Where It All Started

advertisement

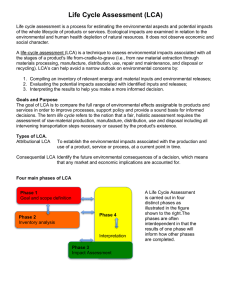

Eleanor Chan WRIT340 (66813) Illumin Assignment Life Cycle Assessment: Bean Counting Energy Intelligently Introduction This is global fact: although the world’s resources are depleting to worrisome levels, global demand for them is skyrocketing, and there are no signs of this trend abating in the decades to come. This leads into the number-one most urgent challenge faced by the world economy: how can they deploy the scarce resources of today more efficiently in order to satisfy an exploding consumer base? Furthermore: in such a way that those resources can still be conserved for the future, in a sustainable manner that will not adversely affect the environment? One way the world is trying to evaluate the feasible solutions to this challenge for everyone everywhere, piece by piece, is by applying Life Cycle Assessment (LCA). LCA is an analytical framework that is all about cataloguing the material inputs and outputs in the production of a product. It is called “life cycle” because the analysis tracks the product’s entire lifetime, from the extraction of raw materials to the recycling/disposal phase. Beginning to end, cradle to grave. In fact, LCA is more commonly referred to as a “cradle-to-grave” analysis to the general public, as the official one-liner definition. This attractive quality of LCA has already prompted governments to adopt it on a national scale, albeit in environmentally conscious countries—a list which excludes the United States. The most notable and prominent application is the European Union’s Ecolabel, a program launched in 1991 to analyze as many products as possible through the LCA lens that has gained considerable traction in Europe [1]. The Rainforest Alliance and Japan’s Ecomark label do not use LCA, but they still assess the environmental impacts of their products because of the need to seek and validate the most sustainable practice possible. 2 More than anything else, LCA is a kind of mindset, a kind of thinking. It is an exhaustive, comprehensive view of a product’s development and frankly, an unnatural way of thinking for people. As humans, we tend to think narrowly and immediately because that is how our brains have naturally evolved for convenience’s sake. However, LCA demands both wide breadth and deep investigation if we ever want to formulate a realistic picture of our products’ environmental impact. Left up to human convenience, we will just willfully ignore the problem for generations to come until it is too late. 3 The Methodology in Question LCA was developed throughout the 1970s before becoming finalized in 1992, when the first complete presentation of the methodology was published in the Environmental Impact Assessment Review. The LCA procedure is now well-established (aside from minor tweaks now and then) and is public information for anyone to consult on the Environmental Protection Agency’s website [5]. The LCA framework always comprises four distinct phases: Figure 1: General LCA diagram [7]. In goal and scope definition, scope is key. An LCA that is too broad will practically be impossible to fulfill according to the guidelines set forth by the ISO. The LCA will usually analyze a discrete, separable component of that product—for example, if you were to conduct an 4 LCA of an office chair, you might only analyze the metal frame. That alone would be a formidable task in the later stages, believe it or not. Anything beyond the boundaries of that metal system, such as the cushioning, would not be considered. LCAs are typically this small in scale unless the product is extremely simple and basic. In inventory analysis, every production process has multiple steps and stages, each with its own subset of inputs and outputs. Here is where those inputs and outputs are inventoried. Even low-concentration outputs are listed, particularly if a trace amount of toxin can bring about lethal harm once released into the environment. This step tracks where each material travels and ultimately ends up. If some of the outputs—like solid waste—in the inventory analysis have detrimental effect once released in the environment, impact assessment is the step where the author of the LCA would make this explicit. If one or several major stages are particularly polluting or energyintensive, they are explicated and described in more detail in the interpretation section. In quick summary, then, the four LCA phases are: Goal and Scope Definition: Defining goals, system boundaries, and fundamental unit. Inventory Analysis: Documenting resources, energy used, solid wastes, and air and waterborne emissions for every stage of the cycle. Impact Assessment of environmental releases, such as toxicity to humans, climate change, acidification of water bodies, etc. Interpretation: Description of one or several major stages that are particularly polluting or energy-intensive. 