Stationary Anode X

advertisement

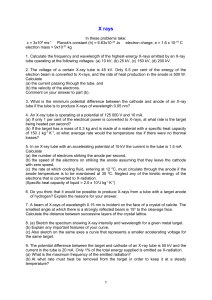

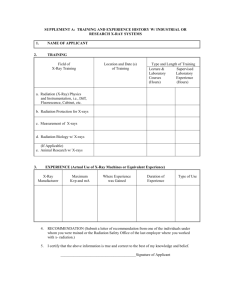

01 X-ray Tube 2 X-rays X-rays are generated from the interaction of accelerated e ’s & a target metal (tungsten). Patient is placed between Xray tube and silver halide film. X-rays passed through the body are absorbed in direct proportion to tissue density. 3 X-rays penetrating the body strike the silver halide film and turn it dark, the more x-rays that penetrate, the darker the area inscribed on the film. Bones & metal absorb or reflect X-rays are inscribed area on film is “lighter” or “more white”. Soft tissues allow more X-rays to penetrate are inscribed area on film is “darker”. 4 Visualizing tissues of similar density can be enhanced using “contrast agents”. Contrast agents: dense fluids containing elements of high atomic number (barium, iodine). Contrast agents absorbs more photons than the surrounding tissue or cavity appears lighter. 5 These contrast agents can be injected, swallowed, or given by enema. 6 electron beam generator tungsten target metal resultant X-ray beam 7 Diagnostic Medical X-Ray Unit Diagnostic (portable) 8 Dental (Diagnostic) X-Ray Unit 9 Diagnostic Medical X-Ray Unit Diagnostic x-ray tube in a mobile x-ray unit 10 11 X-Ray Tube Components Diagnostic Medical X-Ray Unit 12 Tube Components X-ray tube is one of the components of a basic radiographic unit. Other components are: Operating Console X-ray tube Automatic exposure control Exposure control Beam limiting device Diagnostic x-ray tube in a mobile x-ray unit 13 X-ray tube comprise of 3 components: Cathode structure Anode structure Glass envelope Diagnostic x-ray tube in a mobile x-ray unit 14 Functions of X-Ray Tube An x-ray tube converts its input of electrical energy into an output of X-ray energy. In the case of low power equipment, an x-ray tube also acts as a rectifier. 15 Production of X-Rays Requires 3 main components: –Electron source –Method of accelerating electron –Method of stopping (braking) electron 16 X-Ray Tube 17 18 Types of X-Ray Tube Types of X-Ray Tube 2 types of x-ray tube: Stationary Anode X-Ray Tube Rotating Anode X-Ray Tube 19 Stationary Anode X-ray Tube Low electric power. Relative simplicity of design and construction and therefore low cost. Suitable for the production of X-rays at low or medium intensities. Used for applications such as dental radiography and mobile work where no sophisticated procedures such as rapid sequential imaging are required. 20 Rotating Anode X-ray Tube Higher X-ray intensities and electrical power are provide by the anode tube since it has more efficient anode cooling. 21 22 Stationary Anode Tube Stationary anode tube: insert and housing 23 Construction of Stationary Anode Tube 24 Glass envelope Glass envelope is used to enclose the vacuum within the x-ray tube. The envelope is joined to the copper anode at one end and the nickel cathode support at the other reentrant seal. 25 The glass must be a good electrical insulator, or a substantial current will flow through it when a potential difference is applied between the anode and cathode. 26 Cathode Cathode consists of the following components: Filament Focusing cup Supporting wires Cathode support 27 Filament(s) The source of electron is a filament, heated by an electric current. The current increases the vibration of atoms within the filament so much that it emits heat and light. 28 So much heat energy is acquired by the atoms that some of their electrons (outer) can break free and temporarily leave the filament’s surface. This phenomenon is known as thermionic emission. 29 The rate at which electrons are emitted rises with the filament’s temperature. Thermionic emission: emission of electrons from the surface of a metal after heated 30 The filament is made of thin coiled tungsten wire for the following reasons: Tungsten is a good thermionic emitter. Tungsten has a low vapour pressure, i.e. it does not vaporise easily. It therefore lasts a long time. 31 Tungsten is rugged and able to be drawn into the thin wire required. Easy to be shaped 32 An x-ray tube may have 2 filaments of different sizes placed side-by-side. This is known as a dual-focus tube. 33 The 2 filaments produce 2 different sizes of electron foci on the anode, one for general use and the other (smaller) for fine-focus applications requiring less geometric unsharpness. 34 Most modern tubes have twin foci, e.g. 1.2 mm and 2.0 mm, 0.6 mm and 1.2 mm, 0.3 mm and 2.0 mm, etc. 35 Electron Sources (e-) e- produced via thermionic emission Electric current is supplied through the filament Frequently, 2 filaments control the size of the area of interactions of e- with the target and therefore the image quality 36 Focusing cup Focusing cups are usually made of either nickel, molybdenum or stainless steel. Cup shape metal Used to focus electrons towards target material. These materials possess high melting point and is a relatively poor thermionic emitter. 