Useful Carpentry Tips

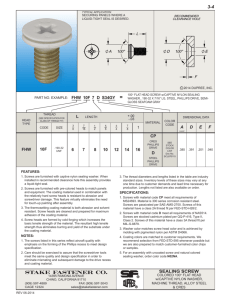

advertisement

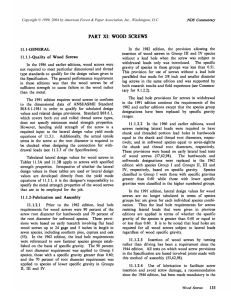

Useful Carpentry Tips SAFETY FIRST, ALWAYS! Don’t build alone. Don’t use tools you don’t know how to use. Wear safety goggles when using power tools. Stay ventilated and hydrated. Don’t build on drugs, alcohol or medication. Often in Stage Troupe, we ignore precision in our measurements. Although this is just theatre, being precise will go a long way. It will help you when you are assembling everything and make your more proud of your work. You can use some tricks to help with this. For example, use other pieces of wood as measuring tools. You can use a scrap piece of lauan (1/8”) and a scrap piece of 1x3 (3/4”) to space something out 7/8”. When building any set, keep in mind all of the doors you will have to take it through, all the corners you will have to go around and all the obstacles in your way. Don’t build a set that you can’t move in. Build it in parts if necessary. Pre-drill almost everything. It takes a few extra seconds (especially if you have a second drill designated for pre-drilling, instead of changing the pit out), but is totally worth it. That way, your wood will be a lot less likely to split and you’ll get clean penetration every time. I usually use a 1/8” drill bit for the course thread drywall screws we usually use. Also, make sure your drill is on high speed, lower torque (high number settings). Pre-drilling is especially important when using wood thinner than 1”, screwing near the edge of the wood, screwing in the same direction as the grain and for detail work. Keep in mind the difference between “Nominal Dimensions” and “Actual Dimensions”. Nominal dimensions are what you call the material, for example “2 by 4” is a nominal dimension. The actual dimension of 2x4 is 1.5”x3.5”. Below is a chart to help. Credit: www.MIStupid.com In general, don’t build with stripped screws. If you find any, throw them out. If you can afford it, throw out all your screws when you strike a set. There are some ways to avoid stripping screws. Make sure your drills are on low speed, higher torque (lower number settings). Apply a lot of pressure when you are screwing in. Gravity is your friend, so if possible, screw from above and put your weight down on the drill. That being said, make sure you are a few threads into the wood, or else you might slip off the head of the screw. If you feel a screw start to strip, stop drilling it and try to take it out; use a new screw. To take out a stripped screw, you may need to do a little extra work. Some alternative methods include: using locking pliers, clamping the drill directly around the screw (no bit), or breaking the screw with a hammer if necessary. The width of most of our saw blades is about 1/8”. This means you can’t cut two pieces of wood at exactly 48” from a 96” piece. Also, ever heard the phrase “Measure twice, cut once”? This is why. Measure every time after you cut. There are a few ways to quickly cut a lot of the same length. One is to cut one piece to the appropriate length, and then mark each of the other pieces using that piece. My personal favorite method is to clamp a piece of wood to the miter saw table at the right distance from the blade using the quick-grip. Then, all you have to do is push your piece against that block and cut. This is especially useful for building legs for platforms, which must be the exact same size or the platform will wobble. There are a few good tricks to building platforms of any size and shape. The frames should be built with 2x4, with an outer frame and a cross-piece at every two to three feet. For most applications, a platform can be faced with ½” plywood. ¾” is unnecessarily heavy and expensive, although it sometimes creaks less. You will never have a problem of a person putting their foot through a sheet of ½” plywood that is properly supported. For legs, you should place them every four feet along the sides, and in the middle if necessary. 2x4 legs are usually fine for any height under six feet. 4x4 legs are also unnecessarily heavy and expensive. Also, make sure you put proper bracing around the legs to hold them in the right place (2 by or 1 by). Attach all framing with 3” drywall screws and attach the plywood with shorter screws. For example, a standard 4’x8’ platform is pictured below. Flats are relatively easy to build. I suggest building the frames with 1x3 or 1x4, as they are usually less warped, definitely less heavy and just easier to deal with than 2x4. Like platforms, build an outer frame and ideally put a cross-piece every two to three feet. Attach all the framing with 3” drywall screws. Face it with lauan (better) or Masonite (cheaper) with short screws. A standard flat is 4’x8’, but you may find that different sizes work better for your purposes. I have gotten into the habit of building strong 4’x10’ flats for sets in the Student Theater. Seams in a set are my personal “pet peeve”. I hate when I can clearly see that a wall which should be solid is actually made of flats. There are a few ways to avoid showing seams as best as possible. The first requires a bit of planning, but is worth it in the end. It’s as simple as this: don’t have lauan seams in the same place as frame seams. For example, if you’re building an 10’x10’ wall, stagger the lauan so that a full piece covers the seams between the flats. In addition, you can cover seams with gaff tape, or even better, with spackle. A can of spackle is not very expensive and it works wonders! When taking out and putting screws in, make sure you apply a lot of pressure. When taking out a screw, hold the piece that the end of the screw is in, so that the screw comes out entirely. Gravity is your friend, try to apply pressure downward, or have someone else push against you. The miter saw can cut angles up to 45° in either direction and 45° on a miter. But what about those difficult 80° angles? The best way I have found to do that is to clamp a scrap piece of 4x4 close to the blade. Then, if you hold the piece you want to cut against the edge of the 4x4, you can cut steeper angles. You may want someone to help hold your work piece if it is of significant size. The picture below illustrates the idea. The table saw is a very useful tool. It can make straight cuts over a long distance in no time, but you must be trained how to safely use it. Consult the TA for Table Saw training. It can be used to cut down large pieces of lauan and plywood, and even to just down the small dimensions of one by and two by. “Toe-screwing” is when you put screws in at an angle to attach one piece of wood to another or to the floor. It’s actually very effective at holding things in place, but should not be used alone to support additional weight. For example, with platforms, make sure you have screws going straight in as well. A picture of toe-screwing is below. For instructions on how to build a periactoid (three-sided triangular prism), consult the guide posted in Readily Available Section 14.