5 The first two steps (Goal and Scope Definition, Inventory Analysis) are the most timeconsuming, exhausting portions of LCA. The latter two (Impact Assessment, Interpretation) are mostly a summarization of results, translating the numbers into more tangible conclusions that will be more digestible for the public (e.g. “Every time a chair is made, five milligrams of Toxin A leeches into the waste water”). As seen in Figure 1, these four phases are not strictly sequential; each phase will necessarily inform the other, especially while the LCA is being conducted. Something discovered in Interpretation might mean refining the Goal and Scope, for example. The Need for LCA LCA budded in the 1960s as a vague response to increasing environmental awareness. The 1970s augmented the need, wherein petroleum shortages sunk most of the industrial world into an energy crisis. Though the 2010s do not face an energy crisis, it is imminent as global demand for resources will keep growing while supply continues to dwindle. The need to track more exact numbers for resoruce consumption drives the social need for LCA. More technically, there is good reason why LCA is defined cradle-to-grave, with a strict requirement on system boundaries: the lack of them can lead to fraudulent advertising. Organic and environmentally-conscious products like to promote environmental friendliness in their advertising, perhaps by boasting that they save x gallons of water compared to the leading competition, or that the carbon footprint in transporting the product from source to destination expelled only y tons of CO2. These labels can be deceptive! These are ambiguous claims that, by themselves, cannot prove true environmental friendliness. 6 First, the water. If you were to analyze the product in an LCA framework, one would have to explicitly state which stage(s) that water was saved, be it during raw material extraction, manufacturing, or product use. Suppose water was saved during the manufacturing process. This is a nice accomplishment. But, if the manufacturing changed the makeup of the product such that more water becomes necessary to ultimately dispose of or recycle the product, it is very possible that there was actually no water saved once the cradle-to-grave breadth of LCA is applied. This is in fact the case for dishwashing detergent [8]. Because a massive amount of phosphates from a variety of sources ends up in lakes, rivers, and drinking supplies, laws were passed in several states to restrict the amount of phosphates in products, starting with dishwashing detergent. (They are actually not the primary contributor to the phosphate releases, but environmentalists insisted that any small change was an improvement for the environment.) Companies developed and released these “greener” detergents to the consumer market, which were warmly welcomed until consumers discovered that the detergents were flat-out incompetent for cleaning dishes. In fact, they often left a white film on the cleaned dishes, making them dirtier than before. It turns out that phosphates are the primary ingredient that gives detergent its cleaning ability. Formerly comprising 8% of the fluid, they can be as low as 0.7% in “green” detergents. Homeowners often had to wash the dishes a second time to dispose of the film. While the “green” detergents may have slightly decreased phosphate leakage into water sources, having to consume twice the amount of water to achieve the same clean results does not spell out a net benefit for the environment. Second, the tonnage of CO2. CO2 is the poster-child greenhouse gas where climate change is concerned, but the public sphere tends to think of CO2 as the only culprit at hand. There are in 7 fact multiple greenhouse gases, and because CO2 happens to be the best known one, it became the basis for defining a common metric to evaluate the GWP (Global Warming Potential) of different gases. This unit is expressed as tons of CO2-equivalent. To demonstrate, one ton of methane is equal to 21 tons of CO2-equivalent, meaning that methane has 21 times the destructive power as CO2 in effecting climate change [4]. (Consider that methane only remains in the atmosphere for 14 years as opposed to CO2’s 100 years. It compensates heavily for its short-livedness with atmospheric damage!) Thus, declaring a transportation carbon footprint of y tons of CO2 could technically be right—but if a product neglects to mention the emission of other greenhouse gases, and claims to be environmentally friendly, then they are spitting outright lies. “Carbon footprint” evaluations are incomplete and inaccurate until all species are accounted for and converted into CO2equivalents. These are only two of infinitely possible methods of false advertising that the average person would be unable to detect. Only the discerning eye, then, can pick out such sinister subtleties. They are covert, and it takes an exacting eye, an exacting methodology, to avoid this kind of convenient make-believe. Because arbitrary boundaries differ from product to product, to person to person, there needs to be a standardized way to define all of this. This is why LCA exists, and why they say to start with the raw materials. This is the only