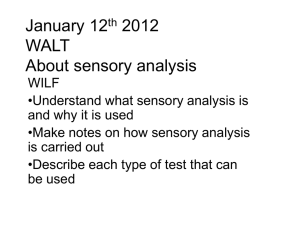

sensory evaluation in qc2

advertisement