Course Notes

advertisement

Unit 04 : Advanced Hydrogeology

Hydraulic Testing

Well Hydraulics

• A water well is a hydraulic structure that is

designed and constructed to permit economic

withdrawal of water from an aquifer

• Water well construction includes:

– Selection of appropriate drilling methods

– Selection of appropriate completion materials

– Analysis and interpretation of well and aquifer

performance

Pumping Well Terminology

Q

s

ho

h

• Static Water Level [SWL]

(ho) is the equilibrium water

level before pumping

commences

• Pumping Water Level

[PWL] (h) is the water level

during pumping

• Drawdown (s = ho - h) is the

difference between SWL and

PWL

• Well Yield (Q) is the volume

of water pumped per unit

time

• Specific Capacity (Q/s) is

the yield per unit drawdown

Cone of Depression

High Kh aquifer

Low Kh aquifer

Kh Kv

• A zone of low pressure is created centred on the pumping well

• Drawdown is a maximum at the well and reduces radially

• Head gradient decreases away from the well and the pattern

resembles an inverted cone called the cone of depression

• The cone expands over time until the inflows (from various

boundaries) match the well extraction

• The shape of the equilibrium cone is controlled by hydraulic

conductivity

Aquifer Characteristics

• Pump tests allow estimation of transmission and

storage characteristics of aquifers

• Transmissivity (T = Kb) is the rate of flow through a

vertical strip of aquifer (thickness b) of unit width

under a unit hydraulic gradient

• Storage Coefficient (S = Sy + Ssb) is storage

change per unit volume of aquifer per unit change in

head

• Radius of Influence (R) for a well is the maximum

horizontal extent of the cone of depression when the

well is in equilibrium with inflows

Steady Radial Confined Flow

Q

r

s

h

b

ho

• Assumptions

Isotropic, homogeneous,

infinite aquifer, 2-D radial flow

• Initial Conditions

h(r,0) = ho for all r

• Boundary Conditions

h(R,t) = ho for all t

• Darcy’s Law Q = -2prbKh/r • Using BC ho = - Q ln(R) + c

2pKb

• Rearranging h = - Q r

2pKb r

• Eliminating constant (c) gives

• Integrating h = - Q ln(r) + c

s = ho – h = Q ln(r/R)

2pKb

2pKb

• BC specifies h = ho at r = R

This is the Thiem Equation

Steady Unconfined Radial Flow

Q

r

s

h

ho

• Assumptions

Isotropic, homogeneous,

infinite aquifer, 2-D radial flow

• Initial Conditions

h(r,0) = ho for all r

• Boundary Conditions

h(R,t) = ho for all t

• Darcy’s Law Q = -2prhKh/r • Using BC ho2 = - Q ln(R) + c

pK

• Rearranging hh = - Q r

2pK r

• Eliminating constant (c) gives

• Integrating h2 = - Q ln(r) + c

ho2 – h2 = Q ln(r/R)

2

2pK

pK

• BC specifies h = ho at r = R

This is the Thiem Equation

Thiem Equation Assumptions

• The equation for unconfined flow can be rearranged to give:

s = ho – h = Q ln(r/R)

2pK (ho+ h)/2

• Compare this with the confined equation:

s = ho – h = Q ln(r/R)

2pKb

• It is clear than the only difference is that the aquifer thickness b

is replaced by (ho + h)/2

• The implicit assumption in the derivation (2-D flow) implies that s

is small compared with ho and that the (ho + h)/2 does not

deviate significantly from ho

• This assumption may not be valid in the immediate vicinity of a

pumping well in an unconfined aquifer

Thiem Equation Applications

• The equation for unconfined flow can be rearranged to give:

K = Q ln(r/R)

p (ho2 - h2)

• Similarly with the confined equation:

K = Q ln(r/R)

2pb (ho – h)

• The radius of influence R is hard to estimate but any two wells

at different radial distance can be used in the equations

K = Q ln(r2/r1)

and

K = Q ln(r2/r1)

p (h22 – h12)

2pb (h2 – h1)

• This means that for a well producing at a steady rate (Q) with a

steady drawdown, any pair of observation points at different

radial distances can be used to estimate K

Specific Capacity

•

•

•

•

•

For a confined well producing at a steady rate (Q) the specific capacity

is given by:

Q = 2pKb

sw ln(rw/R)

This means that for a confined well producing at a steady rate (Q) the

specific capacity is constant.

