Mg(OH) 2 - Bhupalaka

advertisement

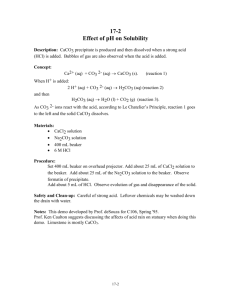

Pengolahan Kimia Penyisihan unsur pencemar dengan cara penambahan chemical agent/bahan kimia sehingga terjadi reaksi kimia, contoh : koagulasi dan presipitasi Prinsip dasar: perubahan bentuk terlarut/tersuspensi menjadi bentuk yang terendapkan (kecuali desinfeksi) sehingga lumpur yang terendapkan termasuk kategori B3 (perlu treatment khusus) Kelebihan pengolahan secara kimia: Efisiensi tinggi (dapat mencapai angka yang diinginkan) Waktu dentensi relatif singkat sehingga volume reaktor/unit pengolahan relatif lebih kecil Kekurangan Ada penambahan zat aditif sehingga meningkatkan konsentrasi Total Dissolved Solid (TDS). Penyisihan TDS relatif sulit dan mahal: membran atau destilasi Meningkatkan beban pengolahan Biaya bahan kimia cukup mahal = biaya untuk energi Softening Benno Rahardyan Faculty of Civil and Environmental Engineering - ITB Private Water System Resources Hard water What is "Hard Water"? Perhaps you have on occassion noticed mineral deposits on your cooking dishes, or rings of insoluble soap scum in your bathtub. These are not signs of poor housekeeping, but are rather signs of hard water from the municipal water supply. Hard water is water that contains cations with a charge of +2, especially Ca2+ and Mg2+. These ions do not pose any health threat, but they can engage in reactions that leave insoluble mineral deposits. These deposits can make hard water unsuitable for many uses, and so a variety of means have been developed to "soften" hard water; i.e.,remove the calcium and magnesium ions. water hardness Hard water is water contaminated with compounds of calcium and magnesium. Dissolved iron, manganese, and strontium compounds can also contribute to the "total hardness" of the water, which is usually expressed as ppm CaCO3. Water with a hardness over 80 ppm CaCO3 is often treated with water softeners , since hard water produces scale in hot water pipes and boilers and lowers the effectiveness of detergents. Table 1. Hardness Classification ---------------------------------------------------------Concentration of hardness minerals milligrams per in grains per liter (mg/l) or gallon (gpg) Level of Hardness parts per million (ppm) ---------------------------------------------------------below 1.0 soft less than 17 1.0 to 3.5 slightly hard 17 to 60 3.5 to 7.0 moderately hard 61 to 120 7.0 to 10.5 hard 121 to 180 above 10.5 very hard more than 180 ---------------------------------------------------------- Problems with Hard Water Mineral deposits are formed by ionic reactions resulting in the formation of an insoluble precipitate. For example, when hard water is heated, Ca2+ ions react with bicarbonate (HCO3-) ions to form insoluble calcium carbonate (CaCO3), as shown in Equation 1. This precipitate, known as scale, coats the vessels in which the water is heated, reduce the efficiency of heat transfer serious effect for industrial-sized water boilers scale can accumulate on the inside of appliances, such as dishwashers, and pipes. Softening Precipitation Neutralization CO2+Ca(OH)2 CaCO3(s) + H2O Ca+2 Precipitation at pH 10 Ca+2 +2HCO3-+Ca(OH)2 2CaCO3(s) + 2H2O Mg+2 Precipitation at pH 11 Mg+2 +2HCO3-+Ca(OH)2 2MgCO3 + CaCO3(s) + 2H2O Mg+2 + CO3= +Ca(OH)2 Mg(OH)2((s) + CaCO3(s) Ionic Balance: addnon non hardness ionic (Na+) : Mg+2 +NaOH Mg(OH)2((s) + Na + Ca+2 +Na2CO3 CaCO3(s) + 2Na+ Precipitation For large-scale municipal operations, a process known as the "lime-soda process" is used to remove Ca2+ and Mg2+ from the water supply. The water is treated with a combination of slaked lime, Ca(OH)2, and soda ash, Na2CO3. Calcium