Management History

advertisement

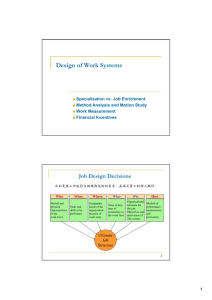

Egyptian Pyramids Great Wall of China Division of Labor (Job Specialization) from The Wealth of Nations by Adam Smith Industrial Revolution The breakdown of jobs into narrow & repetitive tasks. Example of the pin industry among 10 individuals: • They doing a specialized task = 48,000 pins a day • They performing each task separately = 10 pins a day Smith concluded that it increased productivity by increasing each worker’s skill and dexterity, saving time lost in changing tasks, and creating labor-saving inventions and machinery. Machine power was substituted for human power as it was more economical to manufacture goods in factories than at home. “Managers” are required in these factories in order to forecast demand, ensure that enough material was on hand to make products, assign tasks to people, direct daily activities, and etc. Classical Approach Quantitative Behavioral Approach Approach Contemporary Approach Emphasis on ways to manage work more efficiently 2 major theories: • A) Scientific Management • B) Administrative Management Emphasized scientific study of work methods to improve productivity (the rate at which goods are produced) of individual workers Proponents: Frederick Winslow Taylor Frank and Lillian Gilbreth Known as “the father of scientific management” He used the scientific methods to define the “one best way” for doing each job which included: • put the right person on the job with the correct tools & equipment, • had the worker follow his instructions exactly, • and motivated the worker with an economic incentive of significantly higher daily wage differential rate system (piece rate system.) 4 principles of scientific management 1. Evaluate a task by scientifically studying each part of the task 2. Carefully select workers with the right abilities for the task 3. Give workers the training and incentives to do the task with proper work methods 4. Use scientific principles to plan the work methods and ease the way for workers to do their jobs They studied work to eliminate inefficient hand-and-body motions for more productive work performance. Invented a microchronometer for recording a worker’s motions and amount of time spend doing each motion to reduce wasted motions missed by naked eye. Created “therbligs” to classify 17 basic hand motions for more precise way of analyzing a worker’s exact hand movements. Applied scientific management principles and techniques in raising their 12 children and running their household efficiently as known in book wrote by 2 of their children, movies and TV sitcom “Cheaper by the Dozen”. Concerned with managing the total organization Proponents: • Henry Fayol • Max Weber Was the first to identify 5 functions of management: planning, organizing, commanding, coordinating, controlling Developed 14 principles of management which are fundamental rules for managing all kind of organizations Developed theory of authority structures and relations based on ideal type of organization called “bureaucracy.” Division of Labor: clear and well-defined tasks in each division Authority Hierarchy: clear and well-defined positions and chain of command Formal Selection: recruitment is based on ability/qualification Formal Rules and Regulations: clear system of written rules & procedures Impersonality: same rules and controls are applied for everyone Career Orientation: understand the concept of being a manager Later on, he recognized this ‘ideal bureaucracy’ didn’t exist in reality after many people were in positions of authority (esp. government) not because of their abilities but because of their social status. Applies quantitative techniques involve applying statistics, optimization models, information models, computer simulations, and etc. to management activities such as decision making process Example: Linear programming is a technique managers use to improve resource allocation decision A comprehensive approach--led by top management and supported throughout the organization—dedicated to continuous quality improvement, training, and customer satisfaction TQM components are: • Make continuous improvement a priority • Get every employee involved • Listen to & learn from customers & employees • Use accurate standards to identify & eliminate problems Emphasis on importance of understanding human behavior and motivating and encouraging employees toward achievement A series of studies by Elton Mayo and associates during the 1920s and 1930s that provided new insights into individual and group behavior It began with an experiment of whether workplace lighting level affected worker productivity, however, the result was totally contrast with the first assumption. High Experimental Group Control Group Control Group (assumption) Experimental Group (assumption) Productivity Low Adjusted Low-Light Intensity Level High In later experiments, other variables were altered, such as wage levels, rest periods, and length of workday. Finally, according to the later experiments’ results, these studies conclude people’s behavior and attitudes are closely related in which group factors/standards establish individual worker output, namely, employees will work harder they if received added attention, cared welfare from managers. This management approach concerns more on what was happening in the external environment outside the organization, then determine which method should be the best practice 2 contemporary perspectives are: A. System B. Contingency Regards the organization as systems of interrelated parts that operate together to achieve a common purpose Open & Close Systems • Open Systems: Systems that interact with their environment • Closed Systems: Systems that are not influenced by do not interact with their environment 1. 2. Inputs: people, money, information, equipment, materials required to produce an organization’s goods or services Output: products, services, profits, losses, employee satisfaction or discontent, etc. produced by the organization 3. 4. Transformational processes: the organization’s capabilities in management and technology that are applied to converting inputs into outputs Feedback: information about reaction of the environment to the output that affects the inputs External Environment Raw materials Human Resources Energy Financial Resources Information Equipment inputs Organization outputs Transformation Process Feedback Goods Services Emphasizes that a manager’s approach should vary according to the organization size, technologies, individual and the environmental situation “one size doesn’t fit all” Manager will apply method is the best to use under the particular circumstances “flexible” End of Chapter