8.1.1 Speed control circuit by using a throttle valve

advertisement

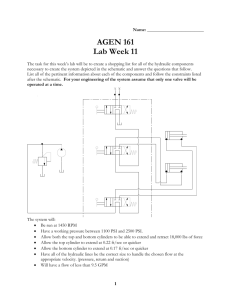

Chapter 8 Basic Hydraulic Circuit Objectives Upon completing this chapter, you will be able to 1. Be familiar with the main hydraulic components and standard symbols used for their representation on circuit diagrams. 2. Explain the operation principle and performance characteristics of some usually used circuits. 3. Identify transmission of power and flow path through the circuits 4. Describe the function of each basic element in a practical hydraulic circuit. 5. Evaluate the safety of operation. 6. Design a circuit to perform a desired function. 1 8.1 Rapid Motion Circuit The purpose for a rapid motion circuit is to obtain a speed as high as possible so as to raise productivity and to reasonably utilize the power of the prime mover. There are some methods to accomplish rapid motion, here we only introduce a regenerative circuit and a high-low pressure pump circuit. 2 8.1.1 Regenerative Circuit The return line from the cylinder is connected back to the supply line. Although both end are under the same pressure, there is a difference in areas on opposite sides of the piston. Thus there is a net unbalanced force which will cause the piston to move to the right. The oil leaving the rod end combines with the pump flow entering the blank end of the cylinder. A regenerate circuit does increase the rod extension speed but it also reduces the output force of the cylinder. 3 8.1.2 Two-pump Rapid Motion Circuit Setting the lower output pressure 6 7 3 5 4 When the load is very small and the systematic pressure is lower than the preset level of the unload valve (element 3), the two pumps delivering pressure oil into the cylinder and the cylinder extending rapidly. Setting the systematic pressure 1 2 Fig. 8-2 two-pump output circuit. The power resource consists of a high-pressure low-flow rate pump and a low-pressure high flow rate 4 pump. 8.1.2 Two-pump Rapid Motion Circuit 6 7 3 5 4 1 2 When the systematic pressure rises to the preset level set by valve 3, valve 3 opens, permitting pump1 to unload. Valve 4 closes. The cylinder extends at a low speed. Pump 1 unloading decreases power loss greatly. With high efficiency the circuit is commonly used in the case where rapid motion is much faster than feed motion. Particularly, the circuit5 is widely used in machine tools 8.1.1 Speed control circuit by using a throttle valve 8.1.1.1 meter-in circuit 1 Introduction 1 2 1 1 2 A variable flow control valve is placed between the pump and the actuator to control the flow rate of the oil into the cylinder. Speed control can be achieved simply by varying the flow rate of fluid into the cylinder. y p p Note: Because the pressure relief valve is opening the discharge of fluid from the pump is held at a approximately constant pressure by the action of the pressure relief 6 valve. 8.1.1 Speed control circuit by using a throttle valve 2 Velocity versus load characteristic When regardless of the leakage and 1 compressibility of oil, the extension 2 speed of the cylinder is: q1 1 v (8 -1) 1 2 A1 The balance equation of the piston is p1 A1 p2 A2 F (8 - 2) y F Thus p1 A1 p p The flow rate of the oil through the throttle valve into the cylinder is: q1 CAT (pT ) m CAT ( p p p1 ) m F m CAT ( p p ) (8 3) A1 7 8.1.1 Speed control circuit by using a throttle valve q1 CAT F m v ( pp ) A1 A1 A1 (8-3) Here, C = flow rate coefficient; AT = the flow area of the throttle; ΔpT= the pressure drop of the throttle valve; m = exponent, when a throttle orifice is a thin wall orifice, m= 0.5 8 8.1.1 Speed control circuit by using a throttle valve With other conditions unaltered the q1 CAT F m speed of piston is proportional to the v ( pp ) A1 A1 A1 flow area of the throttle valve e.g., when area AT1, AT2 and AT3 T3 given we can obtain speed v1,v2 and v3. When the area is not varied, the 3 T2 piston speed will vary with the load 2 T1 1 resistance in a approximate parabola. That is, the load fluctuation will have great influence on the speed stability. The maximum load capacity is Fmax p p A1 When F=Fmax , the pressure difference of both sides of the throttle is equal to zero, no fluid passing through the throttle valve and overall flow rate discharged through the relief valve to the 9 reservoir, the speed of the piston being equal to zero. 8.1.1 Speed control circuit by using a throttle valve 