Set-Up Reduction/ Quick Changeover

advertisement

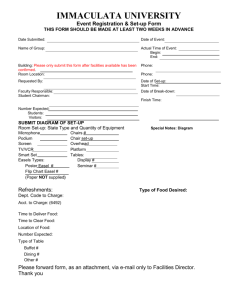

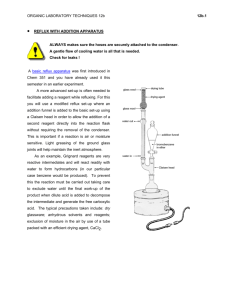

The Lean Enterprise Set-up Reduction/ Quick Changeover Lean Foundations Continuous Improvement Training freeleansite.com Introduction to Set-up Reduction / Quick Changeover Concepts based on a technique commonly called ‘SMED’ - Single Minute Exchange of Die Objectives • Understand the concepts and principles of Setup Reduction. • Share some ideas and understand the benefits of Set-up Reduction. • Apply the concepts, principles and techniques of SMED to accomplish Quick Changeovers !! freeleansite.com Team Beliefs Safety comes first Quality and superior customer satisfaction is our ultimate goal People are our most valued resource Blameless environment Continuous improvement is a way of life Teamwork (customer, supplier, associates) Integrity is never compromised We manage by facts (with data) freeleansite.com What is SMED? SMED stands for: Single Minute Exchange of Die ? Ideally, set-up time should be anything less than 10 minutes … Decreased set-up time; reduces the need for inventory, provides more flexibility and capacity, enables us to better serve our customer! freeleansite.com Benefits of Quick Changeover Less adjustments means less chance for errors Elimination of trial processing reduces material waste Preparation of operating conditions in advance helps stabilize product quality Increases scheduling flexibility/capacity Reduces need for on-hand inventory Improved service levels for customers Smaller runs means less likelihood of large scale defect problems in inventory freeleansite.com Set-up Time Last Good Piece First Good Piece Total elapsed Time freeleansite.com Set-up Time Shigeo Shingo (wrote the book on SMED…) believed that: any set-up time can be reduced by 59/60ths! freeleansite.com Set-up Time There are two types of setup time: Internal Set-up: Those activities that must be performed while the machine is shut down. (Work content done in addition to Machine Time.) Example: Removing dies and tooling External Set-up: Those activities that are performed while the machine is operating. Example: Preparing tooling for the next set-up freeleansite.com Set-up Reduction Process 1. Observe and document the current set-up. 2. Separate Internal and External elements. 3. Improve each element. 4. Observe and document the new set-up process. 5. Standardize the new set-up procedure. 6. Celebrate your success!! freeleansite.com Observe and Document the Current Set Up A. Select a specific set-up for improvement B. Identify a set-up “kaizen” team. C. Observe the set-up process: Video Record the set-up process Complete the Set-up Operations Analysis chart (before Kaizen). D. Prepare a Pareto chart for each time category. freeleansite.com Record and Recommend During this phase we: Observe and document the existing set-up procedure using Time Observation and Video Recording techniques - Analyze all work efforts - Identify short-term solutions that can be implemented with procedural changes, modifications to existing fixtures and minor investment in tooling Video Recording Tips Collect background data Select regular production “Parts” Determine equipment and operation Prepare/Evaluate site Where does operator stand? Where is the best position for the camera? Is there adequate lighting? Narrate Describe what is happening when the operator blocks the camera or leaves the area. Analyze the Time Observation & Video Review Time Observation and Video with the team Identify opportunities Internal vs. External Value Added Vs Non-Value Added Normal vs. Abnormal Seven Types of Waste Automatic, Manual, Walking, and Waiting times Solicit ideas for countermeasures / improvements Observe and Document the Current Set Up Set-up Operations Analysis Chart Mach # From To Area / Department 146 Model A Model B Machining Cell Part # Operation Time Changeover Categories Step No. Changeover Element Element Elapsed Internal 1 Pick-up tools from tool crib (search) 19 19 19 2 Remove Fixture (Fixture Change) 15 34 15 3 Look for Tools (Search) 5 39 5 4 Remove Fixture (Fixture Change) 7 46 7 5 Clean & prepare subplate (Fixture Change) 10 56 10 6 Prepare nex fixture (Fixture Change) 20 1'16 20 7 Put on new fixture (Fixture Change) 8 9 Before Kaizen Analysis 3456 Minutes External Waste x Improvement Plan Mount hand tools on machine x x Mount hand tools on machine Standardize procedures to externalize this step. Establish common tooling for all models. Preset tooling (Tool Change) 6 1'48 6 Standardize procedures to externalize this step. 11 2'14 12 Qualify 1st Piece (Gage) 12 2'26 12 2'26 2'26 2'11 Totals x Air wrench at machine . Eliminate bolts - install quick release. Design SMED cart to load fixture. 