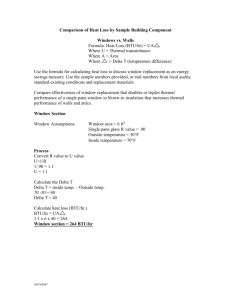

Air Conditioning

advertisement

Department of Mechanical Engineering ME 322 – Mechanical Engineering Thermodynamics Lecture 35 Analysis of Air Conditioning Processes The Five HVAC Processes • Heating – With and without humidification • Adiabatic humidification • Cooling – With and without dehumidification • Adiabatic mixing of moist air streams • Evaporative cooling 2 Heating Without Humidification QH 1 Q H m a h #2 h1# 2 h #2 1 2 # 1 h 1 2 1 2 T1 3 T2 • Constant humidity ratio • Relative humidity decreases • Outlet relative humidity may be too dry to be comfortable Heating with Humidification QH QH ma h1# m water hwater ma h#2 1 2 1' m w1 m water m w 2 m water h #2 h1'# water ma 2 2 h1# 1' 1 1 1' 4 ma m w1 ma 2 1 2 1 T1 m w2 T1' T2 QH ma h #2 h1# 2 1 h water Adiabatic Humidification ma h1# m water hwater m a h#2 1 2 m w1 m water m w 2 m water water ma 2b h 2c 2a # 2 m w2 ma m w1 ma 2 1 h1# 2 1 h water 0 1 1 1 T1 5 The location of state 2 (2a, 2b, or 2c) depends on the state of the water being injected for humidification Cooling Without Dehumidification QC 1 h1# 2 1 h #2 1 2 2 1 T2 6 Q C m a h1# h #2 2 T1' T1 This process is not very common in HVAC systems. Often, the surface of the heat exchanger is below the dew point which causes water to condense Cooling With Dehumidification QC Qc ma h#2 m water hwater ma h1# 1 2 m w 2 m water m w1 m water water ma h1# 2 h 1 2 7 ma # 2 T2 QC 1 1 Tdp T1 2 m w1 ma m w2 ma 1 2 h1# h #2 1 2 h water If Twater is not given, it is common to assume that it is equal to T2 ma1h1# m a 2 h#2 m a3h3# Adiabatic Mixing 1m a1 2 m a 2 3m a 3 m a1 m a 2 m a 3 1 (cold) m a1h1# m a 2 h #2 m a1 m a 2 h3# m a1 h #2 h3# # m a 2 h3 h1# 3 (warm) 2 (hot) h #2 h 3# 2 # 1 h 3 1 2 3 1 1m a1 2 m a 2 m a1 m a 2 3 m a1 2 3 m a 2 3 1 2 3 # # h3 h1 3 1 h #2 h3# 1-2-3 are on a straight line! 8 Evaporative Cooling This is the adiabatic humidification 1 process when the water used for humidification is colder than T1 ma h1# m water hwater m a h#2 2 m w1 m water m w 2 m water water ma 2 2 2 1 1 T2 9 T1 1 h # 2 m w2 ma m w1 ma 2 1 h1# 2 1 h water 0 This system works very well in hot, dry climates. Notice that there can be a significant increase in the humidity levels (both relative humidity and humidity ratio). Department of Mechanical Engineering ME 322 – Mechanical Engineering Thermodynamics Example Combined Cooling and Heating Processes Example Given: In a combined cooling/heating system, moist air enters the cooling section at 90°F, = 50% at a volumetric flow rate of 5000 cfm. Saturated, moist air and liquid condensate leave the cooling section at a temperature that is 15 degrees below the dew point of the entering moist air. After leaving the cooling section, the saturated, moist air enters the heating section. After passing through the heater, the moist air leaves the heating section at 68°F. The