Sparse grid collocation schemes for stochastic convection

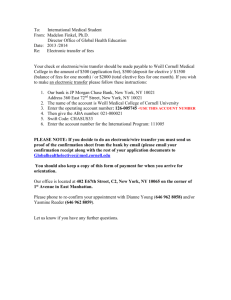

advertisement

Sparse grid collocation schemes for stochastic convection Nicholas Zabaras and Baskar Ganapathysubramanian Materials Process Design and Control Laboratory Sibley School of Mechanical and Aerospace Engineering 188 Frank H. T. Rhodes Hall Cornell University Ithaca, NY 14853-3801 Email: zabaras@cornell.edu URL: http://mpdc.mae.cornell.edu/ CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory MOTIVATION All physical systems have an inherent associated randomness SOURCES OF UNCERTAINTIES Process •Multiscale material information – inherently statistical in nature. •Uncertainties in process conditions Engineering component •Input data •Model formulation – approximations, assumptions. Why uncertainty modeling ? Heterogeneous random Microstructural features Assess product and process reliability. Estimate confidence level in model predictions. Identify relative sources of randomness. Control? Provide robust design solutions. CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Problem of interest Investigate the effects of input uncertainties in natural convection problems. - Results in more realistic modeling - Leads to topology design for enhanced heat and mass transfer problems Consider a 2D natural convection system. Interested in the effects of three kinds of input uncertainties a) Uncertainties in boundary conditions b) Uncertainties in boundary topology c) Uncertainties in material properties CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory REPRESENTING RANDOMNESS:1 Interpreting random variables as functions 1. Interpreting random variables 2. Distribution of the random variable Random variable x Ex. Inlet velocity, Inlet temperature MAP S Real line Sample space of elementary events Collection of all possible outcomes o 1 0.1x Each outcome is mapped to a corresponding real value A general stochastic process is a random field with variations along space and time – A function with domain (Ω, Τ, S) 3. Correlated data Ex. Presence of impurities, porosity Usually represented with a correlation function We specifically concentrate on this. CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory REPRESENTING RANDOMNESS:2 Karhunen-Loèvè expansion 1. Representation of random process Based on the spectral decomposition of the covariance kernel of the stochastic process - Karhunen-Loeve, Polynomial Chaos expansions 2. Infinite dimensions to finite dimensions Random process - depends on the covarience Mean 15 1 • Need to know covariance 0.9 0.8 0.7 10 0.6 Eigenvalue Set of random variables to be found 0.5 0.4 • Converges uniformly to any second order process Eigenpairs of covariance kernel 5 0.3 0.2 0.1 0 0 10 20 30 40 50 60 0 5 10 15 20 Index Set the number of stochastic dimensions, N Dependence of variables Pose the (N+d) dimensional problem CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory KARHUNEN-LOEVE EXPANSION X ( x, t , ) X ( x, t ) X i ( x, t )xi ( ) i 1 ON random variables Deterministic functions Stochastic Mean process function Deterministic functions ~ eigen-values , eigenvectors of the covariance function Orthonormal random variables ~ type of stochastic process In practice, we truncate (KL) to first N terms X ( x, t , ) fn( x, t , x1 , CORNELL U N I V E R S I T Y ,xN ) Materials Process Design and Control Laboratory Problem definition Represent input uncertainties in terms of N random variables. This is possible usually due to the ‘finite dimensional noise assumption’1 g(y) = where g is the appropriate input stochastic process The dependant variables (T,u,p) depend on these N random variables. Reformulate the problem in terms of these N variables 1) I. Babuska, R. Tempone, G. E. Zouraris, Galerkin finite elements approximation of stochastic finite elements, SIAM J. Numer. Anal. 42 (2004) 800–825 CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory UNCERTAINTY ANALYSIS TECHNIQUES Monte-Carlo : Simple to implement, computationally expensive Perturbation, Neumann expansions : Limited to small fluctuations, tedious for higher order statistics Sensitivity