coarse-to-subgrid map - Professor Nicholas Zabaras

advertisement

STOCHASTIC MODELING OF

MULTISCALE SYSTEMS

NICHOLAS ZABARAS

Materials Process Design and Control Laboratory

Sibley School of Mechanical & Aerospace Engineering

188 Frank H T Rhodes Hall

Cornell University

Ithaca, NY 14853

Email: zabaras@cornell.edu

URL: http://mpdc.mae.cornell.edu

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

OUTLINE

Motivation: coupling multiscaling and uncertainty analysis

Mathematical representation of uncertainty

Variational multiscale method (VMS)

Stochastic support method

Stochastic convection-diffusion equations

Computing PDFs of microstructures (Maximum Entropy)

Sparse grid collocation methods (Smolyak quadrature)

Natural convection on rough surfaces

Diffusion in stochastic heterogeneous media

Future research directions

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

NEED FOR UNCERTAINTY ANALYSIS

Uncertainty is everywhere

From NIST

Porous

media

From Intel website

Silicon

wafer

From GE-AE website

Aircraft

engines

From DOE

Material

process

Variation in properties, constitutive relations

Imprecise knowledge of governing physics, surroundings

Simulation based uncertainties (irreducible)

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

WHY UNCERTAINTY AND MULTISCALING ?

Uncertainties introduced across various length scales have

a non-trivial interaction

Current sophistications – resolve macro uncertainties

Micro

Physical

properties, structure

follow a statistical

description

CORNELL

U N I V E R S I T Y

Meso

Macro

Use micro

averaged

models for

resolving

physical scales

Imprecise

boundary conditions

Initial

perturbations

Materials Process Design and Control Laboratory

UNCERTAINTY ANALYSIS TECHNIQUES

Monte-Carlo : Simple to implement, computationally

expensive

Perturbation, Neumann expansions : Limited to small

fluctuations, tedious for higher order statistics

Sensitivity analysis, method of moments : Probabilistic

information is indirect, small fluctuations

Spectral stochastic uncertainty representation

Basis in probability and functional analysis

Can address second order stochastic processes

Can handle large fluctuations, derivations are general

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

RANDOM VARIABLES = FUNCTIONS ?

Math: Probability space (W, F, P)

Sample space

Probability measure

Sigma-algebra

Random variable

F

W

W

W : Random variable

W : (W)

A stochastic process is a random field with variations

across space and time

X : ( x, t , W)

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

SPECTRAL STOCHASTIC REPRESENTATION

A stochastic process = spatially, temporally varying random

function

X : ( x, t , W)

CHOOSE APPROPRIATE

BASIS FOR THE

PROBABILITY SPACE

HYPERGEOMETRIC ASKEY POLYNOMIALS

GENERALIZED POLYNOMIAL

CHAOS EXPANSION

SUPPORT-SPACE

REPRESENTATION

PIECEWISE POLYNOMIALS (FE TYPE)

SPECTRAL DECOMPOSITION

KARHUNEN-LOÈVE

EXPANSION

COLLOCATION, MC (DELTA FUNCTIONS)

SMOLYAK QUADRATURE,

CUBATURE, LH

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

KARHUNEN-LOEVE EXPANSION

X ( x, t , ) X ( x, t ) X i ( x, t )i ( )

i 1

ON random variables

Deterministic functions

Stochastic Mean

process function

Deterministic functions ~ eigen-values , eigenvectors of

the covariance function

Orthonormal random variables ~ type of stochastic

process

In practice, we truncate (KL) to first N terms

X ( x, t , ) fn( x, t , 1 ,

CORNELL

U N I V E R S I T Y

,N )

Materials Process Design and Control Laboratory

GENERALIZED POLYNOMIAL CHAOS

Generalized polynomial chaos expansion is used to

represent the stochastic output in terms of the input

X ( x, t , ) fn( x, t , 1 ,

,N )

Stochastic input

Z ( x, t , ) Z i ( x, t ) i (ξ( ))

i 0

Stochastic

output

Askey polynomials in input

Deterministic functions

Askey polynomials ~ type of input stochastic process

Usually, Hermite, Legendre, Jacobi etc.

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

SUPPORT-SPACE REPRESENTATION

Any function of the inputs, thus can be represented as a

function defined over the support-space

A ξ (1 , , N ) : f (ξ) 0

FINITE ELEMENT GRID REFINED

IN HIGH-DENSITY REGIONS

X Xˆ

L2

2

ˆ

( X (ξ ) X (ξ )) f (ξ )dξ

A

Ch q 1

JOINT PDF OF A

TWO RANDOM

VARIABLE INPUT

CORNELL

U N I V E R S I T Y

– SMOLYAK

QUADRATURE

OUTPUT REPRESENTED ALONG

SPECIAL COLLOCATION POINTS

– IMPORTANCE

MONTE CARLO

Materials Process Design and Control Laboratory

VARIATIONAL MULTISCALE METHOD WITH ALGEBRAIC

SUBGRID MODELLING

Application : deriving stabilized finite element formulations

for advection dominant problems

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

VARIATIONAL MULTISCALE HYPOTHESIS

EXACT SOLUTION

COARSE SOLUTION

INTRINSICALLY

COUPLED

SUBGRID SOLUTION

H

COARSE GRID

RESOLUTION CANNOT

CAPTURE FINE SCALE

VARIATIONS

THE FUNCTION SPACES

FOR THE EXACT SOLUTION

ALSO SHOW A SIMILAIR

DECOMPOSITION

In the presence of uncertainty, the statistics of the solution

are also coupled for the coarse and fine scales

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

VARIATIONAL MULTISCALE BASICS

DERIVE THE WEAK

FORMULATION FOR

THE GOVERNING

EQUATIONS

PROJECT THE WEAK

FORMULATION ON

COARSE AND FINE

SCALES

COARSE WEAK

FORM

SOLUTION FUNCTION

SPACES ARE NOW

STOCHASTIC FUNCTION

SPACES

FINE (SUBGRID)