3 Power and efficiency characteristic The output power of the pump is: Pp p p q p The effective output power of the cylinder is P1 Fv p1q1 The power loss of the circuit is P Pp P1 p p q p p1q1 p p ( q1 q ) ( p p pT )q1 p p q pq1 overflow power loss throttle power loss The efficiency of the circuit is Pp P Pp p1q1 p pq p 10 8.1.1 Speed control circuit by using a throttle valve 4 Meter-out Circuit A1 p1 Δq qp q1 F p2 A2 q2 Δp AT The flow control valve is placed in the return line of the actuator limiting the flow rate of oil from the cylinder. Apply similarly reasoning to the circuit we can obtain the speed versus load characteristic formula of the meter-out circuit. CAT A21 m ( p p A1 F ) m (8 -6) 11 8.1.1 Speed control circuit by using a throttle valve 5 Comparison of the two kind circuits (1) The capacity against overrunning load Meter-out circuits are the most effective in systems that act against overrunning loads. (2)Speed stability Because of the back pressure caused with the throttle valve, the speed stability is better than that in the above meter-in circuit. (3)Heat influence on the system In a meter-in circuit the heat degenerated due to throttle is fed to the actuator which will increase the leakage of the actuator. In a meter-out circuit the heat is fed to the oil reservoir where hot oil is cooled, hence the heat will have little influence on the leakage of the system. 12 8.1.1 Speed control circuit by using a throttle valve (4)Actuating characteristic In a meter-out circuit the system having stopped working for long time the oil in the cylinder has flowed to the reservoir. Therefor, when the system is actuated again, the piston of the cylinder will rush abruptly because the back pressure can not be built up immediately. The piston of the cylinder in a meter-in circuit will not due to throttle effect of the flow control valve. 6 advantages and disadvantages The advantages of meter-in and meter-out circuit is a wide speed control range and finer speed control feature, additionally low in initial cost as well as convenient operation. The disadvantages of throttle speed control circuits is low efficiency, additionally generating substantial amount of heat. The two kinds circuit are suit to be used in the case where the speed and horsepower are low. 13 8.1.2.3 By-pass Control Circuit The flow control valve is connected in parallel to the actuator controlling the flow rate by bleeding-off a portion of the oil back to the tank. It is called bleedoff or by-pass. The relief valve is closing in normal work condition. The sole function of the pressure relief valve is to limit the system pressures in this case. Its setting is 1.25 times as high as maximum load pressure. 14 8.1.2.3 By-pass Control Circuit From formula (8-9) we can see that throttle loss is sole energy loss, hence, the efficiency of the circuit is higher than that in previous speed control circuits. By-pass circuit is suit to be used in the case where the speed stability is not a principal consideration Note that to ensure the speed stability (meter-in, meter-out and by-pass) the throttle valve can be replaced with a pressure compensated flow control valve. When the efficiency is predominating factor a speed control circuit using the variable volume can be considered. 。 8.2.2 Speed Control by Varying Volume Speed control using variable volume is accomplished by varying displacement of a hydraulic pump or a hydraulic motor, therefore there are three ways to control speed: one is to utilize a variable displacement pump, another to utilize a variable displacement motor, the other to utilize both a variable 15 displacement pump and a variable displacement motor. 8.2.3.1 Speed Control Circuit Using Variable Displacement Pump Prevent the system from overloading valve 6 relieves the pressure of pump 1. pump 1 supplies make-up oil for leakage and improves the suction lift condition of pump 3, The circuit returns a portion of oil to the tank via valve 6 that the closed loop is cooled Relieve the pressure of pump 1 4 5 M TM P M n 3 2 1 T M P M n M 6 supply make-up oil for leakage V p 16 8.2.3.2 Speed Control Circuit Using Variable Displacement motor 4 5 nM 3 2 TM PM nM PM TM 6 1 Fig. 8-9 speed control circuit using fixed displacement pump and a variable displacement motor VM Fig. 8-10 speed control characteristic using fixed displacement pump and a variable displacement motor The advantage of the speed control circuit is to keep a constant power at various rotational speed, while disadvantage is a slightly narrow speed adjusting range ( Rc 3 ). 