Material Handling

advertisement

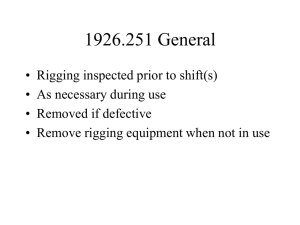

Rigging Hazard Awareness Between the trolley hook and the load is RIGGING Ropes, Slings, Chains Slings inspected daily Proper storage when not in use Suitable protection of rigging when in use (items with sharp corners, etc..) Rules for Rigging Safety Know the weight of the load Know the center of gravity of the load. Make load attachment above the center of gravity of the load. Select hitch that will hold and control. Know the rated capacity of slings and hardware. Rules for Rigging Safety Select sling best suited for load. Inspect all rigging before the lift. Protect sling from sharp surfaces Proper calculation of increased tension caused by sling angles (on all rigging components!). Rules for Rigging Safety Allow for D/d ratio on all wire rope slings. Calculate reductions when using choker hitch. Keep personnel clear from lift area. Lift load a few inches then check rigging Know limitations of all lifting devices used. Lift slowly and stop slowly Rigging equipment for material handling Rigging equipment inspections (By a Competent Person) – Prior to use on each shift – As necessary during its use to ensure that it is safe – Defective rigging equipment removed from service Not be loaded in excess of its recommended safe working load Rigging equipment for material handling Custom design grabs, hooks, clamps, or other lifting accessories, for such units as modular panels, prefabricated structures and similar materials – Marked to indicate the safe working loads – Be proof-tested prior to use to 125 percent of their rated load Rigging equipment for material handling Alloy steel chains Welded alloy steel chain slings – Permanently affixed durable identification stating Size Grade Rated capacity Sling manufacturer Rigging equipment for material handling Alloy steel chains Job or shop hooks and links, or makeshift fasteners, formed from bolts, rods, etc., or other such attachments, shall not be used Rigging equipment for material handling Four grades: – – – – Grade 28 General Utility Chain Grade 43 High Test Chain Grade 70 Binding Chain Grade 80 Alloy Steel Chain: The only one used for overhead lifting G 80 Rigging equipment for material handling Alloy steel chains Inspections – Frequent Visual examination by the user Periodic – Complete link by link inspection of the entire sling and all attachments. – Documented Rigging equipment for material handling Alloy steel chains CP inspections made & based on – Frequency of sling use; – Severity of service conditions; – Nature of lifts being made; and – Experience gained on the service life of slings used in similar circumstances. Such inspections at least once a year Documented & available Rigging equipment for material handling Wire rope slings Protruding ends of strands in splices on slings and bridles covered or blunted Wire rope shall not be secured by knots Except for eye splices in the ends of wires and for endless rope slings, each wire rope used in hoisting or lowering, or in pulling loads, shall consist of one continuous piece without knot or splice Rigging equipment for material handling Mechanical Splice Rigging equipment for material handling Hand Tucked Eye Splice Rigging equipment for material handling Swaged Forged Eye Rigging equipment for material handling Mechanical Splice Rigging equipment for material handling Wire rope slings Shall not be shortened with knots or bolts or other makeshift devices. Legs shall not be kinked Basket hitch shall have the loads balanced to prevent slippage Padded or protected from the sharp edges Rigging equipment for material handling Wire rope Hands or fingers shall not be placed between the sling and its load while the sling is being tightened around the load A sling shall not be pulled from under a load when the load is resting on the sling Rigging equipment for material handling D/d Ratio D - is diameter around which sling is bent. d - is diameter of the sling. D d Rigging equipment for material handling When U-bolt wire rope clips used to form eyes – U-bolt shall be applied so that the "U" section is in contact with the dead end of the rope “Never saddle a dead horse” Rigging equipment for material handling Synthetic webbing (nylon, polyester, and polypropylene). – The employer shall have each synthetic web sling marked or coded to show Name or trademark of manufacturer Rated capacities for the type of hitch Type of material Rated capacity shall not be exceeded Rigging equipment for material handling Synthetic webbing (nylon, polyester, and polypropylene) Remove from service immediately if: – Acid or caustic burns – Melting or charring of any part of the sling surface – Snags, punctures, tears or cuts – Broken or worn stitches – Distortion of fittings Rigging equipment for material handling Shackles and hooks – Manufacturers’ identification – Never weld on hooks or shackles – Working safety latch on hooks Rigging equipment for material handling Recommended Screw Pin Anchor Shackle Not Recommended Recommended Round Pin Anchor Shackle Bolt Type Anchor Shackle Rigging equipment for material handling Never replace a shackle pin with a bolt. The load will bend the bolt. Rigging equipment for material handling Avoid eccentric loads. Bad Good Proper chocking of shackles. Bad Good Rigging equipment for material handling Check wear Check cracks, bending and twisting Check wear and straightness Pin always seated Check opening width Rigging equipment for material handling LOAD Hooks are designed to apply the load at the bottom of the saddle. Rigging equipment for material handling Check for Wear and Deformation Check for Cracks and Twisting Signs of “Opening Up” 15% 10º Check that Hook is Not Twisted Check for Wear and Cracks Rigging equipment for material handling Rigging equipment for material handling Approximately 70%-80% of a straight pull Rigging equipment for material handling 90° basket hitch is approximately twice the capacity of a straight pull 90 1000 LBS 500 LBS 500 LBS How horizontal angle affects slings capacity 1000 LBS 1000 LBS 60° 45° 30° 1000 LBS 1000 LBS 1000 LBS Note: A good operating practice is to keep sling angles from going below 60 degrees Rigging equipment for material handling Calculating the load on sling legs – Divide the total load by the number of sling legs – This quotient is the load on each leg if vertical – Measure the sling from the load attachment point, to the point where it connects with the hook or lifting device; this is ‘L’ – Measure the vertical height from the top of the load to the hook or lifting device; this is ‘H’ – Divide the length of the leg by the height of the sling L H LOAD Load Number of legs) X (L H) = Load each sling leg Example Load = 120,000 pounds 4 load legs ÷ 120,000 equals 30,000 pounds each leg if vertical hitch Sling legs are 20 feet Height from top of load to lifting device is 15 feet 20 ÷ 15 = 1.33 Load on each leg is 1.33 x 30,000 = 40,000 pounds 120,000 lb. Center of Gravity A load is stable when: – The hook is directly above the center of gravity of the load Estimate the center of gravity Lift the load just enough to clear the ground If the hook is not over the center of gravity the hook will travel to the center of gravity CG? Center of Gravity If necessary, set the load down and adjust the rigging If the load tips more than 3°, the rigging should be adjusted The longer the sling legs, the more stable the load will be B A The longer set of sling legs (B) will improve load stability Disposal of waste materials Materials are dropped more than 20 feet to any point lying outside the exterior walls of the building – enclosed chute Disposal of waste materials Disposal of waste materials Disposal of waste materials Debris dropped through holes in the floor without the use of chutes – Completely enclosed with barricades not less than 42 inches high – Not less than 6 feet back from the projected edge of the opening above – Signs warning of falling materials shall be posted at each level – Removal shall not be permitted in this lower area until debris handling ceases above Disposal of waste materials Scrap lumber, waste material, and rubbish – Removed from the immediate work area as the work progresses. Disposal of waste material or debris by burning – Comply with local fire regulations All solvent waste, oily rags, and flammable liquids – Kept in fire resistant covered containers until removed from worksite Questions