fair way to categorize the full material inputs and outputs involved in producing a product. Ending the LCA at recycling/disposal is another way of ensuring a fair assessment. Some products are energy-intensive or polluting during the manufacturing stage, and it is tempting to emphasize this and villainize the product by cutting off the analysis at that point. Opponents to solar panels build their cases this way, arguing that manufacturing solar panels consumes more 8 energy than it can generate on a daily basis, and therefore they call it an unfeasible alternative energy source. Meanwhile, numerous LCA studies on solar panel systems demonstrate the importance of fixing product use in the analysis. Though solar panels do require many raw materials and heavy energy inputs, they recuperate that initial energy cost in about four years, allowing it to produce energy, emission-free, for the remainder of its 20-year lifetime [6]. This upholds the prime appeal of solar panels and counteracts arguments like the above. Limitations Metrics like these are why LCA is often used as a supporting argument for the viability of alternate energy sources. In most cases, though, alternative energy sources are difficult to disseminate because of the high financial costs required (investment, maintenance, etc.). Money is a crucial part of any decision-making process, but completely omitted from LCA, because its developers wanted to leave money out of the consideration, and to emphasize the alreadyintricate analysis on the energy and environmental impacts. Social justice considerations are also beginning to feature heavily in the decision-making process, but is another component not accounted for in LCA. For social justice, in fact, there is a separate social LCA framework being developed, but still in its stages of infancy and not nearly to the point of being as well-defined as environmental LCA. Social justice cannot be translated to numbers as easily as outputs of CO2 or gallons of water, which remains the largest hurdle in its own framework development. The subjectivity makes social LCA a struggle to define. 9 Researchers are attempting to address these limitations of LCA by creating an integrated decision support tool that would feature environmental LCA, social LCA, and financial analysis together [3]. In synthesis, they would form a so-called “triple bottom line” of environmental, social, and economic considerations that would synthesize an optimum solution for decisionmakers in the future, and allow them to tweak the tool to their situation as they deem fit. LCA maintains a low profile in the public conscience, though they are conducted regularly in the scientific community and internally in companies. LCAs, though, are conducted primarily in research and only on existing systems. They are time-consuming and if you want a complete report at all, the scope has to be narrow enough for that to be accomplishable: that, by default, means you will never gain anything near the full understanding of a product’s full environmental impact prior to the product’s full development. They can never be used as a preventive tool. While there are computer simulation tools for LCA, the process is no less exhausting. Without exact information about the product or the company producing it, these LCAs can only provide estimates at best since different companies have different procedures for proessing the same raw material, even if they try to meet the same industrial standard. Internally-conducted LCAs would therefore be the most accurate, but also the most private, since they would divulge company secrets. Where It All Started Scientists engendered the idea of LCA in the 1960s, but the official progenitor of the practiced LCA is actually a rather famous one—surely, you have consumed a product from The Coca-Cola Company, and on multiple occasions. The term LCA was not coined until 1990; until 10 then, these studies were called Resource and Environmental Profile Analyses (REPA). In 1969, the Coca-Cola Company commissioned one of these REPAs in order to answer two questions [9]. First: “Is it feasible to produce our own beverage containers?” Until then, they had contracted outside companies to provide them with the classic glass bottles. Producing in-house would help reduce these costs, but beyond that, Coca-Cola Co. was curious about the net energy cost of their current practice, which included importing the raw materials as well the dissemination of the finished product. Second: “Should we continue using glass, or is using plastic better?” Considering the use of plastic beverage containers was a radical idea for its time, particularly since even the industry was wary of plastic as “an environmental villain.” Further, glass bottles are refillable, and were collected to be refilled in those times. If plastic is used instead, they would more likely be disposed than refilled. Given these considerations, and the pre-existing industry sentiment against plastic, could plastic beat out glass? 