analysis, method of moments : Probabilistic information is indirect, small fluctuations Spectral stochastic uncertainty representation: Basis in probability and functional analysis, Can address second order stochastic processes, Can handle large fluctuations, derivations are general Stochastic collocation: Results in decoupled equations CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory SPECTRAL STOCHASTIC REPRESENTATION A stochastic process = spatially, temporally varying random function X : ( x, t , ) CHOOSE APPROPRIATE BASIS FOR THE PROBABILITY SPACE HYPERGEOMETRIC ASKEY POLYNOMIALS GENERALIZED POLYNOMIAL CHAOS EXPANSION SUPPORT-SPACE REPRESENTATION PIECEWISE POLYNOMIALS (FE TYPE) SPECTRAL DECOMPOSITION KARHUNEN-LOÈVE EXPANSION COLLOCATION, MC (DELTA FUNCTIONS) SMOLYAK QUADRATURE, CUBATURE, LH CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory GENERALIZED POLYNOMIAL CHAOS Generalized polynomial chaos expansion is used to represent the stochastic output in terms of the input X ( x, t , ) fn( x, t , x1 , ,xN ) Stochastic input Z ( x, t , ) Z i ( x, t ) i (ξ( )) i 0 Stochastic output Askey polynomials in input Deterministic functions Askey polynomials ~ type of input stochastic process Usually, Hermite, Legendre, Jacobi etc. CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory CURSE OF DIMENSIONALITY Both GPCE and support-space method are fraught with the curse of dimensionality As the number of random input orthonormal variables increase, computation time increases exponentially Support-space grid is usually in a higher-dimensional manifold (if the number of inputs is > 3), we need special tensor product techniques for generation of the support-space Parallel implementations are currently performed using PETSc (Parallel scientific extensible toolkit ) CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory COLLOCATION TECHNIQUES Spectral Galerkin method: Spatial domain is approximated using a finite element discretization Stochastic domain is approximated using a spectral element discretization Decoupled equations Coupled equations Collocation method: Spatial domain is approximated using a finite element discretization Stochastic domain is approximated using multidimensional interpolating functions CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory WHY ARE THE EQUATIONS DECOUPLED? Simple interpolation Consider the function We evaluate it at a set of points The approximate interpolated polynomial representation for the function is Where Here, Lk are the Lagrange polynomials Once the interpolation function has been constructed, the function value at any point yi is just Considering the given natural convection system One can construct the stochastic solution by solving at the M deterministic points CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory CONSTRUCTING OPTIMAL INTERPOLATING FUNCTIONS Two issues with constructing accurate interpolating functions: 1) Choice of optimal points to sample at 2) Constructing multidimensional polynomial functions Analysis of optimal points for one dimensional functions Consider the one D function Need to approximate this function through a polynomial interpolant Sample the function at a finite set of points Construct the interpolant such that The interpolant can be written as As the number of sampling points increases the approximating quality of the polynomial improves CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory CONSTRUCTING OPTIMAL INTERPOLATING FUNCTIONS As the number of sampling points increases the approximating quality of the polynomial improves. This is irrespective of how one chooses the sampling points. But uniform convergence is not guaranteed To choose optimal distribution of points to ensure uniform convergence, must need a notion of the approximating quality of the polynomial. The Best approximating polynomial is defined such that Every interpolation function can be related to the best approximation polynomial through its Lebesgue constant where the Lebesgue constant is Note that the Lebesgue constant depends only on the node distribution and not on the function. One can find distribution of points that minimize