precipitates as CaCO3, and magnesium precipitates as Mg(OH)2. These solids can be collected, thus removing the scale-forming cations from the water supply. To see this process in more detail, let us consider the reaction for the precipitation of Mg(OH)2. Consultation of the solubility guidelines in the experiment reveals that the Ca(OH)2 of slaked lime is moderately soluble in water. Hence, it can dissociate in water to give one Ca2+ ion and two OH- ions for each unit of Ca(OH)2 that dissolves. The OH- ions react with Mg2+ ions in the water to form the insoluble precipitate. The Ca2+ ions are unaffected by this reaction, and so we do not include them in the net ionic reaction. They are removed by the separate reaction with CO32- ions from the soda ash. Ion-exchange Ion-exchange devices consist of a bed of plastic (polymer) beads covalently bound to anion groups, such as -COO-. The negative charge of these anions is balanced by Na+ cations attached to them. When water containing Ca2+ and Mg2+ is passed through the ion exchanger, the Ca2+ and Mg2+ ions are more attracted to the anion groups than the Na+ ions. Hence, they replace the Na+ ions on the beads, and so the Na+ ions (which do not form scale) go into the water in their place. The ion exchange process Calcium (Ca2+) and magnesium (Mg2+) ions that cause water hardness can be removed fairly easily by using an ion exchange procedure. Water softeners are cation exchange devices. Cations refer to positively charged ions. Cation exchange involves the replacement of the hardness ions with a nonhardness ion. Water softeners usually use sodium (Na+) as the exchange ion. Sodium ions are supplied from dissolved sodium chloride salt, also called brine. In the ion exchange process, sodium ions are used to coat an exchange medium in the softener. The exchange medium can be natural "zeolites" or synthetic resin beads that resemble wet sand. The exchange medium can be natural "zeolites" or synthetic resin beads that resemble wet sand. Softening Process NaZeolite + Ca2+ --> CaZeolite + Na+ and NaZeolite + Mg2+ --> MgZeolite + Na+ Recharging Process NaCl + CaZeolite --> NaZeolite + CaCl and NaCl + MgZeolite --> NaZeolite + MgCl Ion exchange softeners replace Ca++ and Mg++ with Na+ ions. Zeolite medium is recharged with Na+ by NaCl brine when depleted. Ion Exchange Water Softeners Exchange sodium ions for calcium and magnesium ions in water May be dietary hazard - hypertension (adds 140 mg/l of sodium in “Hard” water) Use potassium salt (KCl) for health reasons many people with high blood pressure or other health problems must restrict their intake of sodium. Because water softened by this type of ion exchange contains many sodium ions, people with limited sodium intakes should avoid drinking water that has been softened this way. Several new techniques for softening water without introducing sodium ions are beginning to appear on the market. Types of water softening equipment available Water softeners are classified in five different categories: Manual: There are several types of manual softeners. The operator opens and closes valves to control the frequency, rate and time length of backflushing or recharging. Semi-automatic: The operator initiates only the recharging cycle. A button is pushed when the softener needs recharging and the unit will control and complete the recharging process. Automatic: The automatic softener usually is equipped with a timer that automatically initiates the recharging cycle and every step in the process. The operator needs only to set the timer and add salt when needed. It is the most popular type of softener used. Types