4Flexible Displays a.. - Personal web pages for people of Metropolia

advertisement

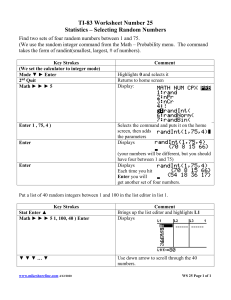

Flexible Displays and E-paper Maxim Dolgobrod Advanced Display and Image Technologies Contents • What are flexible displays • Current status • Development roadmap • Challenges • Market • Main technologies • Application • Future • Conclusion What is a flexible display? Flexible displays are essentially very thin display screens that can be printed onto flexible or stretchable material and then attached to other surfaces or produced in a variety of shapes. 3 Flexible display • Ultimate flexible display is a combination of TFT-LCD and OLED techniques— with advances developed in various fields such as processing, component, and materials. • Display might not be flexible in its application • Core materials: – semiconductor material – insulation material – electrode material – substrate Substrate • substrate is critical to flexible displays development • different types of materials are under investigation, including glass, plastic, polymer films, and metallic foils • must be readily bendable and rollable • must accommodate different types of display technologies at high levels of brightness, contrast ratios, and resolution • must offer low power dissipation • should be able to provide full-color capability to enhance their market acceptability Current status There is a considerable research Most of technologies are still in development and available in form of prototypes The display panel itself is only a small part of the battle. All the ancillary electronics, the power, transistors and circuitry are all things today that are not yet fully flexible at large scales. Industry interest and competition is fierce The Flexible Display Center, at Arizona State University: flexible displays ready for test trials in approximately 3 years. Currently E Ink one of most popular technologies available for commercial use Flexible displays roadmap Source: Displaybank, 'Flexible Display Technology and Market (2007~2017)' report Challenges From traditional rigid substrates to flexible substrate Satisfy the requirements of both substrate and deposited electronics Handle the high processing temperatures encountered when making rigid displays Laminate adhesives that can perform reliably at high temperatures without being affected by stresses Achieving large quantity supply with comparative low cost Flexible displays market - demand forecasts Source: Displaybank, 'Flexible Display Technology and Market (2007~2017)' report History 1970 Electronic paper first developed at Xerox's Palo Alto Research Center 1990 Printing of OLED on flexible substrate discovered 2000 World's first flexible display using electronic ink from E Ink Corporation 2002 Philips finds way to 'paint' LCD screens 2007 First production-ready flexible display manufacturing method developed by FlexiDis, a European-Commission funded technology project 2008 Hewlett-Packard and Arizona State University introduce a prototype of a paper-like, flexible computer display made almost entirely of plastic 11 Main flexible display technologies Flexible LCDs FOLED, Flexible AMOLED E-paper: Electrophoretic, Cholesteric LCDs, Electrowetting Displays (EWD), Electrochromic Displays Interferometric Modulator Technology Flexible LCDs Many display experts believe LCDs are most likely to succeed in large-scale, cost-effective flexible displays Samsung prototyped 5-in. diagonal LCD panel that uses amorphous silicon TFTs. Fujitsu has shown monochrome and color cholesteric LCD, flexible, 3.8in. diagonal panel. Pixel-isolated LCDs for enhancing a flexible LCD's mechanical stability Flexible LCDs 15 FOLED • Organic light emitting device (OLED) built on a flexible base material, such as clear plastic film or reflective metal foil, instead of the usual glass base. • Developed by Universal Display Coporation • Started in 1990s after discovery by research partner at Princeton University that small-molecule OLEDs could be built on flexible substrates FOLED Source: Universal Display Corporation FOLED developed by Universal Display Corporation. Passive matrix display: 0.175 mm thick sheet of plastic, resolution of 80 dpi; 64 levels of grey scale; can show full motion video. Credit: Image courtesy of Universal Display Corporation. 