EPACT 2005

advertisement

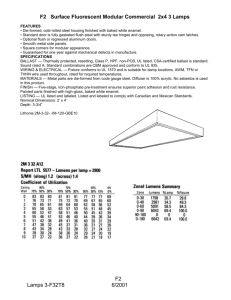

SYLVANIA’S Product Review Dirk Hinterleiter Commercial Engineer Sylvania Brad Salamone Vice President Atlantic Energy Concepts Topics/New Products Fluorescent Lamps/Ballasts Metal Halide EPACT 2005 Fluorescents Lamps OCTRON® ECOLOGIC® Lamps The best T8 products just keep getting better, it’s only natural Hg dosing reduced to 3.5 mg Availability Octron 800, 800XP, & 800XPS linear lamps Conversion complete March 06 700 Series lamps to follow; target summer 2007 4’ lamps followed by 2’ and 3’ lamps What are the benefits? Reduce environmental impact Contributes to sustainable, green building construction Simplifies qualification under LEED-EB 4 Improved OCTRON® XP® T8 Longer Life T8 Fluorescents OCTRON High Efficiency Fluorescent lamps The best, industry leading OCTRON technology, quality domestic manufacturing, & exclusive QUICK 60+® system warranty In May 2006, OCTRON XP lamp performance will be increased. Life will increase to 24,000 hours on instant start ballasts. 5 Octron FO30/800/XP/SS/ECO 30 watt 4ft Energy Saving Lamp 24,000hrs Lamp Life on Instant Start ballasts. 30,000 on PRS ballast Initial Lumens: 2850 94% Lumen Maintenance@ 8000hrs 85CRI 3000k, 3500k, 4100k Not Dimmable 60degree Min. Start Temperature. 6.25% energy savings over 32 watt lamp 6 Octron FO28/800/XP/SS/ECO 28 watt 4ft Energy Saving Lamp 24,000hrs Lamp Life on Instant Start ballasts. 30,000 hrs on PRS ballast Initial Lumens: 2725 94% Lumen Maintenance@ 8000hrs 85 CRI 3000k, 3500k, 4100k Not Dimmable 60degree Min. Start Temperature 12.5% energy savings over 32 watt lamps $0.80/$1.28 per lamp savings/year (3700/6000hrs@ $0.59kwh rate) 7 New Linear OCTRON® Product Strategy Series Watts Lumens CRI Life IS Life PRS 3 hours per start 12 hours per start 3 hours per start 12 hours per start 700 32 2800 75 15,000 24,000 20,000 28,000 800 32 2950 82 15,000 24,000 20,000 28,000 800XP 25 28 30 32 2400 2725 2850 3000 85 85 85 85 24,000 24,000 24,000 24,000 30,000 30,000 30,000 30,000 30,000 30,000 30,000 30,000 36,000 36,000 36,000 36,000 32 3100 85 24,000 30,000 30,000 36,000 800XPS ‘Super T8’ 25W OCTRON SUPERSAVER® May 2006 8 OCTRON® FBO31 CURVALUME® More energy saving solutions with OCTRON OCTRON CURVALUME SUPERSAVER® T8 lamps 6.5% energy savings over standard FB031 lamps on instant start ballasts IS life 26,000 hours @ 12 hrs/st, 18,000@ 3hrs/st PS life 30,000 hours@ 12 hrs/st, 24,000@ 3hrs/st ECOLOGIC® 2750 - 2775 initial lumens, 85 CRI 95% lumen maintenance at 8,000 hours Saves $2.00 per year per 3 lamp luminaire* Qualifies for QUICK 60+® warranty * Operating 4000 hours per year on QHE3X32T8/UNV ISN-SC @ $.10/kWh 9 DULUX® L 28W SUPERSAVER® Product Description: DULUX® L 28W SUPERSAVER® (FT40/DL/28W/SS/IS) Direct replacement for the standard 40W DL lamp Key Innovations: Improved lamp efficacy (100 LPW) Improved fixture efficacy at 35°C fixture ambient Longer life on instant start ballast (20,000* hrs.) High lumen maintenance (~ 88%) Energy efficiency Main Advantages Easy upgrade/retro-fit * Life rating based on 12 hrs per start No ballast change required Quick pay-back 12 DULUX® L 28W SUPERSAVER® 28W DULUX® L SUPERSAVER® System Comparison (3-lamp fixture on instant start ballast) ? Number of Lamps Fixture Watts Ballast Factor Fixture Efficiency* Fixture Lumens Relative Light Output Relative Watts Avg. Rated Life FT40DL/28W/SS/IS 3 88 0.96 77% 6209 95% 90% 20,000** FT40DL 3 98 0.96 72% 