WEAK FORM

COMPUTATIONAL

SUBGRID MODELS

REMOVE SUBGRID

EFFECTS IN THE COARSE

WEAK FORM USING

STATIC CONDENSATION

MODIFIED MULTISCALE COARSE WEAK

FORM INCLUDING SUBGRID EFFECTS

CORNELL

U N I V E R S I T Y

ALGEBRAIC

SUBGRID MODELS

APPROXIMATE

SUBGRID

SOLUTION

NEED TECHNIQUES TO

SOLVE STOCHASTIC PDEs

Materials Process Design and Control Laboratory

VMS – ILLUSTRATION [NATURAL CONVECTION]

Mass conservation

Momentum conservation

Energy conservation

Constitutive laws

v vg

v0

v

v v Ra( ) Pr( ) eg

t

v 2

t

pI 2 Pr( ) (v)

1

(v) [v (v)T ]

2

D

VMS

DERIVE

DERIVE

DEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID

CORNELL

U N I V E R S I T Y

g

OBTAIN FINAL COARSE

ASGS FORMULATION

Materials Process Design and Control Laboratory

WEAK FORM OF EQUATIONS

Energy function space

Test

Trial

E : L2 (W; L2 (T ; H 1 ( D))), g on

E0 w : w L2 (W; H 1 ( D)), w 0 on

Energy equation – Find

the following holds

E such that, for all w E0 ,

(t , w) (v. , w) ( , w) v 0

VMS hypothesis: Exact solution = coarse scale solution +

fine scale (subgrid) solution

'

E E E ', E0 E0 E0 '

VMS

DERIVE

DERIVE

DEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID

CORNELL

U N I V E R S I T Y

OBTAIN FINAL COARSE

ASGS FORMULATION

Materials Process Design and Control Laboratory

ENERGY EQUATION – SCALE DECOMPOSITION

Energy equation – Find E and w E0 such that, for all

E and w E0 , the following holds

Coarse scale variational formulation

( t t ', w) (v. v. ', w) ( ', w) v 0

Subgrid scale variational formulation

( t t ', w ') (v. v. ', w ') ( ', w ') v 0

These equations can be re-written in the strong form with

assumption on regularity as follows

t ' v. ' 2 ' ( t v. 2 ) R

VMS

DERIVE

DERIVE

DEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID

CORNELL

U N I V E R S I T Y

OBTAIN FINAL COARSE

ASGS FORMULATION

Materials Process Design and Control Laboratory

ELEMENT FOURIER TRANSFORM

Element Fourier transform

D

(e)

gˆ (k , )

exp(i

D( e )

SPATIAL MESH

RANDOM FIELD

DEFINED IN

WAVENUMBER SPACE

k x

) g ( x, )dx

h

RANDOM FIELD

DEFINED OVER

THE DOMAIN

Addressing spatial derivatives

kj

kj

g

k x

n j exp(i

) g ( x, )d i gˆ (k , ) i gˆ (k , )

x D( e )

h

h

h

NEGLIGIBLE FOR LARGE

WAVENUMBERS SUBGRID

VMS

DERIVE

DERIVE

DEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID

CORNELL

U N I V E R S I T Y

APPROXIMATION

OF DERIVATIVE

OBTAIN FINAL COARSE

ASGS FORMULATION

Materials Process Design and Control Laboratory

ASGS [ALGEBRAIC SUBGRID SCALE] MODEL

t ' v. ' 2 ' ( t v. 2 ) R

STRONG FORM OF EQUATIONS FOR SUBGRID

1

t f n ( f n 1 f n ),

t

f n f n 1 (1 ) f n

CHOOSE AND APPROPRIATE TIME INTEGRATION ALGORITHM

t n' L( n' ) Rn

TIME DISCRETIZED SUBGRID EQUATION

TAKE ELEMENT

FOURIER

TRANSFORM

2

1

'

k

vk

1 ˆ'

i

2 ˆn Rˆn

n

t

h

h

t

2

1

1 '

1 v

t Rn

n , t c1 2

c2

h t h

t

2

n'

CORNELL

U N I V E R S I T Y

1

2

Materials Process Design and Control Laboratory

MODIFIED COARSE FORMULATION

Assume the solution obeys the following regularity conditions

(v ', w) ( ', v w), ( ', w) v ( ', 2 w) v

By substituting ASGS model in the coarse scale weak form

( t n , w) (v n , w) ( n , w) v ( q0 , w) ht

Nel

( t n v n 2 n , t ( w v w 2 w)

e 1

Nel

( n' , t w /( t ) t v w) 2 w w) 0

e 1

w w /( t )

A similar derivation ensues for stochastic Navier-Stokes

VMS

DERIVE

DERIVE

DEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID

CORNELL

U N I V E R S I T Y

OBTAIN FINAL COARSE

ASGS FORMULATION

Materials Process Design and Control Laboratory

FLOW PAST A CIRCULAR CYLINDER

NO-SLIP

TRACTION FREE

6

Y

RANDOM UINLET

8

4

2

0

0

5

10

15

20

X

NO-SLIP

INLET VELOCITY ASSUMED TO BE A UNIFORM RANDOM VARIABLE

KARHUNEN-LOEVE EXPANSION YIELD A SINGLE RANDOM VARAIBLE

THUS, GENERALIZED POLYNOMIAL CHAOS LEGENDRE

POLYNOMIALS (ORDER 3 USED)

Investigations: Vortex shedding, wake characteristics

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

FULLY DEVELOPED VORTEX SHEDDING

Mean pressure

Second LCE coefficient

First LCE coefficient

Wake region in the mean

pressure is diffusive in

nature

Also, the vortices do not

occur at regular intervals

[Karniadakis J. Fluids.

