Objective: Provide information necessary to relate customer

advertisement

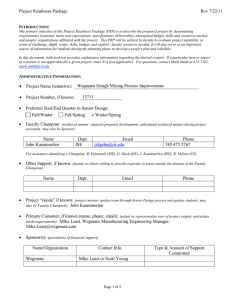

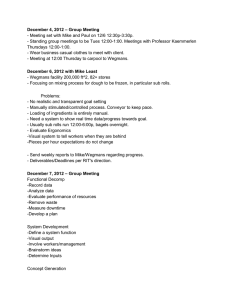

Project Readiness Package Rev 7/22/11 INTRODUCTION: The primary objective of this Project Readiness Package (PRP) is to describe the proposed project by documenting requirements (customer needs and expectations, specifications, deliverables, anticipated budget, skills and resources needed, and people/ organizations affiliated with the project. This PRP will be utilized by faculty to evaluate project suitability in terms of challenge, depth, scope, skills, budget, and student / faculty resources needed. It will also serve as an important source of information for students during the planning phase to develop a project plan and schedule. In this document, italicized text provides explanatory information regarding the desired content. If a particular item or aspect of a section is not applicable for a given project, enter N/A (not applicable). For questions, contact Mark Smith at 475-7102, mark.smith@rit.edu. ADMINISTRATIVE INFORMATION: Project Name (tentative): Project Number, if known: Preferred Start/End Semester in Senior Design: Fall/Spring Spring/Fall Faculty Champion: (technical mentor: supports proposal development, anticipated technical mentor during project Frozen Cookie Capacity Increase P14712 execution; may also be Sponsor) Name John Kaemmerlen Dept. ISE Email jxkpdm@rit.edu Phone 475-2767 For assistance identifying a Champion: B. Debartolo (ME), G. Slack (EE), J. Kaemmerlen (ISE), R. Melton (CE) Other Support, if known: (faculty or others willing to provide expertise in areas outside the domain of the Faculty Champion) Name Dept. Email Phone Project “Guide” if known: (project mentor: guides team through Senior Design process and grades students; may also be Faculty Champion) John Kaemmerlen Primary Customer, if known (name, phone, email): (actual or representative user of project output; articulates needs/requirements) Mike Least (Mike.least@wegmans.com) Sponsor(s): (provider(s) of financial support) Name/Organization Wegmans Contact Info. Mike Least and Scott Young Page 1 of 5 Type & Amount of Support Committed Project Readiness Package Rev 7/22/11 PROJECT OVERVIEW: 2-3 paragraphs that provide a general description of the project – background, motivation, customers, problem you’re trying to solve, project objectives. In the processing of cookie dough for frozen cookies, there are a series of steps. Two of the steps are mixing the dough, and dividing the dough. The challenge is that cookie dough can be divided faster than it can be fixed. So this is a common assembly line problem where there is an identifiable bottleneck, and there is another resource that is underutilized, resulting in lost productivity. This less than optimal production situation results in staffing challenges, the use of overtime (especially prior to holidays when cookie demand increases), and an unevenness to the operation which may cause some team member frustration that could be reduced by making the process run more smoothly and consistently. The students need to start by characterizing the current state. How does the process run today? How do the differences in times to complete process steps manifest themselves – waiting time? Inventory? Other forms of waste? Does the way the process runs, and the interface of the 2 steps, look the same every day, or is there variability? Assuming there is variability, what is its root cause? Can the variability be controlled or reduced? How much of the variability is caused by the way the process is run, vs. outside factors (such as demand variability)? Can product families be defined for different types of cookies, and the proper time values linked to them? Is allocating 4 hours per day to run frozen cookies the best method to schedule them? Is there a time offset between mixing and dividing? Is it optimal? Should it differ by product type? Etc. The students should then define the future state – how the line should be scheduled and run, how the process times can be brought more into balance, how much flexibility is needed in the scheduling, how the need for this flexibility can be recognized, how to reduce the need for overtime, how to monitor performance vs. plan and adjust the process flow as needed, how to balance running frozen cookies and other products through the same work centers, how to sustain the new system design once the students complete the project and leave. DETAILED PROJECT DESCRIPTION: The goal of this section is provide enough detail for faculty to assess whether the proposed project scope and required skills are appropriate for 5th year engineering students working over two quarters. The sequence of the steps listed below may depend on your project, and the process is usually iterative, so feel free to customize. Emphasis is on the “whats” (qualitative and quantitative), not the “hows” (solutions), except for the section on “potential concepts,” which is necessary to assess the appropriateness of required skills and project scope. Not all of the information in this section may be shared with students. (Attach extra documentation as needed). Customer Needs and Objectives: Comprehensive list of what the customer/user wants or needs to be able to do in the “voice of the customer,” not in terms of how it might be done; desired attributes of the solution. Customer needs include: o Documented time values for the process steps, characterized as needed by product type or other process specifics o Description of the current state, in terms of its consistency vs. variability day to day o Tools that will help the area run more smoothly and efficiently, such as visual controls, schedules, standard work, etc. o Better balance of process times for mixing and dividing relative to each other o No adverse consequences in terms of food safety risks o No negative ergonomic impacts (e.g. making people work harder, or creating injury risks) o Consistency of use of the tools across crews and shifts o Recommendations regarding how to sustain the use of the processes, the time values, the scheduling methods, etc., after the students complete the project and depart o Documentation that enables effective training of people that come in new to this work center Page 2 of 5 Project Readiness Package Rev 7/22/11 o Interact with Wegmans engineering, maintenance, and operations