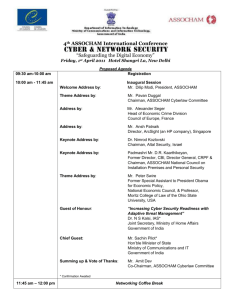

Building Lean Supply Chains

advertisement

Building and Managing the Lean Supply Chain 2004, M. Srinivasan The Supply Chain 1st Tier, 2nd Tier, …, Suppliers Enterprise Distribution Channels Customers The Supply Chain 2004, M. Srinivasan Develop Systems Thinking Lean supply chain principle 1: Improving the performance of every subsystem does not necessarily improve system performance. The sum of local optima does not equate to the global optimum. Improvements in subsystem performance must be gauged only through its impact on the whole system. 2004, M. Srinivasan Systems Thinking and the Theory of Constraints “Find the essence of each situation, like a logger clearing a log jam. The pro climbs a tall tree, locates the key log, blows it, and lets the stream do the rest. An amateur would start at the edge of the jam and move all the logs, eventually moving the key log. Both approaches work, but the essence concept saves time and effort. Almost all problems have a key log if we learn to find it.” -- Fred Smith 2004, M. Srinivasan The Business Ecosystem Regulating Agencies Competitors 1st Tier, 2nd Tier, …, Suppliers Enterprise Distribution Channels Customers The Supply Chain Complementors Stakeholders 2004, M. Srinivasan Dell’s Business Ecosystem Other industries such as airline, automobile, energy, .......... Competitors: Compaq, IBM, HP, Gateway, Toshiba, .......... Regulating agencies: US Government, state governments, Malaysian government, Chinese government, local governments....... Telephone service companies, financial institutes, third-party technical supporters, AD companies, .......... Suppliers: DELL: Customers: o o o o o o o o o o Phillips, Nokia, Samsung, Sony, Acer SCI, Celestica Seagate, Maxtor, Western Digital, IBM Barcelona, HP Hon Hai/Foxteq Quanta, Compal, Acer ........... Close proximity to suppliers o o o Enterprise systems (servers) Notebook computers Desktop computers ............ Direct sale o o o o o o Home & Home Office Small Business (up to 400 employees) Medium & Large Business (over 400 employees) State & Local Government Federal Government Education Healthcare ........... Dell Third-party logistics providers such as UPS, Caliber, transportation companies, .......... Stakeholders: NASDAQ, Complementors: Microsoft, digital device makers, Internet service Investors providers, computer skills trainers, PC game developers .......... Technology development Status of the Economy Culture ............ 2004, M. Srinivasan The Business Ecosystem Lean supply chain principle 2: Focus on improving the performance of the lean supply chain. However, do not ignore the supply chain’s business ecosystem. 2004, M. Srinivasan Steps to Build Lean Supply Chains Develop a systems perspective Understand customers and their expectations Map the supply chain Benchmark best practices Design products and processes to manage demand volatility Create flow across the supply chain Develop supply chain metrics 2004, M. Srinivasan Develop a Systems Perspective For any decision you take consider the following. Does the decision: Help you sell more products? Help reduce investments in resources? Help reduce payments/expenses? 2004, M. Srinivasan Understand Customer Value Critical step: provide what the customer wants Providing the wrong product or service in an efficient way is muda. Eg. Air travel An opportunity for kaikaku (dramatic change): Rethink the delivery system on a product line basis with strong dedicated product teams 2004, M. Srinivasan Understanding Customer Value Identify market segments Document the following: Customer values in each segment (order qualifiers and order winners) Delivery cycle/time expectations of customers in each segment 2004, M. Srinivasan Market Segments: Example %age Orders Market Segmentation Graph 60% 40% 20% 0% Market Segment Staple Stock Direct Seasonal Freight Product Type 2004, M. Srinivasan Customer Values in Each Segment Staple stock (e.g., Stationery) Direct freight (e.g., Sony DSC-S30) Availability (qualifier), cost (winner) Product design (qualifier), quality (winner) Seasonal Convenience (qualifier), availability (winner) 2004, M. Srinivasan Map the Supply Chain The set of all actions required to deliver the finished product or service to the customer “Seeing the Whole” (Systems Thinking) Systematic study of the value stream often reveals a staggering amount of muda Need to “map” the whole process, and identify value-added and non-value added activities across the value stream 2004, M. Srinivasan Supply Chain Map: “As-Is” Physician’s Office Intake Coordinator Hospital Discharge Staff Medical Records Courier Admission RN or Therapist Transcription Outside Supplier Clinical Staff Materials Management Visit Scheduler Clinical Supervisor Patient Telemonitoring System monitored by Office based Nurse Billing and Collections Information flow Paper flow Data flow Supply delivery Adds Value 2004, M. Srinivasan Source of Waste Supply Chain Map: “To-Be” Physician or Physician’s Office Intake Coordinator/ Scheduler Patient Telemonitoring System monitored by Office based Nurse Clinical Supervisor /Case Manager Clinical Staff Outside Supplier Hospital Discharge Staff Materials Management Medical Records Billing and Collections Information flow Data flow Supply delivery Adds Value Source of 2004, M.Waste Srinivasan Monthly Fax of Weekly Schedules Weekly Calls with Daily Schedules Supplier Central Supplies Production Planning Inventory Management System 30 Days Firm Schedule Customer CAPS System Bi-Weekly Schedule Record Receipt PressCuring