The equation for unconfined flow can be rearranged:

Q = pK (ho + hw)

sw ln(rw/R)

Writing hw = ho - sw gives:

Q = - pK (sw + 2ho)

sw

ln(rw/R)

For an unconfined well producing at a steady rate (Q) the specific

capacity reduces with increasing drawdown. The maximum specific

capacity for an unconfined well is given by:

Q = 2pKho

sw ln(rw/R)

Unsteady Radial Confined Flow

Q

r

s

h

ho

b

• PDE 1 (rh ) = S h

r r r

T t

• Solution is more complex than

steady-state

• Change the dependent

variable by letting u = r2S

4Tt

• Assumptions

Isotropic, homogeneous,

infinite aquifer, 2-D radial flow

• Initial Conditions

h(r,0) = ho for all r

• Boundary Conditions

h(,t) = ho for all t

• The ultimate solution is:

ho- h = Q exp(-u) du

4pT u u

where the integral is called the

exponential integral written as

the well function W(u)

This is the Theis Equation

Theis PDE to ODE

•

•

•

•

•

•

Let a = S/T (to simplify notation

where a is called the hydraulic

diffusivity)

PDE 1 (rh ) = a h

r r r

t

u = r2S = ar2

4Tt 4t

So u = ar = 2u

r 2t

r

And u = -ar2 = -u

t

4t2

t

Rewriting the PDE in terms of u:

1 d (r u dh ) u = a u dh

r du r du r

t du

•

•

•

•

Rewriting partial derivatives in

terms of u:

1 d (r 2u dh ) 2u = -a u dh

r du r du r

t du

Rearranging and cancelling:

d (u dh ) = -ar2 dh = -u dh

du du

4t du

du

Expanding the LHS derivative:

u d (dh ) + dh = -u dh

du du

du

du

d (dh ) = -(u + 1) dh

du du

u du

Writing dh/du as h’ gives an ODE:

dh’ = -(u + 1) h’ or dh’ = -(1 + 1) du

du

u

h’

u

Theis Integration

•

•

•

•

•

•

•

The resulting ODE is:

dh’ = -(1 + 1) du

h’

u

Integrating: ln(h’) = -u – ln(u) + c

Simplifying: ln(h’u) = c – u

Inverting: h’u = exp(c).exp(-u)

To eliminate exp(c), use Darcy’s

Law:

lim rh = -Q = lim 2h’u

r 0 r 2pKb u 0

Remember

rh = rh’u = h’ar2 = 2h’u

r

r

2t

lim h’u = -Q = exp(c)

u 0 4pKb

Simplifying: h’ = -Q exp(-u)

4pT u

•

•

•

•

Recall h’ = dh/du

dh = -Q exp(-u).du

4pT u

Integrating:

h = -Q exp(-u) du + C

4pTu u

Finally, using h(,t) = ho to

eliminate C:

ho - h = Q exp(-u) du

4pTu u

The integral is called the

exponential integral but is often

written as the Theis well

function W(u)

s = ho - h = Q W(u)

4pT

Theis Plot : 1/u vs W(u)

10.0

W(u)

1.0

0.1

0.0

1.E-01

1.E+00

1.E+01

1/u

1.E+02

1.E+03

Theis Plot : Log(t) vs Log(s)

Drawdown (m)

10.0

1.0

0.1

0.0

1.E+01

1.E+02

1.E+03

Time since pump started (s)

1.E+04

1.E+05

Theis Plot : Log(t) vs Log(s)

Drawdown (m)

10.0

s=0.17m

1.0

0.1

0.0

1.E+01

1.E+02

1.E+03

Time since pump started (s)

[1,1]

Type

Curve

t=51s

1.E+04

1.E+05

Theis Analysis

1.

2.

3.

4.

5.

6.

7.

Overlay type-curve on data-curve keeping axes parallel

Select a point on the type-curve (any will do but [1,1] is

simplest)

Read off the corresponding co-ordinates on the data-curve

[td,sd]

For [1,1] on the type curve corresponding to [td,sd], T = Q/4psd

and S = 4Ttd/r2 = Qtd/pr2sd

For the example, Q = 32 L/s or 0.032 m3/s; r = 120 m; td = 51

s and sd = 0.17 m

T = (0.032)/(12.56 x 0.17) = 0.015 m2/s = 1300 m2/d

S = (0.032 x 51)/(3.14 x 120 x 120 x 0.17) = 2.1 x 10-4

Cooper-Jacob

• Cooper and Jacob (1946) pointed out that the series expansion

of the exponential integral or W(u) is:

W(u) = – g - ln(u) + u - u2 + u3 - u4 + ..…

1.1! 2.2! 3.3! 4.4!

where g is Euler’s constant (0.5772)

• For u<< 1 , say u < 0.05 the series can be truncated:

W(u) – ln(eg) - ln(u) = - ln(egu) = -ln(1.78u)

• Thus: s = ho - h = - Q ln(1.78u) = - Q ln(1.78r2S) = Q ln( 4Tt )

4pT

4pT

4Tt

4pT 1.78r2S

s = ho - h = Q ln( 2.25Tt ) = 2.3 Q log( 2.25Tt )

4pT

r 2S

4pT

r 2S

• The Cooper-Jacob simplification expresses drawdown (s) as a

linear function of ln(t) or log(t).

Cooper-Jacob Plot : Log(t) vs s

0.0

0.1

0.2

Drawdown (m)

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.E+01

1.E+02

1.E+03

Time since pump started (s)

1.E+04

1.E+05

Cooper-Jacob Plot : Log(t) vs s

to = 84s

0.0

0.1

0.2

Drawdown (m)

0.3

0.4

0.5

0.6

Ds =0.39 m

0.7

0.8

0.9

1.0

1.E+01

1.E+02

1.E+03

Time since pump started (s)

1.E+04

1.E+05

Cooper-Jacob Analysis

1.