4 15 x x 1'42 Run 1st Piece (1st Piece) x Steel plugs for subplate. 4 11 Establish common tooling for all models. Standardize procedures to externalize this step. freeleansite.com x x x x x x x 15 15 Reduce x x Remove preset tools (Tools Change) 1'59 Internal to External See step 2. 22 11 Eliminate Air wrench at machine . Eliminate bolts - install quick release. Design SMED cart to load fixture. 1'38 Load new tooling (Tool Change) 3/7/99 Goal of Improvement Plan 22 10 Date x Observe and Document the Current Set-up Searching - Looking for tools, jigs, fixtures, etc. Fixture Change - Replacing one fixture with another Tool Change - Replacing existing tooling Programming - Making adjustments or changes to a CNC program in order to accommodate the new set-up Walk time - The time an operator must walk to retrieve a fixture, tools etc. 1st Piece - The time required to produce a good unit after the initial set-up Gage - The time required to qualify the 1st piece freeleansite.com Pareto Analysis on each Time Category Set-up Pareto Analysis 80 70 time in min 60 50 40 30 20 10 0 Fixture Chg Search Tool Chg freeleansite.com 1st Piece check Calibrate Gauge Separate the Elements Internal: Those activities that must be performed while the machine is shut down. Example: Removing dies and tooling External: Those activities that are performed while the machine is operating. Example: Acquire fixture/tools for next set-up Both types of actions must be separated. Once the machine is stopped, the associate should never depart to perform any part of the external set up. freeleansite.com Separate the Elements Set-up Operations Analysis Chart Mach # Minutes 14 6 Part # Operation Time Step No. Changeover Element Before Kaizen Analysis 3 456 From To Area / Department Model A Model B Ma chining Cell Changeover Categories Element Elapsed Internal External Waste Improvement Plan Pick-up t ools from t ool crib (s ea rch) 19 19 19 2 Remove Fixt ure (Fixt ure Cha nge) 15 34 15 3 Look for Tools (S ea rch) 5 39 5 4 Remove Fixt ure (Fixt ure Cha nge) 7 46 7 5 Clea n & prepa re s ubpla t e (Fixt ure Cha nge) 10 56 10 6 Prepa re nex fixt ure (Fixt ure Cha nge) 20 1'16 20 7 Put on new fixt ure (Fixt ure Cha nge) 22 1'3 8 22 8 Remove pres et t ools (Tools Cha nge) 4 1'4 2 4 Es t a blis h common t ooling for a ll models . x 3 /7/9 9 Goal of Improvement Plan 1 Eliminate Mount ha nd t ools on ma chine Internal to External x Mount ha nd t ools on ma chine x x S ee s t ep 2. S t eel plugs for s ubpla t e. x x S t a nda rdize procedures t o ext erna lize t his s t ep. Air wrench a t ma chine . Elimina t e bolt s ins t a ll quick relea s e. Des ign S MED ca rt t o loa d fixt ure. 9 Pres et t ooling (Tool Cha nge) 6 1'4 8 6 10 Loa d new t ooling (Tool Cha nge) 11 1'5 9 11 Es t a blis h common t ooling for a ll models . 11 Run 1s t Piece (1s t Piece) 15 2'14 12 Qua lify 1s t Piece (Ga ge) 12 2'26 12 2'26 2'26 2'11 x 15 Internal or External? freeleansite.com x x x x x x x x 15 S t a nda rdize procedures t o ext erna lize t his s t ep. Reduce x Air wrench a t ma chine . Elimina t e bolt s ins t a ll quick relea s e. Des ign S MED ca rt t o loa d fixt ure. S t a nda rdize procedures t o ext erna lize t his s t ep. Totals Date x Develop Improvement Plan 5S +1 (6S) discipline is the key to quick changeover! Every minute spent looking for tools, fixtures, drawings, dies, jigs or other materials adds to the set-up time. A strong 5S foundation, with a ‘point-of-use’ (POU) methodology, will ensure that all required materials are in place when needed, are clean, and in working condition. freeleansite.com Develop Improvement Plan Remember the ‘Wastes’ ? (refer to the 7W’s) Defects Punch Press Over-Production (inventory) Transportation