English

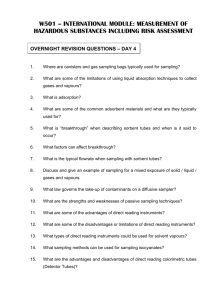

advertisement

Introduction to Occupational Hygiene Associate Professor Brian Davies Davies, SHS, Nov 2006 Assoc. Prof. Brian Davies AM • Worked as an Occupational Hygienist in industry for > 30 years • Certified Occupational Hygienist (ABIH & AIOH) 2 Assoc. Prof. Brian Davies AM • Worked in the steel, aviation & mining sectors (including petroleum exploration) • Currently Associate Professor of Occupational Hygiene & Toxicology at the University of Wollongong, Australia 3 Aim of This Course To introduce participants to the discipline of Occupational Hygiene & demonstrate how it can be applied in the workplace 4 Learning Outcomes At the conclusion of this course you should be able to: 1) Understand the principles of occupational hygiene and workplace sampling 2) Conduct a walk through survey and recognise the chemical, physical & biological agents present 5 Occupational Disease Causes of occupational disease fall into four major areas –Chemical agents –Physical agents –Biological agents –Psycho-social causes 6 Chemical Agents • • • • • 7 Dusts Metals Vapours Gases Pesticides Diseases of the Skin • Dermatitis – inflammation of the skin – two types (irritative & sensitising) • Irritative: alkalis, acids, cement, solvents, some metals & their salts • Sensitising: chrome salts, nickel, cobalt, urea or phenolic resins, some woods • Skin cancer – Coal tar pitch, shale oil, mineral oils (unrefined) • Erythema – Pitch 8 9 10 Diseases of the Respiratory System • Pneumoconiosis – Reaction of lung to presence of dust – Benign (iron, tin, barium) – Symptomatic (coal dust) • Silicosis – Fibrosis & lung cancer • Asbestosis – Fibrous thickening in lower parts of lung, loss of elasticity 11 Diseases of the Respiratory System • Lung Cancer – Mesothelioma (crocidolite) – Chromates, Nickel compounds, CTPV • Bronchial Asthma – Mainly sensitisation – Isocyanates, Colophony fumes, hardwood dusts (cedar, oak & mahogany) – Byssinosis ,Bagassosis • Extrinsic Allergic Alveolitis – Farmers lung (mouldy hay), Pigeon fanciers lung (droppings) 12 Diseases from Metals • • • • • Lead - systemic poison Mercury - organic mercury more toxic Chromium -ulceration, nasal cancers Arsenic - skin cancer Metal fume fever - fumes of metal oxides (eg zinc) • Manganese – motor neuron disorders • Cadmium- kidney disease 13 Vapours • Vapours (Solvents) – Dermatitis – Cause narcosis (CNS depressants) – Some damage peripheral nerves – Some damage kidneys & liver – Some interfere with blood formation – Some can penetrate the skin – Most decompose on heating to toxic compounds 14 Gases • Simple asphyxiants – Replaces oxygen in the lungs (Carbon dioxide) • Irritants – Can cause bronchitis and pulmonary oedema (sulphur dioxide) • Toxic – Causes a metabolic interference with the oxygen taken up by the body (carbon monoxide) 15 Pesticides • Insecticides – Organo-phosphorous compounds – Interfere with enzyme called cholinesterase • Herbicides – Liver ,kidney & lung damage possible with some products 16 Physical Agents • Noise induced hearing loss (NIHL) • Vibration • Ionising radiation • Non-ionising radiation • Heat & cold stress 17 EFFECTS OF NOISE 18 EFFECTS OF NOISE (Cont) Healthy Cochlea Photos showing actual damaged ‘hair cells’ in the inner ear Damaged Cochlea 19 Biological Agents • Viruses-Hepatitis A B & C, HIV • Bacteria-Legionella, Q fever, Anthrax, Leptospirosis • Fungus- Moulds, Histoplasmosis, Farmers lung • Plant-Poison Ivy, 20 Psycho-Social Causes • Stress – The person (lack of physical & mental fitness, inadequate training or skills, poor reward & prospects etc) – Work demand (long hours, shift work, repetitive work) – Environment ( noise, heat, humidity, fumes etc) – Organisation (poor industrial relations, communication, supervision) 21 Relationship to Occupational Hygiene 22 What is Occupational Hygiene ? 'Occupational Hygiene is the discipline of anticipating, recognising, evaluating and controlling health hazards in the working environment with the objective of protecting worker health and well-being and safeguarding the community at large.' 