Fit straight-line to data (excluding early and late times if

necessary):

– at early times the Cooper-Jacob approximation may not be valid

– at late times boundaries may significantly influence drawdown

2.

3.

4.

5.

6.

7.

Determine intercept on the time axis for s=0

Determine drawdown increment (Ds) for one log-cycle

For straight-line fit, T = 2.3Q/4pDs and S = 2.25Tto/r2 =

2.3Qto/1.78pr2Ds

For the example, Q = 32 L/s or 0.032 m3/s; r = 120 m; to = 84

s and Ds = 0.39 m

T = (2.3 x 0.032)/(12.56 x 0.39) = 0.015 m2/s = 1300 m2/d

S = (2.3 x 0.032 x 84)/(1.78 x 3.14 x 120 x 120 x 0.39)

= 1.9 x 10-4

Theis-Cooper-Jacob Assumptions

Real aquifers rarely conform to the assumptions made for

Theis-Cooper-Jacob non-equilibrium analysis

•

•

•

•

•

•

Isotropic, homogeneous, uniform thickness

Fully penetrating well

Laminar flow

Flat potentiometric surface

Infinite areal extent

No recharge

The failure of some or all of these assumptions leads to “nonideal” behaviour and deviations from the Theis and CooperJacob analytical solutions for radial unsteady flow

Recharge Effect : Recharge > Well Yield

15

Drawdown (m)

20

25

30

35

1.E+01

1.E+02

1.E+03

1.E+04

1.E+05

1.E+06

Time since pump started (s)

Recharge causes the slope of the log(time) vs drawdown curve to

flatten as the recharge in the zone of influence of the well

matches the discharge. The gradient and intercept can still be

used to estimate the aquifer characteristics (T,S).

Recharge Effect : Recharge < Well Yield

15

Drawdown (m)

20

25

30

35

1.E+01

1.E+02

1.E+03

1.E+04

1.E+05

1.E+06

Time since pump started (s)

If the recharge is insufficient to match the discharge, the log(time)

vs drawdown curve flattens but does not become horizontal and

drawdown continues to increase at a reduced rate. T and S can

be estimated from the first leg of the curve.

Sources of Recharge

•

•

•

•

Various sources of recharge may cause deviation

from the ideal Theis behaviour.

Surface water: river, stream or lake boundaries

may provide a source of recharge, halting the

expansion of the cone of depression.

Vertical seepage from an overlying aquifer, through

an intervening aquitard, as a result of vertical

gradients created by pumping, can also provide a

source of recharge.

Where the cone of depression extends over large

areas, leakage from aquitards may provide

sufficient recharge.

Recharge Effect : Leakage Rate

15

Drawdown (m)

20

High Leakage

25

Low Leakage

30

35

1.E+01

1.E+02

1.E+03

1.E+04

1.E+05

1.E+06

Time since pump started (s)

Recharge by vertical leakage from overlying (or underlying beds)

can be quantified using analytical solutions developed by Jacob

(1946). The analysis assumes a single uniform leaky bed.

Hantush Type Curves

r/B

0.0

0.05

0.1

0.2

10.0

0.5

Theis Curve

1.0

W(u,r/B)

1.0

2.0

0.1

0.0

1.E-01

1.E+00

1.E+01

1.E+02

1.E+03

1.E+04

1/u

Data are fitted in a manner similar to the Theis curve. The parameter

r/B = r( {K’v / b’} / {Khb} )½ increases with the amount of leakage.

Barrier Effect : No Flow Boundary

15

Drawdown (m)

20

25

30

35

1.E+01

1.E+02

1.E+03

1.E+04

1.E+05

Time since pump started (s)

Steepening of the log(time) vs. drawdown curve indicates an

aquifer limited by a barrier boundary of some kind. Aquifer

characteristics (T,S) can be estimated from the first leg.

Potential Flow Barriers

•

•

•

•

•

•

Various flow barriers may cause deviation from the

ideal Theis behaviour.

Fault truncations against low permeability

aquitards.

Lenticular pinchouts and lateral facies changes

associated with reduced permeability.

Groundwater divides associated with scarp slopes.

Spring lines with discharge captured by wells.

Artificial barriers such as grout curtains and slurry

walls.

Casing Storage

• It has been known for many decades that early time

data can give erroneous results because of removal of

water stored in the well casing.

• When pumping begins, this water is removed and the

amount drawn from the aquifer is consequently

reduced.

• The true aquifer response is masked until the casing

storage is exhausted.

• Analytical solutions accounting for casing storage

were developed by Papadopulos and Cooper (1967)

and Ramey et al (1973)

• Unfortunately, these solutions require prior knowledge

of well efficiencies and aquifer characteristics

Casing Storage

Q

s

dp

dc

Schafer (1978) suggests that an estimate of the critical

time to exhaust casing storage can be made more

easily:

tc = 3.75p(dc2 – dp2) / (Q/s) = 15 Va /Q

where tc is the critical time (d);

dc is the inside casing diameter (m);

dp is the outside diameter of the rising main (m);

Q/s is the specific capacity of the well (m3/d/m)

Va is the volume of water removed from the

annulus between casing and rising main.

