Session 3 Inventory

advertisement

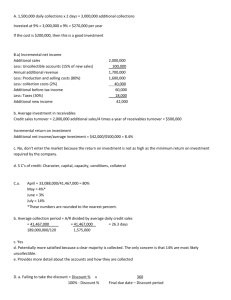

Introduction into Logistics PhD Natasha Lutovinova Logistics Lecturer E-mail: Lutovinova.N@nhtv.nl Room: G1.006 Handbook: Paul R. Murphy & Donald F. Wood, Contemporary logistics (New Jersey 2011), 10th edition 3 Introduction into Logistics Course Outline 12.05 Introduction 13.05 SCM Concept, Inventory 14.05 Demand Management, Warehousing Management 15.05 Transportation Management, International Logistics 16.05 Poster Session CHAPTER 8 Inventory Management 5-3 Learning Objectives To understand the costs of holding inventory To understand reordering concepts To differentiate the various inventory flow patterns 6-3 350 g € 1.32 600 g € 1.84 15 g € 0.36 10 g € 0.22 3-8 Procurement Delivery Manufacturing 5.15 Closing the lead-time gap 5.14 The lead-time gap Logistics lead time Customer’s order cycle Order fullfilment Lead-time gap Logistics lead time Customer’s order cycle Inventory Management Inventories are stocks of goods and materials that are maintained to satisfy normal demand patterns Inventory management Decisions drive other logistics activities Different functional areas have different inventory objectives Inventory costs are important to consider Inventory turnover 9-3 Inventory Management Inventory management (continued) Inventory costs are important to consider Inventory turnover: cost of goods sold divided by average inventory at cost cost of goods sold = inventory turnover average inventory $200,000 $ 50,000 = inventory is sold 4 times per year Compare with competitors or benchmarked companies 10 - 3 Visser, Logistics: Principles, fig.1.8 cost structure of physical distribution 11 - 3 Cost structure of physical distribution Warehousing, packaging, handling External transport Others Inventory costs 22% 38% 6% 34% 12 - 1 Reduction of the lead time Improve delivery reliability Total cost approach Increase flexibility Logistics objectives are mutually interdependent Low inventory turnover = high inventory carrying costs, little (or no) stockout costs High inventory turnover = low inventory carrying costs, high stockout costs Managing the trade-off is important to maintain service levels Inventory Classifications Cycle (or base) stock Safety (or buffer) stock Pipeline (or in-transit) stock Work in process Speculative stock Strategic stock Dead Stock Psychic stock 13 - 3 14 - 3 Inventory-Related Costs Inventory carrying (holding) costs Inventory carrying (holding) costs Obsolescence Inventory shrinkage Storage costs Handling costs Interest charges Insurance costs Taxes Opportunity cost 15 - 3 Inventory-Related Costs Stockouts Stockout costs Trade-offs Exist between Carrying and Stockout Costs 16 - 3 When to Order Fixed order quantity system Fixed order interval system Reorder (trigger) point (ROP) ROP = DD x RC (under certainty) ROP = (DD x RC) + SS (under uncertainty) Where DD = (average) daily demand RC = length of replenishment cycle SS = safety stock 17 - 3 When to Order ROP = DD x RC (under certainty) ROP = (DD x RC) + SS (under uncertainty) DD = daily demand RC = replenishment cycle SS = safety stock Reorder point = 120 pieces 18 - 3 =30 pieces =2 (days) =60 Reorder (trigger) point Ordering Quantity Fixed Variabel Order quantity R, Q R, S Order interval T, Q T, S R = Variable order interval Q = Fixed order quantity T = Fixed order interval S = Variable order quantity 19 - 3 How Much to Reorder Economic order quantity (EOQ) in units EOQ = √2DB/IC Where EOQ = the most economic order size, in units D = annual demand, in units B = administrative costs per order of placing the order C = carrying costs of the inventory (%) I = dollar value of the inventory, per unit 20 - 3 How Much to Reorder Economic order quantity (EOQ) in dollars EOQ = √2AB/C Where EOQ = the most economic order size, in dollars A = annual usage, in dollars B = administrative costs per order of placing the order C = carrying costs of the inventory (%) 21 - 3 Figure 9-2: Determining EOQ by Use of a Graph Calculation of eoq.lnk 22 - 3 How Much to Reorder Economic order quantity (EOQ) in dollars EOQ = √2AB/C A = annual usage B = administrative costs C = carrying costs = $1000 = $25 = 0.2 (20%) EOQ = √2*1000*25/0.2 = $500 order size 23 - 3 How Much to Reorder? Economic order quantity (EOQ) in dollars EOQ = √2AB/C A = annual usage B = administrative costs C = carrying costs EOQ 8544 155 24 - 3 A 3.650 12 € € B 2.000,00 250,00 C 20% 25% How Much to Reorder Economic order quantity (EOQ) in units EOQ = √2DB/IC D = annual demand, in units = 200 B = administrative costs = 25 C = carrying costs =5 I = value per unit = 0.2 (20%) EOQ = √2*200*25/.20*5 = 100 25 - 3 How Much to Reorder? Economic order quantity (EOQ) in units EOQ = √2DB/IC D = annual demand (in units) B = administrative costs C = carrying costs I = value per unit EOQ 183 165 – 178 – 183 – 192 20 – 22 – 24 – 26 22 105 90 – 95 – 100 – 105 270 270 – 280 – 290 – 310 322 300 – 322 – 336 – 344 26 - 3 D 5.000 12 365 3.650 5.200 B € € € € € 50,00 250,00 75,00 2.000,00 75,00 C 20% 25% 20% 20% 15% I € € € € € 75,00 50,00 25,00 1.000,00 50,00 Table 9-3: EOQ Cost Calculations 27 - 3 B C Ordering cost ($) Carrying cost ($) Total cost (sum of ordering and carrying cost) ($) Number of orders per year Order size ($) 1 1,000 25 100 125 2 500 50 50 100 3 333 75 33 108 4 250 100 25 125 5 200 125 20 145 Inventory Flows Safety stock can prevent against two problem areas Increased rate of demand Longer-than-normal replenishment When fixed order quantity system like EOQ is used, time between orders may vary (When reorder point is reached, fixed order quantity is ordered) 28 - 3 Figure 9-3: Inventory Flow Diagram Reorder point Average inventory in units = Q/2 (+ SS) 29 - 3 Contemporary Approaches to Managing Inventory ABC Analysis 30 - 3 31 - 3 Visser, Logistics: Principles, fig.5.4 ABC analysis Contemporary Approaches to Managing Inventory ABC Analysis Just-in Time (JIT) Approach 32 - 3 Figure 9-4: Trailer that opens on the side and is used for rapid discharge of parts 33 - 3 Contemporary Approaches to Managing Inventory ABC Analysis Just-in Time (JIT) Approach Vendor-Managed Inventory (VMI) Inventory Tracking 34 - 3 Inventory Management: Special Concerns FiFo Complementary items Dead inventory Deals Defining stock-keeping units (SKUs) Informal arrangements outside the distribution channel Repair and replacement parts Reverse logistics Substitute Products 35 - 3 Next time: Assignment Obligatory: 36 - 3 Choose a product, draw an inventory flow diagram and describe it