Minutes revised 5_3

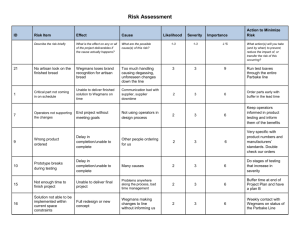

advertisement

December 4, 2012 – Group Meeting - Meeting set with Mike and Paul on 12/6 12:30p-3:30p. - Standing group meetings to be Tues 12:00-1:00. Meetings with Professor Kaemmerlen Thursdays 12:00-1:00. - Wear business casual clothes to meet with client. - Meeting at 12:00 Thursday to carpool to Wegmans. December 6, 2012 with Mike Least - Wegmans facility 200,000 ft^2, 82+ stores - Focusing on mixing process for dough to be frozen, in particular sub rolls. Problems: - No realistic and transparent goal setting - Manually stimulated/controlled process. Conveyor to keep pace. - Loading of ingredients is entirely manual. - Need a system to show real time data/progress towards goal. - Usually sub rolls run 12:00-6:00p, bagels overnight. - Evaluate Ergonomics -Visual system to tell workers when they are behind -Pieces per hour expectations do not change - Send weekly reports to Mike/Wegmans regarding progress. - Deliverables/Deadlines per RIT's direction. December 7, 2012 – Group Meeting Functional Decomp -Record data -Analyze data -Evaluate performance of resources -Remove waste -Measure downtime -Develop a plan System Development -Define a system function -Visual output -Involve workers/management -Brainstorm ideas -Determine Inputs Concept Generation -Collect live data -Signal for when falling behind Ideas for collecting data -Manual -Electronic -Photo cell -Weight -Total cuts Presenting Data -Takt time board -Graph -Green light/red light -Digital upcount Ideas for Signals -Lights (andon) -Sounds (alarm) -Vibration -Reward system -Smell December 7, 2012 with Professor Kaemmerlen -Learn process (4-6 hours) -Pairs of 2 -Identify waste -Ask no questions first ---> then get involved with workers -Simulation model? Questions for floor employees -Do you ever ask for help? -Do you know when you are behind? -Do you know what your throughput should be? -How do you feel about working overtime? -Does management ever let you know if the previous day was good/bad? Identify bottleneck (person or machine?) December 11, 2012 – Group Meeting Review of -Fishbone -Code of Ethics -Gnatt Chart -Time study sheets -Needs & specs -Functional decomp -Pugh charts -Risk assessment Set up meeting with Mike for Wednesday December 12, 2012 with Mike Least - Starting to redefine problem/project - Need to collect several objective options for systems design review - Process improvement - Standardization - Visual Aid - Better documentation - Matt to be added to scheduler emails - Updates every few days - Data collection 12/14-12/21 December 13, 2012 with Professor Kaemmerlen -Employees on floor making changes with anyone knowing -Machine paced -Give 5 suggestions ---> ask Wegmans to pick -If you were training someone how would you do it? Going to Wegmans tomorrow Lost time coming from the pause when the cutter stops and the next batch getting put in hopper → no timing calculated -Dough getting lost (falling out of the machine) and getting added to the next mix Define → Measure → Analyze → Improve → Control December 14, 2012 – Group Meeting Team went to the production floor to make a plan of how to collect data for the following week Made observations and a “mock” time study Confirmed observation schedule with Mike Note from Mike: Just something I was thinking about……..at 60 cuts per minute, the deli sub should have been taking 16 minutes, but you guys were observing 19 to 20 minutes. What was the divider doing during that time (rhetorical question). If the divider was not starved at any point during that 19 minutes, then you might be directed to look at the divider or downstream. If the divider was starved for 3 or 4 minutes, then it does direct you to the mixing. Keep this in mind as you observe. December 18th, 2012 - Group Meeting Review of gnatt, risk assessment, pugh, functional decomposition, and needs and specs Going to Wegmans after this meeting to get security badges Plan for the week: collect data and compile over break Wear a watch to Wegmans when collecting data December 20th, 2012 – Guide Meeting Deliverables Observations we don’t understand Try to understand the data: means, variability etc. Cutting machine sets the pace Another way to signal to QA that a new batch is starting that doesn’t take a minute of downtime? Is this particular QA process necessary? Systems Design Review will be Friday week 5 Add to fishbone o Methods (tools, fixtures, signals, availability of help) o Metrics (expectations, performance, status, decision making) o Give them three “big hitters” Ask Mike what files can and cannot go on Edge website (be made public) Our function: Mix quality dough using specs January 6th, 2013 – Group Meeting Complied slideshow