Note: It is safest to ignore data from pumped wells

earlier than time tc in wells in low-K HSU’s

Distance-Drawdown

• Simultaneous drawdown data from at least three

observation wells, each at different radial distances,

can be used to plot a log(distance)-drawdown graph.

• The Cooper-Jacob equation, for fixed t, has the form:

s = 2.3 Q log( 2.25Tt ) = 2.3 Q log( 2.25Tt ) – 4.6Q log(r)

4pT

r 2S

4pT

S

4pT

• So the log(distance)-drawdown curve can be used to

estimate aquifer characteristics by measuring Ds for

one log-cycle and the ro intercept on the distanceaxis.

T = 4.6Q and S = 2.25Tt

4pDs

r o2

Distance-Drawdown Graph

ro = 126 m

0

Drawdown (m)

1

2

Ds = 3.8 m

3

4

5

1

10

Distance (m)

100

1000

Aquifer Characteristics

• For the example: t = 0.35 days and Q = 1100 m3/d

T = 0.366 x 1100 / 3.8 = 106 m2/d

S = 2.25 x 106 x 0.35 / (126 x 126) = 5.3 x 10-3

• The estimates of T and S from log(time)-drawdown

and log(distance)-drawdown plots are independent of

one another and so are recommended as a check for

consistency in data derived from pump tests.

• Ideally 4 or 5 observation wells are needed for the

distance-drawdown graph and it is recommended

that T and S are computed for several different times.

Well Efficiency

• The efficiency of a pumped well can be evaluated

using distance-drawdown graphs.

• The distance-drawdown graph is extended to the

outer radius of the pumped well (including any filter

pack) to estimate the theoretical drawdown for a

100% efficient well.

• This analysis assumes the well is fully-penetrating

and the entire saturated thickness is screened.

• The theoretical drawdown (estimated) divided by the

actual well drawdown (observed) is a measure of well

efficiency.

• A correction is necessary for unconfined wells to

allow for the reduction in saturated thickness as a

result of drawdown.

Theoretical Pumped Well Drawdown

0

dw = 100 mm

dw = 150 mm

dw = 300 mm

2

6

8

0

10

2

Drawdown (m)

Drawdown (m)

4

12

14

16

4

6

8

10

12

14

18

16

0

20

0.01

10

20

30

40

50

60

Distance (m)

0.1

1 Distance (m) 10

100

1000

Unconfined Well Correction

• The adjusted drawdown for an unconfined well is

given by:

sc = (1 - sa ) sa

2b

where b is the initial saturated thickness;

sa is the measured drawdown; and

sc is the corrected drawdown

• For example, if b = 20 m; sa = 6 m; then the corrected

drawdown sc = 0.85sa = 5.1 m

• If the drawdown is not corrected, the Jacob and Theis

analysis underestimates the true transmissivity under

saturated conditions by a factor of sc/ sa.

Causes of Well Inefficiency

• Factors contributing to well inefficiency

(excess head loss) fall into two groups:

– Design factors

•

•

•

•

Insufficient open area of screen

Poor distribution of open area

Insufficient length of screen

Improperly designed filter pack

– Construction factors

• Inadequate development, residual drilling fluids

• Improper placement of screen relative to aquifer interval

Radius of Influence

• The radius of influence of a well can be determined

from a distance-drawdown plot.

• For all practical purposes, a useful comparative index

is the intercept of the distance-drawdown graph on

the distance axis.

• Radius of influence can be used as a guide for well

spacing to avoid interference.

• Since radius of influence depends on the balance

between aquifer recharge and well discharge, the

radius may vary from year to year.

• For unconfined wells in productive aquifers, the

radius of influence is typically a few hundred metres.

• For confined wells may have a radius of influence

extending several kilometres.

Determining ro

ro = 126 m

ro = 4.1 km

0

Unconfined Well

1

3

Confined Well

4

0

5

2

6

Drawdown (m)

Drawdown (m)

2

7

8

4

6

8

10

12

14

9

16

0

10

20

30

40

50

60

Distance (m)

10

1

10

100

Distance (m)

1000

10000

Unconfined Aquifers

• Most analytical solutions assume isotropic,

homogeneous, confined aquifers or assume

drawdowns are small for the unconfined case.

• There are three distinct parts to the time drawdown

curve in an unconfined aquifer:

– early time response follows Theis equation with the confined

“elastic” storage corresponding to storativity (bSs)

– intermediate times respond as a leaky aquifer with vertical

flow in the vicinity of the pumped well with storage release

controlled by the aquifer Kh/Kv ratio

– late time response follows Theis equation with gravity

drainage providing storage corresponding to the specific

yield (Sy)

Delayed-Yield Response

uB

uA

h

• Unconfined response

is complex with theory

developed by

Boulton, Dagan,

Steltsova, Rushton

and Neuman.