17 8.3 Synchronous circuit Synchronous circuits allow two or more actuators to operate in unison regardless of differences in the magnitude of the load resistance. There are two ways of controlling the synchronization of cylinders or motors: one method is to mechinically link both cylinders or motors together, another is to meter an equal amont of fluid to earch circuit by using either synchronous valves or flow dividers or series cylinders. The former is called mechanical sychronization, the later is called hydraulic synchronization. 18 8.3.1 Mechanically Synchronous Circuit Fig 8-13 Mechanically Synchronous circuit 19 8.3.2 Synchronous Circuit Using Compensated Flow Valves By the two valves being adjusted carefully the flow rate entering each cylinder can ensure to be basically equal. In spite of being simple the two valves are adjusted inconveniently. The circuit is not suit to be used in the case where resistive forces vary frequently or a resistive force of a cylinder is very different from that of another although the two resistive forces are all constant loads 20 8.3.3 Synchronous Circuit using Synchronous Valve The output of each segment of the synchronous valve is equal and respective cylinder receives equal fluid. Deviation from synchronization can be attributed primarily to leakage and the manufacturing deviation of the synchronous valve and cylinders. The synchronous valve which meters equal amounts into cylinder 1 and cylinder 2 causing them to extension in synchronization. 21 8.3.4 Synchronous Circuit Using Flow Divider Hydraulic oil is fed to the flow divider which meters equal amounts into two cylinders causing them to extension in synchronization. The throttle valve functions to eliminate cumulative deviation. Please note: The deviation from synchronization can be attributed primarily to leakage and the displacement deviation of the motors and the cylinders. 22 8.4 Sequencing circuit Sequencing circuits order cycle events, such as the two cylinders, one after another. There are principally two types of sequencing circuit. One is operated mechanically, another is operated by pressure step. The mechanically operated sequencing circuits conclude: • the sequencing circuit by using mechanically operated sequence valve • the sequencing circuit by using electric limit switch The sequencing circuits operated by pressure step conclude: • the sequencing circuit by using pressure operated switches • the sequencing circuit by using sequence valves 23 8.4.1 Mechanically Operated Sequencing Circuit ① ③ ② ④ 1 3 2 4 A advantage of the circuit is that sequential operation is accomplished smoothly, reliably, and with the degree of position accuracy. But it is difficult for strokes and sequences to be modified. When valve 3 shifted to its left position the pump delivery flows through valve 3 into the blank end of cylinder 1 and discharge from the rod end of cylinder 1 through valve 3 to the tank. Thus cylinder 1 extends. At its advance stroke end actuates valve 4 to start the extension of cylinders 2. When valve 3 returns to its right position cylinder 1 retracts. Cylinder 1 on its back stroke de-actuates valve 4, cylinder 2 retracting. 24 ① 2 1 S3 S4 S1 S2 3 1YA 4 2YA 3YA 4YA Fig. 8-18Mechanically operated sequencing circuit by using electric limit switches When solenoid 1YA is energized, valve 3 is shifted to its left position. The delivery of the hydraulic pump flows through valve 3 into the blank end of cylinder 1 and discharge from the rod end of cylinder 1 through valve 3 flow freely to the tank. Thus cylinder 1 extends. 25 ② 2 1 S3 S4 S1 S2 3 1YA 4 2YA 3YA 4YA At the end of the extension stroke of cylinder 1 it comes in the contact with the limit switch S2 which causes 1YA to be deenergized and 3YA energized, valve 4 shifted to its left position. The delivery of the hydraulic pump flows through valve 4 into the blank end of cylinder 2 and discharge from the rod end of cylinder 2 through valve 4 flow freely to the tank. Thus cylinder 2 extends. 26 ③ 1 S3 S4 S1 S2 3 1YA 4 2YA 3YA 4YA At the end of the extension stroke of cylinder 2 it comes in the contact with the limit switch S4 which causes 3YA to be deenergized and 2YA energized valve 3 to be shifted to its right position. The pump delivery flows through valve 3 into the rod end of cylinder 1 and discharge from the blank end of cylinder 1 through valve 3 flow freely to the tank. Thus cylinder 1 retracts. 