37 38 Anode Anode Anode is constructed of the 2 materials copper and tungsten, known as a compound anode. 39 Anode consists of: The block and stem is made of copper. The target or an inset of a thin (~ 2-3 mm) tungsten plate on the inclined face of the copper block. Electrons from the filament are focused on the target. 40 1% of energy is converted to X-rays, plus heat. The anode rotates to increase heat load capacity. 41 e- accelerates to positively charged anode Requires high potential difference to produce x-rays Diagnostic energy range usually 30 kV – 150 kV 42 Target material The target material is made of tungsten for the following reasons: Tungsten has a high atomic number Z of 74. Intensity of an x-ray beam is proportional to Z. 43 Tungsten has a low vapour pressure, so that it does not readily vaporise at its normal working temperature. Tungsten has a high melting point (3387°C), so that it can withstand the heat generated during an x-ray exposure without melting. 44 Tungsten has a relatively good thermal conductivity (½ that of Cu), thus enabling a rapid transfer of heat from the small focal area to the anode block by conduction. 45 Tungsten is a suitable material for machining into the shape and size required. Focal spot: the area within the target material where electrons hit the target to produce x-ray 46 The design of the cathode assembly is such that a socalled line focus is produced on the anode. In fact, the electrons from the filament are focused onto a thin rectangle rather than a line. 47 The face of an anode is set an angle with respect to the axis of the X-ray beam by an amount known as the anode angle. 48 Effective focus, a is given by: a = r sin where, r = true length of the line focus and = anode angle The effective focus is smaller than the true focus, a < r. 49 Advantages of using a line focus Size of effective focus is smaller than the real focus (figure). The filament may thus be relatively long without giving rise to poor geometric unsharpness. 50 Thermionic emission from the filament is proportional to its surface area so that a long filament is able to provide the high values of mA required in many exposures. 51 The area over which the heat is deposited is the area of the real focus. The temperature rise experienced by a large area is less than that experienced by a small area for the same amount of heat, since more atoms are able to take part in the heat transfer process. 52 The line-focus principle enables the heat to be spread over an area about 3 times larger than the effective focus, so enabling a compromise between the requirements of minimising the temperature rise in the target (requiring a large focal area) and minimising the size of the X-ray source (requiring a small focal area). 53 54 Anode Heel Effect Anode Heel Effect Anode heel effect is due to the higher absorption of those X-rays which pass through the greater thickness of target. This effect produced irregularities in the surface of the target as a result of prolonged use of the tube. 55 The formation of such irregularities in the target is known as pitting and is caused by vaporisation of the tungsten from the target (Figure). Figure: Effect of anode grazing 56 The anode heel effect produces a reduction in X-ray intensity for those X-rays which are emitted from the anode at neargrazing angles to the face of the target. 57 Figure shows anode heel variation of X-ray intensity. Intensity IF > IC > ID > IE . Beyond D, e.g. at E, there is no significant radiation, due to absorption within the anode. 58 The anode heel effect may have no practical significance, particularly if field size is small. When the whole width of the beam is used, however, its intensity variation may cause a detectable contrast in image density, from one end to the other. 59 The high temperatures reached by the anodes of such tubes result in thermal stresses within the anode which may cause distortion of the target angle with a consequent reduction in radiation output, a restriction in field size and in extreme cases cracking of the anode. 60 The use of rhenium tungsten alloy as a target material helps to minimize (pitting) crazing of the focal area and the use of high speed, large diameter, compound anodes permits increased loading of the focal area. (faster heat transfer). 61 Crazing is reduced by using a rhenium tungsten alloy (10% rhenium, 90% tungsten) as the target material. Radiation output is therefore maintained at a higher level giving the X-ray tube a longer useful life. 62