18 FOLED Pros Brighter than LCDs Wider viewing angles and faster response times Don't need a backlighting source Thinner and lighter weight Cons More durable, safer and impact resistant Flexible Cost-effective Require a strong barrier against moisture Limited lifetime particularly for the blue color t Vaio with flexible OLED screen (Credit: Scott Ard/CNET) 20 The Sony Reader and Walkman redone with flexible OLED technology. (Credit: Scott Ard/CNET) 21 Flexible AMOLED • enables a lighter and thinner display • high refresh rate • rugged and not prone to breakage • consume significantly less power • large area displays can be made cheaply because of the low temperature process used and their possible roll-to-roll manufacturing. • at the proof-of-concept stage for conformable and rollable displays • Samsung is the leading developer of AMOLED displays • 2009 world’s first flexible AMOLED display with a 6.5” screen announced LCD vs Flexible AMOLED Winner! Electronic paper, e-paper • A display technology designed to mimic the appearance of ordinary ink on paper • Also known as Electrophoretic Paper Display or EPD • Capable of holding text and images indefinitely without drawing electricity, while allowing the image to be changed later • More comfortable to read than conventional displays due to stable image • Considered an eco-friendly technology due to low power consumption • More than a dozen companies have announced work on active e-paper programs • Colour prototypes exist, but their commercialistaion has yet to be started • EPD only recently took off as "the" modern textual and still image display technology E-paper: key features • Flexible and durable • Impact resistant • Long lifetime: It can be updated up to 1 million times • Image retain without power • Reflects light like ordinary paper • Extremely thin • High contrast • Wide view angle: almost 180 degree E-paper • First developed in 1970s by Xerox inspired by the idea of a paperless office • Fujitsu, E Ink and others introduced the EPD in film (active matrix display), flexible form, Seiko launched the first e-paper wristwatch in 2005 • In November 2007 the EPD finally hits the market with Amazon launching Kindle, Sony its e-reader, Bookeen launched the Cybook and iRex its iLiad. • In March 2009 Fujitsu begins consumer sales of world’s first color e-paper mobile terminal FLEPia Electronic paper • Comprises two different parts: – electronic ink, "frontplane” – electronics required to generate the pattern of text and images on the e-ink page, the "backplane". E-paper: production aspects • The production structure of electronic paper is fairly complex. • In many cases this manufacturing is contracted out. • Backplane is manufactured by another group of firms. • Additional group of firms—consumer product firms—who design and market the product into which the e-paper display fits For example, the e-readers marketed under the Sony brand have incorporated e-paper technology from E Ink and backplane technology from Polymer Vision. E-paper: frontplanes •Electrophoretic Technology •Electrochromic Technology •E Ink •Acreo •SiPix •Aveso •Bridgestone •Ntera •Cholesteric LCD Technology •Fujitsu •Hitachi •Kent Display •Kodak •Nemoptic •ZBD Display •Electrowetting Technology •Liquivista •Electrofluidic Technology •Gamma Dynamics •Siemens •Interferometric Modulator Technology •Qualcomm •Photonic Crystal Technology •Opalux •REED Technology •Zikon •Bistable LCDs E-paper: backplanes • HP • NEC • Plastic Logic • Polymer Vision • Prime View International • Ricoh • Samsung • Seiko Epson Gyricon • • first electronic paper greek for ”rotating image” • based on electrocapillarity : movement of coloured liquids against a white background • consists of polyethylene spheres between 75 and 106 micrometres across embedded in a transparent silicone sheet, with each sphere suspended in a bubble of oil so that they can rotate freely. Each coloured sphere is white on one side and black on the other. Xerox closed its Gyricon operation in December 2005 for financial reasons, but is still licensing technology to other companies Further developed by other companies at the FPD 2008 exhibition, Japanese company Soken has demonstrated a wall with electronic wall-paper using this technology • • • E Ink E Ink is a specific proprietary type of electronic paper Also know as electrophoretic frontplane technology Manufactured by E Ink Corporation, founded in 1997 based on research started at the MIT Media Lab Currently mostly available commercially in grayscale Commonly used in mobile devices such as e-Readers and to a lesser extent mobile phones and watches Material is processed into a film for integration into electronic displays Main use for an text-based rendering 35 E Ink Microcapsules, ~ 100 microns in diameter E Ink with color filters E Ink Cons Pros paper-like high contrast appearance twice the contrast of a LCD panel ultra-low power consumption thin, light form unrestricted size slow response time, not suitable for motion picture not possible to implement sophisticated interactive applications due to response time ghosting costly 41 iLiad e-reader in sunlight Citizen's flexible