pressure throughout the system can be assumed to be constant at normal sea-level pressure (29.921 inHg – consistent with the psychrometric chart). Find: (a) The volumetric flow rate of the condensate (gpm) (b) The required refrigeration capacity of the cooling section (tons) (c) The relative humidity of the air leaving the heating section (d) The heat transfer rate required in the heating section (Btu/hr) 11 Example A sketch of the system and a psychrometric chart showing the processes is shown below. QC 1 T1 90F 1 50% V1 5000 cfm QH 3 2 h1# T3 68F water T T2 Tdp1 15 R h h #2 12 3 1 2 # 3 1 2 3 T2 T3 1 Tdp T1 2 3 Properties from the Chart and Tables h1# 38.4 Btu/lbma 3 61% 1 50% 2 h3# 26.0 Btu/lbma h#2 22.5 Btu/lbma 2 1 0.0152 3 1 2 3 0.0089 v1 14.19 ft 3 /lbma Tdp 69F T1 90F T3 68F T2 Tdp 15°F 69 15 F 54°F T2 Twater 54F h water 22.1 Btu/lbmw Table C.1a 13 vw 0.01605ft 3 / lbm Table C.1a QC Example 1 T3 68F water T T2 Tdp1 15 R h1# 38.4 Btu/lbma QC ma h1# h #2 1 2 h water 3 2 T1 90F 1 50% V1 5000 cfm Cooling section analysis … QH 3 61% 1 50% 2 h3# 26.0 Btu/lbma h#2 22.5 Btu/lbma 2 1 0.0152 3 1 3 ft 5000 V min 60 min 21141.6 lbm a ma 1 ft 3 v1 hr hr 14.19 lbm a 2 3 0.0089 v1 14.19 ft 3 /lbma Tdp 69F T1 90F T3 68F T2 Tdp 15°F 69 15 F 54°F T2 Twater 54F h water 22.1 Btu/lbm w Table C.1a Q C m a h1# h #2 1 2 h water lbm a Q C 21141.6 hr Q C 333, 208 14 lbm w Btu Btu 38.4 22.5 0.0152 0.0089 22.1 lbm lbm lbm a a w Btu 27.8 tons hr QC Example 1 The condensate flow is determined by conservation of mass around the cooling section, QH 3 2 T3 68F T1 90F 1 50% V1 5000 cfm water T T2 Tdp1 15 R h1# 38.4 Btu/lbma 3 61% 1 50% 2 h3# 26.0 Btu/lbma h#2 22.5 Btu/lbma m w 2 m water m w1 m water ma m w1 ma m w2 ma 2 1 0.0152 3 1 2 3 0.0089 v1 14.19 ft 3 /lbma 1 2 Tdp 69F T1 90F T3 68F T2 Tdp 15°F 69 15 F 54°F T2 Twater 54F h water 22.1 Btu/lbm w m water m a 1 2 Table C.1a lbm a lbm w lbm w m water 21141.6 0.0152 0.0089 133.2 hr lbm a hr V water lbm w ft 3 hr gal m wvw 133.2 0.01605 0.267 gpm 3 hr lbm 60 min 0.13368 ft Table C.1a 15 QC Example The relative humidity leaving the heating section can be read from the psychrometric chart, 1 QH 3 2 T3 68F T1 90F 1 50% V1 5000 cfm water T T2 Tdp1 15 R h1# 38.4 Btu/lbma 3 61% 1 50% 2 h3# 26.0 Btu/lbma h#2 22.5 Btu/lbma 3 61% Heating section analysis … Q H m a h3# h #2 2 1 0.0152 3 1 v1 14.19 ft 3 /lbma Tdp 69F T1 90F T3 68F T2 Tdp 15°F 69 15 F 54°F T2 Twater 54F h water 22.1 Btu/lbm w lbma Btu Btu Q H 21141.6 26.0 22.5 73,996 hr lbm a hr 16 2 3 0.0089 Table C.1a Example h1# 38.4 Btu/lbma QC QH T1 90F 1 50% V1 5000 cfm 3 2 T3 68F 1 50% 2 h3# 26.0 Btu/lbma 1 3 61% h#2 22.5 Btu/lbma 2 1 0.0152 3 1 2 3 0.0089 v1 14.19 ft 3 /lbma water T T2 Tdp1 15 R Tdp 69F T1 90F T3 68F T2 Tdp 15°F 69 15 F 54°F T2 Twater 54F h water 22.1 Btu/lbm w Table C.1a EES Solution (Key Variables) These are a bit different due to reading the psychrometric chart 17