal variation of process – special causes UCL Upper control limit average = mean LCL Normal variation due to common causes Lower control limit Abnormal variation of process – special causes 2005.06.28. Dr. Pogány - WHO, Pretoria 33/59 Process capability index, Cp acceptance limits Cp = process capability Three sigma: Cp = Six sigma: Cp = 6σ* 6σ* 12σ* 6σ* UCL - LCL = 6σ* =1 =2 σ* ... is the measured standard deviation of the process 2005.06.28. Dr. Pogány - WHO, Pretoria 34/59 Process capability index, Cpk UCL - x Cpk = 3σn UCL ... upper control limit x ... mean of the acceptance criteria, target value σn ... is 50% of the measured standard deviation of the process Cpk shows the closeness of the process mean to the target value. 2005.06.28. Dr. Pogány - WHO, Pretoria 35/59 Output of processes for different Cpk indices nσn = 3σ UCL Cpk 1σ1 m + σ1 -0.166 No. of products OoS (ppm) 691 464 2σ2 m + 2σ2 0.166 308 536 3σ3 m + 3σ 3 0.5 66 807 4σ4 m + 4σ4 0.833 6 210 5σ5 m + 5σ5 1.166 233 6σ6 m + 6σ6 1.5 3.4 2005.06.28. Dr. Pogány - WHO, Pretoria 36/59 Objective and result of process control UCL 1.The process reveals serious risks and it N is not controlled LCL 2.The process is not UCL N yet controlled but acceptance criteria are met LCL 3.The process is under control and UCL the product has a N consistently high quality LCL 2005.06.28. Dr. Pogány - WHO, Pretoria 37/59 Process under control Most points fall near the central line (68% within one σ) A few points fall near the control limits (5% in the third σ) Points shold balance on both sides of the mean Points should cross the mean line often. Points should show a random pattern (no trends, cycles, clustering) 2005.06.28. Dr. Pogány - WHO, Pretoria 38/59 4.8-4.9 Protocols and reports Validation studies are an essential part of GMP and should be conducted in accordance with predefined and approved protocols. A written report summarizing the results recorded and the conclusions reached should be prepared and stored. 2005.06.28. Dr. Pogány - WHO, Pretoria 39/59 Process validation protocol/report Short description of the process with a summary of the critical processing steps or critical parameters to be monitored during validation. Additional testing intended to be carried out (e.g. with proposed acceptance criteria and analytical validation as appropriate). Sampling plan — where, when, how and how many samples are taken. Details of methods for recording and evaluation of results. 2005.06.28. Dr. Pogány - WHO, Pretoria 40/59 Illustrative variables of wet granulation Process step Crystallization Micronization Pre-mixing Wet kneading 2005.06.28. Control or manipulate (independent) variables Particle size Bulk density Speed, time, order of addition Batch (load) size Speed Impeller Chopper Spraying rate Volume of binder solution Granulation time Measured responses or output (dependent) variables Dissolution time Granulation and granule variables Blend uniformity End-point amperage Impeller Chopper Additional solvent volume Dr. Pogány - WHO, Pretoria 41/59 Illustrative variables of wet granulation Process step Drying Sizing Blending Control or manipulate (independent) variables Inlet air temperature (seasonal variation) Drying time (seasonal variation) Cooling time (if applicable) Screen type and size Feed rate Batch size (sub-batches) Speed Blending time 2005.06.28. Measured responses or output (dependent) variables Outlet air temperature LOD Moisture content Granule size distribution (variation of sub-batches) Blend uniformity Bulk density untapped tapped Flowability Yield Dr. Pogány - WHO, Pretoria 42/59 Indentation hardness profiles for tablets of different shape Flat Shallow convex Standard convex Deep convex Ball-shaped 2005.06.28. Dr. Pogány - WHO, Pretoria 43/59 Areas most prone to surface erosion for flat, shallow convex, caplet-shaped and deep convex tablets 2005.06.28. Dr. Pogány - WHO, Pretoria 44/59 Erosion on the surface of the tablet with a logo 2005.06.28. Dr. Pogány - WHO, Pretoria 45/59 Twinning during the coating process for flat-faced and caplet shaped tablets 2005.06.28. Dr. Pogány - WHO, Pretoria 46/59 Measurement points of film thickness across the tablet surfaces FACE EDGE SIDE 2005.06.28. Dr. Pogány - WHO, Pretoria 47/59 Illustrative variables of compression and film-coating Process