the Lebesgue constants CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory FROM ONE DIMENSION TO HIGHER DIMENSIONS Gauss points and Chebyshev points have small Lebesgue constants and can be used as nodes to construct the interpolation function1. Can come up with error bounds for these distribution of points. The interpolation error while using n Chebyshev sampling points is given by From this optimal one dimensional interpolation function, straightforward extension to multiple dimensions using the concept of tensor products. This quickly becomes impossible to use. For instance, if N=10 dimensions ans we were to use n=2 points in each dimension, we would require 210 points to interpolate this function. Look at better ways to sample these points 1. A. Klimke, Uncertainty Modeling using Fuzzy Arithmetic and Sparse Grids, PhD Thesis, Universitt Stuttgart, Shaker Verlag, Aachen, 2006. CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory SMOLYAK ALGORITHM LET OUR BASIC 1D INTERPOLATION SCHEME BE SUMMARIZED AS Ui( f ) a xi X i x i f ( xi ) IN MULTIPLE DIMENSIONS, THIS CAN BE WRITTEN AS (U i1 U id )( f ) xi1 X i1 xid X id (axi1 axid ) f (x i1 , , x id ) TO REDUCE THE NUMBER OF SUPPORT NODES WHILE MAINTAINING ACCURACY WITHIN A LOGARITHMIC FACTOR, WE USE SMOLYAK METHOD U 0 0, i U i U i 1 , i i1 Aq ,d ( f ) Aq 1,d ( f ) (i1 id id )( f ) i q IDEA IS TO CONSTRUCT AN EXPANDING SUBSPACE OF COLLOCATION POINTS THAT CAN REPRESENT PROGRESSIVELY HIGHER ORDER POLYNOMIALS IN MULTIPLE DIMENSIONS A FEW FAMOUS SPARSE QUADRATURE SCHEMES ARE AS FOLLOWS: CLENSHAW CURTIS SCHEME, MAXIMUM-NORM BASED SPARSE GRID AND CHEBYSHEV-GAUSS SCHEME CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory SMOLYAK ALGORITHM Extensively used in statistical mechanics Uni-variate interpolation Provides a way to construct interpolation functions based on minimal number of points Ui( f ) a xi X i x i f ( xi ) Multi-variate interpolation (U i1 Univariate interpolations to multivariate (U i1 U id )( f ) interpolations xi1 X i1 U id )( f ) xid X id ( axi1 (axi1 axid ) f (x , , x id ) xi1 X i1 xid iX id 1 Smolyak interpolation U 0 0, i U i U i 1 , Accuracy the same as tensor product i i1 Aq ,d ( f ) Aq 1,d ( f ) (i1 id id )( f ) i q D = 10 Within logarithmic constant Increasing the order of interpolation increases the number of points sampled CORNELL U N I V E R S I T Y ORDER SC FE 3 1581 1000 4 8801 10000 5 41625 100000 Materials Process Design and Control Laboratory SMOLYAK ALGORITHM: REDUCTION IN POINTS For 2D interpolation using Chebyshev nodes Left: Full tensor product interpolation uses 256 points Right: Sparse grid collocation used 45 points to generate interpolant with comparable accuracy Results in multiple orders of magnitude reduction in the number of points to sample CORNELL U N I V E R S I T Y D = 10 ORDER SC FE 3 1581 1000 4 8801 10000 5 41625 100000 Materials Process Design and Control Laboratory SMOLYAK ALGORITHM: Numerical illustration Interpolating smooth anisotropic functions. Investigate interpolation accuracy as ρ increases. As ρ increases the function becomes steeper in one direction Error defined as deviation of interpolant from actual function For ρ =1000, the function is very anisotropic. The sparse collocation method uses 3329 points to construct an approximate solution with an error of 3x10-5. The full tensor product method uses 263169 points to get the same level of accuracy CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory SMOLYAK ALGORITHM: Numerical illustration Interpolating discontinuous functions. Function has a discontinuity in the y direction. 