27 ④ 1 S3 S4 S1 S2 3 1YA 4 2YA 3YA 4YA At the end of the retraction stroke of cylinder 1 it comes in the contact with the limit switch S1 which causes 2YA to be de-energized and 4YA energized, valve 4 shifted to its right position. The pump delivery flows through valve 4 into the rod end of cylinder 2 and discharge from the blank end of cylinder 2 through valve 4 flow freely to the tank. Thus cylinder 2 retracts. 28 1 S3 S4 S1 S2 3 1YA 4 2YA 3YA 4YA At the end of the retraction stroke of cylinder 2 it comes in the contact with the limit switch S3 which causes 3YA to be de-energized. At this moment, a work cycle is completed. The advantages of using electric limit switches are that it is convenient to modify sequences and strokes. This circuit is suitable to be used in the case where strokes and sequences need 29 adjusting frequently. 8.4.2 Pressure Step Operated Sequencing Circuit When the start button is pressed, it energizes the 1YA and valve 1 is shifted to its left position cylinder 7 extending。 After cylinder 7 is fully extended, the systematic pressure increases and reaches to the setting of pressure switch 3, 1YA is de-energized and 3YA is energized which causes valve 1 to returns to its neutral position and valve 2 to its left position. 30 Thus cylinder 8 extends. Fig.8-19 The sequencing circuit using pressure switches. When cylinder 8 is fully extended the pressure reaches the setting of pressure switch 5, 3YA de-energized and 4YA energized which causes valve 2 to be shifted to its right position. Thus cylinder 8 retracts. When cylinder 8 is fully retracted the pressure increases to the setting of pressure switch 6, 4YA is de-energized and 2YA is energized which cause valve 1 to be shifted to its right position. Thus cylinder 7 retracts. 31 At the end of the retraction stroke of cylinder 7, pressure switches 4 actuate next work cycle unless a stop button is pressed. Note: To ensure sequential operations to be reliable the setting of each pressure switch should be 0.3~0.5MPa higher than the maximum working pressure during the previous stroke but 0.3~0.5MPa lower than the 32 pressure relief valve at least. ① ④ ② ③ 1 2 3 4 5 1YA 2YA 7 6 When 1YA is energized valve 5 is to its left position, which causes the pump delivery to flows through valve 5 into the blank end of cylinder 1 rather than into the blank end of cylinder 2, and the oil from the rod end of cylinder 1 flows freely to the tank. Thus cylinder extends。 Cylinder 1 having finished its extension stroke the systematic pressure increase and reaches to the setting of valve 4, valve 4 opens. The pump delivery flows through valve 5 and 4 into the blank end of cylinder 2, and the oil from the rod end of cylinder 2 flows freely to the tank. Thus 33 cylinder 2 extends. ① ④ ② ③ 1 2 3 4 5 1YA 2YA 7 6 When 1YA is de-energized and 2YA energized which cause valve 5 to its right position. The pump delivery is directed through valve 5 into the rod end of cylinder 2 rather than cylinder 1,and the oil from blank end of cylinder 2 flow freely through the integral check valve of valve 3 and valve 5 to the tank. Thus cylinder 2 retracts。 Cylinder 2 having finished its retraction stroke the systematic pressure increase to the setting of the valve 3 which opens. The oil from pump 6 flows through valve 5 and 3 into the rod end of cylinder 1 and the oil from the blank end of cylinder 1 flows freely to the tank. 34 Thus cylinder 1 retracts. ① ④ ② ③ 1 Please note: 2 3 4 5 1YA 2YA 7 6 To ensure the sequential operation to be reliable the setting pressure of the sequence valve 3 should be higher 0.3~0.5MPa than the maximum load pressure of cylinder 2 during the retraction stroke but lower 0.3~0.5MPa than the pressure relief valve 7. 35 8.5Counterbalance circuit Many operations involve heavy elevated loads that poses a constant threat. When the mechanisms are released from their top-most position they would descend faster and faster if the velocity unlimited. Protection against such hazards is often achieved through the use of counterbalance circuits. The principle of counterbalance circuit is to maintain a back pressure in the cylinder or motor return line. The principle of counterbalance circuit is to maintain a back pressure in the cylinder or motor return line. This section principally introduces two kinds counterbalance circuits: one is the counterbalance circuit by using counterbalance valve, another is the counterbalance circuits by using flow control valve. 