Beam test of the Micromegas ILC-TPC Large - Indico

advertisement

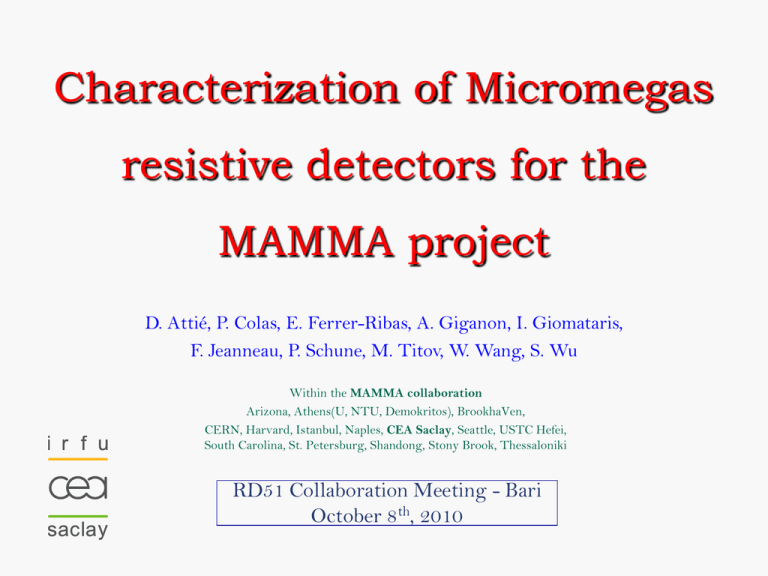

Characterization of Micromegas resistive detectors for the MAMMA project D. Attié, P. Colas, E. Ferrer-Ribas, A. Giganon, I. Giomataris, F. Jeanneau, P. Schune, M. Titov, W. Wang, S. Wu i r f u s a c la y NoV. 11, 2009 Within the MAMMA collaboration Arizona, Athens(U, NTU, Demokritos), BrookhaVen, CERN, Harvard, Istanbul, Naples, CEA Saclay, Seattle, USTC Hefei, South Carolina, St. Petersburg, Shandong, Stony Brook, Thessaloniki RD51 Collaboration Meeting - Bari October 8th, 2010 WP meeting 94 1 Overview • The MAMMA project: Muon Atlas MicroMegas ActiVity (J. Wotschack) • The Saclay beam test in 2009 at Cern: – Resistive detector efficiency in high intensity beam – Preliminary results • Next beam test preparation and resistive bulk characterization – Gain measurement – Stability in time – Spark topology of the resistive detectors • Conclusion David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 2 The MAMMA Project LsLHC = 10 × LLHC = 1035 cm2.s-1 • Increase of the neutron, photon and hadron background • Replacement or upgrade of the muon forward chambers • Requirements: – – – – – – High rate capability (≤ 10 kHz.cm-2) Spatial resolution ~100 µm (θ ≤ 45 °) Radiation hardness and good ageing properties Time resolution ~few ns Level1 triggering capability Large surface Resistive coating may solve the sparking issue • MPGD: Bulk Micromegas – Fast and efficient ion collection – TPC mode possible: sensitivity to incidence angle. – « bulk » production process suitable for large surfaces David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 3 The Saclay beam test setup at CERN (2009) • Aim: test different resistive film detectors and compare behaviour to non-resistive detectors in order to operate in high rate • Telescope: 3 X-Y detectors (10 10 cm2) • Electronics: GASSIPLEX • DAQ: realised by Demokritos • Gas: 95%Ar + 3% CF4 + 2% isobutane • Tested detectors: - Standard bulk detectors - Resistive coating detectors - Segmented mesh detector Detectors in test 1 mm 0.25 mm X Y David.Attie@cea.fr X Y Non-Resistive Resistive Beam 120 GeV π+ SPS-H6 1 mm X Y RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 4 Current and voltage behaviour at 10 KHz/cm² Standard bulk (SLHC2: 2mm) Resistive strip bulk (R6: 1mm, 400kΩ/□) 430V Mesh Voltage Mesh Current 410 1 0,9 430 0,9 0,7 370 ua 440 0,8 390 V 1 uA 0,8 420 0,7 410 0,6 350 0,6 400 0,5 330 0,5 390 0,4 310 0,3 290 270 250 501 1 1001 Time in arbitrary unit 1501 0,4 380 0,2 370 0,1 360 0 350 0,3 0,2 0,1 0 1 1001 2001 3001 4001 5001 Time in arbitrary unit SLHC2: HV=400V (Gain ~3000): R6: - current when sparking < 0.4 mA -voltage drop< 5% HV=390V (Gain ~3000): - current when sparking < 0.08 mA -voltage drop<0.5% Ar /CF4/Iso (95/3/2) David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 5 Summary of the 2009 beam test (Gain~3000) Spark current (mA) Voltage drop 7×10−5 0.4 5% Type Name Pitch Standard bulk SLHC2 2 mm Non resistive R3 2 mm 2 MΩ/□, kapton+insulator 9.6×10−6 0.2 2% R5 2 mm 250 MΩ/□, resistive paste 1.6×10−4 0.1 1.5% R6 1 mm 400 KΩ/□, resistive strip 6.4×10−6 0.08 0.5% R7 0.5 mm tens of KΩ/□, resistive pad 5.9×10−4 0.35 4.5% S1 1 mm - - - Resistive coating Segmented mesh R3 David.Attie@cea.fr Properties Spark rate (s-1∙cm-2) 8 segmentations R5 R6 RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 S1 6 