info on the Freeze Dry Method (Word Download)

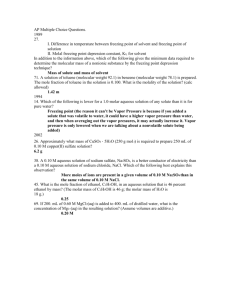

advertisement

PO Box 2423 Lake Oswego, Oregon 97035, USA UncleLarrysPetTreats.com Question: Why Freeze-Dry? The basic idea of freeze-drying is to completely remove water from some material, such as food, while leaving the basic structure and composition of the material intact. There are two reasons someone might want to do this with food: Removing water keeps food from spoiling for a long period of time. Food spoils when microorganisms, such as bacteria, feed on the matter and decompose it. Bacteria may release chemicals that cause disease, or they may just release chemicals that make food taste bad. Additionally, naturally occurring enzymes in food can react with oxygen to cause spoiling and ripening. Like people, microorganisms need water to survive, so if you remove water from food, it won't spoil. Enzymes also need water to react with food, so dehydrating food will also stop ripening. Freeze-drying significantly reduces the total weight of the food. Most food is largely made up of water. In fact, many fruits are more than 80 to 90 percent water. Removing this water makes the food a lot lighter, which means it's easier to transport. The military and camping supply companies freeze-dry foods to make them easier for one person to carry. NASA has also freezedried foods for the cramped quarter’s onboard spacecraft. People also use freeze-drying to preserve other sorts of material, such as pharmaceuticals. Many pharmaceuticals will degrade pretty quickly when exposed to water and air, for the same basic reason that food degrades. Chemists can greatly extend pharmaceutical shelf life by freeze-drying the material and storing it in a container free of oxygen and water. Similarly, research scientists may use freeze-drying to preserve biological samples for long periods of time. Freeze-dried biological samples are also big in the florist world, oddly enough. Freeze-dried roses are growing in popularity as wedding decorations. The freeze-drying process has also been used to restore water-damaged materials, such as rare and valuable manuscripts. (Cont.) It's pretty simple to dry food, drugs and just about any other biological material. Set it out in a hot, arid area, and the liquid water inside will evaporate. The heat gives the water molecules enough energy to "break free" of the liquid and become gas particles. Then, you seal it in a container and it stays dry. (This is how manufacturers make dehydrated meals like powdered soup and baking mixes.) There are two big problems with this approach. First, it's difficult to remove water completely using evaporation because most of the water isn't directly exposed to air. Generally, dehydrating food in this way only removes 90 to 95 percent of the water, which will certainly slow down bacteria and enzyme activity, but won't stop it completely. Secondly, the heat involved in the evaporation process significantly changes the shape, texture and composition of the material, in the same way that heat in an oven changes food. Heat energy facilitates chemical reactions in the food that change its overall form, taste, smell or appearance. This is the fundamental purpose of cooking. These changes can be good, if they make the food taste better (or taste good in a different way), but if you're drying something so you can revitalize it later, the process compromises quality somewhat. The basic idea of freeze-drying is to "lock in" the composition and structure of the material by drying it without applying the heat necessary for the evaporation process. Instead, the freeze-drying process converts solid water -- ice -- directly into water vapor, skipping the liquid phase entirely. In the next section, we'll find out how freeze-drying machines pull this off. The Process The fundamental principle in freeze-drying is sublimation, the shift from a solid directly into a gas. Just like evaporation, sublimation occurs when a molecule gains enough energy to break free from the molecules around it. Water will sublime from a solid (ice) to a gas (vapor) when the molecules have enough energy to break free but the conditions aren't right for a liquid to form. There are two major factors that determine what phase (solid, liquid or gas) a substance will take: heat and atmospheric pressure. For a substance to take any particular phase, the temperature and pressure must be within a certain range. Without these conditions, that phase of the substance can't exist. The chart below shows the necessary pressure and temperature values of different phases of water. You can see from the chart that water can take a liquid form at sea level (where pressure is equal to 1 ATM) if the temperature is in between the sea level freezing point (32 degrees Fahrenheit or 0 degrees Celsius) and the sea level boiling point (212 F or 100 C). But if you increase the temperature above 32 F while keeping the atmospheric pressure below .06 atmospheres (ATM), the water is warm enough to thaw, but there isn't enough pressure for a liquid to form. It becomes a gas. This is exactly what a freeze-drying machine does. A typical machine consists of a freeze-drying chamber with several shelves attached to heating units, a freezing coil connected to a refrigerator compressor, and a vacuum pump. (Cont.) Fig. 1: A simplified Freeze-Drying Machine. With most machines, you place the material to be preserved onto the shelves when it is still unfrozen. When you seal the chamber and begin the process, the machine runs the compressors to lower the temperature in the chamber. The material is frozen solid, which separates the water from everything around it, on a molecular level, even though the water is still present. Next, the machine turns on the vacuum pump to force air out of the chamber, lowering the atmospheric pressure below .06 ATM. The heating units apply a small amount of heat to the shelves, causing the ice to change phase. Since the pressure is so low, the ice turns directly into water vapor. The water vapor flows out of the freeze-drying chamber, past the freezing coil. The water vapor condenses onto the freezing coil in solid