32769 points required to construct interpolant with error 3x10-3. Increasing number of sampling points Issues: Notice that the smolyak method uniformly samples both dimensions. Can the number of sampling points be further reduced by choosing points adaptively in different directions based on the behavior of the function? Can this be done on-the-fly? CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory ADAPTIVE SPARSE GRID COLLOCATION The conventional sparse grid method treats every dimension equally. Functions may have widely varying characteristics in different directions (discontinuities, steep gradients) or the function may have some special structure (additive, nearly-additive, multiplicative). The basis proposition of the adaptive sparse grid collocation is to detect these structures/behaviors and treat different dimensions differently to accelerate convergence. Must use some heuristics to select the sampling points. Such heuristics have been developed by Gerstner and Griebel Have to come up with a way to make the Smolyak algorithm treat different dimensions differently. Generalized Sparse Grids: Convention sparse grids imposes a strict admissibility condition on the indices. By relaxing this to allow other indices, adaptivity can be enforced. Admissibility criterion for a set of indices S. where ej is the unit vector in the j-th direction 1. T. Gerstner, M. Griebel, Numerical integration using sparse grids, Numerical Algorithms, 18 (1998) 209–232. CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory ADAPTIVE SPARSE GRID COLLOCATION Finding the most sensitive dimensions: The generalized sparse grid indices allow one to sample different dimensions differently. To accurately build interpolants using a minimal number of points, most of the points should be concentrated in the directions that have the steepest gradient or have discontinuities Define directional errors to quantify the notion of sensitivity of each direction. Direction error are the interpolation errors achieved by adding sampling points in that specific direction Interpolation procedure: Start from the smallest index. Add indices in each coordinate direction. Evaluate the function at these new indices. Compute the error between evaluated value and estimated value for each direction. The direction with the maximal error need more indices. The function is evaluated in this direction CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory ADAPTIVE SPARSE GRID COLLOCATION: Numerical illustration Interpolating smooth anisotropic functions. Investigate interpolation accuracy as ρ increases. As ρ increases the function becomes steeper in one direction For ρ = 1000, the adaptive sparse grid collocation uses 577 points to generate an interpolation function with error 5x102. The conventional sparse grid collocation uses 1577 points to get the same accuracy. More points sampled in the y direction CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory ADAPTIVE SPARSE GRID COLLOCATION: Numerical illustration Interpolating discontinuous functions. 1 0.9 0.8 0.7 Function has a discontinuity in the y direction. 0.6 0.5 The adaptive method uses 559 points to build the interpolation function, while the conventional method uses 3300 points 0.4 0.3 0.2 0.1 0 0 0.2 0.4 0.6 0.8 1 Conventional sparse grid 1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 Adaptive sparse grid CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory SPARSE GRID COLLOCATION METHOD: implementation Solution Methodology PREPROCESSING Compute list of collocation points based on number of stochastic dimensions, N and level of interpolation, q Compute the weighted integrals of all the interpolations functions across the stochastic space (wi) Solve the deterministic problem defined by each set of collocated points Use any validated deterministic solution procedure. Completely non intrusive POSTPROCESSING 0.301 0.260 0.301 0.260 0.220 0.220 0.180 0.180 0.140 0.140 0.100 0.100 0.060 0.060 0.020 0.020 Compute moments and other statistics with simple operations of the deterministic data at the collocated points and the preprocessed list of weights Std deviation of temperature: Natural convection CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory REFERENCES SPARSE GRID COLLOCATION 1) E. Novak, K. Ritter, R. Schmitt, A. Steinbauer, On an interpolatory method for high-dimensional integration, J. Comp. Appl. Mathematics, 112 (1999) 215–228. 2) V. Barthelmann, E. Novak, K. Ritter, High-dimensional polynomial interpolation on sparse grids, Adv. Compu. Math. 12 (2000) 273–288. 3) A. Klimke, Uncertainty Modeling using Fuzzy Arithmetic and Sparse Grids, PhD Thesis, Universitt Stuttgart, Shaker Verlag, Aachen, 2006. 