of water softening equipment available Demand initiated regeneration (DIR): All operations are initiated and performed automatically in response to the water use demand for softened water. DIR systems generally have two softening tanks and a brine tank. While one tank is softening the other tank is recharging. Off-site regeneration (generally rental units): A used softening tank is physically replaced with a recharged tank. Spent softening tanks are then recharged at a central location. Ion Exchange Water Softener with Sensor- Controlled Recharge Softener Selection Considerations Required grain capacity Daily water use (household population) Water hardness Desired regeneration schedule Initial cost Water conservation Other (Iron removal, etc.) Ion Exchange Water Softener Capacity Rated by grains of hardness treated between regenerations Example: Water hardness = 200 mg/l Softener Capacity = 2000 gr Household Population = 4 persons Calculate: Water Use = 4 persons x 200 l/person-day = 800 l/day Daily Hardness Treated = 800 l/day x 200 mg/l = 160 gr/day Regeneration Interval = 2000 gr/ 160 gr/day = 12.5 days Recommended Softener Sizes Pump Capacity (l/det) Softener Capacity (gr) Water Hardness (mg/l) 50 750 350 80 1000 500 120 1500 850 140 2000 1200 200 3000 1500 Ion Exchange Water Softener Recharge Control Method Water Use + - Initial Cost - -Time Clock -Flow Meter -Hardness - Sensor + Water Softening Permanent magnet water softeners don’t work Electrostatic and catalytic descalers may “descale” water, but don’t soften it Scale will not buildup on pipes, water heater elements, bathtubs etc. Sudsing action of soaps is not improved Typical Programmable Water Softener Controller Reactions CO2+Ca(OH)2CaCO3+H20 Ca(HCO3)2+Ca(OH)2=2CaCO3+2H20 Mg(HCO3)2+Ca(OH)2=MgCO3+CaCO3+2H20 MgCO3+Ca(OH) 2=Mg(OH)2+2CaCO3 MgSO4+Ca(OH) 2=CaSO4 + Mg(OH)2 CaSO4+Na2CO3=CaCO3 + Na2SO4 CaCl2+Na2CO3=CaCO3 + 2NaCl MgSO4+Ca(OH)2=CaSO4 + Mg(OH)2 MgCl2+Ca(OH)2= Mg(OH)2 + CaCl2 CO2+Ca(OH)2Ca+2+2OHCO2+2OH- HCO3HCO3-+OH- CO3-2+H20 Ca+2 +CO3-2 CaCO3 Mg+2 + 2OH- Mg(OH)2 Pretreatment and other variations Prior to softening some preliminary treatment may be advisable if 1. Raw water turbidities exceed 3,000 NTU at times 2. Raw water has high concentration of free carbon dioxide (more than 10 mg/l) 3. The raw water is high in organic colloids of a type that impedes crystallization of calcium carbonate 4. Raw water quality is highly variable over short periods of time 5. Recalcining of sludge is to be practiced Variation of process Single or two stage recarbonation ater conventional lime-soda treatment Sludge recirculation Excess lime treatment with split treatment or recarbonation Post-treatment with polyphophates Coagulation with alum, activated silica, or polymers The use of three-stage treatment The substitution of cation exchangers for soda ash to remove non carbonate hardness The use of caustic soda instead of soda ash CO2+2NaOHNa2CO3+H20 Ca(HCO3)2+2NaOH=CaCO3+Na2CO3+2H20 Mg(HCO3)2+4NaOH=Mg(OH)2+2Na2CO3+2H20 MgSO4+2NaOH=Mg(OH)2 + Na2SO4 Systems expressing hardness of water German degree = Ca and Mg equivalent with 10 mg CaO/liter French degree = Ca and Mg equivalent with 10 mg CaCO3/liter English degree = one grain (0.06480 g) of CaCO3 per gallon (3.785 L) USA = ppm (mg/L) CaCO3 Expressing hardness in milliequivalent/liter 1 milli-equivalent per liter = - - 2.8 German degree 5.0 French degree 3.5 English degree 50 mg CaCO3/liter < 2 meq/L soft water > 5 meq/L hard water Total hardness = amount of Ca and Mg non carbonate hardness + carbonate hardness. Carbonate hardness = Ca and Mg equivalent to bicarbonate content The difference between