feb2s0014579313005243-sup-m0005

advertisement

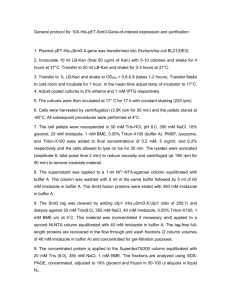

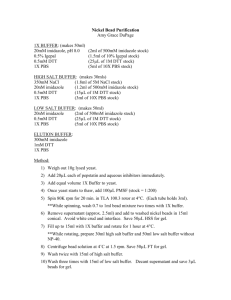

Supporting Information Co-evolution of HAD Phosphatase and Hotdog-fold Thioesterase Domain Function in the MenaquinonePathway Fusion Proteins BF1314 and PG1653 Min Wanga, Feng Songa,1, Rui Wub,2, Karen N. Allenb*, Patrick S. Marianoa and Debra Dunaway-Marianoa* a Department of Chemistry & Chemical Biology, University of New Mexico, Albuquerque, NM USA 87131. b Department of Chemistry, Boston University, Boston, Massachusetts, USA 02215. 1 Present address: 3054 E, Syngenta Crop Protection, LLC, Research Triangle Park, NC 27709 2 Present address: Immunogen. Inc. 830 Winter St, Waltham, MA 02451 Contents: Thirteen pages total, which contain the methods used to synthesize napthoyl-CoA and 1,4dihydroxynapathoyl-CoA; Table SI1 (kinetic properties of the engineered BF1314 HAD domain in the presence of the engineered thioesterase domain); Figures SI1-SI3 (sequence alignments); Figure SI4 (pH rate profile of catalysis by the phosphatase domain of BF1314; Figure SI5 (gel filtration chromatography of the domains of BF1314). 1 Materials and Methods General Biosynthesis products were analyzed and separated by using a Shimadzu LC-20AB HPLC system equipped with Beckman Coulter ultrasphere C18 analytical column and a Restek Ultra II C18 column, respectively. 1H and 13 C spectra were recorded using a Bruker Avance 500 spectrometer. 1H NMR data are reported as follows: chemical shifts (ppm), and multiplicities (s = singlet, d = doublet, t = triplet, q = quartet, m = multiplet). 13C NMR chemical shifts are reported in ppm relative to NH4HCO3 (160 ppm). Mass spectrometric data were obtained at the University of the New Mexico Mass Spectrometry Facility. Preparation of recombinant O-succinylbenzoyl-coenzyme A ligase The gene encoding the O-succinylbenzoyl-coenzyme A ligase (MenE) from E. coli (K12), was amplified from genomic DNA by using a PCR-based strategy and cloned into the pET-23a vector, which adds a His6 tag to the Cterminus of the protein for later purification. The oligodeoxynucleotide primers used in the gene amplification were 5’GGA GCG GTT CAT ATG ATC TTC TCT GAC-3’ (MenE forward), 5’-GAA GTG AAA CTC GAG GGT TAA ATA TTG CTG ACG TTG CAC-3’ (MenE reverse), which contain the restriction endonuclease cleavage sites NdeI and XhoI. Plasmid DNAs were purified using a Qiaprep Spin Miniprep Kit. Gene sequencing was carried out at the Center for Genetics in Medicine, University of New Mexico School of Medicine. Gene expression was carried out in transformed E. coli BL21(DE3) cells. Following growth in 3 L of LB media containing 50 μg/mL carbenicillin at 37 °C for 12 h with mixing at 220 rpm, induction was initiated by the addition of 1 mM isopropyl-1-thio-β-D-galactopyranoside. After incubation for 10 h at 20 °C and 170 rpm, the cells were harvested by centrifugation (6500 rpm for 15 min at 4 °C), resuspended in 300 mL of lysis buffer (50 mM NaH2PO4, 300 mM NaCl, 10 mM imidazole, 1 mM DTT, pH 8.0) and lysed by 2 passages through a French Press cell (12,000 psi). The lysate was centrifuged at 20,000 rpm for 90 min at 4 °C, and the supernatant containing MenE was passed through a Ni affinity column for His6-tagged protein binding. The column was washed with 100 mL of lysis buffer and 100 mL of wash buffer (50 mM NaH2PO4, 600 mM NaCl, 50 mM imidazole, 1 mM DTT, pH 8.0) before MenE was subsequently eluted using 100 mL of elution buffer (50 mM NaH2PO4, 600 mM NaCl, 250 mM imidazole, 1 mM DTT, pH 8.0). The eluant was concentrated by using a 10 kDa Macrosep centricon (Pall Filtron) device. Imidazole was removed by chromatography on a S-200 resin using 50 mM NaH2PO4, 600 mM NaCl, pH 7.5 as the elution buffer. The purity of the protein was 2 determined by using SDS-PAGE and its concentration was determined by using the Bradford assay (absorbance at 280 nm, = 104,770 