REDOX-POTENTIAL MEASUREMENT AS A RAPID METHOD FOR

advertisement

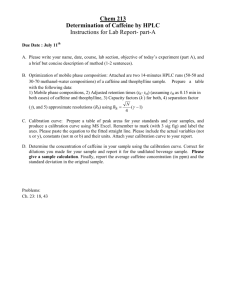

REDOX-POTENTIAL MEASUREMENT AS A RAPID METHOD FOR MICROBIOLOGICAL TESTING Problems in microbiological quality control Classical methods Long incubation time (1-4 days) The applicability, reliability and test price of the methods are concentration-depending: High concentration: dilution and colony counting in the range of 30-300 cfu/ml. Low concentration: MPN method Membrane filtering Redox-potential measurement Physico-chemical base Assuming a chemical reaction: aA+bB cC+dD [C]c [D]d Q = -----------[A]a [B]b Free energy and electric work DG = DG° + R T ln Q DG = - n FDE. n F DE = - n F DE° + R T ln Q Electromotive force RT [C]c [D]d DE = DE° - ------- ln --------nF [A]a [B]b In biological systems The energy source of the growth is the biological oxidation which results in a reduction in the environment. This is due to the oxygen depletion and the production of reducing compounds in the nutrient medium. A typical oxidation-reduction reaction in biological systems: [Oxidant] + [H+] + n e- [Reductant] The electric effect of the changing could be expressed by the Nernst equation: RT [oxidant] [H+] Eh = E0 + ------ ln ---------------nF [reductant] RT [reductant] Eh = E0 - ------ ln ---------------nF [oxidant] [H+] Where Eh is the redox-potential referring to the normal hydrogen electrode (V) E0 is the normal redox-potential of the system (V) R is the Gas-constant R = 8.314 J/mol K F is the Faraday constant F = 9.648˙104 C/mol (J/V mol) n is the number of electrons in the redox system (n=1) Test cell for redox potential measurement Typical redox-curve of the microbial growth E. coli 37 °C, TSB Eh lg N 500 9 400 8 |dE/dt|>DC 200 7 lg Nc 100 6 0 -100 5 -200 -300 lg N0 -400 0 1 2 3 4 TTD 3 4 5 t (h) 6 7 8 9 lg N Eh (mV) 300 The detection time (TTD) is that moment when the absolute value of the rate of redox potential change in the measuring-cell overcomes a value which is significantly differing from the random changes (e.g. |dE/dt| 0.5 mV/min). This value is the detection criterion. As the critical rate of the redox potential decrease needs a determined cell count the detection time depends on the initial microbial count. Redox-curves of several bacteria 500 400 300 Eh (mV) 200 100 0 -100 -200 -300 -400 0 5 10 15 t (h) Campylobacter B. subtilis L. monocytogenes Ent. faecalis Ps. aeruginosa E. coli 20 Effect of the initial Cellconcentration on the redox-curves E. coli in TSB 400 300 Eh (mV) 200 100 0 -100 -200 -300 -400 0 60 120 180 240 300 360 420 480 540 600 660 720 780 840 900 960 t (min) Steril lgN=3,39 steril lgN=4,25 lgN=0,09 lgN=2,38 lgN=4,80 TTD for the redox-potential measurement is: |DE/D t|>1mV/min Effect of the initial cell concentration on TTD E. coli in TSB 6 TTD (h) 5 4 3 2 1 0 2 3 4 lgNo (cfu/inoculum) 5 6 Determination of calibration curves 1. External calibration curve Known microflora The equation of the calibration curve is calculated by linear regression from the log N (determined by classical cultivation) and the TTD (is determined instrumentally) Determination of calibration curves 2. Internal calibration curve Unknown microflora This method is applied when the composition of the microflora is not known and previously constructed calibration curve cannot be taken. In this case, the redox potential measurement is combined with the MPN method. Based on the last dilution levels still showing multiplication, the initial viable count is calculated using the MPN-table. Based on the obtained microbe count and TTD values, the internal calibration curve can be constructed. Determination of the internal calibration curve 1. Determination of the internal calibration curve 2. Determination of the internal calibration curve 3. Validation of the Redox-potential measuring method Test microorganisms and culture media of the tests 1. Microorganisms Escherichia coli Enterobacter aerogenes Citrobacter freundii