Title of the Research Study Presenter name, Associates and

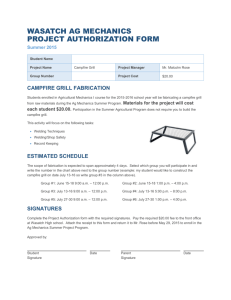

advertisement

Tailgate Design Project DEPARTMENT OF FOOD, AGRICULTURAL AND BIOLOGICAL ENGINEERING Adam Andrews, Mauricio Nieto, John Walter and Erich Widmer RACT Inc. has commissioned a design of a tailgate station for avid tailgate fan and everyday camper. The station, d to be maneuverable without the use of a vehicle, a custom stainless steel 4-burner grill with propane tank insulated cooler, table space on either side of the grill, and pace for all storage needs. Because the unit must be nough to tow behind an automobile, much attention was weight distribution relative to the trailer axels, and a h road test was designed to ensure driving safety of the Figure 1 shows the framing for this unit. Due to the lower tensile strength of aluminum compared with stainless steel the unit framing was overdesigned. CALCS, SIMULATIONS, TESTING AND RESULTS WEIGHT DISTRIBUTION Completion of the tailgate station model in SolidWorks showed the COG located at 23 inches from the rear of the unit. After adding in the additional weight of the grill the COG location changed to 22.25 inches. As this is just a recommendation, it was decided to go forward with design of the tailgate station. Figure 6 shows the completed tailgate station with the grill installed and all compartments empty. In addition to COG, tongue weight needed to be measured. The following method was used in verifying allowable weight: • A cinder block placed under the tow bar to simulate hitch height • Borg scale placed between blocks and tow bar • Scale read 40 lb ODUCTION , Inc. is a sheet metal fabrication company located in Ohio. They specialize in Computer Numerical Control machining, laser/water cutting and welding/fabrication. TW = CTIVES e ht weight mpact Size od storage capacity oking capacity sy to operate neuver with/without a vehicle GN selection was critical due to the 1090lb weight restriction aul master trailer purchased to support the unit. (Harbor ols, 2015) The material selected would need be durable and ght. Stainless steel was initially chosen because of its low t after applying the SolidWorks mass properties tool it was red that the overall weight for this unit was between 850herefore, the material was changed to aluminum alloy, rovided a much lighter unit at 236lb. A comparison of these erials was conducted to support this decision. 4 Annealed Stainless Steel (SS): Density 7.90 g/cm^3 Strength to Weight Ratio (S2WR) 71 kN-m/kg Ultimate Tensile Strength (UTS) 560 MPa Yield Strength (YS) 230 MPa Figure 1: 1”x1”x1/8” 6061-T6 Aluminum Tubing Given the clients design criteria it was determined to locate the grill centered along the rear of the unit. This location was selected in an effort to maintain the recommended center of gravity (COG). The grill selected specifies it’s weight to be 100lb. (Great Grill, 2015) Due to the large weight at the rear there were concerns with tilt while the trailer is unhitched and exceeding the tongue weight while hitched. NOTE: DRAWER, TABLE, STORAGE DOORS SYMMETRICAL FEA ANALYSIS Integrated Finite Element Analysis (FEA) simulations were conducted using SolidWorks software to provide real life data concerning applied loading on the unit and thermal heat transfer through the unit. Results from these tests are provided as follows: DISTRIBUTED LOAD A 100lb distributed load simulation was applied at the grill location. Since the framing around the grill consists of longer tubes it was determined that the results from this analysis would be sufficient to conclude that the yield capacity of the compartment framing would meet the necessary required yield. Figure 6: Picture of completed Tailgate Station CONCLUSIONS COOLER PROPANE HOSE PORT Figure 3: FEA results of applied distributed load at grill location Figure 3 shows a diagram on the left that indicates where the 100lb distributed load was applied. Refer to Figure 1 for additional clarification. The undulation in the bars is an exaggeration of the tensile stresses. The scale to the right shows that the yield is approximately 2.736e+006 N/m^2 at these locations and does not exceed the yield stress of 2.750e+008 N/m^2. STORAGE (Makeitfrom, 2015 and Burnsstainless, 2015) GRILL LOCATION TABLE DRAWER Figure 2: Tailgate Station design with overall dimensions The FEA thermal analysis results shows the worse case scena after using the grill for 4 hours. The highest temperature of 303 remains localized at the grill. Therefore, the only concern in re heat transfer is radiation from the surroundings. Please see ha provided for heat transfer due to radiation. ∗ 100 = 11.9% Recommended weight distribution as follows: • 60% of weight in front of the axle • 40% of weight behind the axle • 10-15% total weight (tongue weight) (eTrailer, 2014) 61-T6 Aluminum alloy was selected: Density 2.70 g/cm^3 Strength to Weight Ratio (S2WR) 115 kN-m/kg Ultimate Tensile Strength (UTS) 310 MPa Yield Strength (YS) 270 MPa g 6061 over S.S. results in a loss of UTS, but this loss is n YS and more importantly S2WR. The gain in S2WR is nt due to the weight restriction. 6061 is stronger compared same weight of SS. – 40 336 Figure 4: FEA results of heat transferred through unit THERMAL ANALYSIS Insulation strips were installed between the grill and unit to maintain control of the overall temperature. The thermal analysis simulation in Figure 4 provides heat transfer data over the course of 4 hours. As evidence by these results the heat stays concentrated at the grill location. This indicates that the material selected provides the necessary dissipation required in order to minimize safety concerns. Installation of the grill at the specified location did not result i tilting. The designed frame successfully supports the grill, the it can be concluded that the framing at the compartments wil support upwards of 100lb. Thermal analysis results show tha is no concern in regards to heat conduction occurring at the from the grill. Any inconclusive results regarding calculations simulations have been validated after successful execution o road tests, which consisted of speed bumps, braking, turning speeds of at least 35mph. In conclusion this design is sound even with the challenges encountered during design and fabrication both the OSU Tailgate Design Team and Lochard that this prototype is a success and a good model from which mass production will produce better designs for future units. BIBLIOGRAPHY • • • • • Makeitfrom.com, (2015). Compare Materials. [online] Available at: http://www.makeitfrom.com/comp T6-Aluminum/Annealed-304-Stainless-Steel/ [Accessed 15 April 2015] Burnsstainless.com, (2015). Stainless Steel. [online] Available at: http://www.burnsstainless.com/stainl eTrailer.com, (2014). Trailer Hitch Receiver Sizes. [online] Available at: https://www.etrailer.com/faq-hit Harbor Freight Tools,. '1090 Lb. Capacity 40-1/2 In X 48 In Utility Trailer'. N.p., 2015. [Accessed. 13 Mar. Great grill, great price et al. 'Kitchenaid 4-Burner Built-In Propane Gas Island Grill Head In Stainless Stee Rotisserie Burner-740-0780 - The Home Depot'. The Home Depot. N.p., 2015. [Accessed. 13 Mar. 2015] ACKNOWLEDGEMENTS • Lochard Inc. www.lochard-inc.com