23 Aims of Occupational Hygiene • Recognition of health problems created within the industrial environment • Evaluation in terms of long and short term effects • Development of corrective measures to control problems 24 Recognition • Need to recognise the problem – What health effects are presenting – What health effects are a possible (walkthrough audits) • Need to understand the process – What is causing the health effect – How are people being exposed 25 Coal Mining Dust Noise Diesel emissions Hazardous substances Fungi Vibration 26 Aluminium Smelter CTPV Heat stress Metal fumes 27 Welding Welding fumes Toxic gases & vapours Radiation 28 Sand Blasting Silica exposure Noise RPE 29 Pipe Laying Welding fumes Heat stress UV radiation 30 Aviation Industry Composites Cu Beryllium Hazardous substances Noise Confined spacesfuel vapours 31 Oil Industry Noise Hydrocarbons Hydrogen sulphide Heat stress 32 What are the risks here ? Gold processing plant in West Africa 33 Gold Processing Plant 34 Gold Room 35 Group Exercise 1 • Break up into allocated groups • List all the health issues you think are present at this gold processing plant (see notes) 36 Evaluation • How can the contaminant of concern be quantified – Chemical, physical or biological – Dust, vapour ,mist, gas, fibre – Sampling method – Is quantification actually necessary 37 Preventative Principles • Substitution • Segregation • Enclosure and mechanical handling • Ventilation • Work practices • Personal protection 38 How do substances effect the body? • Workers need to come in contact with them - gases, vapours, dusts, noise • Need to reach a target organs different target organs for different things • Need to be in sufficient dose to cause harm dose = concentration x duration of exposure 39 Routes of Entry Contaminant IN THE AIR BREATHING SPILL Other ways: Eyes & Ingestion SURFACE SKIN Source :Airmet Scientific 40 Routes of Entry • Inhalation – By far the major entry point for contaminants • Skin Adsorption – Major source of entry for some organic compounds such as phenol and organophosphate pesticides • Eye – Entry point for some solvents • Ingestion – Poor hygiene can allow contaminants (eg lead) to enter the body 41 Target Organs • Upon entry to the body contaminants can have an adverse effect on one or more organs (target organs) – Lungs – Blood – Central Nervous System – Liver – Kidneys 42 What does an MSDS tell you? Detailed information on a dangerous goods or hazardous substance Product Name Codes, Listings Major Uses Ingredients Physical Characteristics Precautions for Use Safe Handling and Storage Information First Aid/Emergency 43 To be useful, MSDS’s, must have… Issue Date Company Details (Not O/S) Substance Name Health Effects/First Aid Engineering Controls Flammable/Fire & Expl. Haz. Storage & Handling Spills & Disposal 44 How do Hygienists Use MSDSs? • As a source of information on – Toxic effects – Exposure standards – Control technologies • Engineering • PPE – Reference to other analogous compounds 45 Group Exercise 2 Evaluating MSDS • Review of some MSDS • What are the key issues wrong with the MSDS’s provided? 46 Hazard Identification • Review the materials , processes & procedures used in the plant – Process flowcharts – MSDSs – Health effects of possible contaminants – International literature 47 A Case Study-Know The Process • Copper, Gold and Silver mine • 200 PPM arsenic in the copper ore – Known by geologist – Solid solution with the copper • Beneficiated with the copper in the float cells – Known by the metallurgist 48 A Case Study- Know The Process • As Concentration now 5000 PPM (0.5%) – 50% slurry, no dust • At port slurry de-watered and dust generated • 10 mg/m3 inhalable dust => 0.05 mg/m3 As • As ES is 0.01 mg/m3 thus possible to have overexposures at dust levels below inhalable dust exposure standard 49 Purpose of a Walk Through Survey • To familarise yourself with the process • To establish potential health risks • Identify any engineering controls • To establish what, where & whom should be monitored 50 Walk Through Survey • When conducting a walk-through