Klebsiella oxytoca Acinetobacter lwoffii Pantoea agglomerans Redox Plate potential counting BBL, TSB TSA, Tergitol BBL, TSB TSA, Tergitol BBL, TSB BBL, TSB BBL, TSB BBL, TSB TSA, Tergitol TSA, Tergitol TSA, Tergitol TSA, Tergitol Test microorganisms and culture media of the tests 2. Microorganisms Redox potential Plate counting Pseudomonas aeruginosa Cetrimide, TSB TSA, Cetrimide Pseudomonas fluorescens Cetrimide, TSB TSA, Cetrimide Enterococcus faecalis Azide, TSB TSA, SlanetzBartley Total count TSB TSA Validation characteristics of the method 1. Selectivity it depended on the media used for identification. Linearity from 1 to 107cfu/test flask. Validation characteristics of the method 2. Sensitivity TTD 60 130 min lg N Detection limit 1 cell/test flask. Quantitation limit The theoretical quantitation limit is 10 cell/inoculum (1 log unit), which is in agreement with the obtained calibration curves. Validation characteristics of the method 3. Range On the base of the calibration curves the range lasted from 1 to 7 log unit. Below 10 cells the Poisson-distribution causes problems, over 107 cells the TTD is too short comparing to the transient processes (temperature-, redoxequilibrum, lag-period of the growth). Repeatability Calculated from the calibration curves: SDlgN = 0.092 SDN = 100.092 = 1.24 = 24% Validation characteristics of the method 4. Robustness The most important parameter is the temperature, which has a double effect on the results – the growth rate of the microorganisms and the measured redox-potential are temperature depending. Performing the measurements at the temperature optimum of microorganisms, the growth rate in a ±0.5 °C interval does not change. The effect of the temperature on the measured redox-potential was determined experimentally. The results showed that the effect of the temperature variation is negligible. Advantages of the redoxpotential measurement 1. Very simple measurement technique. It does not require strict temperature control. Rapid method, especially in the case of high contamination. Applicable for every nutrient broth (impedimetric methods require special substrates with low conductance). Especially suitable for the evaluation of the membrane filter methods. Advantages of the redoxpotential measurement 2. Economic, effective and simple method for heat destruction measurements. Effective tool for the optimization of the nutrient media. The test costs are less than those of the classical methods, especially in the case of zero tolerance in quality control (coliforms, Enterococcus, Pseudomonas, etc.). Application of the redox method 1. Quality control Foods Water Surfaces Heat destruction of bacteria 3. Activity of bacteria 4. Media optimization 5. Efficiency of disinfectants 2. Quality control 1. Foods Enterobacter and total count in raw milk Eh (mV) Nyerstej, 1/2 TSB (T=30 °C) 500 400 300 200 100 0 -100 -200 -300 -400 0 5 10 15 20 25 t (h) 0. hig. 1. hig. 2. hig. 5. hig 6. hig 7. hig. 3. hig. 4. hig Quality control 1. Foods Enterobacter and total count in raw milk Nyerstej belső kalibrációs görbe (1/2 TSB, T=30 °C) y = 2,6486x + 1,34 2 R = 0,9895 20 MPNÖsszcsíra=2,3x106/ml TTD (h) 15 10 MPNEnterob. =2,3x102/ml 5 0 0 1 Összcsira 2 3 Enterobacter 4 5 6 7 hígítás Comparison of external and internal calibration curves Raw milk 14 y = -1.5014x + 15.413 12 R2 = 0.9596 TTD (h) 10 8 6 4 2 0 1 2 Internal 3 External 4 5 6 7 8 9 lgN /ml milk Method time comparison Classical method Redox method Sample lgN 1. 5,18 5,36 2. 5,06 5,36 3. 4,93 4. 6,35 6,36 5. 6,79 6,36 Needed time (h) 72 lg MPN 4,36 Needed time(h) 18 Quality control 2. Water E. coli in still water Escherichia coli lgN (cfu/100 ml) 3 2 1 1. 1. 2. 2. 3. 3. 0 MicroTester Plate 4. 4. Quality control 2. Water Enterococcus in still water Enterococcus lgN (cfu/100 ml) 3 2 1 1. 1. 2. 2. MicroTester Plate 0 3. 