Lecture 7 Review of Difficult Topics

advertisement

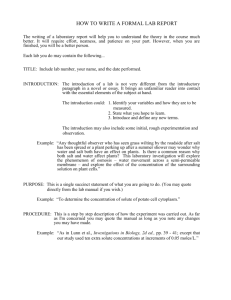

Lecture 7 Review of Difficult Topics MATLS 4L04: Aluminum Section Driving Force for Solidification • From thermodynamics, solidification is spontaneous when Gs – GL < 0 • The more negative this quantity (Gs – GL), the larger the driving force for solidification • What makes this quantity more negative? 2 Nucleation Activation Energy • If a system containing liquid is just below the melting point will it spontaneously solidify? 3 Effect of Temperature 4 Planar Interface Stability – Superheated Liquid • Solidification is controlled by the rate at which latent heat is conducted away from the interface • What happens when a pure solid with a planar front grows into a superheated liquid? 5 Planar Interface Stability – Supercooled Liquid • What happens when a pure solid with a planar front grows into a supercooled liquid? 6 Single Phase - Scheil Solidification • No diffusion of solute in the solid • Perfect mixing in the liquid • Can lead to cored structures (ie. solute concentration gradient in single phase) • Can also end up with eutectic forming at the end of solidification 7 Constitutional Supercooling • Looking at the interface of a steadystate situation • For pure material non-planar growth or dendritic/cellular growth, occurs due to the negative temperature gradient in the liquid (ie. supercooling) • Dendritic growth can also occur in an alloy with a positive temperature gradient in the liquid, as long as there is a composition gradient in the liquid ahead of the interface 8 Solute Hardening • Dislocations themselves have strain energy fields • Dislocations moving through lattice interact with strain fields of solute • This segregation of solute atoms to dislocations makes further movement of the dislocation difficult as it needs to be “torn” away from this lower energy state Factors that Affect the Solubility of an Element • The amount of a solute atom that can be dissolved in a solution depends on the similarity of: 1. 2. 3. 4. Atomic size Crystal structure Electronegativity difference Valence Effectiveness of Different Solute Atoms with Al • In order for a solute to be an effective strengthener it needs to have a good combination of: – Atomic size mismatch • Leads to larger strain fields – Solubility • Leads to more solute atoms present Solute Strengthening Effectiveness Mg R = 0.160 nm Al R = 0.143 nm Fe R = 0.124 nm 3 Key Steps To Creating an AgeHardened Alloy • Step 1: Solutionize • Step 2: Quench • Step 3: Age 13 Nucleation in a Solid • Homogenous • ∆𝐺 = −𝑉∆𝐺𝑉 + 𝐴𝛾 + 𝑉∆𝐺𝑠 • 𝑟∗ • ∆𝐺 ∗ = 2𝛾 ∆𝐺𝑉 −∆𝐺𝑠 = 16𝜋𝛾 3 3 ∆𝐺𝑉 −∆𝐺𝑠 2 14 Aside on Coherency • Interfaces can either be: – Coherent – Semi-coherent – Incoherent Coherent Semi-coherent Coherency Strains Incoherent 15 Particle Growth • Equate flux of solute into the particle v(Cβ-Ce) • To the flux of solute from far away to the interface -D(Cβ-C0)/√(Dt) • Gives a growth rate of x = kt1/2 • When particles continue to grow and their diffusion gradients overlap x=kt1/3 • Also, coherency of interface can effect growth in certain directions 16 Precipitate Evolution • Why does it bother with the intermediate phases? • Nucleation of a phase is dictate by the activation energy 16 3 G* 3(GV GS ) 2 17 18 Solvuses 19 Coherency Strain Hardening • Similar to a solute atom, a particle will cause some coherency strains due to the elastic size mismatch between the particle and the parent lattice atoms • A dislocation will be slowed down by the coherency strains surrounding a particle Chemical Surface Hardening • When a dislocation travels through a particle it must create additional particle/matrix interfacial area • Larger stress (strengthening) required to shear particle and increase interfacial energy Gleiter and Hornbogen (1965) Orowan Bowing • If you try and push a dislocation between two particles it will bend resulting in a dislocation with a certain curvature • The shear stress (τ) required to push a dislocation between two particles such that it reaches a curvature represented by a diameter (d) is given by: • 𝜏= 𝐺𝑏 𝑑 Orowan Bowing • If the stress is reached that bows the dislocation to a diameter equal