6532 100% 100% 15,000** Lamp Type * Typical of 3 lamp 2x2 9-cell parabolic fixture ** When operated on and Instant-Start Ballast at 12 hours per start Energy savings = $20/fixture over the life of the lamp Est. 100,000 fixtures $2.0M in energy savings @ 10¢/KW-hr $438K/yr @ 4,380 hrs per year 13 Electronic Ballasts T8 High Efficiency Electronic Ballasts High Efficiency IS Ballasts Instant Start ballast with the same performance as std ballasts, but with 6% energy saving Universal Voltage (120 through 277) Small can size Less than 10% THD Ballast Wattages (32 Watt Lamps) ISN ISL ISN(28w) ISL(28w) 1L – 28 2L – 55 3L – 83/82 4L – 108/107 25 48 73 95 25 48 72 95 16 22 42 63 84 QUICK 60+® System Warranties Ballast / Lamp System Warranty 60 months on ballast from date of installation Up to 36 months on OCTRON® T8 lamps renewable lamp warranty! Choice of the contractor you prefer, Sylvania Lighting Services or a labor allowance for ballast replacements One Company (OSI) is responsible for having the lights on Warranty applies to new fixtures or a retrofit 17 T-5/T-5HO LAMPS PENTRON® & PENTRON® HO (T5) Fluorescent Lamps Color temperatures: 3000K, 3500K ,4100K & 5000K FP54/800/HO 85 CRI Luminous efficacy to 104 LPW FP28/800 FO32/800 Miniature bi-pin bases New, shorter length for better fit into ceiling grids Higher temperature tolerance Starting temperature -20°F T12 “5K Lumen Systems” profile options 19 PENTRON® & PENTRON® HO PENTRON T5 14W Lumens 1350 2100 2900 3650 21W 39W 28W 54W 35W PENTRON HO T5 24W 80W Lumens 2000 3500 5000 7500 Maintains 95% light output over life 25,000 hours life Operate on QUICKTRONIC® system PS & PHO high frequency electronic ballasts Light output peaks @ 35C NOW available in ECO, 28w and 54w 20 HPS Application Retrofitted with T5/HOs 400W HPS T5/HO 21 MH400/U vs. Pentron T5HO System System Comparison – 4 lamp fixture, 2 ballasts MH400/U Magnetic FP54/841/HO QTP2x54/PHO 20,000 25,000 System Watts 458 240 CRI 65 85 Mean System Lumens** 16920 16215 Relative Mean Lumens** 100% 96% $152.52 $79.90 -- $72.62 Life (hrs) Annual Energy Cost* Annual Energy Savings* * @ $0.09/kWh, 3700 hours per year. ** at 8000 hours using typical 72% fixture efficiency for the MH and 98% for the T5HO system. 22 PENTRON® CONSTANT® More light output over a wider temperature range 90% light output from 5°C (40 °F) to 75°C (165°F) New amalgam technology reduces warm-up time TCLP complaint Ideal for use with 90° C rated QUICKTRONIC® T5HO ballast 23 PENTRON® T5 HO Fluorescent 24 Compact Fluorescents DULUX® T/E/IN AMALGAM Compact Fluorescent Lamps Maintains >90% light output from 40140°F Universal burning position Triple tube design 12,000 hours Life 2700K, 3000K, 3500K, 4100K 82 CRI 18 Watt - 1200 lumens 26 Watt - 1800 lumens 32 Watt - 2400 lumens 42 Watt - 3200 lumens 57 Watt - 4300 lumens 70 Watt - 5200 lumens Dimmable EOL in lamp for 18-42 watt lamps TRIPLE-TUBE DESIGN 26 Metal Halide/ High Pressure Sodium Pulse Start Metal Halide New Technology? NO • Starting in 1984 pulse start technology introduced with all low wattage metal halide lamps YES • Industry has recently developed higher wattage pulse start systems and new electronic systems 28 What is METALARC® PULSE START? Probe Start (Standard) Pulse Start arc tube with ~ 75-150 torr fill pressure Special design for Pulse Start: electrode Increase arc tube fill pressure Removal of probe: Reduced tungsten evaporation probe Clearer, more transparent arc tube Add ignitor to