• Neuman (1975) defines a well function W(uA,uB,h) where each

parameter corresponds to a different time phase:

• early-time response is controlled by uA = r2S/4Tt

• intermediate-times are controlled by h = r2Kv/Khb2

• late-time response is controlled by uB = r2Sy/4Tt

• The Hantush leakage parameter (r/B) is closely related to h

• (r/B)2 = r2Kv’/Khbb’ where the Kv’ and b’ parameters refer to the

leaky bed. If these leaky-bed parameters become aquifer

parameters (r/B)2 = h.

Neuman Type Curves

h

10.0

0.002

0.01

0.04

0.25

1.0

W(uA,uB,h)

1.0

4.0

0.1

0.0

1.E-01

1.E+00

1.E+01

1.E+02

1.E+03

1.E+04

1.E+05

1.E+06

1/u

• The Neuman type curves are fitted to data in a manner similar to

that for Theis curves. Higher values of h indicate more rapid

gravity drainage.

Partial Penetration

• Partial penetration effects occur when the intake of

the well is less than the full thickness of the aquifer

Effects of Partial Penetration

• The flow is not strictly horizontal and radial.

• Flow-lines curve upwards and downwards as they

approach the intake and flow-paths are consequently

longer.

• The convergence of flow-lines and the longer flowpaths result in greater head-loss than predicted by

the analytical equations.

• For a given yield (Q), the drawdown of a partially

penetrating well is more than that for a fully

penetrating well.

• The analysis of the partially penetrating case is

difficult but Kozeny (1933) provides a practical

method to estimate the change in specific capacity

(Q/s).

Q/s Reduction Factors

• Kozeny (1933) gives the following approximate reduction factor

to correct specific capacity (Q/s) for partial penetration effects:

F = L {1 + 7 cos(pL) ( r )}

b

2b 2L

where b is the total aquifer thickness (m);

r is the well radius (m); and

L is screen length (m).

• The equation is valid for L/b < 0.5 and L/r > 30

• For a 300 mm dia. well with an aquifer thickness of 30 m and a

screen length of 15 m, L/b = 0.5 and 2L/r = 200 the reduction

factor is:

F = 0.5 x {1 + 7 x 0.707 (1/200)} = 0.67

• Other factor are provided by Muskat (1937), Hantush (1964),

Huisman (1964), Neuman (1974) but they are harder to use.

Partial Penetration Alternative

• Multiple screened sections distributed over the entire

saturated thickness functions more efficiently for the

same open area.

Screen Design

300 mm dia.

well with single

screened

interval of 15 m

in aquifer of

thickness 30 m.

L/b = 0.5 and 2L/r = 200

F = 0.5 x {1 + 7 x cos(0.5p/2)

(1/200)} = 0.67

300 mm dia.

well with 5 x 3 m

solid sections

alternating with

5 x 3m

screened

sections, in an

aquifer of thickness 30 m.

There effectively are five

aquifers.

L/b = 0.5 and 2L/r = 40

F = 0.5 x {1 + 7 x cos(0.5p/2)

(1/40)} = 0.89

This is clearly a much more

efficient well completion.

Recovery Data

• When pumping is halted, water levels rise towards

their pre-pumping levels.

• The rate of recovery provides a second method for

calculating aquifer characteristics.

• Monitoring recovery heads is an important part of the

well-testing process.

• Observation well data (from multiple wells) is

preferable to that gathered from pumped wells.

• Pumped well recovery records are less useful but can

be used in a more limited way to provide information

on aquifer properties.

Recovery Curve

0

Drawdown (m)

2

4

Drawdown 10 m

6

Recovery 10 m

Pumping

Stopped

8

10

12

-6

0

6

12

18

24

30

36

42

48

54

60

66

Time (hrs)

The recovery curve on a linear scale appears as an inverted

image of the drawdown curve. The dotted line represent the

continuation of the drawdown curve.

72

Superposition

• The drawdown (s) for a well pumping at a constant rate (Q) for a

period (t) is given by:

s = ho - h = Q W(u) where u = r2S

4pT

4Tt

• The effects of well recovery can be calculated by adding the

effects of a pumping well to those of a recharge well using the

superposition theorem.

• The drawdown (sr) for a well recharged at a constant rate (-Q)

for a period (t’ = t - tr) starting at time tr is given by:

sr = - Q W(u’) where u’ = r2S

4pT

4Tt’

• The total drawdown for t > tr is:

s’ = s + sr = Q (W(u) - W(u’))

4pT

Residual Drawdown and Recovery

• The total drawdown for t > tr is:

s’ = s + sr = Q (W(u) - W(u’))

4pT

• The Cooper-Jacob approximation can be applied giving:

s’ = s + sr = Q (ln(2.25Tt) - ln(2.25Tt’))

4pT

r 2S

r 2S

• Simplification gives the residual drawdown equation:

s’ = s + sr = Q ln(t)

4pT t’

• The equation predicting the recovery is:

sr = - Q ln(2.25Tt’)

4pT

r 2S

For t > tr, the recovery sr is the difference between the observed

drawdown s’ and the extrapolated pumping drawdown (s).