January 8th, 2013 – Group Meeting Made necessary changes to slideshow Assigned slides to be presented January 10th, 2013 – Guide Meeting Walk-though of Systems Design review Presentation Create talking points on slides What to expect tomorrow (Wegmans culture) Presentation preparation January 11th, 2013 – Systems Design Review Average dough ball weight should be no less for given goal, usually aim for slightly higher Data holds the most meaning in “minutes per batch” QA would change their methods if a better solution was proposed Surprised about employees changing the cut speed on their own (90 cuts per minute has been in place for about a year) QA delay gives time for printer change-over in mezzanine Group will work with Russ to identify tasks that are necessary and what can be cut from the mezzanine Reduce the 12% loss of time due to the current QA process Going forward: Make a list of tasks done what can we eliminate January 15th, 2013 – Group Meeting Meeting Russ at Wegmans tomorrow at 12 Everyone send their documents to Nick in image file with description or whole file if too large/not picture worthy by tomorrow evening Update files that need to be updated by tomorrow evening Get Edge website in order by Thursday Observing activities done in the mezzanine during QA delay time tomorrow to decide what if any can be eliminated Accumulating conveyor idea to create more time for those workers in mezzanine Green light system for QA? After big hopper dumps first of new batch into the small hopper timer set to green light so that green light will go off after waiting a certain time which will indicate to the QA workers that they need to pull a loaf Priorities 1. Reduce QA delay – design new more efficient process 2. Standardize QA process a. Create signal/process to tell QA when to take sample b. If issue is found +/- drop times to recall c. Documentation January 17th, 2013 – Guide Meeting No loss of yield without the QA delay Notes on Rubric: Specs o o o o No specs list (voice of the engineer) 3/5 currently for specs Safety requirements – how? Batch time goals – how? Something measureable for each need what the target is and if we have hit that goal Norms and Values o Full points Project plan should be on planning and execution page Concept development o Chart w/ pictures o Sketch Systems architecture o Remove “improve visability” o Replace with function “monitor performance vs plan in real time” o Needs improvements Risk Assessment o Actions to minimize risk need to be more specific Too much wiki text should be more attachments things are too difficult to find Should bring plan to guide meetings as agenda Going forward: Meet with Mike and QA dept. New roll bagging method Ask about schedule on the floor they record times that dough is dumped so they do know yield for the day? January 18th, 2013 – Meeting with Mike Least **Let Mike know any time we come on site Figure out time allotment for jobs on mezzanine Is there personnel to help upstairs from downstairs How long can the line accumulate before they need help? Can one packer cover that gap? 12-14 hours a week runs sweets on one belt No divider when they aren’t running sweets so opportunities for help are available If continuous batches you do not need different batch identification tags Going Forward: -Weight/batch system design -Clean up loose ends in the mezzanine For that area: 7 people per hour to operate the whole area Mixer Belt operator Freezer belt operator Packer x2 Breaker upstairs Breaker downstairs January 21st, 2013 – Group Meeting Need: System Inputs, System Design, Green light for QA Clayton – Simulation Becca – Inputs/Outputs & figure out QA light delay time (worst case) Nick – Design & BOM Matt – Mezzanine January 25th, 2013 – Group Meeting Redo specs Document new process plan Edge updates Improvement needs % loss chart Excel spreadsheets from time study Updated risk analysis Systems architecture ARENA simulation Functional decomp. January 29th, 2013 – Group Meeting Review findings from Saturday Finish simulation – Clay Inputs & Outputs into a table – Becca Design of system – Nick Start powerpoint – Matt Test plan – Becca BOM – Nick Plan to meet specs – Matt January 31st, 2013 – Guide Meeting Detailed design review should be Friday week 9 contact Mike Least Week 11 guide meetings What’s missing? Design review goals o Specific next step, obtain feedback Project changes Evolution o Elaborate on 1st bullet Possible performance improvements Duplicate simulation slide to show changes How do we envision to execute this plan? o Mezzanine first? o All at same time? Test Plan: What are we going to test When? How many times? How? February 1st, 2013 – Group Meeting Made more progress on Detailed design review slides Specs