Engrg]

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

VELOCITIES AND FFT

0.6

0.15

0.4

0.2

0.09

V

Amplitude

0.12

0

0.06

-0.2

0.03

0

0.1

-0.4

-0.6

0.2

0.3

Frequency

0.4

0.5

FFT YIELDS A MEAN SHEDDING

FREQUENCY OF 0.162

FFT SHOWS A DIFFUSE

BEHAVIOR IMPLYING CHANGING

SHEDDING FREQUENCIES

CORNELL

U N I V E R S I T Y

Deterministic

Mean

5

8

11

X

14

17

20

MEAN VELOCITY AT NEAR WAKE

REGION EXHIBITS

SUPERIMPOSED FREQUENCIES

Materials Process Design and Control Laboratory

VARIATIONAL MULTISCALE METHOD WITH EXPLICIT

SUBGRID MODELLING FOR MULTISCALE DIFFUSION IN

HETEROGENEOUS RANDOM MEDIA

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

MODEL MULTISCALE HEAT EQUATION

D

u

( K u ) f in D

t

u ( x, 0) u0 ( x) in D

u u g on

THE DIFFUSION COEFFICIENT K IS HETEROGENEOUS AND POSSESSES RAPID

RANDOM VARIATIONS IN SPACE

OTHER APPLICATIONS

– DIFFUSION IN

COMPOSITES

– FUNCTIONALLY

GRADED MATERIALS

FLOW IN HETEROGENEOUS

POROUS MEDIA

INHERENTLY STATISTICAL

DIFFUSION IN

MICROSTRUCTURES

FINAL COARSE

VMS

AFFINE

DERIVE

COARSE-TODEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID MAP CORRECTION FORMULATION

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

STOCHASTIC WEAK FORM

U u : u L2 (W; H 1 ( D)), u u g

V v : v L2 (W; H 1 ( D)), v 0

Weak formulation : Find

u U such that, for all v V

(u,t , v) a(u, v) ( f , v); a(u, v) : ( K u, v)

VMS hypothesis

Exact solution

u u u

C

F

Coarse solution

U U C U F

Subgrid solution

V V C V F

FINAL COARSE

VMS

AFFINE

DERIVE

COARSE-TODEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID MAP CORRECTION FORMULATION

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

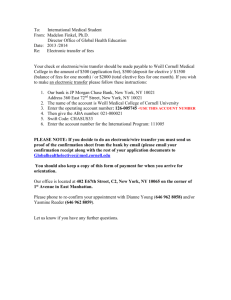

EXPLICIT SUBGRID MODELLING: IDEA

DERIVE THE WEAK

FORMULATION FOR

THE GOVERNING

EQUATIONS

COARSE WEAK

FORM

PROJECT THE WEAK

FORMULATION ON

COARSE AND FINE

SCALES

FINE (SUBGRID)

WEAK FORM

COARSE-TO-SUBGRID

MAP EFFECT OF

COARSE SOLUTION ON

SUBGRID SOLUTION

AFFINE CORRECTION

SUBGRID DYNAMICS THAT

ARE INDEPENDENT OF

THE COARSE SCALE

LOCALIZATION, SOLUTION OF SUBGRID

EQUATIONS NUMERICALLY

FINAL COARSE WEAK FORMULATION THAT

ACCOUNTS FOR THE SUBGRID SCALE EFFECTS

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

SCALE PROJECTION OF WEAK FORM

Find u U and u U such that, for all

F

F

and v V

Projection of weak form on coarse scale

C

C

F

F

v V

C

C

(u,Ct , vC ) (u,Ft , vC ) a(uC , vC ) a(u F , vC ) ( f , vC )

Projection of weak form on subgrid scale

(u,Ct , v F ) (u,Ft , v F ) a(uC , v F ) a(u F , v F ) ( f , v F )

u F uˆ F u F 0

EXACT SUBGRID

SOLUTION

COARSE-TO-SUBGRID

MAP

SUBGRID AFFINE

CORRECTION

FINAL COARSE

VMS

AFFINE

DERIVE

COARSE-TODEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID MAP CORRECTION FORMULATION

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

SPLITTING THE SUBGRID SCALE WEAK FORM

Subgrid scale weak form

(u , v ) (u , v ) a(u , v ) a(u , v ) ( f , v )

C

,t

F

F

,t

F

C

F

F

F

F

Coarse-to-subgrid map

F

F

C

F

F

F

ˆ

ˆ

(u , v ) (u,t , v ) a(u , v ) a(u , v ) 0

C

,t

F

Subgrid affine correction

(u , v ) a(u , v ) ( f , v )

F0

,t

CORNELL

U N I V E R S I T Y

F

F0

F

F

Materials Process Design and Control Laboratory

NATURE OF MULTISCALE DYNAMICS

ASSUMPTIONS:

1

1

NUMERICAL ALGORITHM

FOR SOLUTION OF THE

MULTISCALE PDE

t

SUBGRID TIME STEP t

COARSE TIME STEP

A(t )