Time-Recovery Graph

Est. recovery, s - s' (m)

0.00

2.00

4.00

to’ = 0.12 hrs

6.00

Dsr = 4.6 m

8.00

10.00

12.00

1.E-02

1.E-01

1.E+00

1.E+01

1.E+02

Time after pumping stopped, t' (hrs)

Aquifer characteristics can be calculated from a log(time)-recovery plot but

the drawdown (s) curve for the pumping phase must be extrapolated to

estimate recovery (s - s’)

Time-Recovery Analysis

• For a constant rate of pumping (Q), the recovery any time (t’)

after pumping stops:

T=

Q

= -Q = Q

4pD(s - s’)

- 4pDsr 4pDsr

• For the example, Dsr = 4.6 m and Q = 1100 m3/d so:

T = 1100 / (12.56 x 4.6) = 19 m2/d

• The storage coefficient can be estimated for an observation well

(r = 30 m) using:

S = 4Tto’

r2

• For the example, to’ = 0.12 and Q = 1100 m3/d so:

S = 4 x 19 x 0.12 / (24 x 30 x 30) = 4.3 x 10-4

• It is necessary to use an observation well for this calculation

because well bore storage effects render any calculation based

on rw potentially subject to huge errors.

Time-Residual Drawdown Graph

Residual Drawdown, s' (m)

0

2

4

6

Ds’ = 5.2 m

8

10

12

1.E+00

1.E+01

1.E+02

1.E+03

Time ratio, t/t'

Transmissivity can be calculated from a log(time ratio)-residual drawdown

(s’) graph by determining the gradient. For such cases, the x-axis is log(t/t’)

and thus is a ratio.

Time-Residual Drawdown Analysis

• For a constant rate of pumping (Q), the recovery any time (t’)

after pumping stops:

T= Q

4pDs’

• For the example, Dsr = 5.2 m and Q = 1100 m3/d so:

T = 1100 / (12.56 x 5.2) = 17 m2/d

• Notice that the graph plots t/t’ so the points on the LHS

represent long recovery times and those on the RHS short

recovery times.

• The storage coefficient cannot be estimated for the residual

drawdown plot because the intercept t / t’ 1 as t’ .

• This more obvious, remembering t’ = t - tr where tr is the elapsed

pumping time before recovery starts.

Residual Drawdown for Real Aquifers

Residual Drawdown, s' (m)

0.00

2.00

4.00

6.00

8.00

10.00

12.00

1.E+00

1.E+01

1.E+02

Time ratio, t/t'

•

•

•

•

•

Theoretical intercept is 1

>> 1 indicates a recharge effect

>1 may indicate greater S for pumping than recovery ?consolidation

< 1 indicates incomplete recovery of initial head - finite aquifer volume

<< 1 indicates incomplete recovery of initial head - small aquifer volume

DST

• The drill stem test, used widely in petroleum

engineering, is a recovery test.

Drill

Stem

• Packers are used to isolate the HSU of

interest which has been flowing for some

time.

Valve

• Initially the bypass valve is open allowing free

Packer

circulation.

• When the bypass valve is closed, the

Perforated

formation pressure is “shut-in” and begins to

Section

recover towards the static value.

• The Horner plot is a direct analogue of the

Packer

residual drawdown plot.

Gauge

DST Analysis

• Recall that the final form of the recovery equation is:

ho - h = s’ = 2.3Q log(t)

4pT

t’

• For a DST, the pressure (rather than head) is measured

po - p = 2.3Qm log(t)

4pkb

t’

• Remembering that p = gh,T = Kb and K = kg/m

p (kPa)

po

100

Dp

10

t / t’

1

• The Horner-plot has an

intercept po when t / t’ = 1

• This intercept is taken to be

the static formation pressure.

• K can be estimated from the

gradient of the graph:

• k = 2.3Qm

4pbDp

Slug Test

Displacer

Displaced

Head

Initial

Head

• The recovery test in a borehole after withdrawal

or injection (or displacement) of a known

volume of water is called a slug test.

• The slug test is a rapid field method for

estimation of moderate to low K-values in a

single well.

• The procedure is:

– initial head is noted

– the slug is removed, added or displaced

instantaneously (displacement is best in this

respect)

– head recovery is monitored (usually with a

submerged pressure logging device)

– typical head changes are 2-3 m in 25-50 mm dia.

piezometers so the volume of the slug is typically

only 1-10 litres

Slug Analysis

Tube or

Casing

2ra

•

•

•

•

•

•

•

•

ra

is access tube internal radius

rw is perforated section external radius

L

is length of perforated section

ho is initial head, t = to

h(t) is head after recovery time t

A

is the tube or casing csa = pra2

F

is a shape factor = 2pL / ln(L/rw)

Analysis methods include:

– Hvorslev (1951)

– Cooper et al (1967)

L

2rw

The Cooper analysis considers storage but

the Hvorslev analysis is more widely used.

