Welcome Presentation

advertisement

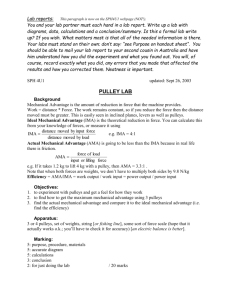

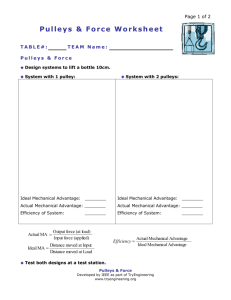

+ TISP: Uruguay 9–10 May 2009 WELCOME! + TISP: Uruguay 9–10 May 2009 Christopher Lester Yvonne Pelham Moshe Kam D.G. Gorham Sort It Out Critical Load Pulleys and Force Ship the Chip + Welcome 3 + Exercise 1: Ship The Chip Package design and the engineering behind shipping products safely + 5 Ship the Chip Objectives Learn about engineering product planning and design Learn about meeting the needs of the customer and society Learn about teamwork and cooperation + 6 Ship the Chip Students will learn… Manufacturing Package Engineering design, manufacture and test Material properties and selection Real world application of mathematics Teamwork + 7 Ship the Chip The Challenge Design a package that will securely hold a potato chip and protect it from breaking when dropped Construct the lightest package to get the highest score Overall score based on: Weight of the package Volume of the package Intactness Score + 8 Ship the Chip Procedure Sketch a design on the worksheet 1. Label your worksheet with Table # and Team Name 2. Construct a model of your package 3. At a test station, drop the package from a height of 1.5 meters 4. Open your package and examine the chip 5. Calculate and record your score 6. Using a second kit, redesign and construct a new package Record the second design on the worksheet 7. Label your package with Table # and Team Name 8. Submit your worksheet and package to the Test Team for overnight testing + 9 Ship the Chip Materials Cardboard – 22 cm x 28 cm 10 Craft sticks 6 Cotton Balls String – 91 cm Plastic wrap – 1 sheet of 22 cm x 28 cm 10 Toothpicks Foil – 1 sheet of 22 cm x 28 cm Paper – 1 sheet of 22 cm x 28 cm 1 Mailing label 1 Potato Chip + 10 Ship the Chip Tools and Accessories Scissors Marking pen Pencils/Pens Calculator Rulers Clear Adhesive Tape Digital Scale Masking Tape + 11 Ship the Chip Scoring Intactness _ Score Overall _ Score Weight _ in _ Kg Volume _ in _ cm3 Intactness score : 100: like new, perfect 50 : slightly damaged; cracked but still in one piece 25 : broken in 2 - 5 pieces 5 : broken in 6-20 pieces 1 : broken into more than 20 pieces; crumbled + 12 Ship the Chip Calculating Volume We will imbed the package in the smallest-volume rectangular prism that contains it We will calculate the volume of the prism; Width x Length x Height For example : 3cm x 4cm x12cm =144 cm3 in the prism shown below If your package weighed 100g and had a volume of 800 cm3 and the chip has arrived broken in 3 pieces: Overall _ Score Intactness _ Score Weight _ in _ Kg Volume _ in _ cm3 25 Overall _ Score 0.3125 0.1 800 + 13 Ship the Chip Procedure Sketch a design on the worksheet 1. Label your worksheet with Table # and Team Name 2. Construct a model of your package 3. At a test station, drop the package from a height of 1.5 meters 4. Open your package and examine the chip 5. Calculate and record your score 6. Using a second kit, redesign and construct a new package Record the second design on the worksheet 7. Label your package with Table # and Team Name 8. Submit your worksheet and package to the Test Team for overnight testing + Exercise 2: Sort It Out! The engineering behind industrial sorting processes + 15 Safety First!! This experiment uses scissors and box cutters! Please be slow, concentrated, and careful when using them + 16 Sort It Out Objectives Learn about engineering of systems and about measurements Learn about sorting mechanisms Get an introduction to Performance Indices and measures of errors Learn about teamwork and cooperation + 17 Sort It Out Sorting through History Miners panning for gold Quality control in food and other industries Bottle sorting for recycling + 18 Sort It Out Different Types of Sorting Image Processing for the operation of Casinos: Off-the-shelf cameras, frame grabbers, and image-processing software used