total hardness and bicarbonate (also called carbonate) hardness is the non carbonate hardness, which corresponds with ions like Cl-, and SO4-- HCO3- I Total hardness Ca+2 Mg+2 HCO3- II Ca+2 Total hardness Mg+2 Solubility in water Substance mg/l meq/l mg CaCO3/l Ca(OH)2 1280 34.9 1730 CaCO3 15 0.3 15 Ca3(PO4)2 Nearly insoluble Mg(OH)2 8.4 0.29 14.5 MgCO3 110 2.62 131 Mg3(PO4)2 Nearly insoluble Disadvantage of phosphate method - Rather expensive (cost of sodium orthophosphate) - Treated water will contain some rest of PO43- For drinking water it is not necessary and even not reccomendable to remove all hardness Lime soda process I CO2+Ca(OH)2CaCO3+H20 II Ca(HCO3)2+Ca(OH)2=2CaCO3+2H20 1 1 IIIa Mg(HCO3)2+Ca(OH)2=MgCO3+CaCO3+2H20 IIIb MgCO3+Ca(OH)2=Mg(OH)2+2CaCO3 III Mg(HCO3)2+2Ca(OH)2=Mg(OH)2+2CaCO3+2H20 2 IV CaCl2+Na2CO3=CaCO3 + 2NaCl 1 Va MgCl2+Ca(OH)2=CaCl2 + Mg(OH)2 Vb CaCl2+Na2CO3=CaCO3 + 2NaCl V MgCl2+Ca(OH)2+Na2CO3=CaCO3 + Mg(OH)2 + 2NaCl 1 1 II, III carbonate hardness reactions IV, V non carbonate hardness reaction needed Ca(OH)2 in meq needed Na2CO3 in meq Lime soda process I IV Ca+2 II CO2 V Lime needed : [CO2] +[HCO3-]+ [Mg+2] Soda needed : [Ca+2] - [HCO3-] + [Mg+2] HCO3- CO2 II I V Mg+2 HCO3- Ca+2 Mg+2 Lime needed : [CO2] +[HCO3-]+ 2[Mg+2] I II III Sodium hydroxide-soda process Advantages - Dosage of NaOH solutions is very simple - By using NaOH the amount of sludge is much less than with Ca(OH)2 as the precipitating agent) NaOH process I CO2+2 NaOHNa2CO3+H20 II Ca(HCO3)2+ 2NaOH =CaCO3+Na2CO3+2H20 IIIa Mg(HCO3)2+ 2NaOH =MgCO3+Na2CO3+2H20 IIIb MgCO3+ 2NaOH =Mg(OH)2+Na2CO3 III Mg(HCO3)2+ 4NaOH =Mg(OH)2+2Na2CO3+2H20 IV CaCl2+Na2CO3=CaCO3 + 2NaCl 1 V MgCl2+ 2NaOH = NaCl + Mg(OH)2 1 II, III carbonate hardness reactions IV, V non carbonate hardness reaction 1 1 2 needed Ca(OH)2 in meq needed Na2CO3 in meq NaOH process I HCO3- CO2 I II V NaOH needed : [CO2] +[HCO3-]+ [Mg+2] Soda needed : ([Ca+2] - HCO3- ) – ([CO2] +[HCO3-]) [Ca+2] - [CO2] - 2[HCO3-] IV Ca+2 II CO2 I, II Mg+2 HCO3- Ca+2 Mg+2 NaOH needed : [CO2] +[HCO3-]+ 2[Mg+2] I II III CaSO4+Na2CO3=CaCO3 + Na2SO4 CaCl2+Na2CO3=CaCO3 + 2NaCl MgSO4+Ca(OH)2=CaSO4 + Mg(OH)2 MgCl2+Ca(OH)2= Mg(OH)2 + CaCl2 Diketahui air mengandung ion Cl=142 mg/l, HCO3-=183 mg/l Ca++ = 120 mg/l Mg++=36 mg/l CO2 terlarut = 66 mg/l Harga bahan kimia Na2CO3 = Rp. 4500/kg NaOH = 4000/kg Ca(OH) = 2500/kg 1. 2. 3. Hitung tingkat kesadahan yang dapat dicapai dengan metode pengendapan yang paling murah. Jawaban didasarkan atas perhitungan dan reaksireaksi Hitunglah tingkat kesadahan yang dapat dicapai dalam proses pelunakan menggunakan Ca(OH)2 jika diketahui bahan proses ini memerlukan kelebihan dosis Ca(OH)2 sebanyak 18,5 mg/l Idem soal 2 menggunakan NaOH jika diperlukan kelebihan dosis NaOH sebesar 16 mg/l Cl-=142 mg/l =142/35.5 = 4 meq/l HCO3-=183 mg/l = 183/61 = 3 meq/l Ca2+ = 120 mg/l = 120x2/40=6 meq/l Mg2+ = 36 mg/l = 36x2/24 = 3 meq/l CO2 = 66 mg/l = 66x2/44 = 3 meq/l Ca2+ Mg2+ > HCO3- bukan hanya kesadahan sementara Kesadahan total = 9 meq/l Kesadahan sementara = 3 meq/l Kesadahan tetap = 6 meq/l Total Ca(OH)2 yang dibutuhkan 333+18,5 = 350 mg/l Naik 350/333 = 1,05 Ksp CaCO3 < Ca2+ + CO3= pada suhu tertentu adalah 0,3 meq/l =[Ca2+][CO3=]/[CaCO3] dengan memperhatikan Ca(OH)2 = Ca2+ + OH350 350 ---- mmol/l ----- mmol/l 74 74 Dengan kenaikan 1,05 pada ion Ca maka Ksp 0,3 x 1,05 = 0,315 meq/l Mg(OH)2 = Mg2+ + OHKsp = 0,24 meq/l Total 0,555 meq/l = 1,64 D CaCO3 1 D = 10 mg/L CaCO3 = 10/(40+12+48)*2 = 0,2 meq/L CaCO3 Ca(OH)2 = Ca2+ + 2OH18,5 mg 18,5 x 2 --------- = 0,5 meq/L 40+34 Tingkat kesadahan 0,5/0,2 = 2,5 D NaOH = Na+ + OH16 mg 16/40 = 0,4 meq Kesadahan 0,4/0,2 = 2 D