M-1 cm-1). Preparation of recombinant 1,4-dihydroxynaphthoyl-CoA synthase The gene encoding 1,4-dihydroxynaphthoyl-CoA synthase (MenB) from E. coli (K12), was amplified from genomic DNA by using a PCR-based strategy and cloned into a pET-14b vector, which adds a His6 tag to the N-terminus of the protein for later purification. The oligodeoxynucleotide primers used in gene amplification were 5’-CAC CAT ATG ATT TAT CCT GAT GAA GCA-3’ (MenB forward), 5’-ATA CCT GCG CGC CTC GAG TTA CGG ATT CCG3’ (MenB reverse), which contain the restriction endonuclease cleavage sites NdeI and XhoI. Plasmid DNAs were purified using a Qiaprep Spin Miniprep Kit. Gene sequencing was carried out at the Center for Genetics in Medicine, University of New Mexico School of Medicine. Gene expression was carried-out in transformed E. coli BL21(DE3) cells. Following growth in 3 L of LB media containing 50 μg/mL carbarnicillin at 37 °C for 12 h with mixing at 220 rpm, induction was initiated with the addition of 1 mM isopropyl-1-thio-β-D-galactopyranoside. After incubation for 10 h at 20 °C 170 rpm, the cells were harvested by centrifugation (6500 rpm for 15 min at 4 °C), resuspended in 300 mL of lysis buffer (50 mM NaH2PO4, 300 mM NaCl, 10 mM imidazole, 1 mM DTT, pH 8.0) and lysed by 2 passages through a French Press cell (12,000 psi). The cell lysate was centrifuged at 20,000 rpm for 90 min at 4 °C, and the supernatant containing MenB was passed through a Ni affinity column. The column was washed with 100 mL of lysis buffer and 100 mL of wash buffer (50 mM NaH2PO4, 600 mM NaCl, 50 mM imidazole, 1 mM DTT, pH 8.0) before MenB was subsequently eluted using 100 mL of elution buffer (50 mM NaH2PO4, 600 mM NaCl, 250 mM imidazole, 1 mM DTT, pH 8.0). The protein was concentrated by using a 10 kDa Macrosep centricon (Pall Filtron) device. Imidazole was removed by chromatography on S-200 resin using 50 mM NaH2PO4, 600 mM NaCl, pH 7.5 as the elution buffer. The purity of the protein was determined by using SDS-PAGE and its concentration was determined by using the Bradford assay. At 280 nm the MenB extinction coefficient = 41,370 M-1 cm-1. Preparation of O-succinoylbenzoate A solution of 2-formylbenzoic acid (27 g, 0.18 mol), iodomethane (49 g, 0.34 mol), and K 2CO3 (14 g, 0.10 mol) in 200 mL of DMF was stirred at reflux for 1 h. The mixture was poured into 150 mL of water and then extracted 3 with CH2Cl2. The organic layer was washed successively with water, aqueous HCl, aqueous NaHCO3, and brine, dried over anhydrous Na2SO4, and then concentrated in vacuo to give a colorless oil, which slowly crystallized to give pure methyl 2-formylbenzoate (30.2 g, 100%). 1H NMR (500 MHz, d4-CDCl3): δ 10.57 (s, 1H), 7.92(t, 2H), 7.60 (m, 2H), 3.93 (s, 3H). A solution of methyl 2-formylbenzoate (2 g, 0.011 mol) in dry dichloromethane (100 mL) containing suspended anhydrous zinc chloride (8.16 g, 0.060 mol) was stirred at 0 °C for 30 min. To this solution was added 1ethoxy-1-trimethylsiloxycyclopropane 19 (4.2 g, 0.024 mol) dropwise at 0 °C. The mixture was warmed to room temperature and stirred overnight. After addition of dilute HCl, the organic layer was separated and concentrated in vacuo, giving a residue that was subjected to flash chromatography on silica gel using 5:1 hexane:acetone as the eluant to yield the lactone. 1H NMR (500 MHz, d4-CDCl3): δ 7.81 (d, 1H), 7.63 (s, 1H), 7.48(s, 1H), 7.42 (d, 1H), 5.50 (t, 1H), 4.05 (t, 2H), 2.39 (m, 3H), 1.94 (m, 1H), 1.18 (s, 3H). C NMR (125 MHz, d4- CDCl3): δ172.31, 169.98, 149.06, 13 133.99, 129.16, 125.53, 121.76, 79.85, 60.47, 29.66, 29.24, 13.97. A solution of the lactone (1 g, 4.27 mmol) in glacial acetic acid (20 mL) containing chromium trioxide (2 g, 0.020 mol) was stirred at room temperature for 12 h. The mixture was diluted with water and extracted with ethyl acetate. Concentration of the extract in vacuo gave a residue that was subjected to silica gel chromatography using 2:1 hexane:acetone as the eluant to yield ethyl o-succinoylbenzoate. 