B (t )

ũC

ūC

Coarse

solution field

at start of

time step

ûF

t

CORNELL

U N I V E R S I T Y

Coarse

solution field

at end of

time step

t

Materials Process Design and Control Laboratory

REPRESENTING COARSE SOLUTION

COARSE MESH

ELEMENT

D( e )

RANDOM FIELD DEFINED OVER THE

ELEMENT

u C ( x, t , )

FINITE ELEMENT PIECEWISE

POLYNOMIAL REPRESENTATION

C

u

1 (t, ) ( x)

USE GPCE TO REPRESENT THE

RANDOM COEFFICIENTS

C

u

1 s0 s (t) s ( ) ( x)

nbf

nbf

PC

Given the coefficients u s (t ) , the coarse scale

solution is completely defined

C

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

COARSE-TO-SUBGRID MAP

COARSE MESH

ELEMENT

D( e )

ANY INFORMATION FROM COARSE

TO SUBGRID SOLUTION CAN BE

PASSED ONLY THROUGH

uCs (t )

uˆ ( x, t , ) 1 s 0 uCs (t )Fs ( x, t , )

F

COARSE-TOSUBGRID MAP

nbf

PC

INFORMATION BASIS FUNCTIONS

THAT ACCOUNT

FROM COARSE

FOR FINE SCALE

SCALE

EFFECTS

FINAL COARSE

VMS

AFFINE

DERIVE

COARSE-TODEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID MAP CORRECTION FORMULATION

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

SOLVING FOR THE COARSE-TO-SUBGRID MAP

START WITH THE WEAK FORM

(u,Ct , v F ) (uˆ,Ft , v F ) a(uC , v F ) a(uˆ F , v F ) 0

APPLY THE MODELS FOR COARSE SOLUTION AND THE C2S MAP

u

C

s

( s Fs ) ,t , v F K uCs ( s Fs ) , v F 0

AFTER SOME ASSUMPTIONS ON TIME STEPPING

(

s

Fs ),t , v F K ( s Fs ), v F 0

THIS IS DEFINED OVER EACH ELEMENT,

IN EACH COARSE TIME STEP

0

CORNELL

U N I V E R S I T Y

t

t

Materials Process Design and Control Laboratory

BCs FOR THE COARSE-TO-SUBGRID MAP

(

s

Fs ),t , v F K ( s Fs ), v F 0

INTRODUCE A SUBSTITUTION

s s Fs

F

F

,

,

v

K

,

v

0

s t

s

CONSIDER AN ELEMENT

x3

x4

F

F

,

v

K

,

v

0

s ,t

s ,

s ,t ( x , t ', ) s ( )

x1

s s

CORNELL

U N I V E R S I T Y

x2

s ,t ( x, 0, ) s ,t ( x, tn , )

Materials Process Design and Control Laboratory

SOLVING FOR SUBGRID AFFINE CORRECTION

START WITH THE WEAK FORM

(u,Ft 0 , v F ) a(u F 0 , v F ) ( f , v F )

CONSIDER AN ELEMENT

x4

x3

WHAT DOES AFFINE CORRECTION MODEL?

– EFFECTS OF SOURCES ON SUBGRID SCALE

– EFFECTS OF INITIAL CONDITIONS

x1

uF0 0

x2

IN A DIFFUSIVE EQUATION, THE EFFECT OF

INITIAL CONDITIONS DECAY WITH TIME. WE

CHOOSE A CUT-OFF

To reduce cut-off effects and to increase efficiency, we can

use the quasistatic subgrid assumption

s ,t u,Ft 0 0

FINAL COARSE

VMS

AFFINE

DERIVE

COARSE-TODEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID MAP CORRECTION FORMULATION

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

MODIFIED COARSE SCALE FORMULATION

We can substitute the subgrid results in the coarse scale

variational formulation to obtain the following

C

C

C

C

C

C

u

,

,

v

u

,

,

v

u

K

,

v

s t s s s t s

s

( f , v C ) K u F 0 , v C u F 0 , t , v C

We notice that the affine correction term appears as an antidiffusive correction

Often, the last term involves computations at fine scale time

steps and hence is ignored

FINAL COARSE

VMS

AFFINE

DERIVE

COARSE-TODEFINE

PROBLEM WEAK FORM HYPOTHESIS SUBGRID MAP CORRECTION FORMULATION

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

DIFFUSION IN A RANDOM MICROSTRUCTURE

– A MIXTURE MODEL IS USED AS AN

EXAMPLE OF GENERATING A

HETEROGENEOUS DISTRIBUTION OF

CONDUCTIVITY

– WE ASSUME THAT THE DIFFUSION

COEFFICIENTS OF INDIVIDUAL

CONSTITUENTS ARE NOT KNOWN

EXACTLY

k* ( ) k*0 k*1 ( )

THE INTENSITY OF THE GRAY-SCALE

IMAGE IS MAPPED TO THE

CONCENTRATIONS

DARKEST DENOTES PHASE

LIGHTEST DENOTES PHASE

k ( x, ) (k ( ) k ( )) I ( x) k ( )

u (x, 0, ) 0

CORNELL

U N I V E R S I T Y

u |( x 1) 0, u |( x 0) 1, k

u

|( y 0,1) 0

n

Materials Process Design and Control Laboratory

RESULTS AT TIME = 0.05

FIRST ORDER GPCE

COEFF

SECOND ORDER GPCE

COEFF

FULLY RESOLVED

GPCE SIMULATION

RECONSTRUCTED FINE

SCALE SOLUTION (VMS)