ballast 29 Pulse Start – What Does It Do? After 8000 Hours Improved lumen maintenance Reduced color shift More light output over life Faster re-strike time Potentially longer life Pulse 30 Standard Improved Lumen Maintenance & Longer Life MS250/PS vs. M250/U Lumen Maintenance 25,000 22,500 20,000 Lumens 17,500 15,000 12,500 10,000 7,500 5,000 2,500 0 0 M250/U MS250/PS 5000 10000 Operating Hours 31 15000 20000 METALARC® Pulse Start Family All existing low wattage metal halide lamps 150W MS175/PS/MED/BU-ONLY (Clear & Coated) MS400/PS/BT28 BU-ONLY & BD-ONLY MS175/PS/BU-ONLY (Clear & Coated) MS400/PS/BU-ONLY (Clear & Coated) MS200/PS/BU-ONLY/ET23.5 MS750/PS/BU-HOR (Clear & Coated) MS200/PS/BU-ONLY (Clear & Coated) MS750/PS/BD-ONLY MS250/PS/BU-ONLY (Clear & Coated) M1000/PS/U/BT37 MP250/PS/BU-ONLY (Clear & Coated) MS320/PS/BU-HOR (Clear & Coated) MP320/350/PS/BU-ONLY (Clear & Coated) MP350/400/PS/BU-ONLY (Clear & Coated) 32 ® ® METALARC POWERBALL TM A Tru-Color Solution CERAMIC Metal Halide Evolution MP Quartz Viable option for non-”color-critical” applications Ceramic Cylindrical Better color stability & higher maintained lumens compared to quartz MH Next step to quartz MH POWERBALL® 34 The next generation of metal halide with patented round ceramic arc tube Up to 95 CRI; best “red” rendering POWERBALL® PLUS: The Future of Ceramic Lighting Higher CRI More Red Additional PAR lenses Powerball Plus CRI = 95 Life = 12000 35 POWERBALL ® = Energy Savings Energy Saving Advantages vs. Halogen Efficient light source: Up to 94LPW vs. 25LPW Requires fewer fixtures Long life: Up to 12000 hrs. vs. 3000 hrs. ECOLOGIC® Types Available Qualify for Energy Rebate Programs Life (hrs) Lumens CBCP CCT 75PAR38CAP/SPL/WSP12 2500 1060 12300 2900 MCP39PAR20LN/830/SP 9000 2000 22000 2900 36 50% Energy Savings! Ceramic Availability : Cylindrical & Powerball® T6 (3K) MC39T6/U/G12/830 MC70T6/U/G12/830 PB MC150T7.5/U/G12/830 PB T6 (4K) MC70T6/U/G12/940 PB MC150T7.5/U/G12/940 BT28 & BT37 (clear & coated) MC39TC/U/G8.5/830 MC70TC/U/G8.5/830 DOUBLE-ENDED MCP50/U/MED/830 PB MCP70/U/MED/830 PB MCP100/U/MED/830 PB MCP150/U/MED/830 PB MCP250/PS/BU-ONLY/940 PB MCP320/PS/BU-ONLY/940 PB PAR TC E17 (clear & coated) MC70T6/DE/830 PB MC150T7.5/DE/830 PB 37 MCP39PAR20/U/830 MCP39PAR30LN/U/830 MCP70PAR30LN//U830 MCP70PAR30LN//U830 PB PLUS MCP70PAR38/U/830/ECO PB MCP100PAR38/U/830/ECO PB MCP150/PAR38/U/830 PB Halogen IR CAPSYLITE IR IR Coated Capsule Infrared Energy Multi-layered thin film InfraRed coating on outer surface of halogen capsule Visible Light Infrared energy is recycled within the IR capsule More visible light generated for each watt consumed Lower energy costs and less heat generated Thin Film Coating 39 TRU-AIM IR MR16 Infrared-coated capsule 37W std 50W 50W std 65W or 71W Same 4000-hr life as non-IR TruAim’s UV-Stop capsule - blocks UV-B & UV-C SP (10o), NFL (25o), FL (40o) 40 CAPSYLITE® IRTM – Product Line PAR20IR PAR30IR NSP 10º 120V 40W NFL 30º 120V 4000hr WFL 40º 120V 50W 3000hr 53W 6000hr 60W 3000hr 80W 3000hr 100W 3000hr PAR38IR NSP 9º 120V NFL 25º 120V FL 40º 120V NSP 9º 120/130V SP 9º 120/130V NFL 25º 120/130V NFL 25º 120/130V FL 40º 120/130V SP 9º 120V FL 30º 120V SP 9º 120/130V WSP 12º 120V NFL 25º 120V FL 30º 120/130V SP 10º 120V NFL 25º 120V SP 10º 120V NFL 25º 120V FL 40º 120V 41 PAR38IR Daylight SP 9º 120V WSP 12º 120V FL 30º 120V The Energy Policy Act of 2005 The Energy Policy Act of 2005: Tax Deductions 2005 EPAct Tax Deduction Provisions