4) T. Gerstner, M. Griebel, Numerical integration using sparse grids, Numerical Algorithms, 18 (1998) 209– 232. STOCHASTIC COLLOCATION 1) B. Ganapathysubramanian, N. Zabaras, Sparse grid collocation schemes for stochastic natural convection problems, J. Comp. Physics, submitted for publication. 2) B. Ganapathysubramanian, N. Zabaras, Modeling diffusion in random heterogeneous media: Data-driven models, stochastic collocation and the VMS method, JCP, submitted. 3) I. Babuska, F. Nobile, R. Tempone, A stochastic collocation method for elliptic PDEs with random input data, ICES Report 05-47, 2005. 4) D. Xiu, J. S. Hesthaven, High order collocation methods for the differential equation with random inputs, SIAM J. Sci. Comput. 27 (2005) 1118–1139 5) F. Nobile, R. Tempone, C. G. Webster, A sparse grid stochastic collocation method for elliptic PDEs with random input data, preprint. CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory NUMERICAL EXAMPLES CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Natural convection with random boundary conditions: A comparison Fluid (Pr=1.0) in a square domain T (y) = 0.5 T (y) = f (y,ω) Computational domain [-0.5,0.5]^2 Left wall maintained at T = 0.5 Right wall maintained at a meant temperature, T = -0.5 Temperature varies spatially along the right wall. These temperatures are correlated. Physically represents the behavior of, say, a resistance heater. Boundary temperature correlation C(y1,y2) = exp(-c|y1-y2|) Solve problem using MonteCarlo methods, GPCE and Sparse collocation CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Comparison Sparse grid collocation GPCE MC Mean temperature distribution Standard deviation of temperature CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Comparison Computational effort MonteCarlo: 65000 samples GPCE: second order expansion Domain: [-0.5, 0.5]x[-0.5, 0.5] Grid: 50x50 quad elements Time steps: 600 dt = 1e-3 Smolyak: level 6 interpolation MonteCarlo just a means to validate, computationally not feasible Compare GPCE and Sparse grid collocation methods All problems solved on 16 nodes of V3 cluster at Cornell Theory Center CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Comparison Sparse grid collocation is computationally very efficient for moderate dimensions. Post processing to obtain higher order statistics is very simple. CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Natural convection with random domains Effect of roughness on natural convection Thermal evolution of fluid on a rough surface heated from below. T (y) = -0.5 Surface characterization: Waviness and roughness Waviness: Large scale variations T (y) = 0.5 y = f(x,ω) Roughness: Small scale perturbations to the surface Representing roughness: Roughness represented by two components: PDF of a point above a datum z and the correlation between two points (ACF) ACF depends on the processing methodology, ex shot peening, sand blasting and milling PDF is usually assumed to be a Gaussian CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Natural convection with random domains Effect of roughness on natural convection Thermal evolution of fluid on a rough surface heated from below. T (y) = -0.5 ACF taken to be a simple exponential correlation C(y1,y2) = exp(-c|y1-y2|) Mean roughness measure is 1/100 of the characteristic length of the domain T (y) = 0.5 y = f(x,ω) The correlation length is set at 0.1 First 8 eigen values represent 96% of the spectrum Computational domain: [-1, 1]x[-0.5, 0.5] Grid 200x100 Pr = 6.4 (corresponding to water) Ra = 5000 Top wall set at T = -0.5 Bottom wall set at T = 0.5 CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Natural convection with random domains Level 4 sparse grid collocation scheme is used Number of points = 3937 Computational effort: 8 nodes of V3 on CTC ~ 500 minutes Temperature and velocity realizations CORNELL U N I V E R S I T Y 0.438 0.313 0.188 0.063 -0.063 -0.188 -0.313 -0.438 8.369 6.449 4.529 2.610 0.690 -1.230 -3.150 -5.070 0.438 0.313 0.188 0.063 0.438 -0.063 0.313 -0.188 0.188 -0.313 0.063 -0.438 -0.063 -0.188 0.438 -0.313 0.313 -0.438 0.188 0.063 -0.063 -0.188 -0.313 -0.438 17.537 13.326 