MEAN

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

RESULTS AT TIME = 0.2

FIRST ORDER GPCE

COEFF

SECOND ORDER GPCE

COEFF

FULLY RESOLVED

GPCE SIMULATION

RECONSTRUCTED FINE

SCALE SOLUTION (VMS)

MEAN

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

HIGHER ORDER TERMS AT TIME = 0.2

FOURTH ORDER GPCE

COEFF

FIFTH ORDER GPCE

COEFF

FULLY RESOLVED

GPCE SIMULATION

RECONSTRUCTED FINE

SCALE SOLUTION (VMS)

THIRD ORDER GPCE

COEFF

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

SUPPORT-SPACE – STOCHASTIC GALERKIN

f ( ( ))

- Joint probability density function of the inputs

A { ( ) : f ( ( )) 0}

- The input support-space denotes the regions where input

joint PDF is strictly positive

Triangulation

of the supportspace

Any function X ( ( )) can be represented as a

piecewise polynomial on the triangulated support-space

h

X ( ( )) - Function to be approximated

X h ( ( )) - Piecewise polynomial approximation

over support-space

L2 convergence – (mean-square)

(X

Error in approximation is penalized

severely in high input joint PDF regions.

We use importance based refinement of

grid to avoid this

CORNELL

U N I V E R S I T Y

h

( ( )) X ( ( )))2 f ( ( ))d Chq 1

A

h = mesh diameter for the support-space

discretization

q = Order of interpolation

Materials Process Design and Control Laboratory

IMPLEMENTATION OF SUPPORT-SPACE

A stochastic process W ( x, t , ) can be interpreted as a random variable at each spatial

point

Two-level grid

approach

A

D

Support-space grid

Spatial domain

• Mesh dense in

regions of high

input joint PDF

Spatial grid

• There is finite element interpolation at

both spatial and random levels

D( e )

( x, )

A( e ')

Element

• Each spatial location handles an

underlying support-space grid

• Highly OOP structure

nbf

nbf ' nbf

i 1

j 1 i 1

f ( x, ) fi ( ) Ni ( x) fi j N 'j ( ) Ni ( x)

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

CAPTURING UNSTABLE EQUILIBRIUM

• Computational details – 1600 bilinear elements for spatial grid

• Time of simulation – 1.5 nondimensional units

Cold wall c 0

1

0.75

Insulated

Y

Insulated

0.5

• Rayleigh number – uniformly

distributed random variable

between 1530 and 1870 (10%

fluctuation about 1700)

• Prandtl number – 6.95

• Time stepping – 0.002 nondimensional units

0.25

0

0

0.25

0.5

0.75

1

X

Hot wall h 1

• Support-space grid – Onedimensional with ten linear

elements

• Simulation about the critical Rayleigh number – conduction below, convection above

• Both GPCE and support-space methods are used separately for addressing the problem

• Failure of Generalized polynomial chaos approach

• Support-space method – evaluation and results against a deterministic simulation

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

FAILURE OF THE GPCE

9.2E-07 5.7E-06 1.0E-05 1.5E-05 2.0E-05 2.5E-05 3.0E-05 3.4E-05

1

-6.4E-08 4.3E-07

1

1.4E-06

1.9E-06

2.4E-06

2.9E-06

3.4E-06

Y-vel

X-vel

0.75

0.75

0.5

Y

Y

Mean X- and Yvelocities

determined by

GPCE yields

extremely low

values !! (Gibbs

effect)

0.25

0

0.5

0.25

0

0.25

0.5

0.75

0

1

X

-5.0E-03 -3.6E-03 -2.1E-03 -7.1E-04 7.1E-04

1

2.1E-03

3.6E-03

0.5

0.75

1

1.6E-03

2.8E-03

4.0E-03

5.2E-03

Y-vel

0.75

Y

Y

0.5

0.5

0.25

0.25

0

0

0.25

0.5

X

CORNELL

0.25

-3.2E-03 -2.0E-03 -8.0E-04 3.9E-04

1

5.0E-03

0.75

X- and Yvelocities

obtained from a

deterministic

simulation with

Ra = 1870 (the

upper limit)

0

X

X-vel

U N I V E R S I T Y

9.3E-07

0.75

1

0

0

0.25

0.5

0.75

1

X

Materials Process Design and Control Laboratory

PREDICTION BY SUPPORT-SPACE METHOD

-5.0E-03 -3.6E-03 -2.1E-03 -7.1E-04 7.1E-04

1

2.1E-03

3.6E-03

5.0E-03

-3.2E-03 -2.0E-03 -7.4E-04 4.9E-04

1

2.9E-03

4.2E-03

5.4E-03

Y-vel

X-vel

0.75

Y

Mean X- and Yvelocities

determined by

support-space

method at a

realization

Ra=1870

Y

0.75

0.5

0.25

0.25

0

0.5

0

0

0.25

0.5

0.75

1

0

0.25

-5.0E-03 -3.6E-03 -2.1E-03 -7.1E-04 7.1E-04

1

2.1E-03

3.6E-03

1

1.6E-03

2.8E-03

4.0E-03

5.2E-03

0.75

Y

Y

0.5

0.5

0.25

0.25

0

0

0.25

0.5

X

CORNELL

0.75

Y-vel

0.75

X- and Yvelocities

obtained from a

deterministic

simulation with

Ra = 1870 (the

upper limit)

