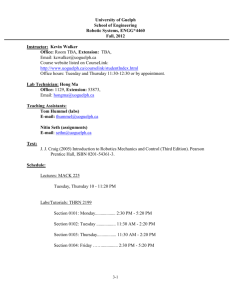

SCSC 585 Introduction to Computer Vision

advertisement

ROBOTICS AT USC UPSTATE We focus on developing novel and innovative robotics applications. First, let’s talk about the RULES!!!! RULE 1: If we are doing an in-class assignment or activity and you are not in class that day, you automatically loose 50 points from this assignment/activity grade and cannot make this up. RULE 2: Absolutely no food or drinks of any kind on your robot table/workarea. RULE 3: You must leave your work station exactly the way you found it your workstation must be properly cleaned up after activities/assignments are completed. RULE 4: When debugging or running a program, be prepared to press the Emergency Stop button at any time. More RULES!!!! RULE 5: Check that no-one is within the robot work envelope when switching arm power on or moving the robot. Always take tool offsets into account. Putting someone in an un-safe situation results in an automatic F in the course. No exceptions. RULE 6: When running a program, the speed on the arm MUST NEVER be set higher than 10% without explicit approval from the instructor first. Putting anybody in an un-safe situation results in an automatic F in the course. No exceptions. RULE 7: Always be aware of your surroundings. Alert others IMMEDIATELY if you observe a possibly dangerous situation. Putting anybody in an un-safe situation results in an automatic F in the course. No exceptions. Course Grading Machines in the lab… Five Stäubli RX60 arms with CS7B controllers 6 dof, Programming environment: V+ Three Adept 550 arms 4 dof, Programming environment: V+ One Staubli RS20 4 dof, Programming environment: VAL3 One Fanuc LR Mate 200iC 6 dof, Programming environment: TPP Stäubli RX60s Some Notable features: Cables pass through inside of joint gearing Stäubli first to make this work… All motors enclosed Reduces particle emissions The two-click air-pressure release value Designed by Stäubli and was an important contribution to industrial robotics. Maintenance is easy Show in class how to check oil and feel for wear. Repair Process (typical in industry) Motors, amps, etc that fail are simply swapped for new components. No trying to fix the faulty component… Why? What’s going on inside the machine? Not the focus of what we do, but here are the basics. Inside the arm… Motor for joint 1 Motor for joint 3 Motor for joint 2 What’s going on inside the machine? Each joint has an amplifier that controls the electricity to it. Of course several other electronics are present, a hard drive, CPU, etc, etc Community Partnerships Stäubli Initial donations of our robotic equipment Paid internship available This could be SEW Eurodrive Paid internship available $30,000 cash donation to fund: YOU Student Research Assistant here in robotics lab! Robotics Summer Camp Materials, food, pay a student assistant About Stäubli… Stäubli is a mechatronics solution provider with three dedicated divisions: Textile machinery, Connectors and Robotics. With a workforce of over 3000, the company generates a yearly turnover surpassing 1 billion Swiss francs. Originally founded 1892 as a small workshop in Horgen / Zurich, Stäubli today is an international group with its head office in Pfäffikon, Switzerland. About SEW Eurodrive… A world leader in drive technology and a pioneer in drivebased automation. Power transmission and motion control products. Introduced the gearmotor in 1931. History of innovations — the first variable speed gearmotor, early development of electronic drives, some of the first successful efforts to decentralize control and the first motor with energy-efficient copper rotors. Curriculum Development Available Courses: SCSC 314 Introduction to Robotics SCSC 399 Independent Study (with van Delden) SCSC 580 Introduction to Artificial Intelligence SCSC 585 Introduction to Computer Vision Automation Focus Area in Computer Information Systems degree. A collaboration between Computer Science, Engineering Technology Management, and Business. Curriculum Development cont… Peer-Reviewed / Published Research Several papers published recently: Sebastian van Delden. 