Spatial resolution • δ: define by residuals of the cluster position and extrapolated track from telescope: • δMM: convolution of: - the intrinsic Micromegas resolution - the track resolution (extrapolated) ~68µm R6(1mm pitch, 400kΩ/□) δ=105µm δMM= 80µm David.Attie@cea.fr R3(2mm pitch, 2MΩ/□) δ=241µm δMM= 231µm RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 7 Cluster size R3 (Kapton, 2mm) R6 (Strips, 1 mm) Size (mm) Size (mm) 8 3.5 7 3.0 6 2.5 5 2.0 Resistive detectors: 4 1.5 3 1.0 2 0.5 1 0.0 0 360 370 380 390 400 410 420 430 360 380 Vmesh (V) Size (mm) 400 420 440 460 Vmesh (V) SLHC2(standard, 2 mm) 2.8 Standard detector: Low cluster size value: decrease the strip pitch Increase the gas diffusion (Dt~700m/ cm) 2.7 2.7 2.6 2.6 2.5 2.5 360 370 380 390 400 410 420 Ar /CF4/Iso (95/3/2) Vmesh (V) David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 8 Track position With hit in the tested detector Without hit in the tested detector Inefficiency due to pillars and misalignment David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 9 Set-up for the next test beam at Cern • New telescope: 3 X-Y detectors(10 x 10 cm2) smaller pitch built in Saclay bulk workshop • Electronics: GASSIPLEX (96 channels per detector) • DAQ: more recent computer recording the spark counting and beam trigger • Gas: 98%Ar + 2% isobutane • Trigger improvement: PMs as close as possible to the telescope • New detectors to be tested: (built at Cern by Rui) Type Resistive coating Name Pitch R8 0,5 mm R9-R11 2mm R12, R13 0.5mm R14, R15 1mm R16, R17 1mm Properties 2 MΩ/□, kapton+insulator 300 KΩ/□, resistive strip Joerg-like Detectors to be tested X Y David.Attie@cea.fr Resistive Resistive Resistive Resistive 0.5 mm 0.25 mm X Y 0.5 mm X Y X Y X RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 Y 10 Gain cures in Ar/Isobutane 2% 100000 Proto12 R09 (kapton 2 MΩ) R10 (kapton 2 MΩ) R11 (kapton 2 MΩ) R12 (strips 300 kΩ) R13 (strips 300 kΩ) R14 (strips 300 kΩ) R15 (strips 300 kΩ) R16 (Joerg type) R17 (Joerg type) Gain 10000 1000 Ar/Iso (98/2) 100 285 300 315 330 345 360 Vmesh (V) David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 11 Signal evolution in time for resistive detectors 750 R08 (kapton 2 MΩ) R10 (kapton 2 MΩ) R12 (strips 300 kΩ) R14 (strips 300 kΩ) R16 (Joerg type) Proto12 standard 700 Signal (channels) 650 R09 (kapton 2 MΩ) R11 (kapton 2 MΩ) R13 (strips 300 kΩ) R15 (strips 300 kΩ) R17 (Joerg type) 600 550 500 450 400 Ar/Iso (98/2) 350 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120 Time (min) David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 12 Normalized signal evolution of the resistive detectors 1.00 Normalized gain 0.95 0.90 0.85 R08 (kapton 2 MΩ) R10 (kapton 2 MΩ) R12 (strips 300 kΩ) R14 (strips 300 kΩ) R16 (Joerg type) Proto12 standard 0.80 R09 (kapton 2 MΩ) R11 (kapton 2 MΩ) R13 (strips 300 kΩ) R15 (strips 300 kΩ) R17 (Joerg type) Ar/Iso (98/2) 0.75 0 10 20 30 40 50 60 70 80 90 100 110 120 Time (min) David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 13 Detector characteristics summary in Ar/C4H10 (97:2) Standard Bulk detector Strip pitch Proto11 Proto12 0,5 mm Proto13 Resistive Bulk detector Strip pitch R8 0,5 mm R9 R10 2 mm Detector capacitance Energy resolution 55Fe (FWHM) Maximum gain 613 pF 18.2% (320V) 26300 (360V) 608 pF 22.2% (310V) 23250 (360V) 604 pF 18% (300V) 25700 (360V) Resistive coating type C-loaded Kapton 2 MΩ/□ R11 R12 R13 0,5 mm