3. Method time comparison Cell count (cfu/ 100 ml) Escherichia coli 256 389 310 618 Enterococcus 44 203 219 Time needed (h) Mikroplate 36 36 Redox (with membrane filtering of 100 ml ) 7,67 7,17 7,50 6,50 11,79 11,00 10,96 Quality control 3. Surfaces Redox curves, table surface, TSB, 30°C 600 3. Eh (mV) 400 Total count: MPN=2.3∙102 200 2. 0 0. -200 1. Enterobacterium: MPN=2.3∙101 -400 0 5 10 15 t (h) 20 25 Quality control 3. – The microflora present on the swab is directly measurable without washing. There is no statistically significant difference between the microbial counts obtained with redox-potential measurements and the plating method. – By help of internal calibration curve, the viable count of surfaces with unknown microflora may also be determined. In further studies of surfaces with identical microflora, the already established calibration curve may be applied as an external calibration curve. Observing the shape of the redoxcurves both the total count and Enterobacterial count can be determined simultaneously, applying non selective nutrient broth (TSB) in a single, common measurement system. Quality control 3. – Comparing the time requirement of the methods, the traditional plating method demands 3 days for the determination of total count while by the redox method, using internal calibration and depending on the level of surface contamination, the viable count can be determined within 15-20 hours or using external calibration curve (depending on the level of the surface contamination) it may be determined within 4-8 hours. – Applying external calibration curve, when washing of swabs and the preparation of dilution series are not necessary, the duration of the examination, the material, tool and labor requirements can significantly be reduced. Applications 2. Heat destruction of bacteria – Campylobacter jejuni Typical changes in redoxpotential Calibration diagrams Campylobacter in different selective broths y = -176,56x + 2026,1 2 R = 0,9738 1800 1600 1400 1200 1000 800 600 400 200 0 2 3 4 5 6 7 8 Heat destruction experiments 3 different models: Classical isotherm model Redox isotherm model Redox anisotherm model Thermal death curve – Classical isotherm method Classical isotherm thermal death curve y = -0,086x + 5,3621 R2 = 0,9987 1,5 lgD 1 0,5 0 -0,5 48 53 58 T (°C) Z=11.62°C 63 Thermal death curve – Redox isotherm method Thermal death curve y = -0,1012x + 6,2336 R2 = 0,954 1,5 lgD 1 0,5 0 -0,5 50 52 54 56 58 T (°C) Z=9.88°C 60 62 64 66 Thermal death curve – combined isotherm results y = -0,092x + 5,7014 R2 = 0,971 Combined thermal death curve 1,5 lgD 1 0,5 0 -0,5 48 53 58 T (°C) Z=10.86°C 63 Simplified determination of zvalue Calibration curve: lgN=a-b·TTD Decimal reduction time: D=-Δt/ΔlgN= Δt/(b· ΔTTD) lgD=lgΔt-lgb-lg(ΔTTD)T From the thermal death curve: lg D 1 T z Simplified determination of zvalue lg D lg Dt lg b lg DTTD 1 T T T T z 1 lg DTTD A T z lgΔTTD is a linear function of temperature, from the slope the z-value can be calculated Determination of z-value from anisotherm heat treatment On the base of calibration curve: Thermal death curve z=9.37 °C y = -0,1067x + 5,5218 R2 = 0,9779 0 -0,1 -0,2 lgD -0,3 -0,4 -0,5 -0,6 -0,7 -0,8 54 55 56 57 T (°C) 58 59 Determination of z-value from anisotherm heat treatment On the base of TTDs: z=9.37 °C Anisotherm heat treatment 3 y = 0,1067x - 3,5787 R2 = 0,9779 lgΔTTD 2,7 2,4 2,1 1,8 1,5 54 55 56 57 Ti(°C) 58 59 Determination of z-value Classical isotherm method Redox isotherm method Redox anisotherm method z-value (°C) from 4 points 11.63 R2=0.999 9.88 R2=0.954 9.37 R2=0.978 Substrates needed 12×6=72 Petri-dishes (dilution series) 12 test flasks 5 test flasks Additional equipment 6 jars and 6 microaerophil sacks - - Incubation time 48 (96)h 35h 35h Applications 3. Examination of microbial activity in soil – Effects of antibiotics Applications 3. Effect of doxycyline (T1 – T5: soil types) Doxycycline TDT-TDTo y = 8.922x 18 16 14 12 10 8 6 4 2 0 2 R = 0.9943 y = 6.8416x 2 R = 0.9498 y = 4.5039x 2 R = 0.9772 y = 13.544x 2 R = 0.9835 0 1 2 3 lgc-lgco T1 T2 T3 T4 y = 2.1526x T5 R2 = 0.9568