Whole Deduction Commercial Building – new construction or renovation Must include building envelope, interior lighting, HVAC and hot water systems One-time tax deduction of up to $1.80/sq.ft. for buildings that beat ASHRAE/IESNA 90.1-2001 by 50% or more Partial Deduction Commercial Building (which includes offices, institutional, retail, and industrial) – new construction or renovation Use if not all systems can comply with 50% energy reduction One-time tax deduction of up to $0.60/sq.ft. for building systems that beat ASHRAE/IESNA 90.1-2001 by some percentage Deduction cannot exceed cost of the measure (design, labor, material) 43 What is ASHRAE/IESNA Standard 90.1? Power density caps, in watt per square foot Two methods to determine your allowance for interior lighting: Building Area Method (AKA the Simple Method) Usually more restrictive than the space by space method Space by Space Method (AKA the Hard Method) Usually more liberal than the Building Area Method, and more complex Sample Lighting Power Densities allowed for building area types: Office 1.3 W/sf Warehouse 1.2 W/sf Retail 1.9 W/sf Sample Lighting Power Densities allowed for space types: Enclosed Office 1.5 W/sf Fine Material Storage 1.6 W/sf General Sales Area 2.1 W/sf + Highlight Merchandise 1.6 W/sf + Display Fine/Jewelry 3.9 W/sf Auto shut-off required for spaces >5000 sf (unless 24 hour operation) ASHRAE/IESNA Standard 90.1 Energy Standards for Buildings, Except Low-Rise Residential Buildings Building Area Method Automotive Facility Convention Center Court House Dining: Bar Lounge/Leisure Dining: Cafeteria/Fast Food Dining: Family Dormitory Exercise Center Gymnasium Healthcare-Clinic Hospital Hotel Library Manufacturing Facility Motel Motion Picture Theatre Multi-Family Museum Office Parking Garage Penitentiary Performing Arts Theatre Police/Fire Station Post Office Religious Building Retail School/University Sports Arena Town Hall Transportation Warehouse Workshop 1989 0.96 2.07 1.44 1.37 1.37 1.37 1.15 2.07 2.07 1.44 1.44 1.15 1.29 0.96 1.15 2.07 1.15 2.07 1.26 1.03 1.44 2.07 1.44 1.44 2.07 2.25 1.29 2.07 1.44 2.07 1.03 0.96 Lighting Power Densities 1999 2001 1.50 1.50 1.40 1.40 1.40 1.40 1.50 1.50 1.80 1.80 1.90 1.90 1.50 1.50 1.40 1.40 1.70 1.70 1.60 1.60 1.60 1.60 1.70 1.70 1.50 1.50 2.20 2.20 2.00 2.00 1.60 1.60 1.00 1.00 1.60 1.60 1.30 1.30 0.30 0.30 1.20 1.20 1.50 1.50 1.30 1.30 1.60 1.60 2.20 2.20 1.90 1.90 1.50 1.50 1.50 1.50 1.40 1.40 1.20 1.20 1.20 1.20 1.70 1.70 2004 0.90 1.20 1.20 1.30 1.40 1.60 1.00 1.00 1.10 1.00 1.20 1.00 1.30 1.30 1.00 1.20 0.70 1.10 1.00 0.30 1.00 1.60 1.00 1.10 1.30 1.50 1.20 1.10 1.10 1.00 0.80 1.40 Space-by-Space Method Common Space Types* Office - enclosed Office - open plan Conference/ Meeting/ Multipurpose Classroom/ Lecture/ Training Lobby Audience/ Seating Area Atrium - first three floors Atrium - each additional floor Lounge/ Recreation Dining area Food Preparation Restrooms Corridor/ Transistion Stairs - active Active storage Inactive storage Electrical/ Mechanical 1989 1.80 1.90 1.80 2.00 1.90 1.60 0.70 0.20 2.50 2.50 1.40 0.80 0.80 0.60 1.00 0.30 1.50 Lighting Power Densities 1999 2001 1.50 1.50 1.30 1.30 1.50 1.50 1.60 1.60 1.80 1.80 1.60 1.60 1.30 1.30 0.20 0.20 1.40 1.40 1.40 1.40 2.20 2.20 1.00 1.00 0.70 0.70 0.90 0.90 1.10 1.10 0.30 0.30 1.30 1.30 * Not all space types are listed Values as originally published 2005 EPAct uses STD 90.1-2001 values as of April 2, 2003 (as published) Other