• K = A ln (h) = ra2 ln(L) ln(h)

F(t - to) ho 2L(t - to) rw ho

Hvorslev Analysis

• K=

•

Tube or

Casing

2ra

•

•

•

•

L

2rw

ra2 ln(L) ln(h)

1.0

2L(t - to) rw ho

0.9

0.8

Plot time against log

0.7

(h/ho)

0.6

0.5

Measure basic time lag

To when ln(h0/h) = 1

0.4

h

K = ra2 ln (L)

ho

0.3

2LTo rw

Time lag To occurs

when: h = e-1ho = 0.37ho

0.2

If To = 1000 secs for a

50 mm dia. x 1 m length

Casagrande piezometer

0.1

with 38 mm dia access

tube K = 2 x 10-6 m/s

To

Time, t - to

Bounded Aquifers

• Superposition was used to calculate well recovery by

adding the effects of a pumping and recharge well

starting at different times.

• Superposition can also be used to simulate the

effects of aquifer boundaries by adding wells at

different positions.

• For boundaries, the wells that create the same effect

as a boundary are called image wells.

• This relatively simple application of superposition for

analysis of aquifer boundaries was for described by

Ferris (1959)

Image Wells

• Recharge boundaries at

distance (r) are simulated by

a recharge image well at an

equal distance (r) across the

boundary.

r

r

• Barrier boundaries at

distance (r) are simulated by

a pumping image well at an

equal distance (r) across the

boundary.

r

r

General Solution

ri

r

rp

r

The general solution for

adding image wells to a real

pumping well can be written:

s = sp si = Q [W(u) W(ui)]

4pT

where up = rp2S and ui = ri2S

4Tt

4Tt

and rp,ri are the distances from

the pumping and image wells

respectively.

• For a barrier boundary, for all points on the boundary rp = ri and

the drawdown is doubled.

• For a recharge boundary, for all points on the boundary rp = ri

and the drawdown is zero.

Specific Solutions

• Using the Cooper-Jacob approximation is only possible for large

values of to ensure that u < 0.05 for all r so the Theis well function is

used: s = Q [W(u) W(ri2u)] = Q [W(u) W(au)]

4pT

rp 2

4pT

• For the barrier boundary case:

s = Q [W(u) + W(au)]

4pT

where a = (ri/rp)2 and 0<a<1

• For the recharge boundary

case:

s = Q [W(u) - W(au)]

4pT

where a = (ri/rp)2 and 0<a<1

Multiple Boundaries

• A recharge boundary and a

barrier boundary at right

angles can be generated by

two pairs of pumping and

recharge wells.

• Two barrier boundaries at

right angles can be

generated by superposition

of an array of four pumping

wells.

r2

r1

r2

r1

Parallel Boundaries

• A parallel recharge boundary and a barrier boundary (or any

pattern with parallel boundaries) requires an infinite array of

image wells.

r1

r2

Boundary Location

s

t1

s

t2

• For an observation well at distance r1,

measure off the same drawdown (s),

before and after the “dog leg” on a

log(time) vs. drawdown plot.

• Find the times t1 and t2.

• Assuming that the “dog leg” is created

by an image well at distance r2 , if the

drawdowns are identical then W(u1) =

W(u2) so u1 = u2.

• Thus: r12S/4Tt1 = r22S/4Tt2

So r12t2 = r22t1 and r2 = r1(t2 / t1)½

• The distance r2 the radial distance from

the observation point to the boundary.

• Repeating for additional observation

wells may help locate the boundary.

Pumping Wells

• The drawdown observed in a pumping well has two

component parts:

– aquifer loss

• drawdown due to laminar flow in the aquifer

– well loss

• drawdown due to turbulent flow in the

immediate vicinity of the well through the

screen and/or gravel pack

• Well loss is usually assumed to be proportional to the

square of the pumping rate:

sw = CQ2

Well Efficiency

• The total drawdown at a pumping well is given by:

st = s + sw = Q W(u) + CQ2 = BQ + CQ2

4pT

• The ratio of the aquifer loss and total drawdown (s/st) is known

as the well efficiency.

s=

W(u)

=

B .

st W(u) + 4pTCQ B + CQ

• Mogg (1968) defines well efficiency at a fixed time (t = 24 hrs).

Thus, writing W(u) as the Cooper-Jacob approximation gives:

s=

1

=

1

.

st 1 + 4pTCQ / [ln (2.25Tt /S) - 2 ln(rw)]

1 + CQ/B(rw)

• Written in this form it is clear that well efficiency reduces with

pumping rate (Q) and increases with well radius (rw), where B is

inversely related to well radius.

• The specific capacity is given by: Q =

1 .

st B + CQ

Step-Drawdown Test

s1

s

Drawdown, s

2

s3

s4

s5

Time, t

• Step-drawdown tests are tests at

different pumping rates (Q)

designed to determine well

efficiency.

• Normally pumping at each

successively greater rate Q1 < Q2 <

Q3 < Q4 < Q5 takes place for 1-2

hours (Dt) and for 5 to 8 steps. The

entire test usually takes place in one

day.

• Equal pumping times (Dt) simplifies

the analysis.

• At the end of each step, the

pumping rate (Q) and drawdown (s)

is recorded.

Step-Drawdown Test Analysis

s/Q (m/m3/d)

• Step-drawdown tests are

analysed by plotting the

reciprocal of specific

capacity (s/Q) against the

pumping rate (Q).

