group alpha presentation 2

advertisement

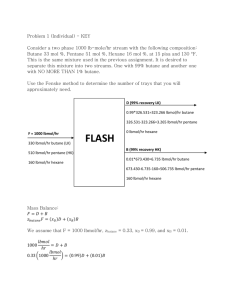

Production of Gasoline Components from Synthesis Gas ChE 397 Senior Design Group Alpha Ayesha Rizvi Bernard Hsu Jeff Tyska Mohammed Shehadeh Yacoub Awwad 2011.02.15 Recap H2 Block Flow Diagram CO H2 Methanol Reactor MeOH DME DME Reactor H 2O MeOH Methanol to Gasoline Reactors Crude Gasoline H2O, trace contaminants Wastewater treatment Light Gas Heavy Gasoline Distillation Columns Storage Light Gasoline Overall Flowsheet Mass Balance Basis: 3307 Tons per Day Syn Gas Syngas to Methanol MeOH: 8226.65 lbmol/hr CO: 8611.72 lbmol/hr H2: 17223.45 lbmol/hr CO: 141.09 lbmol/hr H2: 18.48 lbmol/hr CO: 243.98 lbmol/hr H2: 594.88 lbmol/hr Mass Balance Basis: 3307 Tons per Day Syn Gas DME reaction MeOH: 8226.65 lbmol/hr MeOH: 2468.00 lbmol/hr DME and H2O: 2879.33 lbmol/hr Mass Balance Basis: 3307 Tons per Day Syn Gas Methanol to Gasoline Effluent: 8226.65 lbmol/hr After the MTG Reaction Cooling Separator End Refining LPGPRG Final Recycle Material Balance Methanol Reactor In Syn Gas: CO: H2: Recycle: CO: H2: 8612 17223 12199 29744 Out lbmol/hr lbmol/hr lbmol/hr lbmol/hr purge: CO: H2: product: CO: H2: 244 594.9 141.1 18.48 lbmol lbmol lbmol lbmol MeOH: 8227 lbmol 2.207505519 Material Balance DME Reactor MeOH: H2O: 2.207505519 In: 8227 lbmol/hr 0 lbmol/hr MeOH: H2O: Out: 2468 lbmol/hr 2879 lbmol/hr DME: 2879 lbmol/hr Material Balance Component Profile Component lbmol/hr Component lbmol/hr Assumptions 58.87856 1. All H2 is taken away in the light gas H2 0 C5's C6's 7.870113 2. All CH4 is taken away in the light C1 27.55832 C7's 3.148045 gas CO 0 C8's 1.83636 3. All ethane is taken away in the light CO2 0 C9's 0.655843 gas 0.131169 4. 30% of the propane is taken away C2 = 7.873805 C10's 9.610079 in the light gas C2 8.818661 Benzene 50.32388 5. None of the butane is taken away C3 = 10.49841 Toluene C8 AROM 74.84642 in the light C3 162.3435 C9 AROM 4.842082 6. All CO/CO2 is lost in the light gas iC4 142.1629 C10 AROM 1.832139 7. All water is immiscible with the C4 = 10.23595 C11 AROM other components, leaves 0.261734 completely 0 nC4 42.57285 Methanol Continued above DME H20 Total 0 8. Remaining components are in the second liquid phase 2818.389 3444.69 lbmol/hr Liquid Hydrocarbon = Components C3 C3 iC4 C4 = nC4 C5's C6's C7's C8's C9's C10's Benzene Toluene C8 AROM C9 AROM C10 AROM C11 AROM Total 7.34888 113.64 142.163 10.2359 42.5728 58.8786 7.87011 3.14805 1.83636 0.65584 0.13117 9.61008 50.3239 74.8464 4.84208 1.83214 0.26173 530.2 lbmol/hr Material Balance LPG Flowrates lbmol/hr C1 C2 = C2 C3 = C3 iC4 C4 = nC4 C5's Total 0 0 0 7.348884 113.6405 142.1629 10.23595 42.57285 5.887856 321.8489 lbmol/hr % 0 0 0 2.283334 35.30864 44.1707 3.180358 13.22759 1.829385 Assumptions 1. All of the remaining propane goes out the vapor stream 2. All of the remaining butane goes out the vapor stream 3. 10% of the pentane goes out the vapor stream 4. The liquid component out the stripper is our final product Material Balance Product Composition C5's C6's C7's C8's C9's C10's Benzene Toluene C8 AROM C9 AROM C10 AROM C11 AROM Total 52.9907 7.870113 3.148045 1.83636 0.655843 0.131169 9.610079 50.32388 74.84642 4.842082 1.832139 0.261734 208.3486 lbmol/hr Energy Balance MeOH rxn ΔHF=Σm*cp*(Tout-Tin)+Q Heat of formation: ΔHF= m DME,outΔHF(DME)+m MeOH DME H2O Q:heat loss to surroundings Tin=590°F MeOH,outΔHF(MeOH)+ mH2O,outΔHF(H2O)- mMeOH,inΔHF(MeOH) = -29.2 MM Btu/hr Energy Balance At heat loss of 3400 Btu Tout= 860°F Heat loss to surroundings negligible Reactor Sizing: PV=nRT V=315.6 Ft3 diameter d=8 Ft , height h=25 Ft considering the reactor as a cylinder Area=2*pi*(d/2)*h+2*pi*(r2 /4) =729 Ft2 Residence Time: 5 seconds for MeOH and Durene Reactor. 