codes may use the more recent STD 90.1-2001 Addendum “g” as published in August 2003 Always check for correct table 2004 1.10 1.10 1.30 1.40 1.30 0.90 0.60 0.20 1.20 0.90 1.20 0.90 0.50 0.60 0.80 0.30 1.50 EPAct 2005 Partial Tax Deduction Interim Rules for Commercial Building Lighting Systems Energy-efficient lighting can be used to achieve up to 1/3 of the tax deduction From $0.30/sq.ft for beating 90.1-2001 by 25% Up to $0.60/sq.ft for beating 90.1-2001 by 40% A “sliding scale” approach is used for savings between 25% and 40% Exception: warehouses can get $0.60 but lighting must beat 90.1-2001 by 50% -- all or nothing % of LPD reduction beyond ASHRAE/IES 90.1 2001 <25% 25% 26% 27% 28% 29% 30% 31% 32% 33% 34% 35% 36% 37% 38% 39% 40% >40% Amount of Eligible Tax Deduction /sq.ft. $0.00 $0.30 $0.32 $0.34 $0.36 $0.38 $0.40 $0.42 $0.44 $0.46 $0.48 $0.50 $0.52 $0.54 $0.56 $0.58 $0.60 $0.60 e.g., Beat by 33%, get $0.46/sf 46 EPAct 2005 Partial Tax Deduction What other lighting requirements must be met? Must meet IESNA recommended minimum design light levels Must include all ASHRAE/IESNA Standard 90.1-2001 control requirements (e.g., automatic controls in spaces of 5000 sf or more) Must have bi-level switching in all occupancies except hotel/motel guest rooms, store rooms, restrooms, and public lobbies (bi-level switching not yet clearly defined…) Ballasts must assume highest lamp wattage possible for the calculations What is the window of opportunity? Building must be placed into service between Jan 1, 2006- Dec 31, 2007 to claim the deduction Who gets the deduction? Building owners BUT if the owner is a public entity (e.g. schools), the designer of the system can claim the tax deduction (details of how this will work will be in the implementation guidelines…) Tenants cannot get this deduction directly What else?: Tax deduction rules are very complex -- recommend that customers use a tax consultant. This is a tax deduction provision, not a tax credit – deductions are taken prior to calculating the final tax amount owed, credits are applied to the tax amount itself Rebates can be applied 47 STATE ENERGY CODES 48 ASHRAE 90.1-2001 VS. IECC CODE? EPACT 2005 requires compliance to ASHRAE 90.1-2001 code. Organizations that reside in the state of Pennsylvania must adhere to the IECC code when designing a lighting retrofit scenario. If you meet the IECC code you will meet or exceed the ASHRAE 90.1-2001. Must be able to document wattages before and after lighting retrofit. ASHRAE 90.1-2001=Tax code IECC=Building code 49 Knowledge Required…. Beating 90.1 -2001, while meeting IESNA recommended light levels, will require knowledgeable people For building retrofits or renovation, Survey the building Calculate the existing power density Project the revised power density Predict new lighting levels, ensuring they meet IESNA recommendations Meet lighting control requirements For new construction, Review lighting drawings and space sizes Calculate initial, proposed lighting density Influence change in lighting specification to beat 90.1, while meeting IESNA recommended light levels and control requirements 50 How is Compliance Demonstrated? Will there be inspections of buildings to determine compliance? Who will do them? The secretary of the treasury shall prescribe procedures for the inspection and testing for compliance of buildings that are comparable to the requirements in the Mortgage Industry National Accreditation Procedures for Home Energy Rating Systems. Individuals qualified to determine compliance shall only be those recognized by one or more organizations certified by the secretary of the treasury for such purposes. These compliance inspection requirements are currently under development. 