2010. Getting Your Robotic Arms around Computing Curricula. In the Journal of Computers in Education. Published by the American Society for Engineering Education. vol 1(4). Pp 91-101. Oct-Dec Volume. Sebastian van Delden. 2010. Computer Science Meets Industrial Robotics: A Visual Servoing Project for a Computer Vision Course. In the Journal of Computing Sciences in Colleges. Volume 25, Number 6. Pages 85-92. Select papers from the 15th Annual Northeast Meeting of the Consortium for Computing Sciences in Colleges. Hartford University. Sebastian van Delden. 2010. Industrial Robotic Game Playing: An AI Course. In the Journal of Computing Sciences in Colleges. Volume 25, Number 3. Pages 134-142. Select papers from the 25th Annual Eastern Meeting of the Consortium for Computing Sciences in Colleges. Villanova University, Pennsylvania. January 2010. Sebastian van Delden and Nicole Tobias. 2010. A Novel Approach to 3D Contour Recovery using Structured Light Mounted to a Robotic Manipulator. In the Proceedings of the 15th IASTED International Conference on Robotics and Applications, Cambridge, MA, Pages 167-173, Nov 1-3, 2010. Sebastian van Delden and Frank Hardy. 2009. Robotic Eye-in-hand Calibration in an Uncalibrated Environment. In the Journal on Systemics, Cybernetics and Informatics. Volume 6, Number 6. Pages 67-72. ****Student coauthor Peer-Reviewed / Published Research Several papers published recently: Sebastian van Delden and Wei Zhong. 2008. Effective Integration of Autonomous Robots into an Introductory Computer Science Course: A Case Study. Journal of Computing Sciences in Colleges. Select papers from the Sixth Meeting of the Consortium for Computing Science in Colleges, vol 23(4), pp. 10-19, April 2008. Sebastian van Delden and Benjamin Overcash. 2008. Towards Voice-Guided Robotic Manipulator Jogging. In Proceedings of the 12th World Multiconference on Systemics, Cybernetics and Informatics. Volume 3. Pages 138-144. Orlando, FL. July 2008. Sebastian van Delden, Ricky Farr, and Seth Hensley. 2007. An Automated Camera Orientation Recovery Algorithm for an Eye-in-Hand Robotic Manipulator. In Proceedings of the 5th IEEE International Workshop on Robotic and Sensors Environments. Pages 1-6. Ottawa, Canada. October 12-13, 2007. Sebastian van Delden. 2006. Constructing a Simple Visually-Guided Robotic Part-Grasping System with Off-the-Shelf Components. In Proceedings of the 18th IEEE International Conference on Tools with Artificial Intelligence. Pages 211-216. Washington, DC. November 13-15th, 2006. ****Student coauthors Other Research Contributions Alex Umrysh and Sebastian van Delden. 2011. Object recognition in a Robot Workarea using Hand Gestures. Poster at the 7th Annual SC Upstate Research Symposium. April 15, 2011. Nicole Hodge and Sebastian van Delden. 2010. Contour Recovery using Structured Light mounted to a Robotic Manipulator. Poster at Discovery Day 2010, USC Columbia. April 23rd, 2010. ****Best Poster Award for “Computer Science and Engineering” Nicole Hodge, Robert Mahmoudishad, Mark Parrish, and Sebastian van Delden. 2009. A Novel Robotic Approach to Contour Recovery using Structured Light. Presented at the Fifth Annual USC Upstate Research Symposium. March 27th, 2009 Derrick Thompson, Jose Reyes, and Sebastian van Delden. Spring 2007. Vision-Based Robots Playing Pong. Presented at the Third Annual USC Upstate Research Symposium. April 6th, 2007. William Bittle, Sayed Shahabi, Ashley Bryant and Sebastian van Delden. WOODBURNER: An Automated Robotic Character Etching System. Poster at the Second Annual USC Upstate Research Symposium. April 21st, 2006. *** STUDENT COAUTHORS Ongoing projects. Need Help! Rapid Robotic Application Development using visual and voice cues Android/Robot/Bluetooth: http://www.youtube.com/svandelden#p/u/8/dsdh2WlWwys Summer Camps: http://www.youtube.com/uscupstateresearch#p/u/5/UIVM8SByVDs http://www.youtube.com/watch?v=dxo1NbBblE4 http://www.youtube.com/svandelden#p/u/6/3mItUbcqWms