ice form, in the same way water condenses as frost on a cold day. (Google “How Refrigerators Work” for more information on condensers and refrigeration coils.) This continues for many hours (even days) while the material gradually dries out. The process takes so long because overheating the material can significantly change the composition and structure. Additionally, accelerating the sublimation process could produce more water vapor in a period of time then the pumping system can remove from the chamber. This could rehydrate the material somewhat, degrading its quality. Once the material is dried sufficiently, it's sealed in a moisture-free package, often with an oxygenabsorbing material. As long as the package is secure, the material can sit on a shelf for years and years without degrading, until it's restored to its original form with a bit of water (a very small amount of moisture remains, so the material will eventually spoil). If everything works correctly, the material will go through the entire process almost completely unscathed! (Cont.) The basic process of freeze-drying food was known to the ancient Peruvian Incas of the Andes. Freezedrying, or Lyophilization, is the sublimation/removal of water content from frozen food. The dehydration occurs under a vacuum, with the plant/animal product solidly frozen during the process. Shrinkage is eliminated or minimized, and a near-perfect preservation results. Freeze-dried food lasts longer than other preserved food and is very light, which makes it perfect for space travel. The Incas stored their potatoes and other food crops on the mountain heights above Machu Picchu. The cold mountain temperatures froze the food and the water inside slowly vaporized under the low air pressure of the high altitudes. During World War II, the freeze-dried process was developed commercially when it was used to preserve blood plasma and penicillin. Freeze-drying requires the use of a special machine called a freeze-dryer, which has a large chamber for freezing and a vacuum pump for removing moisture. Over 400 different types of freeze-dried foods have been commercially produced since the 1960s. Two bad candidates for freeze-drying are lettuce and watermelon because they have too high a water content and freeze-dry poorly. Freeze-dried coffee is the best-known freeze-dried product. The Freeze-Dryer Special thanks goes to Thomas A. Jennings, PhD, author of for his reply to the question, "Who invented the first freeze-dryer?" "Lyophilization - Introduction and Basic Principles." There is no real invention of a freeze-dryer. It appears to have evolved with time from a laboratory instrument that was referred to by Benedict and Manning (1905) as a "chemical pump". Shackell took the basic design of Benedict and Manning and used an electrically driven vacuum pump instead of the displacement of the air with ethyl ether to produce the necessary vacuum. It was Shackell who first realized that the material had to be frozen before commencing the drying process - hence freeze-drying. The literature does not readily reveal the person who first called the equipment used to conduct this form of drying a "freeze-dryer". For more information on freeze-drying or Lyophilization, one is referred to my book “Lyophilization Introduction and Basic Principles" or visit the INSIGHTS that appear on our web site. Dr. Jennings' company has developed a number of instruments that are directly applicable to the Lyophilization process, including their patented D2 and DTA thermal analysis instrument. Thomas A. Jennings - Phase Technologies, Inc. Freeze-Dried Trivia Freeze-dried coffee was first produced in 1938, and lead to the development of powdered food products. The Nestlé’s Company invented freeze-dried coffee, after being asked by Brazil to help find a solution to their coffee surpluses. Nestlé’s own freeze-dried coffee product was called Nescafe, and was first introduced in Switzerland. Tasters Choice Coffee, another very famous freeze-dried manufactured product, derives from a patent issued to James Mercer. From 1966 to 1971, Mercer was chief development engineer for Hills Brothers Coffee Inc. in San Francisco. During this five-year period, he was responsible for developing a continuous freeze-drying capability for Hills Brothers, for which he was granted 47 U.S. and foreign patents. (Cont.) How Freeze-Drying Works According to Oregon Freeze Dry - The purpose of freeze-drying is to remove a solvent (usually water) from dissolved or dispersed solids. Freeze-drying is method for preserving materials, which are unstable in solution. In addition, freeze-drying can be used to separate and recover volatile substances, and to purify materials. The fundamental process steps are: Freezing: The product is frozen. This provides a necessary condition for low temperature drying. Vacuum: After freezing, the product is placed under vacuum. This enables the frozen solvent in the product to vaporize without passing through the liquid phase, a process known as sublimation. Heat: Heat is applied to the frozen product to accelerate sublimation. Condensation: Low-temperature condenser plates remove the vaporized solvent from the vacuum chamber by converting it back to a solid. This completes the separation process. Applications of Freeze-Dried Fruits in Confectionery Products In freeze-drying, moisture sublimes directly from the solid state to vapor, thus producing a product with controllable moisture, no need for cooking or refrigeration, and natural flavor and color. History of Food in Space More than 20 years ago, astronaut John Glenn became the first American to orbit the Earth. Among the many tasks Glenn had to perform while in orbit were the first American space experiments in eating food in the weightless conditions of Earth orbit. Glenn's flight was too short to make eating a necessity, but future flights were expected to last many days and even weeks. His experience would help design space food systems. To Order Uncle Larry’s Pet Treats: Contact: Tina Lindel Uncle Larry’s Pet Treats PO Box 2423 Lake Oswego, Oregon 97035, USA UncleLarrysPetTreats@gmail.com email www.unclelarryspettreats.com online