survey – Look for signs of possible exposure (emissions escaping from system, hazardous chemicals, deposits on floors & surfaces, noise equipment etc) – Condition of any control technologies including PPE – Location of workers to sources of contamination 51 Group Exercise 3 • Break into allocated groups • Conduct a walk through survey of area indicated by Brett Young • Return to room and list all potential health risks (if any) you identified • How would you decide which of the possible health risks to quantify 52 How do we evaluate hazards? • Need to establish what the hazard is (or likely to be) • Need to develop a suitable monitoring programme • Need to follow established monitoring techniques 53 How do we evaluate hazards? • Evaluate the results in terms of the hazard (chronic, acute etc) • Make improvements to the workplace if necessary and conduct follow-up sampling • Keep a record of everything 54 What is Monitoring? Process of conducting measurement (s) of the concentrations of airborne contaminants. To estimate risk the following are required; a reliable estimate of exposure a standard for means comparison 55 Exposure Standards “No substance is a poison by itself, it is the dose that makes a substance a poison” (Paracelsus 16th Century) • Hazard <=> Toxicity • Hazard = Toxicity x Exposure 56 Dose Effect Relationship • For each chemical there is a doseeffect relationship – Acute effects (irritants, carbon monoxide) – Chronic effects (benzene , asbestos fibres) Basis of exposure standards 57 Threshold • The dividing line between noeffect and effect levels of exposure • For each substance there is a threshold of intoxication which is usually different for individual substances 58 Dose-Response Curve 59 Individual Susceptibility 60 Threshold of Intoxication For each substance, no matter how toxic, there exists a dose level called the threshold of intoxication which the human body is capable of accepting and detoxifying without injury to itself. 61 Basis of Exposure Standards • Toxicity • Biological action – Asphyxiants – Anesthetics – Carcinogens – Irritants – Systemic poisons 62 What limits exist? • • • • • • 63 ACGIH (USA) HSE (UK) OSHA (USA) MAK (Germany) ASCC (Australia) Many other countries What do they exist for? • Chemical hazards – Vapours, gases, dusts, fibres • Physical hazards – Noise, vibration • Biological hazards – Linked in most cases to chemical hazards 64 Types of exposure standards • • • • • • • 65 TWA (time weighted average) STEL (short term exposure limit) Ceiling/Peak (never to be exceeded) Skin Notation General Excursion Advice Carcinogen category Not otherwise classified Limitations of Exposure Standards • Values do not exist for all substances • They are guides only not fine lines between safe and unsafe • They may not protect all workers but “nearly all workers” 66 Extended Workshifts • Brief and Scala model • OSHA model • Pharmacokinetic model • A more practical approach uses the total time worked per month 67 Which Substance is the Most Toxic ? • 50 PPM • 10 PPM • 2 PPM • 0.5 PPM Each person is allocated only one vote 68 Which Substance is the Most Toxic? • 50 PPM HALOTHANE(ACGIH- USA) • 10 PPM HYDROGEN CYANIDE • 2 PPM SULPHUR DIOXIDE • 0.5 PPM HALOTHANE (ASCC-Australia) Why is there this difference? 69 Why Monitor Workplaces? • To establish the level of risk in respect to adverse health effects in workplaces • To meet regulatory or corporate requirements • To develop appropriate control measures 70 Why Monitor Workplaces (Cont) ? • To measure the effectiveness of control measures • For research purposes • To dispel anxiety 71 Types of Surveys • Initial - to gain information • Basic – qualitative assessment • Detailed - quantitative assessment • Routine – monitor compliance/controls 72 Sampling Strategy •WHO •WHERE •WHEN •WHAT •HOW METHOD 73 Exposure Judgement Outcome • Acceptably low • Too high – Fix the problem • Cannot make a judgement – Need for more information (samples/assistance from others) 74 Inputs to Judgement • • • • • • 75 Process experience Material characteristics Toxicity Workforce characteristics Statistical tools Confidence in exposure limit Who should be monitored? • Everyone? • Those identified as potentially exposed from walkthrough survey or risk assessment? • Controls? 