36 8.5.1 Counterbalance Circuit Using Counterbalance Valve Once the descent velocity of the piston exceeds above theoretical value, the pump can not supply hydraulic oil sufficiently to the cylinder, which causes the pump output pressure or pilot pressure of the counterbalance valve drop down and the counterbalance valve closes. As a result, the descent velocity of the piston will decrease until the velocity reaches theoretical value. The circuit can limit the descent velocity of the piston smoothly and is widely used in the hydraulic crane 37 systems. 8.5.2 Counterbalance Circuit Using flow Control Valve During retraction, the hydraulic oil from the pump flows into the rod end of the cylinder, at the same time, and the hydraulic oil from the blank end of the cylinder flows through the flow control valve to tank. Because of the back pressure the flow control valve sets the descent velocity of the piston is limited. Note: The descent velocity of the piston is related with the magnitude of load and the flow area of the flow control valve. The circuit is used in the case where the requirement to a descent velocity is not very accurate, such as in fork truck 38 systems and excavator systems. . 8.6 Pump-Unloading Circuit A pump unloading means that the pump is developing a minimum amount of horsepower. The purpose for pump-unloading is to prolong expected pump life and to avoid wasting power and generating heat during idle periods. Since the power of a pump is equal to pressure times flow rate, the pump will be unload if either pressure or flow rate is close to zero. There are two kinds of unload cases----one in which when the pump is unloading the actuators need holding pressure, another in which do not. 39 8.6.1 Unloading Circuits Using Neutral Position of Directional Valve In its neutral position a open center directional control valve routes the constant pump output back to tank at very low pressure. Fig.8-23 The unloading circuit using the neutral position of a directional control valve The open center directional control valve is the simplest method used to unload a pump. 40 8.6.2Unloading Circuit Using A Relief Valve With a Vent valve 1 The unloading circuit using a pilot-operated relief valve with a vent valve. When the solenoid is not actuated the pressure relief sets system pressure; when the solenoid is actuated the pump’s outlet is diverted through the pilot-operated relief valve to tank the pump is Fig.8-24 The unloading circuit using a pilot- unloaded. operated relief valve with a vent valve 41 8.6.4 Unloading Circuit Using Pressure-Compensated Variable displacement Pump When the system pressure increases to predetermined levels the pressurecompensation mechanism causes the pump to reduce flow rate to minimum. The pump supplies only make-up oil. The power loss is also very small. The use of this kind pump eliminates the need for both relief and unloading valves, since pump compensates to limit system pressure. Relief valves or hydraulic fuses are usually installed, however, to protect the system against hydraulic shock, thermal expansion of liquid, and possible malfunction of the pressure-compensation mechanism. 42 8.6.3 Unloading Circuit Using Unloading Valve 1YA 2YA 3 4 2 1 Fig. 8-25 The unloading circuit using an unloading valve When 1YA is actuated valve 3 allows oil from the pump to flow into both the cylinder and the accumulator, the cylinder extending. The piston rod having contacted the work piece system pressure rises and reach a preset level, valve 1 opens, so that fluid from the pump passes freely through valve 1 to the tank. Subsequently maintaining pressure is first satisfied by liquid stored in the accumulator. Eventually, as the accumulator empties, system pressure drops sufficiently to close valve 1, bring the pump directly back on-line. 43 Summary The circuits introduced in the chapter are all typical and commonly used circuits. The readers who are interested in the other basic circuits can look over the references list in the book. The purpose for studying basic circuits is grasping the basic principle and features of the circuits, and being able to organically configure them for designs of various hydraulic systems. 44