to develop a Lighting casino-coin sorting system Frame Grabber Digital I/O & Network Connection Camera & Optics PC platform Inspection software Part Sensor + 19 Sort It Out Different Types of Sorting Material Properties of Coin: Current run through left coil, creates magnetic field Magnetic field passes through and is attenuated by coin Right coil receives magnetic field, creates measurable current with different value depending on the coin Coin in Center Transverse line represents direction of magnetic field + 20 Sort It Out Why Coin Sorting is Needed Mixed coins come from a variety of sources and must be sorted out before they can be redistributed Coins from vending machines Coins from parking meters Also helpful to identify fake or foreign coins + 21 Sort It Out Why Coin Sorting is Needed Mixed coins are Sorted Rolled Re-circulated through banks and businesses + 22 Sort It Out Your Turn Groups of 2 You are a team of engineers hired by a bank to develop a machine to sort coins that are brought in by customers. Must mechanically sort 16 mixed coins into separate containers. In our experiment we use washers: ½ Inch 1 Inch You will make TWO 1¼ Inch designs today 1½ Inch + 23 Sort It Out! Parallel Sorter Input Sorting Mechanism ½” 1” 1½” 1¼” Output + 24 Sort It Out! Parallel Sorter Input Sorting Mechanism Output + 25 Sort It Out! Serial Sorter Input Sorting Mechanism Output + 26 Sort It Out Performance Index 1: “Distance Index” How good is it? 1: “Distance” performance ½ ½ ½½ 1 ½in ½ 1 1 1 1 1in 1 index: 1¼1¼ 1¼ 1¼ 1¼ 1¼in 1 1½ 1½ 1½ 1½ 1½in Distance from correct bin here, Derror = 2 bins A washer that does not get sorted has maximum Derror = 3 + 27 Sort It Out Performance Index 2: “Percentage Index” How good is it? 2: “Percentage” performance index: ½ ½ ½½ 1 ½in ½ 1 1 1 1 1 1¼1¼ 1¼ 1¼ 1¼ 1in 1¼in 1 1½ 1½ 1½ 1½ 1½in # of washers incorrectly identified Total # of washers to sort 40 5% Sort It Out! Table Number: Type of Sorter Team Name: Serial Parallel Total washers sorted: # of this type in Container for this size washer: each container 1/2" 1/2": 1": 1" 1 1/4" 16 1 1/2" Number left unsorted: Distance Index: 1 1/4": 1 1/2": Percentage Index: Sort It Out! 16 Table Number: Type of Sorter The Perfect Group Team Name: Serial Parallel Total washers sorted: # of this type in Container for this size washer: each container 1/2" 1/2": 1": 1 1/4": 1 1/2": 1" 1 1/4" 16 1 1/2" 4 Number left unsorted: 4 Distance Index: 0 0 4 4 Percentage Index: 0% Sort It Out! Distance Performance Index sqrt( 0x12 + 0x22 + 0x32 ) = 0 A Perfect Score! Remember: Lower is better Percentage ( Performance Index 0 / 16 ) x 100 = 0% Another Perfect Score! Sort It Out! 16 Table Number: Type of Sorter Not That Perfect Team Name: Serial Parallel Total washers sorted: # of this type in Container for this size washer: each container 1/2" 1/2": 1": 1 1/4": 1 1/2": 1" 1 1/4" 16 1 1/2" 4 Number left unsorted: 4 Distance Index: 0 1 4 1 3 Percentage Index: 6.25% Sort It Out! Distance Performance Index sqrt( 1x12 + 0x22 + 0x32 ) = 1 A Less Than Perfect Score! Remember: Lower is better Percentage ( Performance Index 1 / 16 ) x 100 = 6.25% A Less Than Perfect Score! Sort It Out! 16 Table Number: Type of Sorter Serial The Truly Miserable Team Name: Parallel Total washers sorted: # of this type in Container for this size washer: each container 1/2" 1" 1 1/4" 1 1/2" 1 1 1 1 1/2": 4 1": 1 1/4": 1 1/2": 16 Number left unsorted: Distance Index: 2 6.16 4 2 Percentage Index: 56% Sort It Out! 1/2": 1 1 Number left unsorted: Distance Index: 6.16 Percentage Index: 2 56% Performance Index sqrt( 1x12 + 1x22 + 4x22 + 1x32 + 2x32) = 6.16 Much higher score, much lower performance Remember: Lower is better Percentage ( 2 4 1 1/2": Distance 1 4 1": 1 1/4": 1 Performance Index 9 / 16 ) x 100 = 56.25% Again, much lower performance + 35 Sort It Out Your Turn Mechanical “shaking” of your device is allowed as part of its operation Design (draw) a