Measurement of Bioreactor KLa

advertisement

Measurement of Bioreactor

KL a

Motivations

1.

Biotech/pharmaceutical

industry employing more

Chemical Engineers

• Process

Engineering

• Validation

• Management

• Pilot testing

• Scale-up

2.

Good example of

mass transfer at gasliquid interface

3.

Experience modeling

in both semiempirical and

factorial methods

Types of Products

• Natural Products

– Drugs

•

•

•

•

Penicillin is early example

Taxol

Mupricin

Cyclosporin A, etc.

– Foods

• Fermented beverages

• Fermented dairy products

Types of Products

• Transgenic Products

– Gene for a therapeutic protein inserted in

foreign expression system

•

•

•

•

•

•

•

Factor IX

a-1-antitrypsin

EPO

Antibodies

antithrombin III

tissue plasminogen activator (TPA)

Interferons, etc.

Expression Systems

•

•

•

•

•

Bacterial Cells

Fungal Cells

Plant Cells

Insect Cells

Mammalian Cells

Types of Bioreactors (fermenter)

(often depends on shear sensitivity)

• Stirred tank

– Aerobic or Anaerobic (air-sparged if aerobic)

– Most common for bacterial cells

• Bubble or airlift column

– Good for shear-sensitive cells

• Fixed bed systems

– Trickle beds, hollow membrane fiber

(mammalian cells), etc.

Industrial Stirred Fermenter

Experimental Apparatus

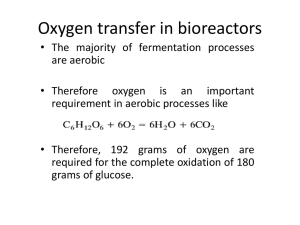

Transport in Bioprocess Systems

Why is KLa Important?

• Dissolved oxygen is an important

substrate in aerobic fermentations. Since

oxygen is sparingly soluble in water, it may

be the growth-limiting substrate in these

fermentations. For bacteria and yeast

cultures, the critical oxygen concentration

is about 10% to 50% of the saturated DO

(dissolved oxygen concentration).

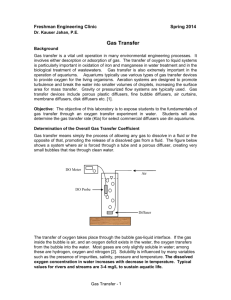

Equation for Transport

Oxygen transfer is usually limited by the liquid film surrounding the

gas bubbles:

mO2 kL a C* CL

where mO2 is the rate of oxygen transfer per volume of bioreactor (mass

O2/ L3 t), kL is the oxygen transport coefficient, [=]L/t, a is the gas-liquid

interfacial area per volume of reactor [=] L2/L3, kLa is the volumetric

oxygen transfer coefficient [=]1/t, C* is saturated DO (dissolved oxygen)

concentration [=] m/L3 (approx. 7 mg/l at 25 deg. C and 1 atm.), CL is the

actual DO concentration in the liquid [=] m/L3

Terms affecting rate

• KLa

– What we are trying to determine and correlate

with mixing speed and aeration rate

– Two quantities multiplied together

• Liquid side (essentially overall mass transfer

coefficient)

• Total area of bubbles in bioreactor

• Can’t be separated

Some Interactions Affecting Oxygen Transport in Aerobic Systems

Terms affecting rate

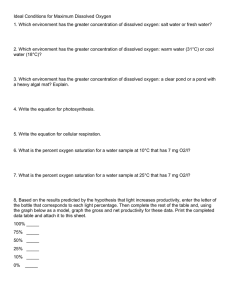

• C* (saturation oxygen concentration; max

solubility of the gas in liquid)

- Constant at a given T and P

- Available in tables (see on-line lab manual)

• CL (C(t)) the oxygen concentration at a

given time during the run; what we

measure

- {C*- CL} = “driving force”

Terms affecting rate

• KL -mass transfer coefficient

• a- interfacial area for mass transfer

Probe response rate needed to get

“real” CL(t) value

1. Gaseous oxygen dissolves in water at

bubble interface and disperses in the

bioreactor

2. Dissolved O2 crosses probe membrane

at tip.

3. O2 in probe is sensed and sent to meter

1

Time constant =1/kLa

2

Time constant =1/kp

3

Fast

Some Interactions Affecting Oxygen Transport in Aerobic Systems

Data Acquisition