9.114 4.902 0.691 -3.521 -7.733 -11.944 0.438 0.313 0.188 0.063 -0.063 -0.188 -0.313 -0.438 15.707 11.772 7.837 3.901 -0.034 -3.969 -7.904 -11.839 12.013 7.773 3.533 -0.707 -4.947 -9.186 -13.426 -17.666 Materials Process Design and Control Laboratory Natural convection with random domains: Mean statistics Pressure Temperature 0.437 0.312 0.187 0.062 -0.062 -0.187 -0.312 -0.437 v velocity 6.530 4.670 2.810 0.950 -0.911 -2.771 -4.631 -6.492 u velocity 4.192 2.528 0.864 -0.800 -2.465 -4.129 -5.793 -7.457 0.355 0.253 0.152 0.050 -0.051 -0.153 -0.254 -0.356 Much more diffuse behavior CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Natural convection with random domains: Higher order statistics Pressure Temperature 15.875 13.758 11.642 9.525 7.408 5.292 3.175 1.058 0.301 0.260 0.220 0.180 0.140 0.100 0.060 0.020 v velocity u velocity 18.599 16.119 13.639 11.159 8.679 6.200 3.720 1.240 CORNELL U N I V E R S I T Y 0.801 0.694 0.587 0.480 0.374 0.267 0.160 0.053 Materials Process Design and Control Laboratory Natural convection with random domains: Mode shifts and PDF’s 0.301 0.260 0.220 0.180 0.140 0.100 0.060 0.020 Location (0,0.25) shows large deviation in temperature. Plot of distribution of temperature and v velocity show a bi-modal nature. Possibility of two distinct modes. Can find most sensitive dimension. Dimension which shows an abrupt change in the variables Temperature v velocity CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Natural convection with random domains: Large dimensions. experimental data Flow over rough surfaces Thermal transport across rough surfaces, heat exchangers Look at natural convection through a realistic roughness profile Rectangular cavity filled with fluid. Lower surface is rough. Roughness auto correlation function from experimental data2 T (y) = -0.5 Lower surface maintained at a higher temperature Rayleigh-Benard instability causes convection T (y) = 0.5 y = f(x,ω) Numerical solution procedure for the deterministic procedure is a fractional time stepping method 2. H. Li, K. E. Torrance, An experimental study of the correlation between surface roughness and light scattering for rough metallic surfaces, Advanced Characterization Techniques for Optics, Semiconductors, and Nanotechnologies II, CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory NATURAL CONVECTION ON ROUGH SURFACES Experimental ACF Experimental correlation for the surface roughness 1 Eigen spectrum is peaked. Requires large dimensions to accurately represent the stochastic space 0.8 0.6 V2 Simulated with N= 20 (Represents 94% of the spectrum) 0.4 0.2 Number of collocation points is 11561 (level 4 interpolation) 0.44 0.44 0.31 0.31 0.19 0.19 0.06 0.06 -0.06 -0.06 -0.19 -0.19 -0.31 -0.31 -0.44 -0.44 0.44 0.31 0.19 0.06 -0.06 -0.19 -0.31 -0.44 CORNELL U N I V E R S I T Y 0 0.5 1 1.5 2 V1 Numerically computed Eigen spectrum Sample realizations of temperature at collocation points 16 12 Eigenvalue 0.44 0.31 0.19 0.06 -0.06 -0.19 -0.31 -0.44 0 8 4 0 5 10 15 20 Index Materials Process Design and Control Laboratory NATURAL CONVECTION ON ROUGH SURFACES FIRST MOMENT SECOND MOMENT Temperature Temperature 0.17 0.14 0.12 0.10 0.08 0.06 0.03 0.01 0.44 0.31 0.19 0.06 -0.06 -0.19 -0.31 -0.44 Streamlines Y Velocity 7.63 6.62 5.60 4.58 3.56 2.54 1.53 0.51 Roughness causes improved thermal transport due to enhanced nonlinearities Results in thermal plumes Can look to tailor material surfaces to achieve specific thermal transport CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory Natural convection in heterogeneous media: large dimensions Alloy solidification, thermal insulation, petroleum prospecting Look at natural convection through a realistic sample of heterogeneous material u=v=0 Square cavity with free fluid in the middle part of the domain. The porosity of the material is taken from experimental data1 T=1 u=v=0 T=0 Free fluid Left wall kept heated, right wall cooled Numerical solution procedure for the u=v=0 deterministic procedure is a fractional time stepping method Porous medium u=v=0 1. Reconstruction of random media using Monte Carlo methods, Manwat and Hilfer, Physical Review E. 59 (1999) CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory FLOW THROUGH HETEROGENEOUS RANDOM MEDIA Experimental correlation for the porosity of the sandstone. Material: Sandstone Eigen spectrum is peaked. Requires large dimensions to accurately represent the stochastic space Simulated with N= 8 Number of collocation points is 3937 (level 4 interpolation) 15 1 0.9 0.8 0.7 0.6 0.5 Eigen spectrum 0.4 0.3 Eigenvalue 10 Numerically computed 5 0.2 0.1 0 0 10 20 30 40 50 60 0 5 10 15 20 Index CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory FLOW THROUGH HETEROGENEOUS RANDOM MEDIA Temperature Snapshots at a few collocation points Temperature 9.1 6.4 3.7 1.0 -1.7 -4.4 -7.1 -9.8 0.9 0.8 0.7 0.6 0.4 0.3 0.2 0.1 14.2 10.1 6.1 2.0 -2.0 -6.1 -10.1 -14.1 CORNELL U N I V E R S I T Y 12.1 8.6 5.1 1.7 -1.8 -5.3 -8.7 -12.2 7.0 4.4 1.8 -0.8 -3.4 -6.0 -8.6 -11.2 Streamlines Temperature 0.9 0.8 0.7 0.6 0.4 0.3 0.2 0.1 Y velocity 0.94 0.81 0.69 0.56 0.44 0.31 0.19 0.06 y-Velocity 0.9 0.8 0.7 0.6 0.4 0.3 0.2 0.1 FIRST MOMENT SECOND MOMENT 0.097 0.084 0.071 0.058 0.045 0.032 0.019 0.006 Y velocity 5.056 4.382 3.708 3.034 2.359 1.685 1.011 0.337 Materials Process Design and Control Laboratory RANDOM TOPOLOGY AND STOCHASTIC COLLOCATION Investigate diffusion through random heterogeneous media - Given experimental image, extract features - Reconstruct 3D microstructures from 2D image - Construct reduced model for the random topology - Get statistics of temperature driven by this random topology 1) S. Umekawa, R. Kotfila, O. D. Sherby, Elastic properties of a tungsten-silver composite above and below the melting point of silver, J. Mech. Phys. Solids 13 (1965) 229-230 2) B. Ganapathysubramanian, N. Zabaras, Modelling diffusion in random heterogeneous media: Data-driven models,stochastic collocation and the variational multiscale method, J. Comp. Physics, submitted CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory RANDOM TOPOLOGY: Reconstruction Given 2D slice, reconstruction techniques to construct 3D microstructures: Gaussian Random Fields, Stochastic optimization, Simulate dannealing ect Match experimental statistics with reconstructed statistics CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory RANDOM TOPOLOGY: Model reduction Represent any microstructure as a linear combination of the eigenimages I = Iavg + I1a1 + I2a2+ I3a3 + … + Inan Image I belongs to the class of structures? It must satisfy certain conditions a) Its volume fraction must equal the specified volume fraction b) Volume fraction at every pixel must be between 0 and 1 c) It should satisfy higher order statistics PCA on the image set. First 10 eigen Thus the n tuple (a1,a2,..,an) must further satisfy some constraints. values represent the structure well =a1 CORNELL U N I V E R S I T Y +a2 + ..+ an Materials Process Design and Control Laboratory RANDOM TOPOLOGY: Model reduction Impose constraints on the set of n-tuples 1) Impose first order constraints : Volume fraction must be matched 2) Impose pixel constraints: Results in a convex hull 3) Sequentially impose higher order constraints on the convex hull to get allowable space of n-tuples Reduced model CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory RANDOM TOPOLOGY: STOCHASTIC COLLOCATION N = 9 dimensions Level 5 interpolation: 15713 deterministic problems Each deterministic problem: 128x128x128 elements Steady state diffusion problem. Look at effect of imposing first order statistics Mean statistics: Contours, iso surfaces and slices Higher order statistics: Isosurfaces of standard deviation, pdf’s at two points and slices of standard deviation CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory RANDOM TOPOLOGY: STOCHASTIC COLLOCATION N = 9 dimensions Level 5 interpolation: 15713 deterministic problems Each deterministic problem: 128x128x128 elements Steady state diffusion problem. Look at effect of imposing up to second order statistics Mean statistics: Contours, iso surfaces and slices Higher order statistics: Isosurfaces of standard deviation, pdf’s at two points and slices of standard deviation CORNELL U N I V E R S I T Y Materials Process Design and Control Laboratory