digital wall clock 21-inches x by 52-inches battery lasts 20 h more than traditional digital clock costs $4000+ 43 Cholesteric liquid crystal displays (ChLCD) • Developed by companies IBM, Philips, HP and Fujitsu, which have demonstrated actual devices • Cholesteric liquid crystal – same crystals as in LCDs – a type of liquid crystal with a helical structure – by applying a current crystals change from a vertical to a horizontal position. • ChLCD technology could become the dominant e-paper technology of the next decade. Cholesteric liquid crystal displays (ChLCD) Pros • flexibility and even bendability • thinness, at approximately 0.8 millimeters • Lightness • a bi-stable nature, requiring no power to maintain an image and very little power to change it • good brightness, contrast, and resolution; • vivid color and a decent refresh rate capable of displaying animation and possibly even video. Electrowetting display (EWD) Developed and patented by Dutch company called Liquavista Merges the advantages of LCDs and e-ink displays Uses a process called electrowetting, which uses small electrical charges to move colored oil within each pixel Electrowetting is a proven process, used for focus mechanisms in cameras and cellphones All the assets of LCD, but with 2x, 3x, 4x the performance Fundamentally brighter, more colourful displays Simplified LCD-like manufacturing process Initially targeted at e-reader markets followed by mobile phones Electrowetting display (EWD) EWD Source: www.displaysearchblog.com 50 EWD Pros uses natural forces and simple materials frame rate 60 times per second, enough to run videos work well in sunlight and viewed picture gets even crisper 3 to 4 more efficient than LCD screens because of the higher level of backlight passing through each pixel. large number of grey scales Cons oil response speed getting enough light to reflect back off the screen in sunshine mass-productions aspects Electrochromic Displays • Display consists of a layer of electrochromic material sandwiched between two electrode layers. • Material changes from one colour to another when stimulated by an electric current. The top electrode layer is made from transparent plastic • The electrochromic mixture used by Siemens, which enables the screen to work so rapidly, include conductive polymers such as polyaniline. • The display is controlled by a printed circuit and can be powered by a very thin printable battery or a photovoltaic cell. • The goal is to be able to create the entire device“ the display and its power source – using the same printing method, so that manufacturing costs would be as low as possible. mirasol displays - fullcolor e-paper Developed by Qualcomm MEMS Technologies, Inc. Uses a reflective technology, called interferometric modulation (IMOD). The technology uses microelectromechanical systems (MEMS) technology to imitate the way butterfly wings shimmer - a process called biomimetics, or imitating things found in nature. In December of 2008 the Institute of Industrial Science (IIS) of the University of Tokyo developed a MEMS display by using roll-to-roll printing technology Expected to be seen on cell phones, e-book readers and tablets by the end of 2010 Mirasol low-power MEMS display for e-readers, in a proof-of-concept built by Qualcomm. Image: Qualcomm MEMS Technologies, Inc. mirasol displays 55 mirasol displays Pros color very low power consumption, no backlight easy to view in the sunlight no delay in screen refreshing due to faster refresh rate Amazon Kindle • 6" E Ink electronic paper display • 600 x 800 pixel resolution at 167 ppi • 16-level gray scale • Price: $259 57 Fujitsu Flepia • 8” Color e-paper • 768 dots x 1,014 dots (XGA) • Color • • • 260,000 colors (3 Scans) 4,096 (2 Scans) 64 colors (1 Scan) • Redraw speed: • • • 1.8 seconds (1 Scan) 5 seconds (2 Scans) 8 seconds (3 Scans) • Price: ~ 849 € 58 Application areas Newspapers • Interior design E-books • Smart cards Digital signage • Automotive consoles Medical • Mobile Toys and games • Military equipment Clothing TVs Future The Morph concept from Nokia Image: Nokia Holy grail of e-paper Will be embodied as a cylindrical tube, about 1 centimeter in diameter and 15 to 20 centimeters long, that a person can comfortably carry in his or her pocket. It will cost less than $100. Conclusion E-paper display technology has now become an integral part of ebook reading devices. 2010 year of e-paper based devices. CES 2010 had a lot of new e-paper devices being announced. Color e-paper to come in few years, first products possibly in 2011 -2012 The technology of printed electronics will deliver low-cost production Give away e-paper display products by 2015. Content availability 63 Questions? Questions? 64 Thank you!