76 Types of Sampling • Grab • Short-term • Long-term • Continuous • Bulk 77 78 Bulk Sampling • Substance(s) identification only • Cannot be related back to airborne concentration • Can sometimes be used with other direct methods to calculate worstcase scenarios 79 What should be monitored • Contaminants identified in walkthrough survey or risk assessment 80 What type of sample? • Area – Should only be used to assess the effectiveness of control strategies – Does not take account of an individuals movements – Has no legal standing • Personal – Accounts for movement of workers – All exposure standards are based on personal sampling 81 How many samples? • Single samples – Some legislation is based on single sample compliance – Approach has issues due to variability within an exposure cloud • Multiple samples – Improved accuracy but how many samples are enough • Statistically based sampling – Most accurate approach but time consuming and very costly 82 How long should samples be collected? • Substance properties – Acute or chronic adverse health effects • Duration of work shift – Shift length – Work pattern within shift 83 What method should be used? • If possible always use recognised standard methods – Some industries have statutory methods • Some reference methods are: – NIOSH – UK HSE (MDHS) • Always check validity of non standard methods to ensure they withstand external scrutiny 84 After Data Collection • How will the data be evaluated? • How will data be stored and communicated to stakeholders? • What is unacceptable? – Statutory requirement – Corporate requirements 85 Statistical Based Monitoring • Approach developed in 1970’s by NIOSH • Collect a statistical sub-set of worker exposure to represent all persons’ exposure in a SEG (HEG or KEG) • Sampling must be random • Number of samples collected determined by required confidence level 86 87 Process of statistical monitoring • Establish similar exposure groups (SEGs)- This may require preliminary sampling • Develop statistically based sampling schedule • Collect data according to defined programme 88 Process of statistical monitoring • Statistically analyse data • Modify exposure groups (if required) • Final report or ongoing reports • Ongoing data collection (maintenance sampling) 89 Establish Similar Exposure Groups (SEGs) • Can be defined by: – process and environmental agent – process, job and environmental agent – process, job, task and environmental agent – process, task and environmental agent – work teams – non-repetitive work 90 Establish Similar Exposure Groups • Observational – Simplest form but least accurate • Sampling – Preliminary sampling to establish groups • Combination of observation and sampling – Most accurate approach 91 Longwall Mining 92 Continuous Miner (Panel) 93 Basic SEG Structure- Coal Mine SEG Description No. Workers 1 2 3 4 5 6 Longwall Panel Methane Drillers Tailgate Workers Outbye Workers Surface Workers 94 60 70 14 8 60 16 Outbye Workers- Secondary SEG Structure Task Materials crew Belts Diesel workshops Cable crews 95 Number 35 5 8 12 Revision of SEGs • SEGs should be revised when: – New data is available – A change to the process occurs – New jobs are created – New contaminants may be present 96 Methods of estimating No. of Samples • Q: How many times do I need to make measurements for the results to be statistically valid and useful? A: Depends on information you need. Compliance Research Corporate requirement Degree of confidence 97 Practical Options • Point of diminishing returns • Reasonable approximation of exposure profile possible with about 6-10 samples (AIHA 1998) • As exposure standard approaches exposure limit this number increases depending on level of confidence required 98 Source : AIHA (1998) 99 Random Sampling • Need for defined sampling period – 64 weeks normal but can be as low as you wish – Very hard to manage major programmes below 16 weeks • All samples must be collected