51 Example Scenarios Basic Example Assumptions: 20,000 square foot office building Proposed lighting system delivers appropriate levels for office tasks Proposed lighting system beats ASHRAE/IESNA 90.1-2001 by 40% Corporate tax rate of 33% Results: Owner earns maximum tax deduction of $0.60 per square foot $0.60 per square foot X 20,000 square feet X 33% = $4000 one-time tax deduction 53 Warehouse Applications Warehouse Space General Layout Open high bay warehouse space IES recommended target illuminance for warehousing and storage: 10-30 fc. 60’x80’x30’ 70/30/10 reflectances Conditioned space (25°C) Baseline system: 400W std. metal halide/mag. ballast 9 open high bay aluminum reflectors Criteria 1 for 1 retrofit Illumimance levels the same 55 Impact of Energy Codes on Warehouse Space ASHRAE/IESNA Standard 90.1 Warehouse High Bay Active storage Space-by-Space Method: 2001 – 1.1 W/sq ft 2004 – 0.8 W/sq ft Building Area Method: 2001 – 1.2 W/sq ft 2004 – 0.8 W/sq ft REMEMBER Warehouse MUST exceed by 50% No “Sliding Scale” General High Bay Lighting System Wattage Lighting Power Density (W/ft2) M400/U-CWA Ballast Aluminum high bay 458 0.86 28.6 F 22% $0.00 4-lamp T5HO Aluminum high bay 236 0.44 17.7 P 60% $0.60 6-lamp T5HO Aluminum high bay 356 0.67 27.1 F 39% $0.00 6-lamp T8/QHE ISH Aluminum high bay 218 0.41 18.0 P 63% $0.60 56 Maint (fc) Pass/Fail ASHRAE 2001 % Exceeding 90.1 - 2001 Sp by Sp (%/Ded.) Warehouse Space Existing Lighting System Metal Halide Fluorescent Fixtures Fluorescent Fixtures Exit Signs 267 405 176 19 Proposed Lighting System High-Bay Fluorescent Fixtures High Efficient Fluorescent Fixtures Re-Lamp/Ballast LED Exit Signs 57 421 405 176 19 Warehouse Space Warehouse Lighting System Summary Sheet Existing Energy Costs Proposed Energy Costs Yearly Energy Savings Annual Maintenance Savings System Warranty Savings Break-even point $146,284.19 $55,341.48 $90,942.71 $3,634.62 $16,115.85 3.35 years 58 Warehouse Space CASH FLOW ANALYSIS YEAR: 1 2 3 4 5 Total at 10 years SAVINGS ENERGY SAVINGS HVAC SAVINGS TOTAL $90,943 $2,398 $93,341 $93,216 $2,458 $95,675 $95,547 $2,520 $98,067 $97,935 $2,583 $100,518 $100,384 $2,647 $103,031 $1,018,866 $26,870 $1,045,736 MAINTENANCE MATERIAL COSTS EXISTING SYSTEM LABOR COSTS EXISTING SYSTEM MATERIAL COSTS PROPOSED SYSTEM LABOR COSTS PROPOSED SYSTEM SAVINGS (EXISTING VERSUS PROPOSED) WARRANTY SAVINGS $11,929 $7,821 $10,885 $5,231 $3,635 $16,116 $12,228 $8,017 $11,157 $5,362 $3,725 $16,519 $12,533 $8,217 $11,436 $5,496 $3,819 $16,932 $12,847 $8,423 $11,722 $5,633 $3,914 $4,339 $13,168 $8,633 $12,015 $5,774 $4,012 $3,335 $133,649 $87,623 $121,947 $58,605 $40,720 $57,240 TAX DEDUCTION REALIZED TOTAL $37,026 $56,776 $20,244 $20,750 $8,253 $7,347 $37,026 $97,961 COSTS FINANCING COSTS MONITORING COST TOTAL ($423,287) $0 ($423,287) $0 $0 $0 $0 $0 $0 $0 $0 ($423,287) $0 ($423,287) CASH FLOW CUMULATIVE CASH FLOW PAYBACK IN YEARS ($273,169) $115,919 $118,817 $108,771 ($273,169) ($157,250) ($38,433) $70,338 1.63 2.80 3.35 4.28 59 $110,378 $180,716 5.38 $757,436 QUESTIONS? Want to reduce your utility costs? Can you qualify for EPAct 2005 tax deduction? Call Atlantic Energy Concepts for a lighting assessment, 610-916-5013. 60