mechanical sorter that can separate the ½in, 1in, 1¼in, 1½in washers Input: either Parallel – all 16 washers are inserted at start of your sorter together; or Serial – 16 washers are inserted at start of your sorter one at a time Output: Each size of washer in its own physical container or surface Materials: glue, tape, paper or plastic plates, cardboard, scissors or hole punch, foil, paper, cardboard tubes washers + 36 Sort It Out Your Turn You will have 45 seconds to allow your sorter to operate Predict the value of the two performance indices for your design Construct your sorting mechanism Test it! Can you do better? You will make TWO designs today: one PARALLEL and one SERIAL Mechanical “shaking” of your device is allowed as part of its operation + 37 Sort It Out Conclusion Did your sorting mechanism work? If not, why did it fail? What were your performance index values? What levels of error would be acceptable in: Medical Equipment manufacturing? Nail manufacturing? What redesigns were necessary when you went to construct your design? Why? + Exercise 3: Pulleys & Force All about force and how pulleys can help reduce it + 39 Pulleys & Force Objectives Learn about pulleys and pulley systems Learn how using multiple pulleys can dramatically reduce required force Learn how pulley systems are used in machines and impact everyday life Learn about teamwork and problem solving in groups + 40 Pulleys & Force Basics of Pulleys: Two orientations Fixed Pulley Movable Pulley + Pulleys & Force The tension in the rope, T, is always the same everywhere Fixed pulley allows for change in direction of applied force Sum of the forces: vertically Basics of Pulleys Compound Pulley 2 T = 100 N T = 50 N 41 + 42 Pulleys & Force Mechanical Advantage Mechanical Advantage (MA) is the factor by which a mechanism multiplies the force or torque put into it. Ideal MA: Actual MA: This movable pulley system has a mechanical advantage of 2 + 43 Pulleys & Force Work Work is the amount of energy transferred by a force acting through a distance Work = Force x Distance Work = Force x Distance A bigger mechanical advantage decreases the force required, but increases the distance over which it must be applied The total amount of work required to move the load stays the same + 44 Pulleys & Force Efficiency The ratio between Actual and Ideal mechanical advantage is Efficiency Frictionless system = 100% Efficiency + 45 Pulleys & Force Pulleys in the World Pulleys have long been used on sailing ships to handle the rigging and move the sails Even with large mechanical advantages, it still takes many people to do the work! + 46 Pulleys & Force Pulleys in the World Pulleys are used in elevators to change the direction of the tension in the cable, reduce power required of lift motor + 47 Pulleys & Force Pulleys in the World Industrial cranes lift large loads for construction and transportation + 48 Pulleys & Force Measuring Tension Spring Scale Calibrate: Hold spring scale at eye-level and turn adjustment screw until the internal indicator is precisely aligned with the top zero line Measure: Create a loop in the end of the rope you want to measure tension in; attach spring scale to loop. Hold the spring scale steady and read off the tension measurement. + Pulleys & Force Your Turn Groups of 2 Develop 2 systems to lift a filled soda bottle 10cm with 1 pulley 2 pulleys Build your systems Measure the distance the soda bottle moves and compare it to the distance you had to pull Measure the force you must exert on the string and compare it to the force that is finally transmitted to the soda bottle What is the actual mechanical advantage? What is the ideal mechanical advantage? Calculate the efficiency of each system 49 + 50 Pulleys & Force Your Turn Now join with one other group at your table Develop 2 different systems to lift a filled soda bottle 10cm with all 4 pulleys Build both systems What are their actual mechanical