11 Figure 2: The ultimate winner. [2] The Coca-Cola REPA actually even made the company “comfortable” with the switch from glass to plastic, because the report revealed that plastic was not as toxic as they had believed. How much, exactly? Nobody knows—the REPA is trade secret to this day since it contains intimate details on the company’s operations. Would the Coca-Cola Company still choose plastic over glass today, given the global strain on petroleum resources? You hardly need the REPA to know that answer—a cursory glance in the marketplace suffices. In the aftermath of this REPA, hordes of companies followed Coca-Cola’s move, and for years afterward, REPAs analyzed nothing else but beverage containers. You have LCA and Coca-Cola to thank for the ubiquitous soda bottles. 12 It’s All Engineering to Me. LCA involves a whole different way of thinking unfamiliar to the average person, in that we need to define a system and rigorously define the rest of the process with respect to the initial definitions. Everything is possible when considered in its theoretical stages, but the people who make the ideas reality and actualizable are the engineers. In fact, this is why the origins of LCA are traced back to the Coca-Cola Company in 1969 and not to any of the earlier scientists who toyed with the idea: Coca-Cola Co. was the first to practice and apply LCA. To apply scientific principles to the real world is in fact the total job description of an engineer. They are the best equipped to apply this thinking to products because that is how they are trained in science: define a system and surroundings, and describe the inputs and outputs of the system. LCA is the essence of their schooling. Definition of system and surroundings is arbitrary from person to person, but once there are rules for how to set them, those inflexible definitions give great power and insight for the process as a whole. It is a subtlety that LCA hounds upon. Conclusions LCAs have been the tool used by industry to evaluate the environmental impact of their products, starting with Coca-Cola in 1969 (and responsible for the ubiquitous plastic soda bottles) and now being practiced with regularity in the scientific community as well as many companies in industry. Governments have put LCA into practice with the European Union being the most 13 singular example. Many other ecolabels exist (e.g. Japan’s Ecomark, Rainforest Alliance), though without the rigorous basis of LCA. In a world whose resources will only be demanded more and more as the supply dwindles, all countries must determine how to survive in these new conditions. Because of this urgency, it is important to be thorough and encompassing in the way that LCA demands. LCA is not the end-all solution, but a means to approach the issue. It is one of many ways to combat this issue, but it stands powerfully alone as a scientific methodology of the engineers, by the engineers, for the world of engineers and non-engineers alike. 14 Works Cited [1] C. Goldsmith, “EC Sets 'Ecolabel' for Green Products,” NY Times, Dec. 1991. News article discussing the EU’s adoption of the Ecolabel, and its reception in the EU. [2] Coca-Cola. [Online]. Stock image. Available: http://images.monstermarketplace.com/online-market/coca-cola-16-9-oz-plastic-bottle-6pk-500x500.jpg. Stock image of Coca-Cola plastic bottle for a visual point. [3] E. Chan et al, “Solar Powered Charge Stations: LCA Thinking,” KSU, Manhattan, KS, Conf. LCA XII, 2012. LCA conference paper introducing the idea of a synthesized decision tool to determine a triple bottom line consideration: optimization between economic, environmental, and social factors. [4] EPA, “Greenhouse Gas Equivalencies Calculator” [Online]. Available: http://www.epa.gov/cleanenergy/energy-resources/calculator.html Calculates tons of CO2-eq. for various greenhouse gases. [5] EPA, “LCA 101 Document,” EPA. http://www.epa.gov/nrmrl/std/lca/lca.html The documentation for standardized LCA. This is a heavy home of information; trying to add more sources that are already present in this one would be redundant. [6] Good Company, Life-Cycle Environmental Performance of Silicon Solar Panel [online]. Rep. Oregon State Government, Aug. 2008. Available: http://www.oregon.gov/ODOT/HWY/OIPP/docs/solar_panel_lifecycle.pdf?ga=t A study commissioned by the state of Oregon, analyzing the environmental impacts of various solar panels and calculating the energy payback time. 15 [7] Mr3641. Public Domain. [Online]. Available: http://upload.wikimedia.org/wikipedia/en/e/ea/PhasesOfLifeCycleAnalysis.png. July 28, 2012 [date accessed]. Simple graphic adequately illustrating the four phases of LCA. [8] Navarro, Mireya, “Cleaner for the Environment, Not for the Dishes,” NY Times, Sept. 2010. News article discussing the impact of decreasing phosphate levels in dishwashing fluid. [9] R.G. Hunt and W.E. Franklin, “LCA – How it Came About – Personal Reflection on the Origin and Development of LCA in the USA,” Franklin Assoc. Ltd., Prairie Village, KS, Tech. Rep. Int J. LCA 1 (1), 1996. Article that discusses the landmark Coca-Cola REPA, that kicked off LCA development.