DFM Blend 900 seconds 1.33 0 Days Days Compound PreForm PreCure 5700 18 4500 seconds 0.26 seconds Days Value Added Time: 0.35 days; 0.09 Days seconds FIFO PressCuring slab 18810 0.09 Days seconds 0.68 Days Production Lead Time 3.34 days; Sales Warehouse Finishing Pack 45 0.07 seconds 0.54 Days seconds 12 Days Value Added Ratio: 10.5% Customer Demand: 4,560 units/day Supply Chain Map: “As-Is” 2004, M. Srinivasan Monthly Fax of Weekly Schedules Weekly Calls with Daily Schedules Supplier Central Supplies Production Planning Inventory Management System 30 Days Firm Schedule CAPS System Customer Daily Orders Bi-Weekly Schedule Record Receipt Mixed-Model Build Schedule PressCuring DFM Blend 900 seconds 0.03 0 Days Days Compound PreForm PreCure 1800 seconds 18 seconds 4500 seconds 0.11 Days Value Added Time: 0.30 days; 0 Days PressFIFO Curing slab 0.03 Days 18810 seconds Finishing 45 seconds 0.13 Days Production Lead Time 0.60 days; Sales Warehouse 6 Days Value Added Ratio: 50% Customer Demand: 6,200 units/day Supply Chain Map: “To-Be” 2004, M. Srinivasan Another kind of Supply Chain Map FLOW Arrivals/Day From Agent From Computer RUNS RAPS RAINS RERUNS Total 2.9 15 3.8 17.3 39 DISTRIBUTION Number of Clerks= 4.00 Available Minutes= 1800.00 ServiceTime Load 68.5 198.65 50 750 43.5 165.3 28 484.4 1598.35 Utilization 0.89 FLOW Arrivals/Day 1.4 6.3 1.6 5.3 14.6 FLOW Arrivals/Day 0.8 4.3 1.1 7 13.2 UNDERWRITING 1 Team 1 Available Minutes= 450 ServiceTime= Load 43.60 61.04 38.00 239.40 22.60 36.16 18.70 99.11 435.71 Utilization 0.97 UNDERWRITING 2 Team 1 Available Minutes= 450 ServiceTime= Load 43.60 34.88 38.00 163.40 22.60 24.86 18.70 130.90 354.04 Utilization 0.79 Released 1 day prior to due date FLOW Arrivals/Day 0.7 4.4 1.1 5 11.2 UNDERWRITING 3 Team 1 Available Minutes= 450 ServiceTime= Load 43.60 30.52 38.00 167.20 22.60 24.86 18.70 93.50 316.08 Utilization 0.70 2004, M. Srinivasan Benchmark Best Practices Develop performance metrics Identify world class organizations; study their operations strategies and tactics 2004, M. Srinivasan Benchmark Best Practices Lean supply chain principle 3: Focus on customer needs and process considerations when designing the product delivery system. Enterprises can gain tremendous competitive advantage through best-in-class practices that cut across industries. 2004, M. Srinivasan Designing Products and Processes: Coping With Demand Volatility Can you smooth demand volatility? Key observation: Much of the demand volatility is selfinduced Sales promotions and rebates End-of-the-month syndrome (“Channel Stuffing”) Batching New product introductions … 2004, M. Srinivasan How Can We Reduce Demand Volatility? Have no promotions Reduce lead times and produce in small lots Postponement strategies Exploit product structures Exploit commonality and delay commitment Aggregation 2004, M. Srinivasan How to Manage Demand Volatility: The RAP Principle Before Raw Material Fabrication Sub-Assembly Final Assembly Finished Goods After 2004, M. Srinivasan How to Manage Demand Volatility: The RAP Principle Lean supply chain principle 4: Maximize external variety with minimal internal variety. It is desirable to maintain inventories in an undifferentiated form for as long as it is economically feasible to do so 2004, M. Srinivasan Managing Demand Variation As far as possible, avoid using inventory to buffer variation Less chances of misallocation Inventory seriously impedes flow Lean supply chain principle 5: Buffer the variation in demand with capacity, not inventory 2004, M. Srinivasan Percentage of Orders Product Delivery Strategies “At-Once” “At-Lead-Time” “Beyond-Lead-Time” Customers Customers Customers Wk 1 Wk 2 Wk 3 Wk 4 Wk 5 Wk 6 Wk 7 Wk 8 Replenishment Lead Time Lead Time = 3 to 5 weeks The Customer Time-Based Demand Profile 2004, M. Srinivasan Product Delivery Strategies: Product Structures Build to stock (BTS) Finished goods made in anticipation of demand. Customers’ orders are met from inventory Assemble to order (ATO) Subassemblies produced according to forecast. Required items are drawn from wip and assembled when orders are received. Very little finished goods inventory carried 2004, M. Srinivasan Product Delivery Strategies: Product Structures Build to order (BTO) Products built in response to actual customer orders. Usually these are standard products with a few options Engineer to order (ETO) New product designed and produced in response to specific customer needs. Lead times include relevant elements of engineering design and manufacturing 2004, M. Srinivasan Product Structures: Resulting Lead Times FG Build to Stock Customer LT Assemble-to-Order Assembly Customer LT Build-to-Order RM Assembly Customer LT 2004, M. Srinivasan Create Flow Creating flow requires a systems perspective Lack of flow results in inventory or work imbalance somewhere in the supply chain Improved flow reduced lead times To create flow, all processes should “row the boat” at the same pace – the concept of flow balance Suppliers Facility Customers 2004, M. Srinivasan Creating Flow To enhance flow, use pull signals for execution where possible Lean supply chain principle 6: Use forecasts to plan and pull to execute. A system that reacts to pull signals will have less variation than a comparable system that adopts a push mode of operation. 2004, M. Srinivasan Develop Metrics Using a Systems Perspective “Tell me how you will measure me and I will tell you how I will behave.” Does the metric: Help you sell more products? Help reduce investments in resources? Help reduce payments/expenses? 2004, M. Srinivasan