-3.2E-03 -2.0E-03 -8.0E-04 3.9E-04

1

5.0E-03

X-vel

0.5

X

X

U N I V E R S I T Y

1.7E-03

0.75

1

0

0

0.25

0.5

0.75

1

X

Materials Process Design and Control Laboratory

SPARSE GRID COLLOCATION

If the number of random inputs is large (dimension D ~ 10

or higher), the number of grid points to represent an output

on the support-space mesh increases exponentially

GPCE for very high dimensions yields highly coupled

equations and ill-conditioned systems (relative magnitude of

coefficients can be drastically different)

Instead of relying on piecewise interpolation, series

representations, can we choose collocation points that still

ensure accurate interpolations of the output (solution)

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

SMOLYAK ALGORITHM: SPARSE GRIDS

Full tensor product grid:

289 points

Example of using sparse grids to build interpolating functions:

Discontinuous functions

Sparse Grid: 65 points

Left to right: Improving interpolation depth

Number of points required to construct

For an error around 2x10-2:

interpolating functions reduces combinatorially.

Required number of points using sparse grids 3300

Reduction more significant as the number of

Required number of points using full tensor products: 32769

dimensions increases

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

SMOLYAK ALGORITHM

LET OUR BASIC 1D INTERPOLATION SCHEME BE SUMMARIZED AS

Ui( f )

a

xi X i

x

i

f ( xi )

IN MULTIPLE DIMENSIONS, THIS CAN BE WRITTEN AS

(U i1

U id )( f )

xi1 X i1

xid X id

(axi1

axid ) f (x i1 ,

, x id )

TO REDUCE THE NUMBER OF SUPPORT NODES WHILE MAINTAINING

ACCURACY WITHIN A LOGARITHMIC FACTOR, WE USE SMOLYAK METHOD

U 0 0, i U i U i 1 ,

i i1

Aq ,d ( f ) Aq 1,d ( f ) (i1

id

id )( f )

i q

IDEA IS TO CONSTRUCT AN EXPANDING SUBSPACE OF COLLOCATION

POINTS THAT CAN REPRESENT PROGRESSIVELY HIGHER ORDER

POLYNOMIALS IN MULTIPLE DIMENSIONS

A FEW FAMOUS SPARSE QUADRATURE SCHEMES ARE AS FOLLOWS:

CLENSHAW CURTIS SCHEME, MAXIMUM-NORM BASED SPARSE GRID AND

CHEBYSHEV-GAUSS SCHEME

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

SMOLYAK ALGORITHM

Extensively used in statistical mechanics

Uni-variate interpolation

Provides a way to construct interpolation

functions based on minimal number of

points

Ui( f )

a

xi X i

x

i

f ( xi )

Multi-variate interpolation

(U i1

Univariate interpolations to multivariate

(U i1 U id )( f )

interpolations

xi1 X i1

U id )( f )

xid X id

( axi1

(axi1

axid ) f (x ,

, x id )

xi1 X i1

xid iX id

1

Smolyak interpolation

U 0 0, i U i U i 1 ,

Some degradation in accuracy

i i1

Aq ,d ( f ) Aq 1,d ( f ) (i1

id

id )( f )

i q

Maximal reduction when the

function is assumed to be smooth

CORNELL

U N I V E R S I T Y

D = 10

ORDER

CC

FE

3

1581

1000

4

8801

10000

5

41625

100000

Materials Process Design and Control Laboratory

SPARSE GRID COLLOCATION METHOD

Solution Methodology

PREPROCESSING

Compute list of collocation points based on number of

stochastic dimensions, N and level of interpolation, q

Compute the weighted integrals of all the interpolations

functions across the stochastic space (wi)

Solve the deterministic problem defined by each set of

collocated points

Use any validated deterministic

solution procedure.

Completely non intrusive

POSTPROCESSING

0.301

0.260

0.301

0.260

0.220

0.220

0.180

0.180

0.140

0.140

0.100

0.100

0.060

0.060

0.020

0.020

Compute moments and other statistics with simple

operations of the deterministic data at the collocated

points and the preprocessed list of weights

Std deviation of temperature:

Natural convection

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

USING THE COLLOCATION METHOD FOR HIGHER DIMENSIONS

1. Flow through heterogeneous random media

Alloy solidification, thermal insulation, petroleum prospecting

Look at natural convection through a realistic sample of heterogeneous material

Square cavity with free fluid in the middle

part of the domain. The porosity of the

material is taken from experimental data1

Left wall kept heated, right wall cooled

Numerical solution procedure for the

deterministic procedure is a fractional time

stepping method

1. Reconstruction of random media using Monte Carlo methods, Manwat and Hilfer, Physical Review E. 59 (1999)

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

FLOW THROUGH HETEROGENEOUS RANDOM MEDIA

Experimental correlation for the porosity of the

sandstone.

Material: Sandstone

Eigen spectrum is peaked. Requires large

dimensions to accurately represent the stochastic

space

Simulated with N= 8

Number of collocation points is 11561 (level 4

interpolation)