step Control or manipulate (independent) variables Compression Machine speed Granule feed rate Precompression force Compression force Punches and dies Film-coating Inlet air temperature Inlet air flow Spray rate Spray atomizing pressure 2005.06.28. Measured responses or output (dependent) variables Weight variation Content uniformity Friability Hardness Thickness Disintegration Dissolution time and profile Yield Outlet air temperature Tablet-bed temperature Coat quality Yield Dr. Pogány - WHO, Pretoria 48/59 Illustrative variables of tablet packaging Process step Blistering Bulk packing Control or manipulate (independent) variables Machine speed Machinability of blister material Forming temperature Forming pressure Sealing temperature Sealing pressure Tablet counter Incomplete tablets Machine speed 2005.06.28. Measured responses or output (dependent) variables Leak testing Appearance Minimum information is legible Yield Number of tablets Detection, counting Pilfer-proof Labeling Yield Dr. Pogány - WHO, Pretoria 49/59 4.10 Scientific approach Processes and procedures should be established on the basis of the results of the validation performed. 2005.06.28. Dr. Pogány - WHO, Pretoria 50/59 Commitment (validation) batches Process validation reports should be submitted in the application for prequalification. Formal studies of production scale batches (not less than three) are required to identify the critical variables. Provisional equipment control parameters and the corresponding in-process acceptance criteria must be deduced from the results of experiments with the validation batches. Critical parameters are to be monitored, non-critical ones should be tested occasionally. 2005.06.28. Dr. Pogány - WHO, Pretoria 51/59 RETROSPECTIVE VALIDATION Annual Product Review Annual FPP quality review (1) Starting materials used in the product, especially those from new sources. Critical in-process controls and finished product results. All batches that failed to meet established specification(s). All critical deviations or non-conformances and related investigations. All changes carried out to the processes or analytical methods. Marketing Authorisation variations submitted, or granted, or refused, including those for third country dossiers. 2005.06.28. Dr. Pogány - WHO, Pretoria 53/59 Annual FPP quality review (2) Results of the stability monitoring programme. All quality-related returns, complaints and recalls, including export only medicinal products. Adequacy of previous corrective actions. For new marketing authorisations, a review of postmarketing commitments. A list of validated procedures and their revalidation dates. A list of qualified equipment, support utility systems and their requalification dates, including calibration programmes. 2005.06.28. Dr. Pogány - WHO, Pretoria 54/59 Case summary of 20 batches (1) Statistics Mean Median SD Range Minimum Maximum Conf. level, 95% Accept. Crit. 2005.06.28. Av. wt. mg Dissolution % Assay % 347,6 346,9 5,2 22.3 337.0 359.3 2.4 99,6 100,0 2.5 10.0 95.6 105.6 1.3 98,2 95.0 103.8 1.0 350±5% 75%, 40' 90-110 Dr. Pogány - WHO, Pretoria 97,5 2.2 8.8 55/59 Case summary of 20 batches (2) 1. Acceptance criteria for assay and dissolution rate are loose and should be tightened. 2. Potentially critical impurities are not tested. 3. IPC data are not included in the retrospective analysis of batch records. 2005.06.28. Dr. Pogány - WHO, Pretoria 56/59 BEST PROCESS MINIMUM REQUIRED INPUT MAXIMUM OUTPUT AT NO COST TO SOCIETY (industrial safety, labour safety, internal and external environment protection) 2005.06.28. Dr. Pogány - WHO, Pretoria 57/59 COSTS OF QUALITY Visible costs, e.g., waste and returned goods Hidden costs, e.g., wrong decisions, non-competitive manufacturing process, low yield, maintenance, idle machine time, workers attitude, etc. 2005.06.28. Dr. Pogány - WHO, Pretoria 58/59 Main points again Manufacturing methods are the same in the innovative and generic industries. Pharmaceutical development is a major source of early identification of critical product and process parameters. Validation batches should be tested extensively to establish preliminary/tentative IPC parameters. Annual product review results in continuous improvement of products and processes. 2005.06.28. Dr. Pogány - WHO, Pretoria 59/59