to the spacing between particles the dislocation can break free from the particles with a small increase in stress • 𝜏𝑦 = 𝐺𝑏 𝐿 Strengthening Effect Mechanisms of Strengthening with Time 1. Solute strengthening 2. Coherency Strain Hardening 3. Chemical Surface Hardening 4. Orowan Bowing Softening vs. Strengthening • It is not uncommon that Aluminum alloys need to undergo a softening process – Ex. Softening a cold-rolled sample between passes to allow for further deformation – Softening will decrease strength and increase ductility • Most of the strengthening techniques used for Aluminum alloys have an associated softening technique Strengthening Technique Softening Technique Age hardening Solution heat treatment Overageing (undesirable) Grain refinement Grain growth Work hardening Recovery, recrystallization, Solute hardening None 25 Particle Coarsening / Oswald Ripening • Solubility of solute in the matrix near small precipitates is higher than that of large precipitates • Results in a concentration gradient in the matrix leading to transfer of solute from small particles to large particles • Large particles grow while small particles dissolve 26 Recovery • Lowers the energy of a deformed material by: – Annihilation of dislocations • Dislocations of opposite signs move through the material until they can cancel one another – Spatial rearrangement of dislocations • Dislocations are arranged such that they are in an arrangement that is lower in energy • This new arrangement minimizes the interaction of similar strain fields between dislocations • Note: Recovery does not change the shape of grains just the dislocation structure 27 Recovery Kinetics • In order to increase the rate at which recovery occurs – Increase the temperature – Increase the level of stress – Reduce the solute content – Reduce the presence of second phase particles 28 Recrystallization • Nucleation and growth of strain (dislocation) free grains consuming deformed or recovered material • Mechanism of Strain Induced Boundary Migration (SIBM) Grain II Grain I Grain II Grain I nucleus 29 Solute Drag • If there is significant solubility of solute in aluminum or the material is being heated in the single phase region and the solute is present in solution, then it can slow down recrystallization kinetics through the mechanism of solute drag • Solute atoms tend to be in lower energy states at grain boundaries and will often segregate there • During recrystallization when these boundaries are trying to move, they are slowed by the solute as the boundary mobility is dependent on solute diffusion 30 Grain Boundary Pinning / Zener Drag • A dispersion of particles creates a pinning pressure that will oppose the pressure that drives the movement of the grain boundary during recrystallization • Pinning force of one particle is F = πrγ • There are N particles per unit volume 3𝑓𝑣 𝑁= 4𝜋𝑟 3 • The number of particles that will intersect with the grain boundary is 3𝑓𝑣 𝑁𝑖𝑛𝑡 = 2𝑟𝑁 = 2𝜋𝑟 2 • The Zener pinning pressure per unit area is 3𝑓𝑣 3𝑓𝑣 γ 𝑃𝑧 = 𝐹𝑁𝑖𝑛𝑡 = πrγ = 2𝜋𝑟 2 2𝑟 31 Recovery vs Recrystallization Recovery • Partial recovery of properties • Microstructure of rearranged dislocations • Structure of grains related to the deformed grains • Some reduction in strength and increase in ductility Recrystallization • Complete recovery of properties • Microstructure with much fewer dislocations • New grains formed with no relation to old structure • Much softer and more ductile 32 Grain Growth • Grain boundaries are regions of disorder and therefore increase the energy of a material • Therefore, there is a driving force to reduce the number of grain boundaries in order to lower the energy • This manifests itself in the process of grain growth • As grain growth requires the movement of grain boundaries, this is a thermally activated process 33 Marking Rubric on Lab Report Students will obtain 70 % Marks of the lab report part (50 marks) as long as submitting the report before due day. The marking rubric for the remaining 30% depends on the report quality including Objective and Background information 10 Procedure 20 Result and discussion 40 Conclusion 10 References (at least 10 references) 10 Format 10