ProblemInventoryBasics

advertisement

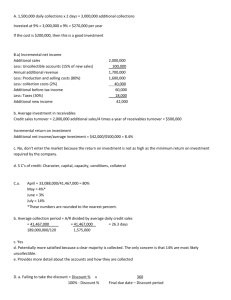

Assignment; Basic Inventory Model Problem 1: A toy manufacturer uses approximately 32000 silicon chips annually. The Chips are used at a steady rate during the 240 days a year that the plant operates. Annual holding cost is 60 cents per chip, and ordering cost is $24. Determine a) How much should we order each time to minimize our total cost b) How many times should we order c) what is the length of an order cycle d) What is the total cost What is the Optimal Order Quantity 2 DS EOQ H D = 32000, H = .6, S = 24 2(32000)( 24) EOQ 1600 .6 How many times should we order Annual demand for a product is 32000 D = 32000 Economic Order Quantity is 1600 EOQ = 1600 Each time we order EOQ How many times should we order ? D/EOQ 32000/1600 = 20 what is the length of an order cycle working days = 240/year 32000 is required for 240 days 1600 is enough for how many days? (1600/32000)(240) = 12 days What is the Optimal Total Cost The total cost of any policy is computed as TC (Q / 2) H ( D / Q ) S The economic order quantity is 1600 TC .6(1600 / 2) 24(32000 / 1600) TC 480 480 TC 960 This is the total cost of the optimal policy Assignment; Problem 2 Victor sells a line of upscale evening dresses in his boutique. He charges $300 per dress, and sales average 30 dresses per week. Currently, Vector orders 10 week supply at a time from the manufacturer. He pays $150 per dress, and it takes two weeks to receive each delivery. Victor estimates his administrative cost of placing each order at $225. His inventory carriyng cost including cost of capital, storage, and obsolescence is 20% of the purchasing cost. Assume 52 weeks per year. a) Compute Vector’s total annual cost of inventory system (carrying plus ordering but excluding purchasing) under the current ordering policy? b) Without any EOQ computation, is this the optimal policy? Why? Assignment; Problem 2 c) Compute Vector’s total annual cost of inventory system (carrying plus ordering but excluding purchasing) under the optimal ordering policy? d) Compute EOQ and total cost of the system e) What is the ordering interval under optimal ordering policy? f) When do you order? g) What is average inventory and inventory turns under the original policy and under the optimal ordering policy? Inventory turn = Demand divided by average inventory. Average inventory = Max Inventory divided by 2. Average inventory is the same as cycle inventory. h) Compute the flow time under the two policies. Current Policy Problem 6.3 flow unit = one dress flow rate d = 30 units/wk costost C = $150/unit fixed order cost S = $225 H = 20% of unit cost. lead time L = 2 weeks ten weeks supply Q = 10(30) = 300 units. 52 weeks per year a) Annual demand = 30(52) = 1560 Number of orders/yr = D/Q = 1560/300 = 5.2 (D/Q) S = 5.2(225) = 1,170/yr. Average inventory = Q/2 = 300/2 = 150 H = 0.2(150) = 30 Annual holding cost = H (Q/2) = 30(150) = 4,500 /yr. b) Without any computation, is this the optimal policy? Why? Without any computation, is EOQ larger than 300 or smaller Why c) Total annual costs = 1170+4500 = 5670 Optimal Policy d) Compute EOQ Q* = EOQ = 2 DS 2(1560)225 = 153 units. H 30 His annual cost will be 4,589 e) What is the ordering interval under optimal ordering policy? We order D/Q = 1560/153 = 10.2 times A year is 52 weeks. Therefore we order every 52/10.2 = 5.1 weeks Optimal Policy f) When do you order (re-order point) ? An order for 153 units two weeks before he expects to run out. That is, whenever current inventory drops to 30 units/wk * 2 wks = 60 units which is the re-order point. Whenever inventory reaches 60 we order 153. This process is repeated 10.2 times a year. Every 5.1 weeks. Inventory Turns g) What is average inventory and inventory turns under the original policy and under the optimal ordering policy? Inventory turns = yearly demand / Average inventory Average inventory = cycle inventory = I = Q/2 Current policy inventory turns = D/(Q/2)= 1560/(300/2) Current policy Inventory turns = 10.4 times per year. Optimal policy inventory turns = D/(Q/2)= 1560/(153/2) Optimal policy inventory turns = = 20.4 turns roughly double Flow time h) Compute the flow time under the two policies. Average inventory = cycle inventory = I = Q/2 Current average inventory = 300/2 = 150 Throughput? R? R= D R= 30 /week Current flow time RT= I 30T= 150 T= 5 weeks Optimal average inventory = 153/2) = 76.5 Optimal flow time RT=I 30T= 76.5 T = 2.55 weeks Did we really need this computations? Assignment; Problem 3 Complete Computer (CC) is a retailer of computer equipment in Minneapolis with four retail outlets. Currently each outlet manages its ordering independently. Demand at each retail outlet averages 4,000 per week. Each unit of product costs $200, and CC has a holding cost of 20% per annum. The fixed cost of each order (administrative plus transportation) is $900. Assume 50 weeks per year. The holding cost will be the same in both decentralized and centralized ordering systems. The ordering cost in the centralized ordering is twice of the decentralized ordering system. Assignment; Problem 3 Decentralized ordering: If each outlet orders individually. Centralized ordering: If all outlets order together as a single order. a) Compute EOQ in decentralized ordering b) Compute the cycle inventory for one outlet and for all outlets. c) Compute EOQ in the centralized ordering d) Compute the cycle inventory for all outlets and for one outlet e) Compute the total holding cost + ordering cost (not including purchasing cost) for the decentralized policy f) Compute the total holding cost plus ordering cost for the centralized policy Decentralized Policy Four outlets Each outlet demand D = 4000(50) = 200,000 S= 900 C = 200 H = .2(200) = 40 If all outlets order together in a centralized ordering, then S= 1800 2DS Q H 2(200000)( 900) 40 =3000 With a cycle inventory of 1500 units for each outlet. The total cycle inventory across all four outlets equals 6000. With centralization of purchasing the fixed order cost is S = $1800. 2(4 200000)( 2 900) EOQ 40 =8485 and a cycle inventory of 4242.5. Total holding & ordering costs under the two policies TC S ( D / Q) H (Q / 2) Decentralized TC 900(200000 / 3000) 40(3000 / 2) TC 60000 60000 120000 Decentralized: TC for all 4 warehouses = 4(120000)=480000 Centralized TC 1800(800000 / 8485) 40(8485 / 2) TC 169711 169700 339411 339411 compared to 480000 about 30% improvement