Resistive strips 300 kΩ/□ R14 R15 R16 R17 David.Attie@cea.fr 1 mm Resistive Joerg-Type Detector capacitance Energy Resolution 55Fe (FWHM) Max. gain 633 pF 23,1% (310V) 25100 (365V) 1,45 nF 23,2% (320V) 12850 (360V) 1,67 nF 22,1% (310V) 23250 ( 360V) 1,72 nF 21,4% (310V) 24100 (360V) 637 pF 24,4% (320V) 25700 (360V) 643 pF 29,3% (300V) 35500 ( 360V) 943 pF 26,7% (320V) 34300 ( 360V) 941 pF 28,9% (310V) 33000 (360V) 941 pF 34,3% (320V) 33000 ( 365V) 943 pF 29,8% (310V) 33650 (365 V) RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 14 Simple model • See M. Lupberger talk given in the last meeting RD51 in Freiburg. • U= W B.f.R.G B , =RC=0 – W: lambert-W function – G: gain with G = eA+B.U – f: signal frequency – R: resistance of the coating – C: capacitance of the coating • The source were in contact with the Mylar windows at the detector center: f should be constant but a new set-up has to be done to improve it. • For G330V=3 000, f~150 Hz to 250 Hz David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 15 Spark study Measurement through a 1 MΩ resistor Detector divide in four parts Sparks triggered by source (241Am) HVdrift = -450V (5 mm gap) HVmesh up to sparks arising Threshold = 1V 1OO mm 23 strips 23 strips 23 strips 23 strips 1OO mm • • • • • • Oscilloscope 1MΩ Channel 1 Channel 2 David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 Channel 3 Channel 4 16 Standard bulk Trigger on Channel 2 Vmesh = 330V David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 17 Resistive Kapton 2 MΩ/□ Vmesh = 380V Trigger on Channel 3 Connector issue on channel 4 David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 18 Spark behaviour in resistive detectors • Trigger on Channel 2 • Vmesh = 340V R14, Resistive strips 300 kΩ/□ David.Attie@cea.fr R17, Joerg like RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 19 Charge seen by the strips • Trigger on Channel 2 • Vmesh = 340V & Vmesh = 360V R14, Resistive strips 300 kΩ/□ • G380V ~ 2 G360V • Q380V ~ 1.2 Q360V R17, Joerg like 20 David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 Spark topology of resistive detectors • Resistive strip detector has similar spark signal (exponential) than non-resistive detector but with an attenuation about 30 % and similar time constant (=RC) • Carbon-Loaded Kapton and Joerg-like detectors have shaping-like signals but the Joerg-like detector signal are shorter and ten times smaller • Signal from CLK are seen on the adjacent pads. Detector type Sparking HV Released charge Signal duration Standard -330V Few tens nC <50 s CLK -380V Few nC 100-250 s Resistive strips -340V Few nC 50 s Joerg-like -350V < 0,2 nC 50-100 s David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 21 Conclusions • It is still to soon to say that a resistive coating could solve the spark from operation. • In some configuration the resistive coating is able to contain or even suppress the spark signal. • We are now ready for the next beam test at Cern to determine in high rate condition operation the efficiency of the various resistive Micromegas. • After the choice of a technology spark proof, other stages are to come, ageing studies, larger surface, etc… David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 22 David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 23 Garfield simulation for Argon/Isobutane gas mixture David.Attie@cea.fr RD51 Collaboration Meeting, Bari ̶ October 8th, 2010 24