C

B

Q (L/s)

• The intercept of the graph at

Q=0 is B = W(u)/4pT and the

slope is the well loss

coefficient, C.

• B can also be obtained

independently from a Theis

or Cooper-Jacob analysis of

a pump test.

• For Q = 2700 m3/d and s =

33.3 m the B = 0.012 m/m3/d

• If C = 4 x 10-5, then CQ2 =

18.2 m

• The well efficiency is

33.3/(33.3+18.2) = 65%

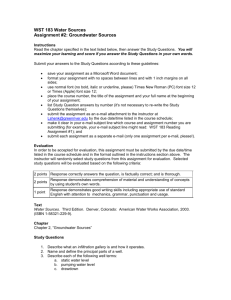

Well Yield

Well yield

US gpm

< 100

< 170

< 350

< 700

< 1000

< 1800

< 3000

< 3800

< 6000

L/s

<6.4

<11

<22

<44

<64

<110

<190

<240

<380

Nom. pump dia. Opt. casing dia. Min. casing dia.

m3/d

550

950

1900

3800

5500

9800

16000

21000

33000

in

4

5

6

8

10

12

14

16

20

mm

100

130

150

200

250

300

360

410

510

in

6

8

10

12

14

16

20

24

30

mm

150

200

250

300

360

410

510

610

760

in

5

6

8

10

12

14

16

20

24

mm

130

150

200

250

300

360

410

510

610

• The chart is used to select casing sizes for a particular yield.

The main constraint is pumping equipment.

• For example, if the well is designed to deliver 4,000 m3/d, the

optimum casing dia. is 360 mm (2 nom. sizes > pump dia.) and

the minimum 300 mm.

• The drilled well diameter would have to be 410 to 510 mm to

provide at least a 50 mm grout/cement annulus.

Pump Test Planning

• Pump tests will not produce satisfactory estimates of either

aquifer properties or well performance unless the data collection

system is carefully and QA/QC is addressed in the design.

• Several preliminary estimates are needed to design a

successful test:

–

–

–

–

–

–

–

Estimate the maximum drawdown at the pumped well

Estimate the maximum pumping rate

Evaluate the best method to measure the pumped volumes

Plan discharge of pumped volumes distant from the well

Estimate drawdowns at observation wells

Simulate the test before it is conducted

Measure all initial heads several times to ensure that steadyconditions prevail

– Survey elevations of all well measurement reference points

Number of Observation Wells

• Number depends on test objectives and

available resources for test program.

– Single well can give aquifer characteristics (T and

S). Reliability of estimates increases with

additional observation points.

– Three wells at different distances are needed for

time-distance analysis

– No maximum number because anisotropy,

homogeneity, and boundaries can be deduced

from response

Pump Test Measurements

• The accuracy of drawdown data and the results of subsequent

analysis depends on:

– maintaining a constant pumping rate

– measuring drawdown at several (>2) observation wells at different

radial distances

– taking drawdowns at appropriate time intervals at least every min

(1-15 mins); (every 5 mins) 15-60 mins; (every 30 mins) 1-5 hrs;

(every 60 mins) 5-12 hrs; (every 8 hrs) >12 hrs

– measuring barometric pressure, stream levels, tidal oscillations as

necessary over the test period

– measuring both pumping and recovery data

– continuing tests for no less than 24 hours for a confined aquifers

and 72 hours for unconfined aquifers in constant rate tests

– collecting data over a 24 hour period for 5 or 6 pumping rates for

step-drawdown tests

Measuring Pumping Rates

• Control of pumping is normally required as head and

pump rpm changes. Frequent flow rate

measurements are needed to maintain constant rate.

• Lower rates

– periodic measurements of time to fill a container of known

volume

– “v” notch weir - measure head (sensitive at low flows)

• Higher rates

–

–

–

–

–

impellor driven water meter - measure velocity (insensitive)

circular orifice weir - measure head v=(2gh)½

rectangular notch weir - measure head

free-flow Parshall flume (drop in floor) - measure head

cutthroat flume (flat floor) – measure head

Measuring Drawdown

• Pumped wells

– heads are hard to measure due to turbulence and pulsing.

– data cannot reliably estimate storage.

• Observation wells

– smallest possible diameter involves least time lag

– screens usually 1-2 m; longer is better but not critical should

be at same depth as centre of production section

– if too close (< 3 to 5 x aquifer thickness) can be strongly

influenced by anisotropy (stratification)

– if too far away (>200 m unconfined) Dh(t) increases with time

so a longer test is required – boundary and other effects can

swamp aquifer response

Drawdown Instrumentation

• Dipmeters

– let cable hang to remove kinks

– rely on light or buzzer, have spare batteries

• Steel tapes

– read wetted part for water level (chalking helps)

– hard to use where high-frequency readings are needed

• Pressure gauges

– measure head above reference point

– need drawdown estimates to set gauge depth

• Pressure tranducers/data loggers

– hang in well and record at predetermined interval

– can be rented (cheaply) for tests

– remote sites (no personnel) and closest wells (frequency)