Productivity Problems

advertisement

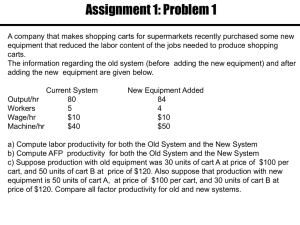

Assignment 1: Problem 1 A company that makes shopping carts for supermarkets recently purchased some new equipment that reduced the labor content of the jobs needed to produce shopping carts. The information regarding the old system (before adding the new equipment) and after adding the new equipment are given below. Current System Output/hr 80 Workers 5 Wage/hr $10 Machine/hr $40 New Equipment Added 84 4 $10 $50 a) Compute labor productivity for both the Old System and the New System b) Compute AFP productivity for both the Old System and the New System c) Suppose production with old equipment was 30 units of cart A at price of $100 per cart, and 50 units of cart B at price of $120. Also suppose that production with new equipment is 50 units of cart A, at price of $100 per cart, and 30 units of cart B at price of $120. Compare all factor productivity for old and new systems. Assignment 1: Problem 1 Output/hr Workers Wage/hr Machine/hr Current Situation 80 5 $10 $40 New Machine Added 84 4 $10 $50 (a) Compute labor productivity Old System : 80/5 = 16 units/worker New System : 84/4 = 21units/worker (b) Compute all factor productivity Old System : 80 / (5×10 + 40) = 0 .89 units/$ New System : 84 / (4×10 + 50) = 0.93 units/$ Assignment 1: Problem 1 (c) Now suppose: Production with old equipment was 30 units of cart A at price of $100 per cart, and 50 units of cart B at price of $120. Production with new equipment is 50 units of cart A, at price of $100 per cart, and 30 units of cart B at price of $120. Compare all factor productivity for old and new systems. AFP of the Old System = [(30)(100)+(50)(120)] / [5×10 + 40] = 9000/90 = 100 AFP of the New System = [(50)(100)+(30)(120)] / [4×10+50] = 8600/90 = 95.6 Assignment 1: Problem 2 A company has introduced a process improvement that reduces processing time for each unit so that output is increased by 25% with less material but one additional worker required. Under the old process, five workers could produce 60 units per hour. Labor costs are $12/hour, and material input was $16/unit. For the new process, material is now $10/unit. Overhead is charged at 1.6 times direct labor cost. Finished units sell for $31 each. a) b) Compute single factor productivity of labor in the old system. (Compute it in four possible ways.) Compute all factor productivity for both old and new systems. Factor Output Old System 60 New System 60(1.25) = 75 # of workers Worker cost Material Overhead Price 5 $12/hr $16/unit 1.6(labor cost) 31 6 $12/hr $10/unit 1.6(labor cost) 31 Problem 2; An additional computation Factor Output # of workers Worker cost Material Overhead Price Old System 60 5 $12/hr $16/unit 1.6(labor cost) 31 New System 75 6 $12/hr $10/unit 1.6(labor cost) 31 a) Compute labor productivity for the old system Labor Productivity = 60/5 = 12 units per worker Labor Productivity = [(60)(31)]/5 = 372 $ per worker Labor Productivity = 60/[(5)(12)] = 1 unit per dollar Labor Productivity = [(60)(31)]/[(5)(12)] = 31 Problem 2; AFP Factor Output # of workers Worker cost Material Overhead Price Old System 60 5 $12/hr $16/unit 1.6(labor cost) 31 New System 75 6 $12/hr $10/unit 1.6(labor cost) 31 b) Compute AFP Since there is only a single output, in the numerator we can have either # or $. Since it is all factor productivity, in the denominator we must have $ Problem 2; AFP Factor Output # of workers Worker cost Material Overhead Price Old System 60 5 $12/hr $16/unit 1.6(labor cost) 31 New System 75 6 $12/hr $10/unit 1.6(labor cost) 31 Old System Denominator of all factor productivity is computed as (5)(12) + (16)(60) + (1.6) (5)(12) = 1116 The numerator is (60)(31) = 1860 All factor productivity for old system = 1860/1116 = 1.67 New System [(75)(31)]/ [(6)(12) + (10)(75) + (1.6) (6)(12)] = 2.48 1.67 in the old system, 2.48 in the new system Assignment 1.3 3. A milk factory seeks advice from an external consulting company concerning its business and production processes. The final consulting report describes several steps to increase productivity including implementation of cutting-edge processing techniques through more powerful filtering systems. Existing System Proposed System 12 9 Milk Output/hour 1,000 gallons 1,400 gallons Wage Rate/hour $12 $12 Filtration Cost/hour $120 $170 Workers a) b) c) Calculate the labor productivity for the existing as well as the proposed system. Find the All-Factor Productivity for both systems. Assume that current processing includes 700 gallons of Grade-A milk sold at $2.40/gallon and 300 gallons of Grade-B milk at $1.90/gallon. Furthermore, assume that under the proposed system, processing will include 600 gallons of Grade-A milk at $2.40/gallon and 400 gallons of Grade-B milk at $1.90/gallon. Compare all-factor productivity for both the existing and the new system. 8 Assignment 1.3 a) Labor productivity for the existing system Labor Productivity = 1000/12 = 83.33 gallons per worker Labor Productivity = 1000/[(12)(12)] = 6.94 gallons per dollar Labor productivity for the proposed system Labor Productivity = 1400/9 = 155.56 gallons per worker Labor Productivity = 1400/[(9)(12)] = 12.96 gallons per dollar Assignment 1.3 b) All factor productivity for the existing system AFP = 1000/[(12)(12)+120] = 3.79 gallons per dollar All factor productivity for the proposed system AFP = 1400/[(9)(12)+170] = 5.04 gallons per dollar Assignment 1.3 c. Existing system 700 gallons A @ $2.40/gallon = 1,680 300 gallons B @ $1.90/gallon = 570 12 labor @$12, $120 filtration AFP (existing) = [1680+570/[(12*12)+120] AFP (existing) = 2250/264= 8.52 c. Proposed system 600 gallons A @ $2.40/gallon = 1440 400 gallons B @ $1.90/gallon = 760 9 labor @$12, $170 filtration AFP (proposed) = [1440+760]/[(9*12)+170] AFP (proposed) = 2200/278=7.91