without bias – Sampling schedule based on random numbers • Need to write a detailed sampling protocol – Any deviations must be accounted for in protocol and noted at time of event 100 Sampling Schedule 101 Lets do some monitoring • Dusts & fibres • Vapours & gases • Noise • Biological monitoring 102 Dusts & Fibres 103 Composition of Dusts Fibrogenic reactions (quartz) Carcinogenic response (chromates) Irritation (acid mists) 104 ISO/CEN Convention (PM 10) Source :Airmet Scientific 105 Relative size of particles Inhalable dust 100 micron RESPIRABLE Thoracic dust 30 micron THORACIC (PM10) Respirable dust 10 micron INHALABLE • 1 3 7 Source :Airmet Scientific 106 10 30 100 Respirable Dust •Gets deep into the lung •Not easily removed •Invisible to human eye • 4.0 micron at 50% cut Source :Airmet Scientific 107 The Cyclone Separates the RESPIRABLE dust •Inlet points down Suction from top Contains cassette Source :Airmet Scientific 108 Parts of a Cyclone •Retaining ring •Cyclone top •Cassette (filter) •Main Body •Grit pot Source :Airmet Scientific 109 Inhalable Dust •Affects the whole of the respiratory system •100 micron at 50% cut Source :Airmet Scientific 110 The I.O.M. sampler •Inhalable sampler •Cassette system •All collected dust is IOM cassette Transport clip measured •Easily handled IOM sampler •No contact with filter •Multi fraction sampling with foam inserts Front cover Cassette front Source :Airmet Scientific 111 Filter Support grid O ring Body IOM Cassette FILTER Source :Airmet Scientific 112 •IOM Cassette. •Cassette and filter are pre and post weighed as a single unit The IOM complete •Place cassette in body Screw front cover on Source :Airmet Scientific 113 Sample Train •Is made up of : •Pump •Connecting tube •Sampler •Any accessory SAMPLER CONNECTING TUBE PUMP Source :Airmet Scientific 114 Calibration •Connect from pump to sampling head •Connect from sampling headto calibrator Adjust flow to require flowrate Source :Airmet Scientific 115 Soap Film Meter 116 Electronic Flowmeter 117 Position of Sampling Device •ALL Exposure limits are based 300mm Hemisphere on around the nose •PERSONAL SAMPLES and mouth And MUST be taken in the Breathing Zone Source :Airmet Scientific 118 Taking the Sample •Place sample train on person: Start pump Note start time At end of sample: Note stop time Source :Airmet Scientific 119 Direct Reading Instruments • Hund Tyndalometer • Dust Trak • R & P PDM 120 Hund Tyndalometer 121 Dust Trak 122 Problems with direct reading instruments • Most devices cannot distinguish between water droplets from suppression sprays and dust particles 123 R & P Personal Dust Monitor 124 TEOM Series 3600 Personal Dust Monitor 125 Real Time Data 126 Remote Control Miner Operator, Major Exposure Variables Mass Concentration [mg/m ³] 5 Mass Concentration 4 Cumulative Concentration 3 2 1 Projected Exposure 0 6:00 7:12 8:24 9:36 10:48 12:00 Time 127 Source: CDC-NIOSH Pittsburgh Research Laboratory 13:12 14:24 15:36 16:48 18:00 Fumes • Use open face sampling head (IOM or other) • Analyse collected material for contaminants • Need to be careful of filter pore size – Welding fume typically <1 um 128 Types of Fibres • Asbestos • Synthetic or MMMF 129 Asbestos • Fibrous silicate minerals • Main types – Chrysotile – Amosite – Crocidolite – Actinolite – Anthophylite – Tremolite 130 Health Effects • Pleural Plaques • Asbestosis • Lung Cancer • Mesothelioma 131 Management of Asbestos • Identification – dispersion staining microscopy, XRD & IR • Assessment - Membrane filter method • Control- Removal, encapsulation, monitor 132 Bulk Amosite Copyright A Rogers 133 Asbestos-Ships Lagging Copyright A Rogers 134 Tremolite Rock and Fibre Copyright A Rogers 135 Calcium Silicate and Amosite Copyright A Rogers 136 Dispersion Staining for Identification Copyright A Rogers 137 Polarised Light – Ist order Red Copyright A Rogers 138 Types of SMF • Glass fibre – Reinforcing filament – Glass wool – Ultra fine glass fibre • Mineral wool – Rock wool – Slag wool • Ceramic fibre – Refractory ceramic fibres 139 Health Effects of SMF • Significantly less potent than asbestos • Larger fibre sizes induce irritation • No fibrosis has been demonstrated • Some slight risk of lung cancer but debate continues 140 Measuring Airborne Fibres MEMBRANE FILTER METHOD Pump and filter (cellulose ester) Phase contrast microscopy Sampling (Occupational & Paraoccupational) Filter mounting and clearing Kohler illumination Specific counting rules Certified counters 141 Membrane Filter Method Slide Copyright A Rogers 142 Vapours & Gases 143 Sampling Systems Sampling systems – Active • Pump and adsorption tube (vapours) • Pump and liquid absorption (gases & vapours) – Passive • Solid adsorption (vapours) • Direct reading (gases & vapours) 144 Vapour Sampling •With sorbent tubes Main bed Precision drawn glass tube Back-up bed Retaining clip Foam separator Source :Airmet Scientific 145 Breakthrough? •When a sorbent if full to capacity, breakthrough occurs Source :Airmet Scientific 146 Breakthrough is when a tube becomes full and rereleases the hazard Tube Holder 147 Gas/Vapour Sampling Train •Break off both ends of a sorbent tube (2mm min dia, or 1/2 dia of body) Put tube in low flow adapter/tube holder Make sure tube is in correct way around Source :Airmet Scientific 148 Calibration of a tube •Connect to calibrator •Adjust flow at low flow adapter Use soap film or electronic meter Source :Airmet Scientific 149 Taking the Sample Place sample train on person: •Start pump •Note start time •At end of sample: •Note stop time Source :Airmet Scientific 150 After the sampling •Remove tube •Place covers on tube •Send off for analysis with details of sample Don’t forget to send a BLANK Source :Airmet Scientific 151 Sample bags - gases •Made from Tedlar •Inert •Valve/inlet with septum •No auto shut off •Fill by flow X time •Designed as single use Source :Airmet Scientific 152 Bag filling •Do not overfill •Bag will take 3 times stated volume Fill to correct volume by setting flow rate and time… otherwise? More pressure means more migration Source :Airmet Scientific 153 Badges - Dosimeters Protective disk Sorbent bed Small Light Membrane Support grid Void for solvent Source :Airmet Scientific 154 No pump Needs air movement to work Badges and their sorbents •Activated sorbent •Over 100 chemicals •No need for backup layer if method followed •Larger molecules can dislodge smaller ones •Does not work in ‘still air’ conditions Source :Airmet Scientific 155 Direct Reading Instruments 156 Cross Sensitivity (CO Sensor) H 2S SO2 NO NO2 Cl2 H2 HCN C 2H 4 157 ~ 315 ~ 50 ~ 30 ~ -55 ~ -30 < 40 40 90 Challenge concentration 100ppm of each gas Filters for Contaminant Gases H2S SO2 NO NO2 Cl2 H2 HCN C2H4 158 Unfiltered Filtered ~ 315 ~ 50 ~ 30 ~ -55 ~ -30 < 40 40 90 < 10 <5 < 10 ~ -15 < -5 < 40 < 15 < 50 ‘Port’a’man!’ 159 Noise 160 Common Terms • SLM – Sound Level Meter (instrument consisting of a microphone, amplifier and indicating device (SLM/dosimeter) • Dosimeter – SLM that can record history • dB – decibel – measurement of Sound Pressure Level • Sound power – total sound energy radiated by a source 161 Common Terms • Leq – equivalent continuous noise level of a fluctuating sound over time ie LAeq8hr = 8 hrs (A weighted). • A Weighting – scale with frequency response - human ear • C Weighting – scale to determine level of hearing protection required (high) 162 Introduction to Sound Level Meters • Integrating or nonintegrating • Type 0,1 – precision • Type 2 – general/industrial use • Type 3 – indication only • Filters and weighting networks A, C, lin • Frequency analysis – 1/3 and octave band • Primarily for walkthrough survey work 163 Introduction to Dosimeters • SLM with ability to provide an integrated noise exposure over a given period (ie work shift – 8, 10, 12 hr) • Most provide data logging with ability to set statistical parameters, alarm levels, and record peaks in addition to exposure in increments – normally 60 sec. 164 What is Noise Dosimetry? • Noise dosimetry is used to determine occupational exposure over a work period. • Particularly relevant where noise sources are cyclic or where an operator moves around a large area of a workplace with many difference noise sources. 