1H NMR (500 MHz, d4-CDCl3): δ 7.78 (s, 1H), 7.66 (d, 1H), 7.53 (t, 2H), 4.10 (d, 2H), 2.70 (d, 1H), 2.52 (s, 1H), 2.43 (s, 1H), 2.24 (s, 1H), 1.22 (s, 3H). 13C NMR (125 MHz, d4- CDCl3): δ 204.48, 174.12, 168.32, 148.91, 134.66, 130.56, 126.36, 125.40, 122.23, 106.49, 61.23, 33.90, 28.98, 14.00. A solution of ethyl o-succinoylbenzoate (1 g, 4.0 mmol) in 50 mL methanol containing 3 mL of 50% (w/v) aqueous NaOH was stirred at room temperature overnight. Concentration in vacuo gave compound Osuccinylbenzoate. 1H NMR (500 MHz, d4-H2O): δ 7.67 (d, 1H), 7.61 (s, 2H), 7.57 (q, 1H), 3.23 (t, 2H), 2.57 (t, 2H), 13 C NMR (125 MHz, d4- H2O): δ 201.61, 174.64, 169.56, 130.74, 124.31, 122.32, 120.59, 120.22, 31.06, 27.18, 24.88. MS: m/z calculated for C11H18O3 [M+H]+, 221.03; found 221.04. Enzymatic synthesis of 1,4-dihydroxynaphthoyl-CoA 1,4-Dihydroxynaphthoyl-CoA was biosynthesized by using the menaquinone pathway proteins MenE and MenB. To a solution of o-succinylbenzoate (26.1 mg, 100 mmol), coenzyme A (44 mg, 56 mmol), and ATP (30.9 mg, 4 56 mmol) in 470 μL of reaction buffer (20 mM Tris, 1 mM MgCl2, 50 mM NaHCO3, pH 7.8) was added 10 μL MenB (2 mM) and 20 μL MenE (300 uM). The resulting mixture was incubated at 37 °C for 30 min and filtered by using a Microcon ultracel centrifuge filter (pore size 30 kDa). The filtrate was subjected to Shimadzu LC-20 HPLC using a Beckman Coulter ultrasphere C18 analytical column and a linear gradient from (100% solvent A) to (60% solvent A plus 40% solvent B) over 45 min at a flow rate of 1 mL/min. Solvent A was 50 mM ammonium acetate (pH 5.9) and solvent B methanol. Fractions containing DHN-CoA were combined and lyophilized to give a solid. 1H NMR (500 MHz, D2O): δ 8.69 (s, 1H), 8.63 (s, 1H), 8.47 (s, 1H), 8.41 (s, 1H), 7.91 (s, 1H), 7.78 (s, 1H), 6.24 (d, 1H), 6.14 (d, 1H), 4.66 (s, 1H), 4.32 (s, 2H), 4.06 (s, 1H), 3.91 (s, 1H), 3.74 (s, 1H), 3.68 (s, 2H), 3.51 (m, 4H), 2.79 (s, 1H), 2.50 (s, 1H), 2.33 (s, 1H), 0.98 (s, 3H), 0.87 (s, 3H). Mass spectrometric analysis: observed 954.13 Da; calculated (M+H for C32H42N7O19P3S) 954.15. 5 Table SI1. Steady-state kinetic values measured for the HAD-thioesterase fusion protein BF1314, the engineered thioesterase domain (BF-TE) and a 1:1 mixture of the engineered HAD domain (BF-HAD) and thioesterase domain (BF-TE) for catalysis of 1,4-DHN-CoA thioester hydrolysis (50 mM K+ HEPES, pH 7.5, 25 oC). Enzymes BF1314 BF-TE BF-TE + BF-HAD kcat -1 (s ) (1.2 ± 0.1) x 101 < 1 x 10-4 < 1 x 10-4 Km (µM) 7.0 ± 0.5 --------------- kcat /Km -1 -1 (M s ) 1.7 x 106 --------------- 6 7 Figure SI1. Sequence alignment of Bacteroidetes HAD-thioesterase fusion proteins. The numbering system used is based on the BF1314 sequence. 8 Figure SI2. Alignment of the thioesterase domains of the fusion proteins BF1314 and PG1653 with the E. coli thioesterase ydiI and the B. vulgatus thioesterase BVU2420. The sequence numbering is based on the BF1314 sequence. 9 Figure SI3. The sequence alignment of the HAD phosphatase B. thetaiotaomicron BT3352 (gi 299856912) with the HAD-thioesterase fusion proteins BF1314 (gi 53712606), BT4699 (gi 29350107) and PG1653 (three strains represented: gi 34541294, gi 188994326, gi 490721436). 10 Figure SI4. The variation in the value of the kcat/Km measured for engineered BF1314 HAD domain-catalyzed hydrolysis of glycerophosphate with reaction solution pH. 11 40 30 25 15 kDa Figure SI5. Size exclusion chromatography of a 1:1 mixture engineered BF1314 thioesterase domain and engineered BF1314 phosphatase domain monitored by SDS-PAGE. The SDS-PAGE gel (below, stained with Coomassie Blue) of chromatographed fractions shows in the first lane, the ladder of protein molecular weight markers, and in subsequent lanes the engineered BF1314 phosphatase domain (first peak) and the engineered BF1314 thioesterase domain (second peak). 12