15

1

0.9

0.8

0.7

0.6

0.5

Eigen

spectrum

0.4

0.3

Eigenvalue

10

Numerically

computed

5

0.2

0.1

0

0

10

20

30

40

50

60

0

5

10

15

20

Index

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

FLOW THROUGH HETEROGENEOUS RANDOM MEDIA

Temperature

Snapshots at a few collocation points

Temperature

9.1

6.4

3.7

1.0

-1.7

-4.4

-7.1

-9.8

0.9

0.8

0.7

0.6

0.4

0.3

0.2

0.1

14.2

10.1

6.1

2.0

-2.0

-6.1

-10.1

-14.1

CORNELL

U N I V E R S I T Y

12.1

8.6

5.1

1.7

-1.8

-5.3

-8.7

-12.2

7.0

4.4

1.8

-0.8

-3.4

-6.0

-8.6

-11.2

Streamlines

Temperature

0.9

0.8

0.7

0.6

0.4

0.3

0.2

0.1

Y velocity

0.94

0.81

0.69

0.56

0.44

0.31

0.19

0.06

y-Velocity

0.9

0.8

0.7

0.6

0.4

0.3

0.2

0.1

FIRST MOMENT

SECOND MOMENT

0.097

0.084

0.071

0.058

0.045

0.032

0.019

0.006

Y velocity

5.056

4.382

3.708

3.034

2.359

1.685

1.011

0.337

Materials Process Design and Control Laboratory

USING THE COLLOCATION METHOD FOR HIGHER DIMENSIONS

2. Flow over rough surfaces

Thermal transport across rough surfaces, heat exchangers

Look at natural convection through a realistic roughness profile

Rectangular cavity filled with fluid.

Lower surface is rough. Roughness auto

correlation function from experimental data2

T (y) = -0.5

Lower surface maintained at a higher

temperature

Rayleigh-Benard instability causes

convection

T (y) = 0.5

y = f(x,ω)

Numerical solution procedure for the

deterministic procedure is a fractional time

stepping method

2. H. Li, K. E. Torrance, An experimental study of the correlation between surface roughness and light scattering for rough

metallic surfaces, Advanced Characterization Techniques for Optics, Semiconductors, and Nanotechnologies II,

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

NATURAL CONVECTION ON ROUGH SURFACES

Experimental ACF

Experimental correlation for the surface roughness

1

Eigen spectrum is peaked. Requires large

dimensions to accurately represent the stochastic

space

0.8

0.6

V2

Simulated with N= 20 (Represents 94% of the

spectrum)

0.4

0.2

Number of collocation points is 11561 (level 4

interpolation)

0.44

0.44

0.31

0.31

0.19

0.19

0.06

0.06

-0.06

-0.06

-0.19

-0.19

-0.31

-0.31

-0.44

-0.44

0.44

0.31

0.19

0.06

-0.06

-0.19

-0.31

-0.44

CORNELL

U N I V E R S I T Y

0

0.5

1

1.5

2

V1

Numerically computed

Eigen spectrum

Sample realizations

of temperature at

collocation points

16

12

Eigenvalue

0.44

0.31

0.19

0.06

-0.06

-0.19

-0.31

-0.44

0

8

4

0

5

10

15

20

Index

Materials Process Design and Control Laboratory

NATURAL CONVECTION ON ROUGH SURFACES

FIRST MOMENT

SECOND MOMENT

Temperature

Temperature

0.17

0.14

0.12

0.10

0.08

0.06

0.03

0.01

0.44

0.31

0.19

0.06

-0.06

-0.19

-0.31

-0.44

Streamlines

Y Velocity

7.63

6.62

5.60

4.58

3.56

2.54

1.53

0.51

Roughness causes improved thermal transport due to enhanced nonlinearities

Results in thermal plumes

Can look to tailor material surfaces to achieve specific thermal transport

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

Statistical characterization of microstructures

Can we compute statistical response

of a class of microstructures

subjected to applied loads based on

limited experimental information?

Features of a microstructure

Grain size (in 3D,

grain volume)

When a specimen is

manufactured, the

microstructures at a

sample point will not

be the same always.

Orientation

Distribution

Function

Rodrigues’

representation

FCC fundamental

region

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

Technique employed

Maximum entropy (MAXENT): The probability distribution that maximizes entropy and

satisfies the given (experimental/simulation-based) information is the least-biased

estimate that can be made.

Problem formulation

Numerical implementation

Limited microstructures computed

using phase field simulations

We employ the voronoi cell

tessellation technique for

representing microstructures.

Extract features of the microstructure

Geometrical: grain size

Texture: ODFs

Conjugate

Compute a PDF of microstructures

Entropy

gradient

Compute bounds on macroscopic properties

microstructure

feature constraints

Meshing a statistical class of microstructures

using CUBIT

CORNELL

U N I V E R S I T Y

features of microstructure, I

Given information about

microstructures. We use grain

size and texture features

Materials Process Design and Control Laboratory

Statistical class of 3D Aluminium polycrystals

Three statistical

Aluminium polycrystal

samples generated using

phase field simulations

Comparison of grain size distributions

between a phase field simulation from the

representative class and a MaxEnt sample

First four

statistical

moments of

grain sizes

(volumes)

Probability mass function

0.25

Grain volume distribution

using phase field simulations

pmf reconstructed using MaxEnt

0.2

0.15

0.1

0.05

0

0

CORNELL

U N I V E R S I T Y

2000 4000 6000 8000 100001200014000160001800020000

Grain volume (voxels)

Materials Process Design and Control Laboratory

ODF reconstruction using MAXENT

Input ODF

0.35

Grain size distribution of a

microstructural sample.

Comparison with the MaxEnt

distribution

Probability mass function

0.3

0.25

Reconstructed

samples using

MAXENT

0.2

0.15

Represent

ation in

FrankRodrigues

space

Rcorr=0.9644

KL=0.0383

0.1

0.05

0

0

5000

10000

15000

Grain volume (voxels)

20000

25000

A microstructural specimen computed from the

MaxEnt distribution

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

Statistical variation of properties

Homogenization scheme:

First order stress averaging

Scheme employing Hill’s criterion

60

How to mesh a

microstructure?