personnel early and continuously during the design and testing phases to insure the design and implementation approaches chosen are agreeable to the key stakeholders o During MSD II, test and prototype as much of the new design as possible and practical, including soliciting team member and management feedback o Deliver a bottom line business benefit, such as reducing the overtime needed in weeks prior to peak demand by ___ %, as a result of better designed, planned, and executed processes in this work center o Increase the production capacity per day in this work center by ___ hours or ___ % Functional Decomposition: Functions and sub-functions (verb-noun pairs) that are associated with a system/solution that will satisfy customer needs and objectives. Focus on “what” has to be achieved and not on “how”it is to be achieved – decompose the system only as far as the (sub) functions are solution independent. This can be a simple function list or a diagram (functional diagram, FAST (why-how) diagram, function tree). The function at a systems level deals with a management process for the relationship of the 2 process steps that works effectively. The students need to have a system that captures functions such as document work tasks, characterize work tasks, assign time values to work tasks, schedule team members each day, insure use of documentation in training, insure use of documentation in executing the work, enable monitoring of performance to schedule, enable corrective action if team is behind schedule, enable effective real time communication of plan vs. actual, etc. Potential Concepts: Generate a short list of potential concepts (solutions) to realize the system and associated functions. This may involve benchmarking or reverse engineering of existing solutions. For each concept and its associated function(s), generate a list of key tasks or skills needed to design and realize the function(s), and identify which disciplines (ME, EE, CE, ISE, …) are likely to be involved in the design and realization of the function(s). See the “PRP_Checklist” document for a list of student skills by department. Potential concepts, skills, and tasks should not be shared with students. . The use of lean process improvement tools; use of excel or simulation as a scheduling tool; use of motivational tools; comparing visual scheduling vs. computer based; use of visual tools to track plan vs. actual work progress. Specifications (or Engineering/Functional Requirements): Translates “voice of the customer” into “voice of the engineer.” Specifications describe what the system should (shall) do in language that has engineering formality. Specifications are quantitative and measureable because they must be testable/ verifiable, so they consist of a metric (dimension with units) and a value. We recommend utilizing the aforementioned functional decomposition to identify specifications at the function/ sub-function levels. Target values are adequate at this point – final values will likely be set after students develop concepts and make tradeoffs on the basis of chosen concepts. Consider the following types of specifications:geometry (dimensions, space), kinematics (type & direction of motion), forces, material, signals, safety, ergonomics (comfort, human interface issues), quality, production (waste, factory limitations), assembly, transport/packaging, operations (environmental/noise), maintenance, regulatory (UL, IEEE, FDA, FCC, RIT). The primary spec, but not the only spec, is the gain in productivity – 20 minutes a day, 40 minutes a day, …? Another key spec is the overtime reduction issue. There are also the need for specs re: sanitation practices, food quality, ergonomic impacts. Constraints: External factors that, in some way, limit the selection of solution alternatives. They are usually imposed on the design and are not directly related to the functional objectives of the system but apply across the system (eg. cost and schedule constraints). Constraints are often included in the specifications list but they often violate the abstractness property by specifying “how”. Use “tools” that are easily accessible to Wegmans people, such as Excel. In documenting work, use any forms or templates Wegmans has for documenting standard work. Also, the students will need to make themselves available when the work is occurring at Wegmans, which is largely in the 6 to 10 pm timeframe. Project Deliverables: Expected output, what will be “delivered” – be as specific and thorough as possible. Documentation as described above; a scheduling tool; a table of time values for tasks, properly Page 3 of 5 Project Readiness Package Rev 7/22/11 characterized by conditions, products, process specifics, etc.; improvement suggestions; pilot or full scale implementation of changes Budget Estimate: Major cost items anticipated. This project is not resulting in any build of devices, so the budget is essentially zero. Intellectual Property (IP) considerations: Describe any IP concerns or limitations associated with the project. Is there patent potential? Will confidentiality of any data or information be required? None anticipated. The students should not post in Edge, or otherwise share, any product cost or schedule information they are given access to, nor any proprietary process information. Other Information: Describe potential benefits and liabilities, known project risks, etc. Continuation Project Information, if appropriate: Include prior project(s) information, and how prior project(s) relate to the proposed project. STUDENT STAFFING: Skills Checklist: Complete the “PRP_Checklist” document and include with your submission. Anticipated Staffing Levels by Discipline: Discipline How Many? Anticipated Skills Needed (concise descriptions) EE ME CE 4 ISE Process improvement, production control, time study, standard work development and documentation, work methods design, kaizen, regression, ergonomics Other OTHER RESOURCES ANTICIPATED: Describe resources needed to support successful development, implementation, and utilization of the project. This could include specific faculty expertise, laboratory space and equipment, outside services, customer facilities, etc. Indicate if resources are available, to your knowledge. Category Description Faculty Page 4 of 5 Resource Available? Project Readiness Package Rev 7/22/11 Environment Equipment Materials Other Prepared by: John Kaemmerlen Date: Page 5 of 5 8/15/13