165 Typical Dosimeter 166 How do you determine what is required? • Noise survey, contour plans, dosimetry • Is the survey based on reaction to specific complaints or issues. • Is it a baseline survey to establish “hearing protection zones”. 167 How do you determine what is required? • Does the employer wish to assess suitability of hearing protection. • Where does/do the worker/s spend the bulk of their time 168 Noise Exposure Dosage Guide (unprotected) 169 Limiting dB(A) Maximum duration 85 8 hr 88 4 hr 91 2 hr 94 1 hr 97 30 min 100 15 min 103 7 min 106 4 min 109 2 min 112 1min 115 30 sec Evaluation of data 170 Types of data evaluation • Statutory requirement – Straight comparison to exposure standard • Statistical sampling – Statistical evaluation 171 Statutory Requirement • <<ES - acceptable • ES – unacceptable but more sampling may improve situation • >>ES - unacceptable 172 Statistical evaluation of exposure data • Need to define what you are trying to achieve • Need some understanding of statistics • Need to realise that nothing is perfect and there is still a possibility of overexposure • Need to define when it is better to fix the problem rather than keep sampling 173 Statistical Computer Packages • Many packages available – Hygienist (Dutch), LogNorm2, IH stats • IH Stats (AIHA as part of book package) – Excel based but limited in application (50 data points), no ANOVA • LogNorm2 (AIHA but also visit www.lognorm.net) – Easy to use, good graphics but problems when applied to noise exposure – Requires minimum of 6 data points 174 Statistical Metrics • • • • • 175 GM & GSD MVUE 95 % UCL 95 % ile UTL Data Treatment-Typical Example Inhalable Dust – Personal sampling on a random schedule over 16 weeks. 5.5 6.8 214 10. 4.2 33 11.2 38 1.4 4.4 22 22 Total = 20 samples 176 13 13 1.4 26 9.7 43 2.3 40 Sequential Plot of Data 177 Log Probability Plot Logprobability Plot and Least-Squares Best-Fit Line 99% 98% 95% 90% 84% 75% 50% 25% 16% 10% 5% 2% 1% 0 1 10 Concentration 178 100 1000 Typical Example - Descriptive Statistics (LogNorm 2 with ES of 10mg/m3) • • • • • • GM GSD MVUE (estimate of mean) Lands 95% UCL UTL (95%,95%) Exceedance Fraction 95%UCL = 13.9 mg/m3 = 3.7 = 30.7 mg/m3 = 82.1 mg/m3 = 326 mg/m3 = 73.2 % 95% confidence that 95% exposures < 326 mg/m3 95 % confidence that exposures > ES 73.2% of the time 179 BHP Billiton (Chronic effects) • 95 % UCL of MVUE < 0.5 ES (Acceptable) • 95% UCL of MVUE >0.5 but <ES (ALARP) • 95% UCL of MVUE > ES (Unacceptable) 180 BHP Billiton (Acute effects) 95% Upper Tolerance Limit < ES Note=Only where warning properties are adequate and olfactory fatigue is not a problem 181 Other Approaches • RioTinto – Prefer the use of 95% UCL of MVUE • South African mining industry must supply 90 % ile and GM to check for correct banding • Alcoa and Merck Inc No more than 5% of exposures to exceed ES (95% ile) 182 Other Approaches • AIHA suggests using UTL < ES (considered good statistic for comparison to ES but very conservative) 183 Using Data to Drive Improvement • Need accessible database to store information • Graphical presentations to management have best effect • Useful to measure effectiveness of controls overtime • Useful to dispel myths 184 Data Presentation Exposure to Kryptonite 1 0.9 0.8 Unacceptable 0.7 mg/m3 0.6 0.5 0.4 ALARP 0.3 Acceptable 0.2 0.1 0 Transport 185 Gen Hand Maintenance Management Surface Mining Drilling What can companies do? • Inspect workplaces for potential health hazards • Seek advice from occupational hygienists to evaluate those hazards • Introduce appropriate control strategies • Ensure any control strategies are maintained 186 What are the benefits ? • Healthy & happy workforce – Evidence to show this leads to increased productivity • Lower compensation payments – It is illogical to harm people and then compensate them for their suffering. Fix the problem so no one gets hurt • Reduced corporate pressure – Always a good outcome 187 A point to remember In many cases it is simpler and cheaper to fix the problem rather than conduct a sampling programme! 188 bdavies@uow.edu.au 189