10 seconds for MTG Reactors. Component Name Component Type DMEREACT FLASH-flash vessel GASMEHX HCCOOLER HEATER HEATEX MEOHRXN 3PHASESP-flash vessel ACCMLTR-flash vessel GASPROD1 GASPROD2 GASPROD3 HCSHEAT HEATER2 HEATER3 HEATER4 STRIPPER-cond STRIPPER-cond acc STRIPPER-reb STRIPPER-reflux pump STRIPPER-tower Catalyst DAT REACTOR DVT CYLINDER DHE FLOAT HEAD DHE FLOAT HEAD DHE FLOAT HEAD DHE FLOAT HEAD DAT REACTOR DVT CYLINDER DVT CYLINDER DAT REACTOR DAT REACTOR DAT REACTOR DHE FLOAT HEAD DHE FLOAT HEAD DHE FLOAT HEAD DHE FLOAT HEAD DHE FIXED T S DHT HORIZ DRUM DRB U TUBE DCP CENTRIF DTW TRAYED Catalyst Totals: Equipment Cost Total Direct Cost (USD) (USD) 162000 450000 143000 295100 25900 102000 20200 98200 791300 1.21E+06 47200 157800 170000 450000 47000 178200 42700 155700 2.00E+06 6.00E+06 2.00E+06 6.00E+06 2.00E+06 6.00E+06 16000 77100 14800 77700 14800 77700 14800 77700 15800 77300 13100 69200 13900 69900 4200 30000 89900 243700 10000000 10000000 1.76E+07 USD 3.19E+07 USD Equipment Costs Pricing Gasoline What affects the Gasoline Prices Seasonal Switch in Gasoline blends Crude Oil Cost Taxes and Fees Supply and Demand Transportation and Distribution Cost http://www.api.org/aboutoilgas/gasoline/uplo ad/PumpPriceUpdate.pdf Economics of Products Average gasoline price in the city of Chicago is $3.29 per gallon Nationwide the average is $3.13 per gallon Our gasoline price with low olefin and low Durene is roughly about $ 2.63 per gallon Product: $84.6 Million / year LPG : $5.4 Million / year Major Components of Gasoline Total Percentage Composition Components n-Alkanes Branched Alkanes C5, C6, C7, C9, C10C13 17.3% C4, C5, C6, C7, C8, C9, C10-C13 32.0% Cycloalkanes C6, C7, C8 Olefins C6 5.0% 1.8% Aromatics Benzene, Toluene, Xylenes, Ethylbenzene, C3 – Benzenes, C4Benzenes 30.5% Major Components of Gasoline Properties of Gasoline Blends Octane Number (MON/RON) ranges (83/96 – 90/102) Reid Vapor Pressure (psi) ranges (5 - 12) Final Boiling Point (°C) ranges (180 - 210) Sulfur (ppm) ranges (10 - 50) Mixtures of C5-C10 Hydrocarbons Refinery Whiting, IN Refinery Joliet, IL Newton County MTG Process, IN Transporting to Refineries Joliet, IL Key supplier of refined petroleum products to the Midwest. 250,000 barrels of crude per day Produces ~9 million gallons of gasoline, diesel fuel/day. http://www.exxonmobil.com/Corporate/Files/joliet _brochure.pdf Whiting, IN 405,000 barrels of raw crude oil/day Produce 15 million gallons refining products. Whiting Refinery Modernization Project http://www.bp.com/sectiongenericarticle.do?categor yId=9030203&contentId=7055766#7205736 Transport of Gasoline Pipeline transport Railroad transport Gasoline truck transportation Gasoline Blending Conversion process in petroleum refining Fluid Catalytic Cracker (FCC) • Cracking hydrocarbons by vaporization • breaking long chained highboiling hydrocarbon molecules • presence of a fluidized powdered catalyst Alkylate Catalytic Reforming • Isobutane is • Petroleum refinery alkylated with low naphtha molecular weight • low octane alkenes • presence of a strong acid catalyst • high octane • sulfuric acid or liquid products hydrofluoric acid Questions from Presentation 1 Catalysts: Is How long do they last? ZSM-5: Pressure and temp (305 psi, 350ºC) is 52 days gasoline >10% olefins? No, our product is 3.73 wt% olefins. May change with other conditions Durene High melting point 3-6% from literature 2% Limit 1% in our gasoline Blending Other Methods End! Questions From Last Presentation Removal of the water is desirable because the catalyst may tend to become deactivated by the presence of the water vapor at the reaction temperatures employed, but this step is by no means essential Sulfuric Acid Alkylation The Alkylation reaction combines Isobutane Butylene with light Olefins primarily a mix of and Propylene in the presence of a strong acid catalyst, Sulfuric Acid This process results in upgrading the gasoline blend to a high octane blending component. Low Olefin Content (3.73 wt%)