We employ hexahedral

elements using Cubit

software

Mean std

Equivalent stress (MPa)

50

Mean stress-strain

curve

40

30

Aluminium polycrystal

with rate-independent

strain hardening. Pure

tensile test.

20

10

0

0

1

2

Equivalent strain

CORNELL

U N I V E R S I T Y

3

Statistical variation of

homogenized stressstrain curves.

-4

x 10

Materials Process Design and Control Laboratory

HETEROGENEOUS DIFFUSION

a) Two phase materials

b) Micro-emulsions,

c) porous media,

d) ceramics

e) Polycrystals

f) Foams, blends

- To apply physical processes on these

heterogeneous systems

- worst case scenarios

- variations on physical properties

Different morphology, anisotropy

Aim: To develop a procedure to

predict statistics of properties of

heterogeneous materials

undergoing certain phenomena

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

OVERVIEW OF METHODOLOGY

Given certain properties P1, P2, ..

Pn, that the structure satisfies.

STEP 1

These properties are usually

statistical: Volume fraction, 2 Point

correlation, auto correlation

Reconstruct realizations of the

structure satisfying the properties.

Monte Carlo, Gaussian Random

Fields, Stochastic optimization ect

STEP 2

Solve the heterogeneous property

problem in the reduced stochastic

space for computing property

variations.

Collocation schemes

CORNELL

U N I V E R S I T Y

STEP 3

Construct a reduced stochastic

model from the data. This model

must be able to approximate the

class of structures.

KL expansions, FFT and other

transforms, Autoregressive models,

ARMA models

Materials Process Design and Control Laboratory

EXAMPLE: THERMAL DIFFUSION THROUGH TUNGSTEN—SILVER MATRIX

MC-Potts model, generate

microstructures database.

Apply the KL transform

Z

First 9 eigen values are

enough

X

Tungsten-silver composite image1

15

Z

10

5

0

0

Y

1.5807E-02

1.4753E-02

1.3699E-02

1.2645E-02

1.1592E-02

1.0538E-02

9.4840E-03

8.4303E-03

7.3765E-03

6.3227E-03

5.2689E-03

4.2151E-03

3.1613E-03

2.1076E-03

1.0538E-03

0

5

5

Y 10

10

15

X

15

1. S. Umekawa, R. Kotfila and O.D. Sherby, Elastic properties of a

tungsten-silver composite above and below the melting point of silver, J.

Mech. Phys. Solids 13 (1965)

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

REDUCED MODEL FOR THE STRUCTURE

Represent any microstructure as a linear combination of the eigen-images

I = Iavg + I1a1 + I2a2+ I3a3 + … + Inan

=a1

+ ..+ an

+a2

Image I belongs to the class of structures?

It must satisfy certain conditions

a) Its volume fraction must equal the specified volume fraction

b) Volume fraction at every pixel must be between 0 and 1

c) It should satisfy higher order statistics

Thus the n tuple (a1,a2,..,an) must further satisfy some constraints.

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

REDUCED MODEL FOR THE STRUCTURE

Constraints on the coefficients

15

a v

10

i i

v

i

5

a I ( j ) 1, j 1: NPixels

a I ( j ) 0, j 1: NPixels

i i

0

i

-5

i i

i

-10

10

15

15

10

20

-15

-10

-5

0

5

10

15

5

Construct the Convex Hull of the set of linear inequalities.

This is the allowable set of coefficients.

This represents the space of allowable microstructures

0

-5

In this space all the structures are equiprobable.

This represents a stochastic space in (n-1) dimensions.

Actually a plane in n dimensions, Call this the ‘material

plane’

CORNELL

U N I V E R S I T Y

-10

-15

11

11.5

12

12.5

13

13.5

14

14.5

15

15.5

16

Materials Process Design and Control Laboratory

PHYSICAL PROBLEM UNDER CONSIDERATION

Structure size 20x20x20 μm

Tungsten Silver Matrix

T= -0.5

T= 0.5

Heterogeneous property is the

thermal diffusivity.

Tungsten: ρ 19250 kg/m3

k 174 W/mK

c 130 J/kgK

Left wall maintained at -0.5

Silver:

ρ 10490 kg/m3

Right wall maintained at +0.5

k 430 W/mK

All other surfaces insulated

c 235 J/kgK

Diffusivity ratio αAg/αW = 2.5

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

COLLOCATION SCHEME: SAMPLE REALIZATIONS

First column: conductivity

Second column: Temperature

15

10

5

0

-5

-10

-15

11

CORNELL

U N I V E R S I T Y

11.5

12

12.5

13

13.5

14

14.5

15

15.5

16

Materials Process Design and Control Laboratory

MEAN STATISTICS

Temperature isosurfaces

Mean temperature: No variations closer

to the surfaces, significant variations

inside

Mean distribution of silver

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

SECOND ORDER STATISTICS

Temperature slice

Property slice

Left, isosurface of

temperature deviation

0

0

5

5

y

10

10

15

15

CORNELL

U N I V E R S I T Y

x

0

0

5

5

y

10

10

15

Right, isosurface of

properties

x

15

Materials Process Design and Control Laboratory

HIGHER ORDER STATISTICS

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory

Future research directions

Algorithms to address the curse-of-dimensionality

Adaptivity in the support space, adaptive sparse-grid

quadrature rules, SPDE model reduction, etc.

Stochastic multiscale advection-diffusion-reaction

Stochastic multiscale modeling in materials

Information-theoretic algorithms for

coupling statistics across length scales

Robust design techniques

Interface stochastic and statistical

(Bayesian) computation

CORNELL

U N I V E R S I T Y

Materials Process Design and Control Laboratory