New ideas? Have a neat idea you want to implement? INTRODUCTION TO INDUSTRIAL ROBOTICS Sebastian van Delden USC Upstate svandelden@uscupstate.edu Industrial Robotics Primarily assist in the automaton of the manufacturing process 78% welding and material handling 10% assembly Over a billion dollars of new industrial robots shipped to North America each year on average. However, America lags behind several European and Asian countries. Trends in Industrial Robots Industrial Robots currently in use Why Automate?? Robot prices continue to drop while labor wages grow Faster, more accurate/flexible Operate in dangerous environments Example Robot Makers Maker Programming Language* ABB FANUC HP IBM Motoman (Yaskawa) Staubli AMPL Karel, Proficy MDS AML JRC V+, VAL3 * Are constantly evolving, with the new trend in off-line programming environments… What do you study in Robotics? Depends… Engineering programs would focus on the actual physical design of the machine, motors, gearing etc. Computing programs would focus more on the application side of robotics: programming, incorporating input sensors (cameras, etc), networking/communication, etc.. Programming the machine to do something interesting. Our focus here at USC Upstate Tech programs would focus on basic electronics, maintaining/servicing the machines, etc… BASIC INDUSTRIAL ROBOTICS CONCEPTS Which will be covered in this course… Representing Objects in 3D Space Position and Orientation A frame is rigidly attached to each object to define position and orientation A frame is just a 3D coordinate system. Transformations Moving one frame with respect to another one is called a transformation. Matrices and Transformations We will learn how to use matrices to internally represent and manipulate transformations, and position and orientation information Applicable to several fields: Robotics 3D modeling and programming Computer Vision Some Manipulators Concepts Consists of rigid links and joints which allow relative motion of neighboring links The orientation of a rotary joint is measured with a joint angle. Orientation of a prismatic (sliding) joint is measured with a joint offset. The number of degrees of freedom (dof) is the number of joints of a manipulators. Singularity Point – Manipulator try to move its joints at infinite speed to continue fluid motions. (gunner example) Some Manipulators Concepts cont… An end-effector is what is attached at the free end of the robot Gripper, pointer, welder, camera, etc.. Represented with a tool frame A base frame is attached to the non-moving base. Frames are also assigned to each joint. The robot’s work envelope (or work space) is everything that the robot can reach. Manipulator jogging is the process of manually moving the arm around. Typical frames in a robotic environment Typical work envelope schematics Input/Output A robot can gathering data from its environment with input sensors Buttons, switches, keyboard, microphone, camera A robot uses its actuators (motors) and endeffectors (grippers, etc) to effect its surroundings. We’ll learn how to make our robots gather images from a camera so that it can interact with the environment based on this visual data. Kinematics Treats motion without regard to the forces which cause it. Forward Kinematics of Manipulators: compute position and orientation of the end effector given a set of joint angles. EASY(er) Inverse Kinematics of Manipulators: given the position and orientation of the end effector, calculate all possible joint angles that could achieve this position and orientation. HARD Staubli RX60s – As many as 8 possible ways to achieve end effector pose Typical robot schematic/dimensions – needed to calculate Kinematics Finally, by the end of this course, we’ll know how to Program and operate our Stäubli V+ manipulators. Do simple Stäubli VAL3 and Fanuc TPP programming. Calculate end-effectors transformations and other gripper concepts. Calculate the Forward Kinematics of a manipulator. Understand basic Inverse Kinematics and trajectory generation.