Waiting Tool Cart Inspection (mass) Motion Storage area for Dies Processing, itself + “Unused Creativity” freeleansite.com Tool Room Develop Improvement Plan Specifically: A. Convert as much of the internal set up to the external set up. B. Eliminate or reduce the internal and external set up. C. Eliminate the adjustment process. Ultimate Goal: Eliminate Set-up! freeleansite.com measure separate convert freeleansite.com external external internal internal external Steps: Reduce internal work gradually – eliminate unecessary work internal reduce/eliminate (repeat) Employ Improvement Initiatives Once as much of the internal set-up has been converted to external set-up and waste has been eliminated: – standardize the external set-up actions – utilize quick fasteners – use supplementary tools – at the ‘point of use’ (POU) freeleansite.com Employ Improvement Initiatives Developing the Improvement Plan: • What must be done while the machine is shut down? What can be done while the machine is running? Challenge every element in the set-up ! Establish a sound 6S (5S+1) foundation. freeleansite.com Improvement Checklist – an example Station tools, jigs, dies, etc. near the machine. (POU) Assure that all jigs, gauges, dies, tools, etc. function before the set-up begins. Perform as many External elements as possible prior to the set-up. Two people working together may reduce net set-up time Use functional clamps: One turn/ One motion Use visual control to eliminate adjustments. freeleansite.com Application Best Practices 1) Make minor modification to the existing fixtures. 2) Implement Point-of-Use (POU) techniques. 3) Identify additional tooling to remove attachment from internal to external. 4) Adopt standardized tooling. 5) Document time savings. Application Best Practices - Continued For example: Slots in fixture and T-Bolts reduce attachment time. A new part holder reduced the time required to load and unload parts to fixture. Swing hook eliminated the need to remove nut from bolt. Extra set slides allow detach to be completed on external time. Other ideas 1. Quick Changeover begins and ends with the 5S’s. 2. Change the Internal set-up into External, then improve the remaining Internal set-up time. 3. Bolts are our Enemies. 4. If you have to use your hands make sure your feet stay put. 5. Don’t rely on Special Fine-tuning skills. 6. Standards are standard: they are NOT flexible. 7. Standardize all SMED Operations freeleansite.com Ideas The die heights of a punch press or molding machine can be standardized by using the liner (spacer) so that stroke adjustment will be unnecessary. Source: Toyota Production System - Yasuhiro Minden freeleansite.com Ideas Examples of Quick Fasteners Usually a bolt is the most popular fastening tool. But because a bolt fastens at the final turning of the nut can loosen at the first turn, a convenient fastening tool that would allow only a single turning of the nut should be devised. Source: Toyota Production System - Yasuhiro Minden freeleansite.com Ideas freeleansite.com Ideas freeleansite.com Ideas For example: A slide clamp reduced the time required to load and unload parts to fixture. 2 hold-down clamps eliminated the need to tape parts during a glue-up operation. Set slide allows quick (temporary) alignment of 2 parts. Document the New Set-up A. List each element on the Set-up Operations Standard Chart (after Kaizen) B. Video tape the new set-up procedure. C. Record the set-up time for each element D. Note areas for future improvement. freeleansite.com Standardize the New Procedure Set-up Operations Standard After Kaizen Mach # Minutes From To Area / Department Date Part # Operation Time Step No. Changeover Element Element Elapsed Changeover Categories Internal External Waste freeleansite.com Comments / Future Improvement Plans Standardize the New Procedure The Set-up Operations Standard chart will become the basis for the new set-up procedure. Prepare the appropriate detail and work instructions that will be included on the Setup Operations Standard chart. Assure that all appropriate personnel are trained in the new procedure. freeleansite.com The Lean Enterprise Set-up Reduction/ Quick Changeover Lean Foundations Continuous Improvement Training freeleansite.com