Test Plan Simulation Risk assessment Completed peer review February 7th, 2013 – Guide Meeting -Downtime timer -QA indicator -Weight batch system Review of Detailed Design Review Slides o Project Evolution One long sentence o Specs Mention key ones we are trying to hit o Yield = process quality not productivity o Process Simulation Change slide titles so same title isn’t 4 in a row o Downtime Documentation Create a list so operator can just check How much of a sample of data is good enough? February 8th, 2013 – Detailed Design Review To pull based on a time bracket is not a problem for the QA department % Utilization of mezzanine employees? o Change the simulation to show this o Include different products in the simulation (bagels vs subs) New box maker holds less boxes o More frequent changeover with less time per changeover Actual schedule of breaker and when they can SQF Capacity of bagel line if they slowed down line would help with packing and also gap between mixes o Complaints from stores that bagel boxes have been too light Could this be due to the speed of the employees trying to keep up? Justification for an additional person? o Run rate increases o Reduction in OT o Part timer is an option o Only during bagel production? Remix may lower due to consistent product more accurate dough ball sizes Signal to load dough? o Can’t load new dough until previous exits large hopper? o PLC into photo cell so elevator won’t work if photo cell hasn’t given signal Plan to cover all conditions ***For list of action items and actions taken see Project Review Deliverables February 12th, 2013 – Group Meeting -Deliverables due check for Thursday -Project Plan -Schedule week 11 review -Tuesday 12-6 everyone is free Matt new PPT of DDR ClaySimulation updates BeccaEmployee matrix Downtime timer sheet February 14th, 2013 – Guide Meeting Waiting for Mike response on DDR currently out of office maybe contact Jamie Use simulation as a tool to show employees they are capable of working with no QA delay? Information from Mike on scheduling and breaks What do we want from Wegmans starting day 1 MSDII? Get with buyer from Wegmans give them a BOM o Start looking up products o Meet with Dave? February 15th, 2013 – Meeting at Wegmans with Jamie and Dave Need: LED display timer Ultrasound sensor Indicator lights (2) Beam break sensor All the rest is logic Wegmans will order parts February 19th, 2013 – Week 11 Review with Guide -Keep auditing Wegmans with project activity -Talk to Russ about what we will need him to do as far as communication with employees Russ communicates with one of us present in case of questions Risk assessment pictures are fuzzy o Maybe change pictures to links May need more test time than you think o Popular MSDII problem Went over rubric and where team stood in each category and where there was room for improvement Add actions or comment to refer to other pages in minutes March 5th, 2013 – Group Meeting Contact Wegmans – find out status of parts Group meetings will be 12:30-1:30pm on Thursdays Guide meetings will be 10-11am on Tuesdays Trying to meet Wegmans Thursday at 2ish March 7th, 2013 – Meeting at Wegmans with Mike Requested employee scheduling info Instead of ultrasonic sensor use photo cell QA light set to light up somewhere in the middle of the batch Need time to run a whole batch (CT) Downtime timer – hook up to cutter of use photo sensor List of problem codes based on machine March 12th, 2013 – Guide Meeting Go over meeting with Mike Bagels out of scope Wegmans getting quotes from Atlas now Add downtimes to simulation? o May not have enough data Additional data collection possibilities? Can simulation show slower belt speed can benefit bagel line CT – dough drops to last dough ball reaches QA Get prepared for installation and testing – set up meeting with Russ to prepare employees for changes Set goals for end of week 3 end of week 6 and end of week 9 Poster template in MyCourses fill it out in PPT send to Chris March 15th, 2013 – Group Meeting Employee schedule matrix created Downtime report spreadsheet created Test plan Employee responsibility…card? poster? Verbal? Update project plan Edge updates We have a meeting with Russ Monday at noon Go over downtime sheet have him train employees on it Ask if we can get feedback from employees about responsibilities Will need to prepare mezzanine employees for no gap Divider should never be running empty March 18th, 2013 – Meeting at Wegmans with Russ QA documentation strategy discussed Russ – request for data collection column for the number of belts running (1 or 2) Russ – happy with the form and will present to employees at next team meeting Russ will let us know when the form is activated so we can assist with implementation