advantages? Ideal? Which one has a better efficiency? Why do think that is? + 51 Pulleys & Force Conclusion Which system required the least amount of force to lift the bottle? How did this system rank in its mechanical advantage? Do you think the size of the pulley makes a difference in the ideal mechanical advantage? Actual? How could you further increase the efficiency of your most efficient pulley system design? What other engineering problems were solved with pulleys or pulley systems? + 52 Spring Scale www.arborsci.com + End of Saturday Exercises 53 + TISP: Uruguay Sunday, 10 May 2009 54 + Exercise 4: Critical Load Structural engineering and how to reinforce the design of a structure to hold more weight. + 56 Critical Load Objectives Learn about civil engineering and the testing of building structure Learn about efficiency ratings and critical load Learn about teamwork and the engineering problem solving + 57 Critical Load Great Structures of the World Millau Viaduct Millau, France World’s Tallest Bridge 2460m long 434m pylon height 270m road height December, 2004 + 58 Critical Load Great Structures of the World Yokohama Landmark Tower Yokohama, Japan Japan’s Tallest Office Building 296m tall 70 floors including office and hotel July, 1993 + 59 Critical Load Great Structures of the World Beijing National Stadium – “Bird’s Nest” 110,000 tons of steel used in construction 3,000,000 cubic meters Opened June, 2008 World’s Largest Steel Structure 258,000 square meters 5 years to construct + 60 Critical Load Great Structures of the World Crystal Cathedral Garden Grove, California, USA World’s Largest Glass Building 12 stories tall 12,000+ panes of glass 16,000-pipe organ Opened 1980 + 61 Critical Load Great Card Structures of the World Skyscraper of Cards 2007 World Record House of Cards Over 7.5 meters tall No glue or tape; just cards Built 2007 by Bryan Berg in + 62 Bryan Berg at Work A “cardstacker” from Santa Fe, NM, USA + 63 Critical Load What is Critical Load? Force is placed on a structure Force Structure can support up to a certain force created by the weight At a certain point, the structure will fail, breaking The maximum force the structure can sustain before failure is known as the “Critical Load” Force + 64 Critical Load Efficiency A high critical load is not the only parameter to consider Is the best bridge made by filling a canyon with concrete? It certainly would have a high critical load! Consider also the weight of the structure Lighter is better, given the same critical load These two parameters are combined in an “Efficiency Rating”: + 65 Critical Load Your Turn Groups of 2 Up to 12 cards + 1m tape Devise a plan to build a load bearing structure Should have a flat top Support load with base area of 10x10cm at least 8 cm above the table No altering of cards allowed – just tape! No wrap-ups of tape Tape is used to connect cards only + 66 FREQUENTLY ASKED QUESTIONS STRUCTURE NEEDS TO BE CONNECTED BENDING OF CARDS IS ALLOWED CUTTING OF CARDS IS NOT ALLWOED YOU CAN ATTACH SEVERAL CARDS TOGETHER TO MAKE A THICKER CARD THE TOP OF THE STRUCTURE SHOULD ALLOW FOR A LOAD WITH 10X10CM BASE HEIGHT SHOULD BE AT LEAST 8CM + 67 Critical Load Your Turn Example: Supports load Load is at least 8cm above table Cards failed after load of 2.4kg Structure made with 4 cards Efficiency rating: 2.4 kg / 4 cards = 0.6 kg/card 8.5 cm height + 68 Critical Load Your Turn Your efficiency rating: [Load at Failure] / [# of cards used] Predict Build Test what the rating of your design will be your design it! Discuss improvements, then repeat exercise for a second design + 69 Critical Load Conclusion What was your efficiency rating? How close were you to your prediction? How was your design different from the best design? How would you change your design? Why? What other factors would you need to take into consideration if your Card House were a real office building? + End of Sunday Exercises 70