process Russ also likes the reports the spreadsheets no further recommendations Team follow up with Mike for status update Russ will create process for the team to pick up forms weekly to generate reports March 19th, 2013 – Guide Meeting Go simulate the equipment “test” it to prove that it works 2 week approval process Mike looking into getting competitive quote Fridays would be ideal so we can be there for a longer period Ask if there is anything that we can do to expedite the approval process Test plan add all specs maybe at the bottom mentioning how they were fulfilled Get a set time that we can go in and simulate this March 21st, 2013 – Group Meeting Develop test plan for non mechanical testing Set up meeting with Wegmans Add to project plan March 26th, 2013 – Guide Meeting Spiral downtime recording doc – looks okay Discussion on plan for Wegmans testing tomorrow Maybe play next week’s meeting by ear – if nothing new may not have to meet Kaemmerlen possibly come Wednesday night to observe process – talk to Mike about how we can make this happen March 26th, 2013 – Phone Conference with Mike, Paul & Russ Walk through test plan o Step 2: team member communicates to QA if next dough goes up before that that would reset the timer Document remix weight for test doughs What will the QA pull time be o 10 minutes and 30 seconds Is it possible to let Kaemmerlen in? Friday or Monday conference call to review how it went? April 5th, 2013 – Group Meeting Work on report Work on poster Update minutes Team assessments/Peer review Plan for next Friday to collect data for 20 batches April 9th, 2013 – Guide Meeting Ask Mike if anything else within project domain that we can do (layout, flow, storage) Previous testing done at the best case scenario Test gives Wegmans data to discuss Next testing this Friday Deliverables could be a list of observations Instillation – end of week 10 What does a minute of downtime cost? (idle labor, loss production, machine costs, etc) More product out for the same labor hours Batch time went from 15.4 to 13.1 min Capture findings in a “test plan report” Send paper draft to Kaemmerlen Test results is biggest part of MSD II Any time someone on the floor is having to rely on memory is an opportunity for improvement April 16th, 2013 – Guide Meeting Test plan file and schedule matrix file not opening properly on edge New box maker hopefully installed next week Testing numbers are good Project plan waiting for time from Wegmans to come do a third testing What is “key” to these changes becoming normal? Q for Mike “Has there been an impact on Saturday OT” – won’t know until its implemented full time What is the lead time for the parts? Change the “time reduced” on the poster from a time to a percentage – easier to comprehend for people reading the poster 75% of the paper due Friday of week 8 Get test results in edge – can be just a snapshot of some data points End of week 8 for poster Week 10 review presentation – schedule for Friday (approx 35 min including Q&A) April 16th, 2013 – Phone Conference w/ Mike Paul & Russ Mezzanine employees reported to Russ that they were feeling fatigued Find % utilization of upstairs employees? What is their potential vs. what they are being asked to do Test again for wheat deli subs Friday 8am-11am April 23rd, 2013 – Guide Meeting Ergonomist coming in on Friday to assess mezzanine Talk to M. Marshall about ergo stuff before hand? The more studies we can quote the better Try to get same amount of remix into each batch? Is this likely? 3 people on mezzanine at night 2 people during the day Mike says the mezzanine goes from lifting __ lbs/min to __lbs/min with the changes Paper exchange Friday at 1 Downtime timer cannot be hooked up to cutter? It runs empty regardless, but shouldn’t because it’s bad for the blades Breaker beam? April 30th, 2013 – Guide Meeting Friday went to the mezzanine with the ergonomist o Waiting on results from that o 3 vs 2 people on different shifts for same requirements/expectations o Twisting and opening of plastic bags got brought up o Lack of standard work – present this as an opportunity in final review Here is what we did differently slide o Under estimate of cost o Delayed narrowing of scope Test plan – should be fine needs to refer to EDGE Specs o Present data and statements o Integrated data set and overall conclusion “two sentence” paragraph of the bottom line – put it on the top of the edge site Functionality and Performance – we are good Paper is due end of week 10 “Operating Principals” one page doc (say to use for a new supervisor) Sketch of the simulation layout in the paper Mezzanine tasks graph add to paper In the presentation – did you learn anything? Team reviews add to the norms and values page